[Trade Journal]

Publication: Electrical Engineering

Chicago, IL, United States

vol. 5, no. 26, p. 33-86, col. 1-2

THE CONSTRUCTIVE FEATURES OF TRANSMISSION LINES.

BY ARTHUR VAUGHAN ABBOTT, C.E.,

Chief Engineer of the Chicago Telephone Company.

The ability to utilize energy may be considered as an accurate exponent of the civilization of a nation. In the earliest condition of savagery man only serves himself by the labor of his own hands. With increasing development, the power of animals or of captive men, as slaves, is employed, but it is not until a relatively high degree of civilization is attained that mankind avails himself of the forces of nature.

The nineteenth century may aptly be termed the century of energy A hundred and fifty years ago the steam engine was unknown. A century ago the President-elect rode on horseback to Washington for inauguration. Fifty years ago the postal service was the only means of intercommunication, and was chiefly accomplished by stage coach and pony mail-bag. Ten years ago the horse formed the only means of urban transit. Now, by the aid of express trains, the continent is spanned in a shorter period of time than was formerly required for a journey from New York to Boston. A message may be sent from London and received in New York at an earlier date (local time) than that upon which it was sent. In all the cities and towns the lightning is harnessed, and it draws our cars, turns our motors and performs for us a host of useful services . Thus the present century may be appropriately characterized as the era of the utilization of energy, for, through the aid of the steam engine and the water wheel, the previously unemployed forces of nature can be employed. It is necessary that the machinery which the mine or the waterfall sets in motion be located directly at the source of supply, as it is impracticable in any way to transfer from one point to another the supplies or forces thus obtained. Within ten years, however, that peculiar form of energy known as " electricity " has been found to be particularly susceptible to transportation , and by means of its aid it is possible to carry from place to place , over distances of considerable magnitude, very large amounts of power. In order to accomplish this, it is essential to have a road along which the electricity may travel and to which it may be entirely confined, in order that it may not prove an enemy instead of a friend. Transmission lines are the electrical paths, the construction of which it is now necessary to consider in detail . The earliest transmission line came into existence when the first Morse receiver ticked out the words What Hath God Wrought ! The first lines consisted of illy arranged sticks upon which the iron wires for transmitting the necessary battery current were secured , simply by means of strings. Viewed from the window of the passing train such a line left upon the retina of the traveler's eye an impression similar to that produced by the quills upon the back of the fretful porcupine." Anybody could build a telegraph line, and, consequently, everybody did , and the figure of the old - time lineman , with his impudent swagger, billy-cock hat, leather jacket and pair of plyers, is familiar to all electricians. With the possibility of the transportation of large quantities of energy the transmission line has rapidly risen to the dignity of an engineering structure, and now must be designed with the utmost care, that it may be mechanically and economically successful .

Transmission lines may be divided into two parts with regard to the method of construction: First , Aėrial lines are those which, as their name indicates , are built above the surface of the ground. Second, Underground lines are those which are placed beneath the surface of the earth , chiefly for the sake of avoiding an uncomfortable complexity of aėrial circuits .

In every transmission line three points must be considered:

First , It is necessary to provide for the electrical energy a sufficient and adequate conductor, in order that the power to be transported may be carried without undue loss.

Second , The mechanical arrangement for sustaining and pre serving this conductor in its appropriate position with relation to other objects must be carefully planned and appropriately designed to meet the exigencies of each case.

Third, The conductor must be appropriately electrically protected from coming in contact with other objects.

The first of these requisites, being entirely confined to the adequate design of the conductor cross-section, involving a consideration of electrical laws pure and simple, does not properly belong to the constructive features of transmission lines. The remaining two, namely, the mechanical and electrical properties which are necessarily embodied in every transmission line, will form the points of present consideration. Every aėrial line is constructed by setting into the earth a sufficient number of poles of the requisite dimensions to carry the circuits for which the line is designed. If care be taken to construct aėrial lines of sightly and well-arranged poles, properly proportioned to the work which they are called upon to perform and carefully maintained in a neat and orderly appearance, three fourths of the objections arising from the rickety structures that formerly encumbered the streets would disappear entirely, and, had electrical companies been sufficiently far- sighted to design and maintain appropriate structures for the purpose, half of the underground work which now exists or may be demanded in the future could have been obviated . The heaviest aėrial lines are those which have been designed for telegraphic and telephonic purposes, as, owing to the multiplicity of circuits which are in service, these enterprises require lines of much greater magnitude than those of electric light, electric railway or power transmission plants.

