[Trade Journal]

Publication: The Telegraphic Journal and Electrical Review

London, England

vol. 6, no. 120, p. 41-42, col. 1-2

|

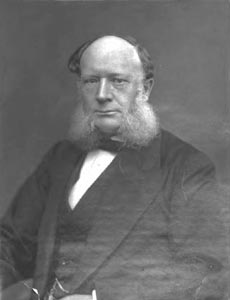

CHARLES WILLIAM SIEMENS.

Dr. Charles William Siemens, F.R.S., the celebrated engineer, who has gained a world-wide reputation through his researches on heat and electricity, his economical application of fuel, his metallurgical processes, and his scientific investigations, was born at Lenthe in Hanover, on the 4th of April, 1823. He received his education at the Gymnasium of Lubeck, the Art School of Madgeburg, and the University of Gottingen. Here he had the advantage of sitting under Wohler and Himly, and laid the foundation of that knowledge in mechanics, chemistry, and physics, which he has ever since so well applied to useful results.

In 1842 he entered as a pupil the Engine Works of Count Stolberg, and there became acquainted with tools and their uses, and with methods of work, thus obtaining that practical knowledge which helps to make the engineer. In 1843 he visited England for the purpose of introducing a method of gilding and silvering by galvanic deposit, principally the invention of his elder brother, Werner Siemens. He returned immediately to Germany, and in the same year, the brothers invented a Differential Governor for Steam Engines. In 1844, C. William Siemens again came to England to patent this invention, and has ever since remained in this country, of which he became a naturalized subject in 1859.

In the same year (1844) was brought out the process of "Anastatic Printing," which invention wag due to the two brothers, and was described by Professor Faraday in a lecture before the Royal Institution in 1845.

About this time Mr. Siemens was variously engaged; he was at times occupied upon railway works,»upon improvements at Hoyle's Calico Printing Works, and upon several other inventions. Between the years 1844-47 he was occupied inter alia with the Chronometric Governor, the regulating action of which results from a differential movement between the engine and a chronometer. Several of these governors are in use at the Royal Observatory, Greenwich, for controlling the motion of transit and recording instruments.

In 1846 was introduced the double cylinder airpump, in which the two cylinders are so combined that the compressing side of the first or larger cylinder communicates with the suction side of the second and smaller cylinder, whereby the limit of exhaustion is very much extended.

It was in 1847 that Mr. Siemens turned his attention to the then new study of the dynamical theory of heat, and also to the use of a regenerator for recovering that portion of the heat which presents itself at the exhaust port of a caloric engine.

The same year he constructed in the factory of Mr. John Hick, of Bolton, a regenerative engine using superheated steam, the principle attempted to be realised being to recover the latent heat of the steam by restoring to the same for each stroke only such an amount of heat as was expended in the production of mechanical effect. The fuel of the engine was consumed also by air previously heated to a considerable point by means of a regenerator or heat exchanger.

The first engine constructed upon this principle was of four horse-power. An engine of twenty horse-power was placed in the Paris Universal Exhibition of 1857, but not realizing altogether the expectations of its designer, another of six horsepower was substituted, made by M. Farcot, of Paris, and was found to work with considerable economy. The use of superheated steam was attended with difficulty, however, and the invention has not been very extensively introduced.

In 1851 Mr. Siemens introduced his water-meter, which, both in its original and in a modified form, has been very extensively used both in this country and on the continent, the number in use being nearly 30,000. They act equally well under all varieties of pressure, and with constant or intermittent supply; they have been tested to register the flow to within 2j per cent, of the measured quantity, and are manufactured in this country by Messrs. Guest and Chrimes at Rotherham, and in Berlin by Messrs. Siemens and Halske.

