[Trade Journal]

Publication: Electrical Age

New York, NY, United States

vol. 19, no. 23, p. 356-358, col. 1-2

POWER FROM NIAGARA FALLS.

The 16th of November, 1896, marks an epoch in the history of Buffalo and one in which the whole manufacturing aspect of that busy city within a short time may be metamorphosed. One minute after midnight, with the closing of five sets of switches the power from the cataract at Niagara was brought into the city of Buffalo.

The history of the generating station of the Niagara Falls Power Co. is already so well known to our readers that we will not refer to it except to say that the three great two-phase generators are all in use furnishing power to the factories in and immediately around Niagara. The most recent addition to the powerhouse equipment is one of the General Electric Company's converters to take the two-phase current from the generators at 2,200 volts and turn direct current into the lines of two or three railroad companies at a pressure of from 575 volts to 600 volts.

When the question of the transmission of power from Niagara to Buffalo was under discussion, the merits of the three-phase system as compared with the two-phase system for transmission purposes were canvassed. It was shown to the satisfaction of the Power Company that, in using the three-phase system for transmission, a large economy could be made in the transmission installation, and the three-phase system of the General Electric Company was selected.

The current from the Falls is generated by the Niagara Falls Power Co., which transmits the power as far as the city limits of Buffalo. All the construction work in connection with this installation was effected by the Cataract Construction Company, while the distribution, after it has reached the city limits, is in the hands of a sub-company entitled the Cataract Power & Conduit Co.

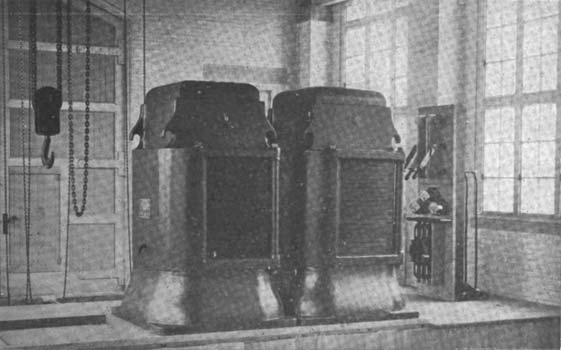

The two-phase current, starting from the generators in the power house, is led first to the switchboard and then in lead-covered cables through the covered "Bridge of Sighs," which passes over the canal of the Niagara Falls Power Company to a spacious transformer house which has been erected on the opposite side of the canal. Here the cables are connected to four switches on a blue marble switchboard. From this board they pass to the step-up transformers, the largest in the world, erected on a platform at one end of the power house and placed over an air-tight chamber. Each has a capacity of 935 K.W., or 1,250 horse-power, and stands ninety-four inches high, on a base sixty-four by fifty-six inches, and weighs 25,000 pounds.

The problem of cooling these transformers has been solved by driving a blast of cold air up through the air passages provided in the core and coils. The blast is furnished by a large blower driven by five horse-power multi-polar motor, which is belted to it. It is in these transformers that the two-phase system is abandoned and the current given three-phases, and raised from 2,200 volts alternating to 11,000 volts. Provision is also made in these transformers for raising the voltage to 22,000 volts as soon as higher pressure shall have become necessary.

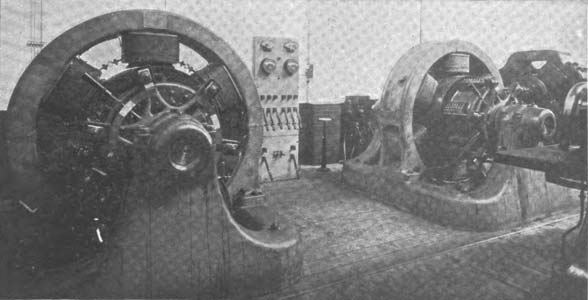

| |||

| Rotary Converters, Buffalo. |

From the transformers three cables pass to the high tension switchboard standing beside them. This switchboard is also of marble, and carries three high tension switches, each switch being separated by a marble barrier about one inch thick. This partition prevents arcing from switch to switch at the high pressure used. The switchboard also carries current indicators and three special fuse carriers. From the transformer house the wires pass through lightning arresters to the first pole of the pole line standing immediately in the rear of the building.

