Medium Span Line Construction; various line mentioned and insulators used on them; Hemingray Santa Ana illustrated

|

[Trade Journal] Publication: The Journal of Electricity, Power and Gas San Francisco, CA, United States |

||||||||||||||||||||||

|

In Eighth Annual Convention Assembled. Being an Installment of the Invaluable Papers Presented Before the Monterey Meeting of the Pacific Coast Electric Transmission Association, June 21-22, 1904. ADDRESS OF WELCOME. BY HON. R. F. JOHNSON, MAYOR OF THE CITY OF MONTEREY, CAL.

IN behalf of the people of the city of Monterey, I assure you it is more than an honor for me to cordially welcome the members of the Pacific Coast Electric Transmission Association assembled here in this, one of the most historic and picturesque places of the State of California. It was here in the beautiful bay of Monterey, in its calm and emerald waters, where Commodore John Drake Sloat anchored his squadron, consisting of three sailing sloops, or ships of war, in July, 1846, and with 250 marines and seamen went ashore and in the name of the United States raised the Stars and Stripes over the Custom House, where they have waved ever since. A few blocks away from here you behold Colton Hall; it was there the first constitutional convention convened, composed of delegates who migrated here from nearly every State in the Union and framed our State paper that all Californians read with pride to the present day. A little to the northwest, and within our city limits, can be seen traces of an old Mexican fort with its antiquated guns and trenches. This place was occupied, also, by Generals Fremont, Halleck and Lieutenant Sherman in 1846. Today this historic site is barricaded and occupied by the 15th Infantry, who are exercising the arts of war in order to preserve peace. To the east, and within a few blocks, is the famous Del Monte, unsurpassed in its landscape scenery, fragrant with the perfume of beautiful bright colored flowers, and a most healthful climate. It is, then, in this delightful garden-like spot, we most heartily welcome you in your deliberations on this the most important question of the transmission of power by electricity, and hope your visit will be long remembered for its useful ness and the pleasant time you will enjoy among us. The question of electric transmission is not only of the greatest importance to every progressive municipality, but the great problems of municipal sanitation, lighting and power are interwoven with it. There is nothing in modern or ancient times which conduces as much to health, convenience and comfort, as well as the pleasure and happiness of the inhabitants of a city, than this question of electrical transmission. It closely unites the suburb with the heart of the town. It has shortened the distance between remote parts of the city by means of the electric cars, which pass along with that rapidity and comfort and cleanliness as if we were riding in splendidly equipped carriages. The wonderful changes produced by electric transmission in our cities are beyond calculation. This mysterious electric current has literally, as well as figuratively, electrified our cities and towns with light and motion and imbued them with new life, and the cities blessed with this new life-given electric fluid have become more than a dream of the past; and we today stand with wonderment and amazement at the magical changes continually transpiring before our eyes through the medium of this mysterious power. Our own city of Monterey has experienced and felt the wonderful transformation which electric transmission can bring and accomplish. Monterey, sometime in the past known as “Sleepy Hollow,” has received a current of this vital, invigorating, magical fluid, and we now have a wide-awake modern city with all improvements that electricity can bestow, with bright hopes for the future of greater development and growth. The bright and cheerful vision of the still greater changes and possibilities the future will bring in useful inventions and astonishing improvements for the benefit of mankind, which will redound to his greater well-being, can only be pictured and painted by those, no other than whom are more qualified than the members of this Association who are now gathered here. Again I welcome you in our midst with the best of wishes of the citizens of the city of Monterey. · · · · MEDIUM-SPAN LINE CONSTRUCTION, BY CLEM A. COPELAND.

