[Trade Journal]

Publication: Western Electrician

Chicago, IL, United States

vol. 41, no. 12, p. 212-214, col. 2-3,1-2

Transmission Plant of the Niagara,

Lockport and Ontario Power

Company.

From time to time the Western Electrician has kept its readers informed of the operations at Niagara Falls by the various power-generating and transmitting companies. Conspicuous among these companies is the Niagara, Lockport and Ontario Power Company, which on July 7, 1906, put in operation its first transmission lines, marking the inauguration of the first undertakings in the matter of distributing Niagara power over a large section of the country, and the beginning of an enterprise which is one of the most important of its kind in the world.

Several accounts of this company's plans and operations have appeared, in the Western Electrician, the principal one being in the issue of February 24, 1906. Now that the plant is well in operation, .a further account of the equipment and methods of operation will be of interest. The following details and illustrations are taken from the paper of Mr. Ralph D. Mershon, chief engineer of the company, read at the Niagara Falls convention of the American Institute of Electrical Engineers on July 26, 1907:

The plans realized at present and contemplated for the immediate future involve a maximum transmission distance of 160 miles. This distance puts the plant among the longest transmissions of the world. The prospective system is a comprehensive one for the delivery of power in the United States within an economic transmission radius of Niagara Falls, and especially for its delivery in the northern and western portions of the state of New York. The company expects within the next two years to be transmitting 60,000 horsepower, and its present right-of-way purchases are with reference to an ultimate transmission of 180,000 horsepower. The plans of the company as at present laid out contemplate the transmission of this power by means of main lines and branch lines therefrom; the contracts for power being, wherever possible, made for delivery of the power at the main-line voltage of 60,000 less line drop. Where, however, the business of a given territory will justify it, the company will install step-down transformer stations for the delivery of power at a lower voltage. Each of the main transmission circuits will be capable of receiving and transmitting 30,000 horsepower at 60,000 volts, and it is intended always to provide a sufficient number of spare main transmission lines to insure continuity of service on the main line.

The Niagara, Lockport and Ontario Power Company is a transmission company only; that is, it buys the power to be transmitted and has, therefore, no generating plant of its own. The power for the transmission is generated in the hydraulic power station of the Ontario Power Company, situated on the Canadian side of Niagara Falls. This plant has been described in the Western Electrician. The transmission lines of the Ontario Power Company extend from their transforming station to a point some six miles farther down the Niagara River, at which point the lines connect to circuits spanning the Niagara River. The Niagara, Lockport and Ontario Power Company takes delivery of the electric power at the international boundary line in the middle of the Niagara River.

The installation which the company has now in opteation is for receiving 30,000 horsepower and delivering this amount, less the line loss. The main transmission consists of two lines in duplicate. From the Niagara River to Lockport, a distance of 16 miles, there are two lines on the company's private right-of-way, each capable of transmitting 30,000 horsepower. From Lockport to Mortimer, a distance of 57 miles, there is a line on the company's private right-of-way having a capacity of 20,000 horsepower. From Mortimer east to Syracuse, a distance of 81 miles, there is a line on the company's right-of-way having a capacity of 10,000 horsepower. From Lockport to a point about 11 miles east and thence south on the company's private right-of-way to the West Shore, thence on the West Shore to Pittsford, is a line having a capacity of 20,000 horsepower. From Pittsford on the West Shore right-of-way east to Syracuse is a line having a capacity of 10,000 horsepower. From Lockport south to a point south of Buffalo there are two transmission lines on the private right-of-way of the company, each having a capacity of 30,000 horsepower. These two lines south are tapped into the two lines coming from the Niagara River to Lockport, and constitute, therefore, at present, a branch line; but they will be eventually extended clear through to the Niagara River, and it is in anticipation of this extension that they are constructed with the full capacity of 30,000 horsepower. As will be seen from the above, the distance from the Niagara River to Syracuse is 154 miles. In addition to this the transmission from the transforming station of the Ontario Power Company to the Niagara River has a length of about six miles, making, as previously mentioned, a maximum transmission of 160 miles.