Between the years 1856 and 1861, Mr. Siemens, in conjunction with his brother Frederick, worked out the Regenerative Gas Furnace, an invention with which his name will ever be remembered. This furnace is too well known to require a detailed description, and we shall here only explain its main features. There is first the gas producer, a brick chamber with three openings, one above for the admission of fuel, which is closed after a charge is thrown in, a second below for the admission of a regulated quantity of air, and a third above for the exit of the gas, which consists of carbonic oxide, mixed with hydro-carbons, and diluted with air. The gas after rising perpendicularly to some height from the producer, traverses an overhead tube, and then descends a downtake to the foot of the regenerators. By this arrangement there is a continual flow of gas towards the furnace, the downward portion of the current to the furnace being always heavier than the upward from the producer. The regenerators are four chambers containing firebricks, so arranged as to allow a free passage of air or gas through them; these fire-bricks will be heated if hot air or gas pass through, and will heat cool air or gas. The regenerators are divided into pairs of two, one regenerator of each pair being connected by means of a suitable valve with the atmosphere, and the other with the producer. The furnace is placed above the regenerators, and there are two ports entering it, the one from the gas, the other from the air regenerator, and two leaving it to the other gas and air regenerator. When in action, and the furnace is at a certain high temperature, air enters the air regenerator from the atmosphere, and gas the gas regenerator from the producer; these are heated as they traverse the brickwork, and finally combine in the furnace, adding the heat of the brickwork through which they have passed to that of chemical combination or combustion: the heat melts or heats the work, and then the product of combustion passes down the exit regenerators which it heats to a high temperature ; after a certain time, generally half an hour, the direction of the current is reversed by reversing valves. Each pair of regenerators is thus alternately employed to heat the entering air and gas and cool the products of combustion, which finally leave the chimney at a comparatively low temperature.

By this arrangement of furnace great economy is attained, great cleanliness in working, and purity of flame; but it has been principally valuable as, owing to the great heat obtainable, it has enabled metallurgical processes to be employed, which cannot be attempted in ordinary furnaces. The temperature is limited theoretically by the point of dissociation, and practically by the resistance to fusion offered by the refractory materials used in its construction.

This is hardly the journal in which to refer at length to metallurgical processes, but a memoir of Dr. Siemens would certainly be most incomplete if we did not refer shortly to his process of producing steel by direct fusion of the ores and other raw material.

Since 1867 Dr. Siemens has manufactured steel on the open hearth of his regenerative gas furnace. Reaumur, in 1722, made steel by the fusion of malleable iron with cast iron in a clay crucible, and, acting upon this hint, Dr. Siemens persevered in his experiments, and thousands of tons of steel are now made of nearly the same mixture upon the open hearth of the furnace that has just been described. But it has taken years of hard labour, close attention to important details and circumstances, great powers of resource, and a commanding determination to overcome opposition, to say nothing of the expenditure of much capital before this result has been attained. Dr. Siemens made many attempts in England, and studied the question with his friend, the late Mons. L. Lechatelier, Inspecteur General des Mines. Meanwhile Messrs. Emile and Pierre Martin, who had received licenses from Dr. Siemens, succeeded in producing cast steel by melting together pig iron, cast iron, and spiegeleisen. This kind of open-hearth steel 'making is now known as the Siemens-Martin process, and may be described as follows:—First, a bath of melted pig iron is formed on the bed of the furnace, and iron or steel scrap is added, till, by repeated trials, a sample taken out and cooled in water is found to be of the right temper. Then ferro-manganese or spiegeleisen is added, and when this is melted the charge is drawn off. The consumption of coal is from 13 to 14 cwt. for every ton of steel produced. In a modification of the process introduced into extensive practice by Dr. Siemens, pig iron is melted on the furnace bed, and iron ore then added in the proportions of from 20 to 24 cwt. of ore to five tons of pig iron.

Dr. Siemens is now erecting furnaces which wilj hold a charge of 10 tons, and will produce 20 to 30 tons of steel in 24 hours. This steel is much employed for all kinds of machinery purposes where high quality and uniformity are essential, and also in the construction of steel ships and boilers, which are gradually supplanting iron.

While introducing the Open Hearth Process as a considerable advance in the mode of production of steel, Dr. Siemens has been working to accomplish the further result of making steel and iron direct from the ore, and with this end in view, he constructed, in 1866, his sample steel works at Birmingham, and, in 1867, he sent several samples of steel produced in this manner to the Universal Exhibition at Paris. The first experimental attempts led to the construction of the Rotatory ' Furnace, by which that end is effected; and although it is as yet only employed upon a limited scale, its use is gradually extending. The latest results obtained with this furnace, were communicated at the autumn meeting of the Iron and Steel Institute, at Newcastle, last year.

