[Trade Journal]

Publication: The Journal of Electricity, Power and Gas

San Francisco, CA, United States

vol. 15, no. 1, p. 11-14, col. 1-2

PORCELAIN INSULATORS: THEIR MANUFACTURE AND TESTING (1)

BY H. W. CROZIER.

AS porcelain is now recognized as the only satisfactory material for insulators, particularly for pressures of ten thousand volts and over, a short description of methods of manufacture and testing may be of interest. Electrical engineers working on overhead lines will be interested in knowing that porcelain can be made in any desired shape or form by following certain methods in the design of the parts. As the shrinkage from the wet clay to the finished article is 15 per cent., square corners and great thicknesses are debarred.

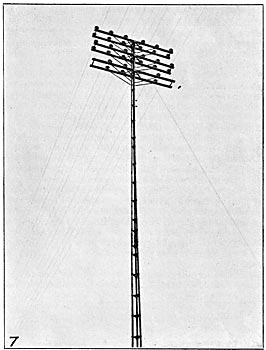

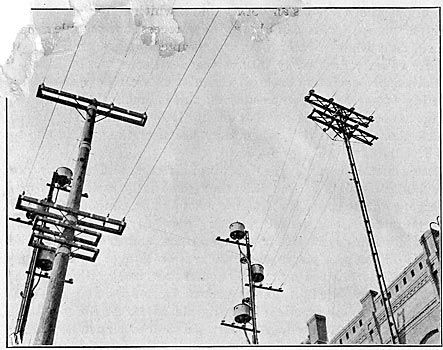

| |||

| Figure 7. Steel Poles in Southern California |

Pieces should be designed for as near uniform section as possible and changes in thickness can only be obtained very gradually. As a rule a thin piece of porcelain will have as high a dielectric strength as a thick piece; so that, save for mechanical reasons, there is no advantage in making pieces more than three-sixteenths of an inch thick, as a piece three-sixteenths of an inch thick will stand 50,000 volts test for one minute. In large insulators pieces up to three-fourths of an inch may be made, but three-fourths of an inch should not be used except in the very largest sizes - fourteen inches in diameter and over. In ordinary work one-half inch to five-eights of an inch should serve every purpose, and insulators made up of two, three, or even four shells can be easily made. The parts can be put together with Portland cement or with glaze and are mechanically as strong as if made of one piece. Electrically, insulators made of many pieces are superior to solid ones on account of the higher dielectric strength of the pieces.

The usual methods of the pottery are used for working the porcelain and but few variations are introduced. The screw thread offered difficulties for years; but the introduction of a valve in the bottom of the screw-forming tool to allow entrance of the air as the tool was withdrawn overcame this difficulty. The screw thread is not used in Europe-made insulators, as screw machines are used only in this country. The equipment for clay working consists of ball-mill and filter press with pumps. The ball-mill usually consists of a wooden tank eight feet in diameter and eight feet long, in which the clays are put with sufficient water to make a very liquid mixture. Quartz pebbles, which are obtained from glacial drifts in Greenland and brought here as ballast, are also inserted in the ball-mill for the purpose of thoroughly pulverizing the clay. The ball-mill is run about three hours, when the liquid clay is run into tank which contains a stirrer so that the clay may be kept in that liquid condition until needed.

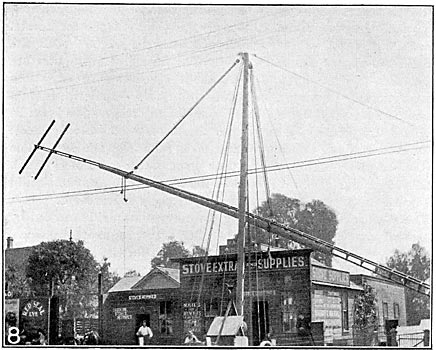

| |||

| Figure 8. Steel Poles in Southern California |

The filter press consists of a rack containing cast iron plates with canvas bags set between the plates. Each plate and canvas bag has a hole in the center through which the liquid is pumped by a force pump. The canvas is of such quality that the water only will leak through, and the clay will be retained. After pumping about an hour the pressure finally reaches 150 pounds and the press is found to be full. The press is then opened and the clay removed and put in storage.

There are two general processes used in the manufacture of porcelain insulating articles: One called the dry process and the other called the wet process. The essential feature of the dry process is the use of steel dies in which dry pulverized clay is placed and pressed to the form desired. The forms may be of any desired shape, provided there is sufficient arrangement made for withdrawing the dies. Holes may be inserted and the dies are very similar to molds used in casting iron and other metals, with the exception that no cores can be used, save such as can be made a solid part of the die, or withdrawn with the die.