The power is brought across the Niagara River by means of aerial cables spanning the river, and delivery of the power is taken by the transmission company at the international boundary line. The cables are brought across the river in three spans, one span from steel cantilevers at the top of the cliff on the Canadian side to steel towers at the water's edge on the Canadian-side, another span from the water-edge towers on the Canadian Side to the corresponding towers on the American side and a third span from the steel water-edge towers on the American side to the steel cantilevers at the top of the cliff on the American side. The use of cantilevers is necessitated mainly by reason of the steep angle at which the cable descends from the top of the cliff. Their use also makes possible the required clearance between the cable and the slope of the gorge, a point of special importance on the American side in view of the fact that one of the branch lines of the New York Central Railroad is on the American slope of the gorge. The steep slope of the cable at the cantilevers would make it bear upon the upper petticoat of the insulator supporting it, if the cable were attached to the top of the insulator in the usual way.

| |||

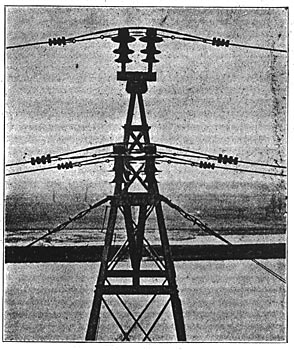

| Top of Double-Guyed Steel Tower. |

The steel cantilevers and the river-edge towers are all designed to withstand the most extreme conditions of sleet and wind that will probably ever exist. The requisite mechanical strength of the insulation at the points where the cables are attached to the steel structures is obtained by using a sufficient number of line insulators; and the proper distribution among these insulators of the forces which will come upon them is effected by means of malleable cast-iron caps cemented to the tops of the insulators, and to which the cables are fastened.

| |||

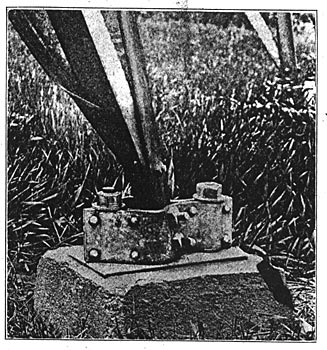

| Method of Fastening Tower to Foundation. |

With the exception of that portion of the main line on the West Shore between Churchville and Syracuse, the main-line structures are all steel towers and the standard line-span is 550, feet. On some portions of the transmission line, however, much longer spans are used, the longest at present installed, being 1,253 feet. In some cases these long spans had to be provided with towers heavier than the standard, but in some cases it was possible to put them up with little, if any, modification of the standard tower construction. For a number of reasons, the principal one being lack of the requisite space, it was necessary to use on the West Shore right-of-way between Churchville and Syracuse wooden construction of special design the standard span being 220 feet. In every case on the 60,000-volt lines, each line of towers or wooden structures carries only one three-phase circuit. The main-line conductors installed so far are all of aluminum cable, except on a portion of the line between Mortimer and Syracuse, where, because of the long spans employed, it is preferable to use copper.

| |||

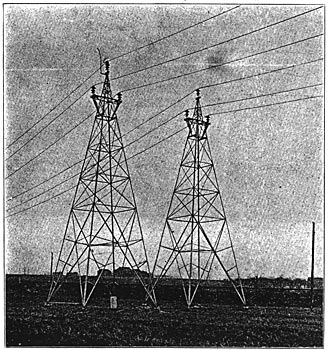

| Line-Structure Lightning Arrester on Steel Tower Niagara, Lockport and Ontario Power Company. |