It was in 1868 that he originated the Landore Siemens-Steel Works, which manufacture upwards of 1,000 tons of cast steel per week, and are, therefore, among the most extensive works of the kind in this country.

The Steel Company of Scotland, Vickers and Co. of Sheffield, the London and North Western Railway Works at Crewe, and other leading works, both in this country and abroad, are licensed by Dr. Siemens for the production of steel according to the processes we have described; the works in this country are capable of producing 250,000 tons, whilst the actual production last year in finished articles was over 140,000 tons.

Ever since the year 1848, Dr. Siemens has been interested in telegraph engineering. In 1858 he established, with his brother, Dr. Werner Siemens, and Mr. Halske, of Berlin, and with his brother, Mr. Carl Siemens, then of St. Petersburg and now of London, Siemens, Halske, and Co.'s Telegraph Works in London, which are now known as those of Messrs. Siemens Brothers. They have been considerably extended since their formation, and from them telegraph lines have been shipped to various quarters of the globe. The Indo-European telegraph line was constructed by Siemens Brothers in connection with their Berlin house, as also the North China Cable, the Platino-Brazileira Cable, and others. But the most important telegraphic enterprise that Dr. Siemens has been identified with, is that for which the celebrated steamship Faraday was built.

This vessel, constructed according to designs of which the conception was due to Dr. Siemens, was employed in 1874 in laying the Direct United States Cable, and succeeded in paying out nearly the entire length in perfect condition; but as the stormy season had set in, it was deemed advisable to buoy the cable and to defer any further attempts to finish laying it until the summer of 1873. The Faraday, therefore, returned to England, and during the winter was refitted, and in June succeeded in completing the work. But a fault was discovered, and another return to England for a piece of cable of sufficient length to repair the damage was found necessary. Early in September the cable was put in complete working order, and on the 15th was opened to the public for the transmission of messages.

The Faraday is a peculiar vessel, having stem and stern alike. She was built by Messrs. Mitchell and Co., at Newcastle, and is 360 ft. long, with 52 ft. beam and 36 ft. depth of hold. She has a rudder at each end, and either of them can be rigidly fixed when required. Two screw propellers, driven by a pair of compound engines, furnish the motive power, and are so placed at a slight angle to one another, that the vessel can turn in her own length when the engines are worked in opposite directions. As the ship can steam backwards of forwards with the same facility, in case a fault is discovered in the cable in the bow compartment, it is not necessary to pass the cable astern before hauling it in, but merely to reverse the motion of the ship, having the stern rudder fixed and making the bow the stern, and a small engine hauls in the cable over the drum just employed to pay it out. The Faraday was fitted out with everything necessary for laying the cable, as well as for grappling and recovering lost cable, and a steam launch carried on deck to be used in landing shore ends, was found to be of much service.

The Direct United States Cable, in the successful completion of which Mr. Carl Siemens, Mr. L. Loeffler, and several of the leading employes of the firm of Siemens Brothers, so zealously co-operated, must be regarded as an important step in Telegraph Engineering.

In the scientific world the labours of Dr. Siemens have been appreciated. He is a member^ of many learned societies. He was elected a fellow of the Royal Society in 1862, and in the year 1869 and 1870 he served on its council. He has long been a prominent member of the Institution of Civil Engineers, being a member of its council and of that of the British Association. He, at intervals, has been one of the managers and vice-president of the Royal Institution, and has been president of the Institution of Mechanical Engineers. He was also the first president of the Society of Telegraph Engineers, and has been again this year unanimously elected to this honourable position. He was elected president of the Mechanical Section for the conferences held under the auspices of the Loan Exhibition, and gave a valuable inaugural address on " Measures." The Iron and Steel Institute claim him as one of their most honoured members, and last year he was elected president of the Institute, a position which he still holds.

He was elected president of the International Patent Congress at Vienna, and shortly after an honorary member of the Austrian Society of Engineers and Architects.

In the February of last year, after his recent visit to America, he was elected an honorary member of the American Philosophical Society, and in October of the same year was elected with Mr. Bessemer the first honorary members of the very ancient Society the Gewerbe-Verein of Berlin.