DISTRIBUTION engineering is a new and distinct branch of the electrical profession, and involves the design and construction of long distance or cross-county transmission lines and city distributing systems for all electrical industries. It is a fertile field for the electrical engineer, because the present state of the art is so exceptionally crude. To thoroughly appreciate this, let one write a bibliography of references in this branch of engineering. It will be found that in the surprisingly few instances, mostly in Europe, where study and skill have been expended on distributing systems and lines, the description of them is a little more than an aggravation in its briefness and unsatisfactory allusions to a deserving subject. It has been the chief desire of companies to get to the customer with some sort of a line and obtain a swift revenue, while the engineer has not considered it worth his while to spend more than a wisp of his time on line work. ‘The result has been that more than seventy-five per cent. of the troubles experience i in the distribution of power, both as to number and cost, have occurred outside the central and substations. The major part of the cost of these troubles has been due to lack of confidence in electricity as a power fund and convenience which does not always show on the books. These remarks apply as well to telephone and telegraph lines and distributing systems as those for light and power. Not only have lines been excessively troublesome, but they have cost too much. With a view to eliminating both of these faults on cross-country lines The Edison Electric Company of Los Angeles has been experimenting on several special methods of distributing system design. The one immediately concerned may be termed medium-span cross-country construction. The ordinary length of spans, say from 120 to 140 feet, which have been used for the lines, have evidently been transplanted from early days and from localities where snow and ice load down wires to their breaking point even with hundred-foot spans. The conditions obtaining around a newly contemplated line should be as carefully studied as those surrounding the hydraulic and central station installations. Transplanting engineering may not always thrive in new soil. The conditions encountered in the valley districts of Southern California are: 1. No snow and ice. 2. A temperature ranging for 20 degrees Farhenheit at night in winter to 140 degrees in the sun in the sum mer. (That is, a wire will become that hot.) 3. Occasional severe dry north summer winds which blow hay and mustard stalks upon the lines. 4. Frequent interference with lines by wild cats, buzzards, sandhill cranes, mudhens and owls—especially the may and June owls. 5. Numerous and almost unavoidable hedges of eucalyptus trees from 50 to 150 feet tall, which, with the assistance of winds, shed twigs and long shreds of bark onto the lines. 6. Rapid decay of poles, some rotting off in four years, while the average life is eight. 7. High cost of poles, the cheapest being cedar, and in thirty-five and forty-foot lengths costing from $5 to $10 in the yard. Experience with bare aluminum cable suggested to the writer that stranded copper cables might be used in long span construction. and it was proposed to take good stocky forty-foot cedar poles, space them 225 feet apart, space the wires forty-five inches apart, and employ a sag of from fifteen to twenty-four inches, depending on the installation temperature. It was designed that a three phase construction for a voltage as high as 40,000 with one or two circuits of Nos. 3, 4, 5, and 6 cable with single cross-arms, and Nos. o, 1, and 2 with double cross-arms, should be used. The longest continuous long span work previously employed was in Europe on the Paderno-Milan transmission, with solid No. 1 wire and in which steel lattice work poles were spaced 1go feet. In the light of subsequent experience it would seem that if stranded wire had been used the poles could have been made a little heavier and taller and spaced twice as far apart. On the Vizzola-Ticzno-Milan transmission, also, steel latticed poles about the same distance apart had been used.

These ideas were received with temerity. It was argued that in case a wire broke so and so would happen; but if stranded and carefully installed they will not break. It was also argued that in case the poles rotted the line would be weakened more than if the poles were nearer together. But it would seem that a line should be kept in good repair, whether the poles were many or few, either by letting down five feet or stubbing. An engineer would not buy a boiler with more tubes in it than necessary and let them get in poor repair because there were enough tubes left to keep the boiler safe.

It was argued that in case the top of a pole burned off at the brace, as sometimes happens on the 30,000-volt line, No. 6 wire would not support the weight on a 450- foot span. Accordingly two experimental spans of 250 feet were constructed and strung with bare solid ‘‘second hand’’ medium hard drawn copper, and while it is not necessary to go into great detail in regard to this test, it is sufficient to say that it was amazing the abuse these wires stood before breaking. No. 6 aluminum cable was also tested, and stretched so far before breaking that it also deserves much respect. The stretching factor of safety of copper wire is scarcely appreciated by engineers, and after these tests the writer very nearly recommended solid wire for 225-foot spans. In fact, by referring to the June number of the Engineering Magazine, 1903, we find a description of a European steel pole line which evidently employs 246-foot spans with solid No. 2 and 00 wires on forty-foot poles. This is in connection with the thirty-eight-mile transmission from Cenischia, Italy.