The first of the steel towers installed were of the tripod type, made of lap-welded pipe; but the later towers, and those which in the near future will be installed, are of structural shapes and galvanized. The later towers are interchangeable; that is, the gliyed and unguyed towers are exactly similar except for the guys and double insulators of the former. Contrary to the practice which has heretofore been followed in the matter of steel line towers, the towers of this transmission line are mounted on foundations of reinforced concrete. These foundations are designed to utilize the weight of the earth around them in resisting uplift. The towers and their foundations are capable of withstanding transverse forces which will be brought upon them when the line cables are covered with 0.5 inch of ice all around them and the wind blowing trartsverse to the line at a velocity of 75 miles an hour. The towers have the same strength in all directions; that is, they are capable of withstanding the same forces in the direction of the line that they are capable of withstanding transverse to the line; but to meet the contingency, not likely to occur, of all three cables breaking at once, in which case the full tension of all the cables might be brought upon the towers, there are at intervals along the line certain towers guyed both ways in the direction of the transmission line and having double fixtures.

| |||

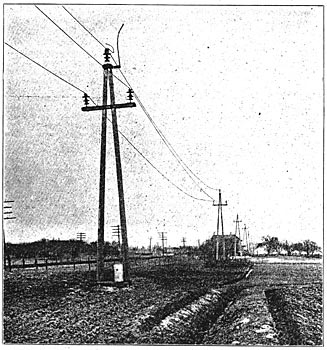

| A-Frame Construction, Showing Line-Structure Lightning Arrester. Niagara, Lockport and Ontario Power Company. |

As stated above, on the West Shore right-of-way it was necessary to use wooden line structures. The type of construction employed is that which has been designated by the company as "A-frame construction." By adopting this type of construction, in which each structure consists of two poles instead of one, it is possible to use twice the length of span that would be used in ordinary wooden pole construction, and employ therefore one-half the number of insulators. On some portions of the West Shore right-of-way it was necessary to use steel construction, and in such places there were installed galvanized lattice steel poles.

In a number of places on the main line, both on the West Shore and on the private right-of-way, it is necessary to cross the Montezuma marsh. Where this marsh was crossed with steel-tower construction, the concrete foundations for the steel towers were built by first excavating the swamp through the soft mud until the soft marl, forming the sub-stratum of the swamp, was reached. On the marl was laid a platform of two layers of corduroy, and on this platform was built the concrete foundations, the weight of which was made sufficient to take care of any uplift which will come upon the towers.

| |||

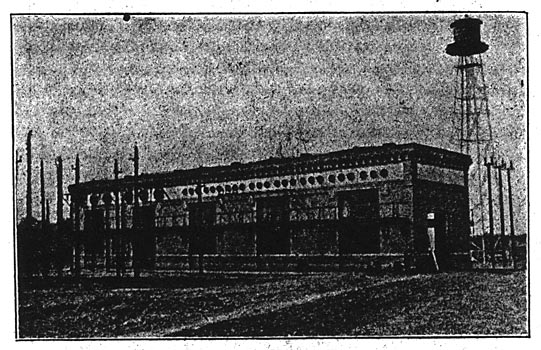

| Lockport Sub-Station, Showing 11,000-Volt Outdoor Lightning Arrester. |

In some of the towers and A-frames there is a horn attached to a cap on the top of the insulator and another horn alongside of it fastened to the structure and extending some distance above the insulator. This comprises a combined line-structure lightning arrester, or spark-gap, and lightning rod. It has been decided to make a careful trial of this method of protection of the line before resorting to a grounded cable, partly because of the great expense of the grounded cable and partly because there is no reason to think, so far, that it will necessarily afford complete protection in every case. For the present these line-structure lightning-arresters will be installed only on the top cable in view of the fact that during the last lightning season, in the course of which a number of insulators were broken by lightning, more than three-fourths of the insulators so broken were top insulators.