|

| Step-Up Transformers, at Niagara |

The pole line erected by White, Crosby & Co. runs along one side of a special right of way thirty feet wide. The number of poles in this line is about 21,000; they range from thirty-five to sixty-five feet in length and are set about seventy-five feet apart. Each pole is provided with two twelve-feet cross-arms for the transmission line, and one small cross-arm for a telephone line. Each side of each cross-arm has space for three pins to carry three insulators, provision being thus made for four circuits of three wires apiece; the capacity of each circuit being 5,000-H.P. at 11,000 volts pressure, and 10,000-H.P. at 22,000 volts pressure. On the outside of each upper cross-arm is a small iron pin, eighteen inches high, which serves to carry a galvanized barbed wire used as a lightning conductor and connected to the ground at the foot of every fifth pole.

The insulators used are of the double petticoat pattern. Each weighs about twelve pounds and is provided with two annular grooves in the bottom, which effectually prevent any moisture getting to the central pin on which the insulator is placed. The outside of the insulator is provided with a gutter running to a point on each side to carry off the water. These insulators were subjected to a rigid test of 40,000 volts alternating, to determine the electrical resistance, and not until they had withstood this pressure satisfactorily were they accepted.

The length of the line is twenty-six miles. The overhead conductors are of bare, stranded copper, each conductor having a diameter of 350,000 circular mils., and each lies in a groove at the apex of the insulators. When the line approaches the station at Buffalo, which it does along the banks of the Erie Canal, it is changed from overhead to underground, the wires passing from the last pole into a small brick terminal house. In this house, connections are made with the underground cables through lightning arresters. The underground cable is rubber covered and sheathed with lead, and is of the same diameter as the overhead conductor. It is laid in a subway consisting of vitrified tile ducts, each duct having a hole three inches in diameter. The subway consists of twelve of those ducts, laid eighteen inches below the surface of the ground, and surrounded on all sides by four inches of concrete. Three ducts only are in present use. The insulation of these cables was tested to withstand 80,000 volts.

The subway terminates in a small brick structure erected in the rear of the Niagara street power house of the Buffalo Railway Company. This contains the stepdown transformers. On entering this small house, the wires are connected to another switchboard carrying high voltage switches and fuse carriers separated by partitions of marble in the same manner as on the high tension switchboard at the Niagara Falls end of the transmission. From this board, cables are carried through lightning arresters 1o the transformers, of which there are three, two being in use and the third being held in reserve. Each weighs 7,000 pounds, is eighty-two inches high with a base measurement of forty-seven by thirty-six inches. In the step-down transformers, the pressure is reduced from 10,700 volts to 370.

A system of cooling the transformers similar to that used with the step-up transformers at the Niagara end is used.

From the step-down transformers., the three-phase current, divided into two circuits, passes over six cables to the main floor of the power house of the Buffalo Railway Company, where they are connected to another switchboard. Thence they pass to the two rotary converters, each of 500 H.-P. capacity. These converters are six-pole machines, and in their operation, the three-phase alternating current at 370 volts is changed into direct current at 500 volts, suitable for delivery to the feeder line of the electric street railway. Each converter armature is provided with three collector rings at one side and a commutator at the other, and maybe started either by the alternating current or by direct current from the railway lines. The converters may be used in parallel with the other generators, or the current can be thrown directly into the feeders of the railway system.

The lightning arresters of the Wirt type have been especially designed for heavy voltage transmission work and are single pole. They consist of strips of marble upon which are mounted eleven cylinders, giving one air gap space one thirty-second of an inch for each thousand volts, with an allowance of twenty-five per cent, rise in the potential. In the action of the arrester, the large metal cylinders serve to chill the arc so that, on reversal of the current, the arc is extinguished, no dependence being placed upon any non-arcing property of the metal to put out the arc. In order to limit the current on short circuit, and thus the heating effect, a special solid graphite rod of low non-inductive resistance is used. The arresters are similar to those used on the Big Cottonwood transmission at Salt Lake City, which have effectually protected the machinery in many severe storms, and are now being used extensively in transmissions where high voltages are employed.

The entire apparatus used in the transmission of the current from Niagara Falls to Buffalo is from the shops of the General Electric Company, having been designed especially for this special service.