The writer knows of no case where a good solid medium hard drawn wire has broken without a good apparent excuse, such as a burn-off. He has known of such breaks on poor wire which did not come up to the company’s standard specifications. The moral is that with rigid specifications followed by tests, much longer spans with solid coppercan be made. We have eight miles of No. 5 line with 150-foot spans with wire which did not stand a very good test which has given no trauble. Stranded copper, however, is superior for 225-foot span work in that: 1. A careless lineman in nicking it reduces its strength less than by nicking a solid wire. A test was made on one cable during which one strand broke at a five-inch sag on 225 feet, but the cable still stood up. 2. Its strength is more uniform throughout its length and therefore a less sag can be safely depended upon. 3. It has a higher strength per square inch because the wires are smaller and are individually stronger. 4. It has a spring effect or untwisting factor of safety. 5. It has a higher elastic limit. 6. It is believed, but not proven, that stranded copper will not burn off so easily as solid wire on account of its radiating facilities, and because one or two strands will hold the cable intact if the other strands burn off. It costs from 8 to 12 per cent. more than solid wire of the came conductivity. Following out these considerations, four miles of experimental line were installed in two sections. One in the Lytle Creek district near San Bernardino, two miles long, of three-strand No. 5 copper, and the other at Anaheim, of No. 5 seven-strand copper. In the former a 500-toot span was inserted. Otherwise the constructions are identical and have stood over a year and have passed through the most severe wind storms known in this section for many years. The poles and corner pins now stand perfectly straight, although another new line near by with 140-foot spans and six wires leans badly from the wind. ‘These medium-span lines were of course installed with care and with trusty men who have been with the company for several years.