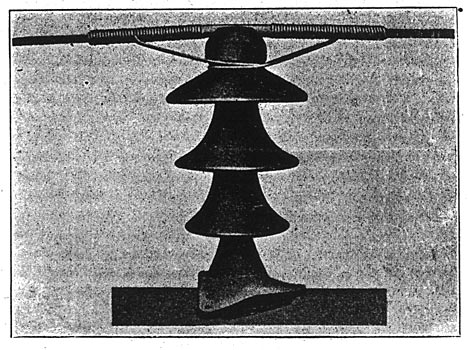

%%The insulator used on all the main-line construction is one especially designed by Mr. Mershon for this plant. It has probably the greatest factor of safety as regards flashing, etc., of any insulator in practical use today, and is considerably larger and heavier than any insulator of which corresponding use has heretofore been made. It consists of three shells nesting in each other and cemeted together by means of neat Portland cement, the whole insulator being cemented in a similar manner to a steel pin before attachment to the tower. The total height of it from the edge of the lower petticoat to the top of the head is 19 inches. The diameter of the upper petticoat is 14.5 inches. The insulator used on some of the branch lines is smaller and less expensive than that for the main line, partly because the branch lines receive in general a somewhat lower voltage than the main line and partly because the lines, carrying the small amounts of power they do, are not considered to be entitled to the same insurance as the main line.%%

Each branch line has in series with it, at the point where it is tapped off the main line, 60,000-volt outdoor fuses to cut-out the line in case of trouble upon it. The fuses consist of lengths of thin copper wire 16 feet long, run through an ordinary small rubber bathroom hose and laid in clips on top of a wooden bar, supported at each end and the center by line insulators mounted on poles. The fuses are parallel to each other, in the same horizontal plane, and the distance from center to center is about 25 feet. These fuses have so far proved very satisfactory, but will probably in time be replaced with fuses of the expulsion type. There are only three sizes of cables used on the main transmission line, designated by the company as 3/3, 2/3 and 1/3, respectively. The 3/3 cable is aluminum cable, consisting of 19 strands and having a total area of 642,800 circular mils, being equivalent to 400,000 circular mils copper. The areas of cross-section of the other cables are, respectively, 2/3 and 1/3 that of the large one.

In ordinary straightaway work the cables lie in the top groove of the insulator, and the pull of the cable is taken care of by means of two aluminum wire ties around the neck of the insulator. One of these ties extends each way along the cable. The tie itself consists of a single loop around the neck of the insulator, the two ends of the loop being twisted around the line cable. The result is that the cable is not really fastened to the insulator at all, but simply lies in the top groove. The ties do not. therefore, perform any function, except when there is a pull on the cable tending to slide it in the direction of its length. The advantage of such a tie is twofold. First, the full strength of the tie wire is developed, which is not the case if a tie is twisted or "pig-tailed," since, in such case, the tendency is for the tie to cut itself in two at the twist; second, the tie does not damage the soft aluminum cable, as would be the case with most of the other ties usually employed.

In other than straightaway work, and where it is desirable that the method of fastening to the insulator shall be such as will withstand a pull equal to the full strength of the cable, in case the cable should break, the tie mentioned above is not used, but instead there is employed a cable-clamp and a yoke extending each way on the cable.

| |||

| 60,000-Volt Main-Line Insulator With Tie and Cable Protection. |

In every case the cable near the insulator is protected from possible arcs, so that in the event of an arc there will be a chance for the circuit-breaker at the generating station to open before the cable shall have been burned off. This protection is accomplished in the top groove of the insulator by means of sheet aluminum wrapped around the cable at this point to a thickness of one-eighth inch, and is accomplished on each side of the head of the insulator to a distance of 12 inches from the head partly by the turns of the tie-wire mentioned above and partly by an additional serving of tie-wire. Where, in the case of the use of cable clamps, no tie-wire is used, its absence is made up for by additional serving.

At intervals along the line there are provided disconnecting switches for sectioning the line to facilitate testing out in case of trouble or cutting out any portion of the line which is damaged. There are also provided at certain points in connection with these disconnecting switches cross-connecting switches, enabling the interconnection of different portions of the two lines.