In 1871 he was brought into the Athenaeum Club by the Managing Committee, and has since then served as a member of the same committee. He is also a member of the Philosophical and Royal Society Clubs.

Dr. Siemens has presented many scientific papers to these societies. His first paper was presented to the Institution of Civil Engineers on the 17th of May, 1853, and was entitled, "On the Conversion of Heat into Mechanical Effect." It was the first paper published in this country which considered the subject of heat engines from the point of view of the mechanical theory of heat, and, although a quarter of a century has nearly elapsed since it was read, it may be to-day taken as a guide to the subjects to which it has reference. Between this period and 186o he described his governor, steam engine, and water-meters, in papers to the Institution of Mechanical Engineers.

In 1862 he presented to the Institution of Civil Engineers a very elaborate paper " On the Electrical Tests employed during the construction of the Malta and Alexandria Cable, and on insulating and protecting submarine cables."

In 1863 he prepared a paper on " Observations on the Electrical Resistance and Electrification of some Insulating Materials, under pressures up to 3oo atmospheres," which was published in the British Association Report for that year. The two main points brought out were that the inductive capacity of gutta-percha is not affected by increased pressure and that of india-rubber is diminished.

In 1866 Dr. Siemens presented to the Royal Society a scientific paper on " Uniform Rotation," which is printed in the Philosophical Transactions.

On the 14th February, 1867, was read his paper "On the conversion of dynamical into electrical force without the aid of permanent magnetism," which is peculiarly interesting as being the first scientific enunciation in this country of the dynamoelectric principle upon which the most powerful light producing machines depend.

Another scientific paper presented by him to the same Society in 1871, "On Electrical Resistance," was made the Bakerian Lecture for that year. It treats of a method of measuring variation of temperature by variation of electrical resistance; and the new instruments described in this paper, the electrical resistance thermometer and pyrometer, in connection with the differential voltameter, are already being appreciated as valuable auxiliaries in thermometry, and in metallurgical research. These instruments allow of the measurement of temperature without any break, from the lowest attainable degree of cold to a temperature approaching that of the fusion of platinum.

Between this period and 1876 he read various papers, principally on metallurgical questions, before the Iron and Steel Institute, the Chemical Society, and the British Association.

In February, 1876, he read a paper " On the Action of Light on Selenium," before the Royal Institution, and presented his paper " On determining the depth of the Sea without the use of the Sounding Line, and on an Attraction Meter," to the Royal Society, which has since been published in the Phflosophical Transactions of that body.

Many ether papers presented by Dr. Siemens to scientific bodies (notably that on puddling iron, read before the British Association in 1868, showing incontestably that the carbon and silicon can be made to leave the pig metal by the action of the fluid oxide of iron present, alone), all treating of subjects of varied scientific and practical value, might be here considered, but we must be content to refer our readers for particulars to the Transactions of these bodies.

In a short memoir of this kind, and one treating, moreover, of a busy worker, whose every day and hour is employed, although much has been said, a great deal remains unsaid, and we shall complete this with a list of the awards Dr. Siemens has obtained.

The Society of Arts presented him with its gold medal for his regenerative condenser in the year 1850, and the Institution of Civil Engineers, in the Session 1852-53, with its Telford medal for the paper already referred to.

In 1851 and 1862, Dr. Siemens received prize medals of the London Exhibition, and in 1867 was awarded a Grand Prix at the Universal Exhibition, of Paris for his regenerative gas furnace and steel process. In 1869 the degree of Doctor of Civil Law, Honoris causd, was conferred upon him by the University of Oxford, and in 1874 he received the Royal Albert medal for his researches on heat, and for his metallurgical processes. In 1875 he received the Bessemer medal of the Iron and Steel Institute "in recognition of the valuable services he has rendered to the iron and steel trades by his important inventions and investigations."

Dr. Siemens was appointed first a Commander and subsequently a Dignatario of the Brazilian Order of the Rose. It is not often that life-long exertions like these are recognized by governments, and hence among the few recognitions of this description, this from the Emperor of Brazil must have been of a very pleasing character as coming, moreover, from a Potentate so qualified to judge of scientific and technical merit.

|