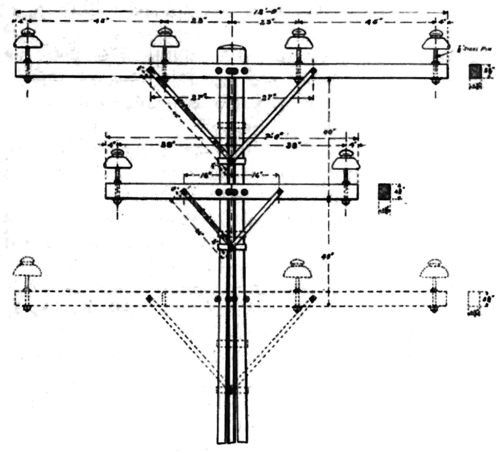

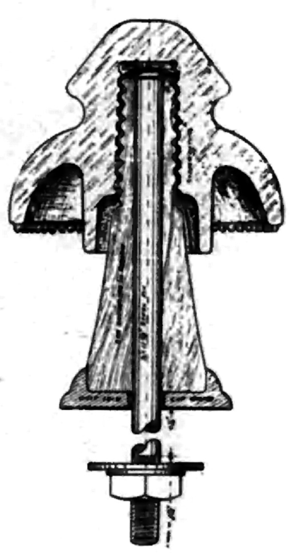

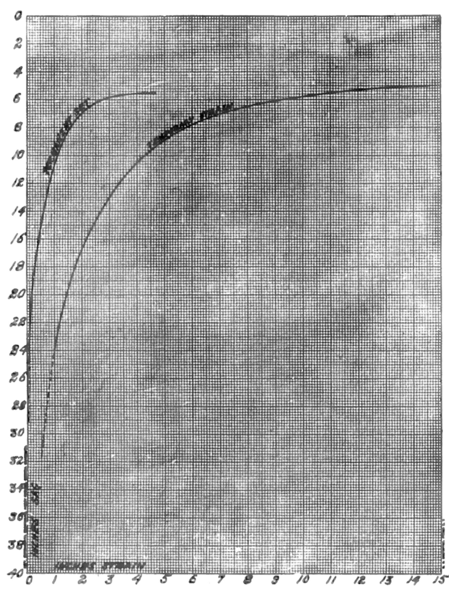

The top cross-arm of Figure 1 with three cables only, No. 13 Locke oak pins with a bolt center, two and one-quarter inch washers under each pin and nut, ordinary deep-groove double-porcelain insulators (selected) with a piece of copper wire netting under each to prevent the burning of pins, three strands of No. 17 medium hard drawn copper wires twisted together for a telephone cable which was strung on transposition glass and No. 13 Locke pins, and transposed every third pole, were some of the features of construction. Mogul paint was used on all threads, nuts, and points of contact of iron and wood and in the ganes, and galvanized iron wrapped around the poles under the guy wires. The strand was not allowed to touch the ground and was spliced by twisting with an annealed and flattened copper tube. (See Electrical World, Volume XLIII, 1904). A double lock tie of No. 8 wire was used with a wood covered tie wrench and no pliers and come-alongs were allowed on the job. All kinds were eliminated with a splice. They are both 10,000-volt lines and the advisability of using deep-groove double-petticoat insulators will be questioned. Seven years actual service, however, has shown them just as good as any. In fact, there are indications that they are better. They seem to discharge the line without burning the pins. Mechanically speaking, they are superior because the wire is let down closer to the cross-arm. They should, however, be used with caution because the conditions on other systems and localities might not be similar. The following are representative specifications used for stranded copper cables: 1. This copper cable is to be used for long span work with 225 to 300-foot span. The cable must be bare and composed of seven medium hard drawn copper wires. The cable must have a resistance of .3944 ohms per 1000 feet; that is, equivalent to No. 6 of 100 per cent. Mathiessen’s standard conductivity. 2. The cable must have a lay not greater than four inches; that is, one turn of each wire around the cable in four inches of its length. 3. The cables are to be furnished in such lengths that no splicing of individual strands is necessary. When the length of one wire in the strand runs out, the whole cable is to be cut at this point by the manufacturer, which is to be eventually spliced by means of copper sleeves when the line is constructed. 4. The cable must be pulled through a non-corroding grease bath before being reeled to prevent the chafing of the cable against itself in shipment. Paraffine is suggested. The reel must be braced with tongue and grooved. The strength of the cable must be such that it can be pulled up to a five-inch sag on a 225-foot span. (To be strung with a fifteen to twenty-four inch sag on the actual line.) In accepting the cable, seven samples will be tested from various portions of the shipment and five must stand a five-inch sag, while two will be allowed to break at this sag. Twenty-five samples of individual strands will be taken from the shipment and given a twisting test; that is twisted six times on and off its own diameter. In such a test the strands must show absolute uniformity of material and drawing. The surface of these individual strands must present a good luster and be free from seams, drawing nicks and slivers. 5. Bids are solicited on this cable, manufacturers to specify weight per foot and price per foot. The writer lays great stress on the old twisting test, as it is found to be an extremely good gauge of uniformity of the product. It is not considered advisable to have a wire of 70,000, 50,000, 30,000, 65,000, 40,000 pounds per square inch ultimate strength at various points along its length. It is more advisable to have it uniformly from 45,000 to 50,000. The twisting test determines this, and in a rough way the tensile strength. Tests on the seven-strand Anaheim cable and the three-strand telephone cable showed an ultimate strength of 59,500 pounds per square inch, corresponding to a five-inch sag on 225 feet. An actual span was used for the test and remarkably uniform results were obtained, the cable breaking at just five inches sag each time. A stress-strain diagram of this cable is given herewith. Note that at five and one-half inches sag the cable had stretched eleven inches in 225 feet and had a permanent set of 4.6 inches. Subsequent cables have broken uniformly at 63,250. After all, the important factor of this work is, has the engineer ‘‘done for a dollar what any fool can do for two,’’ which brings us up to a consideration of comparative costs. At the time when this matter was first being discussed, five and one-fourth miles of 30,000-volt line was built from Mentone to the new Mill Creek No. 3 power house. The ground was exceedingly rocky, which made the cost of digging holes from $1.50 to $3.30 each, and the cost of stringing and hauling very great, with two three-phase circuits of No. 4 and 125- and 120-foot spans. A saving of 16 per cent. could have been effected by 225-foot medium span construction with cables, and the line would have been safer because the wires would have been forty-five inches apart instead of thirty-six inches. With No. 6 the saving would have been 21 per cent., while with No. 3 wire, which is about the practical limit of this kind of work, a saving of 11 per cent would have been obtained. There is now being constructed nine and one-half miles or more of medium-span line in Lytle Creek, near San Bernardino, directly in the path of the severe north winds, of the 40-foot, wood pole, 225-foot span construction, with deep groove double porcelain insulators on 10,000 volts. Half of it is to be strung with No. 5 and half with No. 6 cables, and a saving of 24% per cent. and 26% per cent. will be effected. This is a single circuit line prepared for drawing in another one eventually. In single circuit lines where wire is a smaller percentage of cost the greatest percentage of saving obtains.