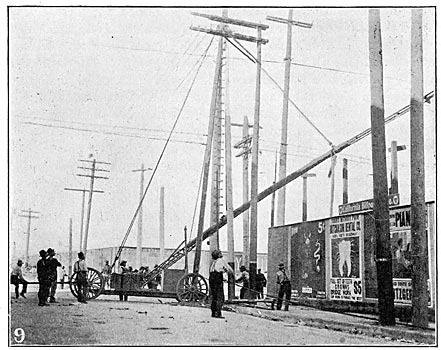

| |||

| Figure 9. Steel Poles in Southern California |

In the wet process all the work is done in plaster dies and each factory contains a plaster department where dies and forms of all kinds are made. The method is quite simple. A block of plaster is taken as near the shape of the finished article as convenient and put in a lathe and turned to the desired form. Other parts which cannot be put in a lathe are formed by means of file and knife, as the plaster is quite easily cut. The pattern is made considerably larger than the desired finished article and the shrinkage allowed is usually one-seventh, for the wet process, although this varies with the type of clay, and with the amount of moisture present, but is usually a constant in any one factory. The finished pattern is smeared with oil, for the purpose of keeping other plaster from sticking to it, and cast-iron forms are used which determine the shape of the outside block. These are set over the pattern and liquid plaster poured in, making the finished mold. Molds are made in two or three pieces, depending on the size and shape of the article desired. Usually, however, two pieces are sufficient to allow for projections. Large insulators, however, require three pieces, which are made in the form of one large ring and two smaller pieces, to take the center part of the insulator where the wire is tied.

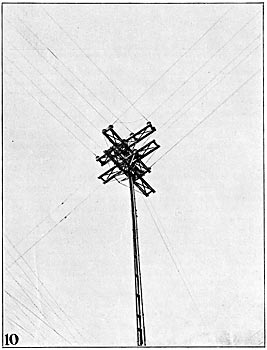

| |||

| Figure 10. Steel Poles in Southern California |

There are two general ways of making insulators by the wet process, one "jiggering" on a wheel and the other pressing in a rotating press. The jiggering method is the ancient potter's wheel, used with plaster dies. The plaster die is set on the wheel and tempered clay put in it and pounded down to fill the mold. The wheel is rotated and the clay worked by hand to the desired shape with the aid of a "former" of wood or iron which is supported near the wheel and pressed into the rotating mass of clay by the workman.

The machine for making the screw thread of an insulator consists of a frame holding a traveling screw and stationary nut. The screw is rotated in either direction by means of friction clutches and there is a stop and cut-off so that the travel of the screw can be regulated. A plaster die with an iron holder is set beneath the screw and the screw is started by means of a pedal. On the end of the screw is a tool made of crucible steel which is in the shape of a the desired cavity in the insulator. A small valve is in the bottom of the screw-tool to allow the air to enter when the screw is withdrawn from the soft clay. The machine is operated very rapidly and the screw runs about 200 revolutions per minute. Other forms which do not have a screw are made on this machine also, provided they are not any larger than about ten inches in diameter and ten inches deep.

| |||

| Figure 11. Steel Poles in Southern California |

All insulators made are left in the molds and stacked up in the factory for about six hours, after which time the plaster has absorbed enough of the moisture so that the parts may be handled if care is taken. As soon as the pieces can be handled without distortion they are taken to wheels and laid on plaster forms. The outside parts, or parts which have been in contact with the plaster molds, are finished off smooth. Finished insulators are set in the drying room and kept about two weeks, after which time the clay is thoroughly dry and quite hard, — so hard in fact that it is necessary to use a knife to make any impression upon it.

In the dry process the clay, after coming from the filter presses, is worked in a pug mill and re-pressed in other filter presses. The re-pressed clay is dried and is then ground up until it is much finer than sugar, when it is sent to the machine room. It should contain enough moisture to adhere if strongly compressed.

| |||

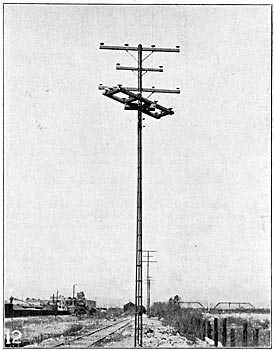

| Figure 12. Steel Poles in Southern California |

The machines used for pressing the clay are as a rule worked by means of cams and fly-wheels to obtain the requisite pressure. Hydraulic presses are used to a certain extent for the larger pieces, but do not work fast enough on the small sized pieces to suit most managers. This does not mean that hydraulic presses will not work well on small pieces; because, by means of multiple dies, sixteen, twenty-five or thirty-six pieces, or even more, may be made at one stroke. The dies are quite costly, however, and require the highest skill for their manufacture. Knobs, cleats, socket parts, fuse block, and jobber pieces all must be made to exact dimensions, are made by the dry process, but as a rule nothing larger than about one pound is attempted.

