[Newspaper]

Publication: The Los Angeles Record

Los Angeles, CA, United States

vol. 31;City Edition, no. 10312, p. 2A, col. 2-5

All Day Long They Blow and Blow

|

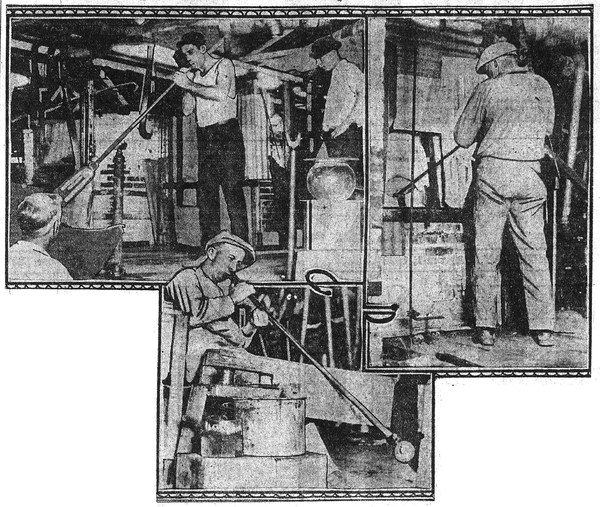

Top, left, G. Cornell, blowing ice holder for fruit juice container, and James Carlson, a helper, at the McLaughlin Glass Company, Fifty-second and Long Beach boulevard. Upper left, Bert Mosley gathering glass from furnace and, lower, Mosley blowing hot glass.

BY AGNES UNDERWOOD

FOREVER blowing bubbles!

Rather a hot job in this particular case, yet these same bubbles furnish some of the most important necessities of our life. It is really surprising to look around and see and count the many things used in our daily routine made of glass.

Through the courtesy of the owners of the McLaughlin Glass company, we took a trip through their factory yesterday and were amazed at the way the various things were made of glass and the ease and rapidity with which the work is carried on.

It is almost impossible to imagine anything as hot as the furnace in which the glass is melted. In looking into the small opening from which the glass is gathered, it seems that we are looking at the bricks on the bottom of it, the mixture inside being so transparent.

The heat waves coming from this furnace are so terrific that it is not an uncommon thing for the workers to faint, especially during the summer season, and the gatherers who take the glass directly from the furnace, have a job that is a “job."

The glass is drawn out on the end of a long hollow iron rod, and unless the blower knows his business, and works fast, the glass falls before it has had time to set. Some of the articles are entirely hand blown, some blown into a mold and some just molded. Of course the latter are the cheaper grade. After they have been blown or molded into the desired shape, they are tempered in one of the hot ovens for several hours, then the rough edges are ground or cut.

* * *

ONE man was making those beautiful glass lamps that are filled with pretty colored water. Imagine our surprise when he told us that there was from 16 to 20 pounds of glass in each one of the particular kind he was making. How many of us could get that much red hot glass on the end of a stick and make it stay where we wanted it too. Another man, who was described to us as a mechanic, makes beautiful little glass bud vases, with a green snake wound around them to make the stand for them; others were making the ice container for these fruit juice containers we see on soda fountains; another crew were making fish bowls while still others were making insulators for telephone and telegraph poles. Every man had a certain little important thing to do and every one was right on the job to do his share.

Few of us realize the skill, downright hard work and "blows" required to furnish us with some of our "glass" comforts of life.