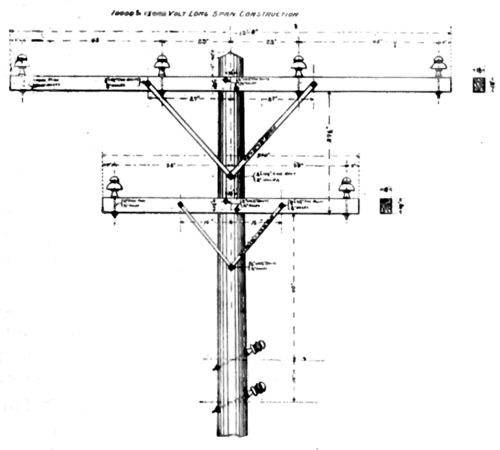

The company is now building fourteen miles of line from Los Angeles to Inglewood to connect the old United Electric Gas & Power Company’s beach town, thirty eight-mile, 17,300-volt transmission system, which the Edison Company has lately acquired, with the 30,000-volt Edison proper system. This is composed of six No. 4 seven-strand copper power wires, strung on a new special porcelain insulator and the three-strand telephone cable mentioned above. Thirty thousand volts will be impressed on the line. The forty-foot poles are of steel and placed 300 feet apart. The cross-arms are of wood because of the danger of birds burning wires off by grounding, but special iron pins have been designed and all pins are to be grounded together by a fine wire underneath the cross-arm to prevent burning of the wooden parts. The soil is mostly sand, and a cylinder of cement five feet deep is used to set the poles in. Even then the cost is only $48.00 per mile more than a wood pole line with 125-foot spans, because wood poles would have to be taller than forty feet. If, however, forty-five-foot wood poles and 225-foot spans had been used, the cost would mean an advantage of 20 per cent. over an ordinary 225-foot span cedar pole line. This saving is due to the large cost of forty-five-foot poles. The cost of a forty-foot tripartite pole made by the Franklin Rolling Mill of Franklin, Pa., in this steel construction, is about $35.00 f. o. b. Los Angeles, as against $9.00 for a forty-five-foot cedar pole, so that the above figures are rather surprising. The 30 per cent. + $48.00 per mile excess cost of the 300-foot span steel line over the 225-foot span wood line is what the company pays in first cost to prevent depreciation. The advantage is gained that, should the line ever be changed or moved, the poles would be as good as new for a new place. Ordinarily, in such cases, even though the poles are not rotted badly, they are not worth placing again without sawing off. This principle, which is often lost sight of, is especially applicable to city distributing systems. It will be observed that this construction is especially advisable on lines with small wires, i. e., telegraph, telephone and power lines of Nos. 3, 4, 5 and 6 wire. The percentage saving on single circuit lines is especially great, and the percentage saving is greater the greater the cost of poles and digging holes, and particularly where the poles must be hauled a great distance and when the company must provide tents and eating facilities along the line in building. On high voltage lines, where the insulators cost considerably, the saving is very patent. Perhaps the principal mechanical, and therefore ultimate, monetary advantage in medium or long span work is the greatly reduced trouble with insulators and pins, and burning off of poles, and in fact all the troubles which lines are heir to, by making the parts fewer and each better, which, by the way, greatly reduces the necessity for double-pole lines. In other words, make good porcelain eggs and make them larger and stronger than are usually laid, put them in one good strong basket, and watch the basket, and it will not cost so much to watch the basket, either, as it usually does. It will often be found, especially in this western country, that, by building a line quickly, not only is money saved in construction, but revenue and profit is more quickly obtained or lost power more promptly eliminated. Medium span wood pole lines are built in 60 per cent. of the time usually employed. This construction would seem advisable also for long distance telephone and telegraph work in certain sections, and where it is presupposed that a first-class line of long life and of no trouble while it lives is the more economical one in the end. Only in rare instances does the fifteen to twenty inches sag instead of eight make any difference in the height of poles. Private telephone lines should be at least five feet below the lowest power crossarm, and at least eight feet above the tallest trees, which usually dictates the height of poles. These methods may become important in case a double-pole line is considered advisable where small amounts of power are transmitted at high pressure or small distances. It may be argued that copper for telephone work on long-distance transmission lines is too expensive, but it will last forever, be freer from induction, and its percentage of total cost per mile is very small. It is dangerous to pull in a new telephone line alongside of an old old one on transmission lines when the old one is worn out. But if iron must be used, why not use three-strand steel wire on long span work and the above figures will not be altered by more than 1 per cent. The question of the preservation of poles from decay is of some importance in this discussion. Granting that a good, cheap, practical method of preserving poles at from $0.75 to $1 per pole can be found—and we are making rapid progress in this direction—the saving by using this medium-span construction is greater than cited above, and entirely removes the question of the greater weakening of the line by the decaying of poles in the longer span construction. In conclusion, it may be said that by effecting a saving of from 10 to 30 per cent. in lines ordinarily costing from $700 to $1700 per mile, and having from three to twelve of the smaller sizes of wire, a slight advance has been made in the art, in the field of light construction, where the cost of poles, freight and haulage is great, especially as they are better and safer lines than are ordinarily built with more cost, or stating it another way, they are as cheap as the cheapest allowable lines and twice as safe and free from trouble and danger.

|