On a considerable portion of the company's right-of-way is a wagon road for use in patrolling the line and delivering materials for construction or repair. At certain points along the line there are patrol houses for the storage of material, for taking care of teams and for the comfortable housing of the patrolmen. Each house has in it sleeping room, kitchen and sitting room. On all of the transmission lines also the company has a private telephone line on a separate set of wooden poles. Taps from this line are brought into each of the transmission houses, and in addition to this the line patrolmen have portable telephones which can be connected to the telephone line at any point.

Most of the contracts which the company has for the supply of power cover the delivery of the same at the main-line voltage, so that, so far, the company has installed only three sub-stations, two of them of considerable size at Lockport and Gardenville, respectively, and one at Baldwinsville, a very small and comparatively inexpensive one. The stations at Lockport and Gardenville have each a normal capacity of 3,000 kilowatts, not including the spare apparatus. They are so designed that their capacity can be indefinitely increased. The Baldwinsville station has a capacity of 750 kilowatts.

The 60,000-volt bus-bars at the Lockport and Gardenville sub-stations are outdoors; in otherwords, these bus-bars have been treated exactly as if they were part of the transmission line and located out of doors in a manner, so far as insulation is concerned, similar to the transmission-line cables. In connection with them are disconnecting switches for making various combinations of the apparatus connected to them. Of course the disconnecting switches are not intended to break the working current. When it is necessary to break the circuit under load, it will be accomplished by means of the 60,000-volt electrically operated oil switches installed in the station which, in the case of the Lockport sub-station, serve also for the control of the two lines to the Buffalo district.

Another feature out of the ordinary in connection with this station is the lightning-arrester equipment. This equipment is also out of doors and consists of a number of horn-type lightning arresters mounted on wooden poles in much the same manner as such arresters are ordinarily mounted. The installation differs, however, from the ordinary lightning-arrester installation of this kind in that, instead of there being only one pair of horns for each line conductor there are three such pairs. One pair is set for a comparatively low-striking electromotive force and has in series with it a high resistance; the next pair is set for a higher striking electromotive force and has in series with it a lower resistance; a third pair is set for very high-striking electromotive force and has in series with it a fuse.

The theory on which these arresters are installed is that for ordinary slight static disturbances in the line the arrester having the lower striking electromotive force will discharge, and since it has in series with it a comparatively high resistance the resultant disturbance to the system due to the generated current which follows the discharge will be comparatively slight. A more severe static disturbance (whether due to lightning or to any other source) will cause both the arrester having the lowest gap and the arrester having the next higher gap to discharge simultaneously, thus affording two discharge paths to earth, the combined resistance and inductance of which is considerably lower than that of the first path. This will mean a somewhat more severe disturbing effect on the system due to the generated current which follows.

There will be installed shortly on the company's system two switching stations, one at Mortimer and one at Syracuse. The one at Syracuse will be for taking care of the two incoming 10,000-horsepower lines and the outgoing lines to the consumers in Syracuse. The one at Mortimer will be for taking care of the two incoming 20,000-horsepower lines and five outgoing lines, two of them being a line in duplicate to Rochester; two of them the line in duplicate to Syracuse, and one the Avon branch line, supplying several installations, among them the station of the Erie Railroad Company, operating its trolley line between Rochester and Avon. Both these switching stations will be equipped with the 60,000-volt electrically operated oil switches, reverse relays and other apparatus necessary for properly manipulating the circuits which they control.

The transmission plant has been built in accordance with the designs of Mr. Mershon; acting as chief engineer of the Niagara, Lockport, and Ontario Power Company, and has been constructed under his supervision and that of his assistant in the work, Mr. H. L. St; George. The construction work has been done by the Iroquois Construction Company of Buffalo, headed by General Francis V. Greene, president, the construction work itself being directed by Mr. E. B. H. Paine, vice-president and chief engineer of the construction company, assisted by Mr. Walter S. Skinner and Mr. S. Piek.