Tubes are made by squirting wet clay through a die by means of a steam-operated machine. The machine consists of two cylinders in a vertical position; the upper one, for steam, about twelve inches in diameter and provided with valve, etc., for its operation, and the lower one provided with a plunger about eight inches in diameter. A lump of clay is put into the lower cylinder and the plunger caused to decend. The clay is forced out of the die in the bottom in the form of a long tube from which pieces are broken off by hand and laid on a board. When twenty pieces are collected the board is passed to a second operator and all the pieces are cut to length at once by the simple operation of sawing off the ragged ends. The tubes are then taken to a machine which has a turret head holding eight mandrels just fitting the tubes. By pressing a pedal, an arm holding a die is caused to press against the end of one of the mandrels and form the head of the tube. The turret head rotates at each stroke of the machine and the operator occupies himself with withdrawing the finished tubes and putting on others. Tubes are fired in a vertical position.

| |||

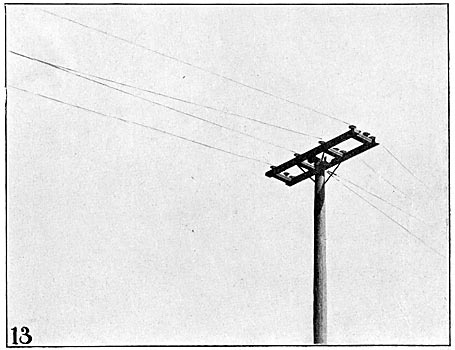

| Figure 13. Steel Poles in Southern California |

The dried insulators are taken to the glaze table and dipped in the glaze, which is simple a liquid clay which melts and forms a glaze at the temperature necessary to vitrify the porcelain body. After about twenty-four hours further drying the insulators are taken to the Kiln-room and placed in saggars and loaded in the kilns. If insulators are made of two or more shells and are not more than ten inches in diameter the parts may be united by putting them together with a little extra glaze, and firing the whole together. Saggars are pots made of burned fire-clay and are used to protect the insulators from the direct flames. The setting of a kiln is usually a very delicate job as the saggars must be piled up to a height of ten feet, and proper space must be left between each row of saggars to allow proper circulation of the flames and gases.

Kilns used for firing insulators are usually fourteen feet in diameter and ten feet in height, and have a brick floor with flues underneath. In the best arrangement, an outside stack is connected by an underground flue. This gives a clear kiln and by proper arrangement of the flues an even temperature can be obtained clear to the bottom. Eight grates for a fourteen foot kiln is the usual arrangement, and either coal or gas is used for fuel. Gas is very convenient and is used where the supply can he relied on; but even where gas is plentiful the cheap potteries at times use coal because a failure of the gas supply might ruin a kiln of material.

Temperature measurements are made by means of small pyramidal pieces of porcelain called pyrometric cones. These are prepared at the Ohio State University and are made to melt at various temperatures. The potter accordingly selects four cones, one of which will not melt at a temperature which he intends to reach, and sticks them in a piece of clay, so that the cones stand in a vertical position and can be seen through peep-holes in the kiln. These holes are normally closed by fire-brick. A number of these sets of cones are put in the kiln and during the firing the fireman can tell quite accurately the condition of the kiln by watching the cones. As the temperature rises the cones melt one by one, and when all the cones but the highest numbered ones are melted the kiln is finished and may be cooled off. It takes about forty-eight hours to fire a kiln and twenty-four hours more for the cooling.

For the purpose of detecting faults in the finished porcelain pieces an electrical test should be made on all insulators to be used on 6000 volts or over. A convenient testing set consists of a number of 10,000 volt transformers, connected in series, and as many of these are used as is necessary to obtain the desired testing pressure. A single transformer can be used also; but the regulation at different voltages varies so much that a skilled operator is necessary. The dynamo should give as near a sine wave as possible, but this point is not essential, as a spark-gap is used to measure the pressure.

The pieces to be tested are set on pins on a rack, each pin having a conducting wire through its center. A wire stretched overhead has chains suspended from it and these chains are laid on the top of the insulator or attached to suitable electrodes. About thirty insulators are tested at once. The current is applied for a minute or more; when, if of sufficient intensity, the defective pieces speedily puncture and are removed. In the manufacture of large insulators, where details are watched, the proportion punctured will be about 8 per cent. but if care is not taken in the drying-room, the loss may be as high as 15 per cent. or even 25 per cent.

It is usually difficult to test insulators made of two or three pieces and glazed together, because sufficient pressure cannot be used for the proper searching out of faults. For this reason insulators cemented after testing are much safer, as it is then known that the separate pieces are sound. As a rule there is no reason for testing complete insulators whose pieces have been previously tested, unless it is desired to watch their behaviour under test. Insulators should be designed to stand any pressure which can be applied to them; that is, they should stand a pressure which will maintain an arc clear around them. This makes, with an iron pole, an efficient lightning check and may be used in the future as an additional safeguard.

Water is sometimes used as an electrode for testing purposes, as it is supposed to flow into cracks, if present, and search out weaknesses. Its usefulness is questionable as it has a tendency to increase the leakage over the surfaces and to distribute the pressure. On account of the leakage over it is usually impossible to obtain as high a pressure on a piece of porcelain as if tested dry and the current keeps arcing over. The use of water also interferes with the final inspection, which should be made before shipment.

(1) From The California Journal of Technology, Volume IV, page 91, October 1904.