| |||

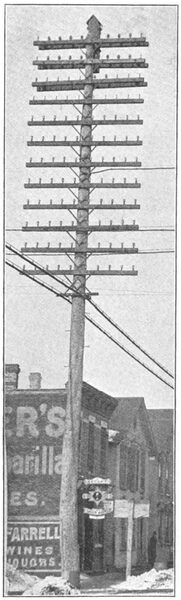

| Fig. 1. |

|

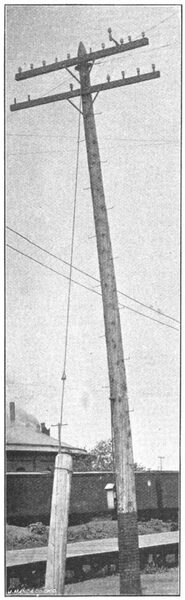

| Fig. 2. |

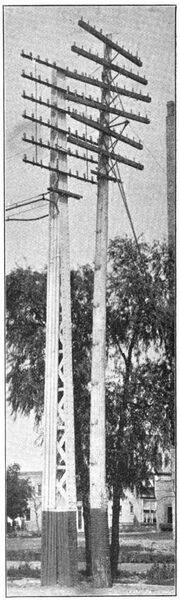

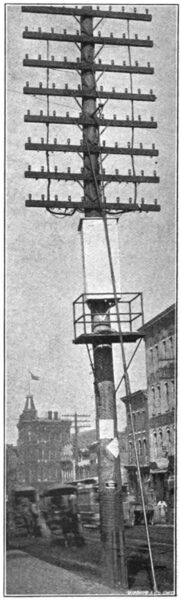

A view of the appearance of a properly constructed pole line is given in Fig. 1 . From this illustration it will be perceived that the line consists of tall, straight poles, some sixty feet in height, carrying twelve cross-arms and supporting beneath the lower arm two aėrial cables. For city work the poles chosen should be from forty to sixty feet in height, depending upon the number of circuits that they are intended to carry; should not be less than seven to eight inches in diameter at the top, and at the butt they may be as large as it is practicable to obtain the timber. They should be carefully selected from live timber, should have the bark removed, and be thoroughly shaved, after the knots and branches are carefully trimmed off. For country work or for lines where only two or three wires are to be carried, poles twenty-five to thirty feet in height and from five to six inches in diameter at the top are sufficient. Each pole should have its top carefully roofed or chamfered on each side, at an angle of forty - five degrees, in order to avoid the square surface which would, otherwise, afford a lodgment for snow and ice and greatly shorten the life of the pole by causing it to absorb moisture and then to rot.

| |||

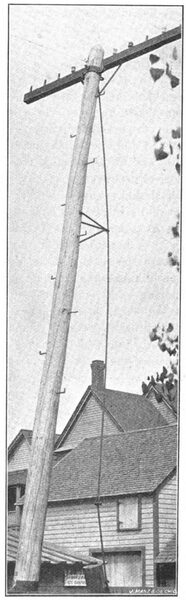

| Fig. 3. |

| |||

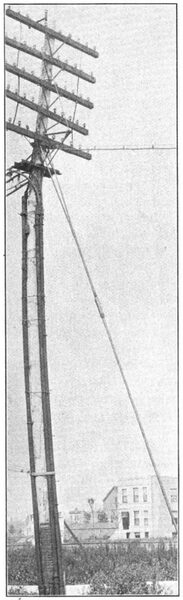

| Fig. 4. |

Before the pole is set it is customary to cut the gains, or trans verse slots, for the cross-arms, which are sawn into the pole of the appropriate size to receive the arm. The gains are usually set twenty inches apart, vertically, along the top of the pole, and are cut four and one-fourth inches in width to receive the arm. The gains and the roof should receive two good coats of white lead, in order to preserve the surfaces from moisture. For city work each pole should receive a good coat of white lead previous to its erection and a subsequent coat after it is in place. It is an open question as to whether the painting of the pole conduces to its longevity or not, as some authorities consider the pole will rot just beneath the surface of the ground sooner than above the surface, even if unpainted. There can, however, be no question that painting adds sufficiently to the appearance to render it a necessity, at least, in all cities and towns. Setting is accomplished by excavating the necessary hole in the ground, from five to six feet in depth, into which the pole is placed and secured by thoroughly ramming the earth around it. In loamy or clayey locations the work may be expedited by the use of a pole augur, a contrivance resembling a huge gimlet, capable, in soils of this description, of rapidly drilling a hole of the required size and depth. With large and heavy poles the pole auger is not a machine of sufficient capacity to be effectively used. Recourse may be had to a digging machine constructed on similar principles to pieces of apparatus used in pile setting. The apparatus consists of two strong steel elliptical blades that are firmly riveted to a barrel-shaped steel cylinder. The whole apparatus is supported by means of a heavy wooden tripod or working wagon. The digging machine is suspended by means of a fall, that it may be rapidly and easily raised and lowered. Heavy arms are attached to the top of the steel barrel, and a crosspiece is provided that, by means of a swivel, will permit the digging machine to be rapidly rotated by a gang of men, after the fashion of a ship's capstan. By lowering the machine so that the point of the apparatus impinges upon the ground and then manning the crossbar, a hole of any desired size may be rapidly drilled. In practice, it is found that aa gang of five men will excavate a hole for a twenty-four-foot pole, six feet in depth, in from fifteen to twenty minutes. In sandy locations, where it is likely that the banks will cave in, a sand barrel forms a useful device. This consists of a semi- circular iron case a little larger than the butt of the pole, which may be placed upon the surface of the ground and the excavation per formed by means of long -handled shovels excavating the sand from the inside of the case. As fast as the excavation is made the case sinks through the earth, preserving the sides. After the pole is set and the hole refilled, by means of a fall, the sand-barrel may be hoisted out of its place in the ground, and, as it is split into two parts secured by hinges, unclasping the hinges suffices to remove it from the pole. Where the soil is particularly weak, or, in the case of anchor or guy poles, upon which the line stresses are particularly severe, it is advisable to secure the pole by tamping around the butt a foundation of two or three feet of concrete. A good mixture for this purpose consists of one part Rosendale cement, three parts sand and five parts of crushed stone, which are thoroughly mixed, moistened and rammed around the pole. Poles are usually planted by providing a sufficient gang of men to lift them bodily into place, setting them in the holes by means of pike staves, to aid them in lifting the pole into place. Where a number of poles of similar size are to be set, such as in electrical railway work, it is customary to supply a working wagon carrying a derrick, whereby the pole may be hoisted and planted.

| |||

| Fig. 5. |

| |||

| Fig. 6. |

| |||

| Fig. 7. |

| |||

| Fig. 8. |

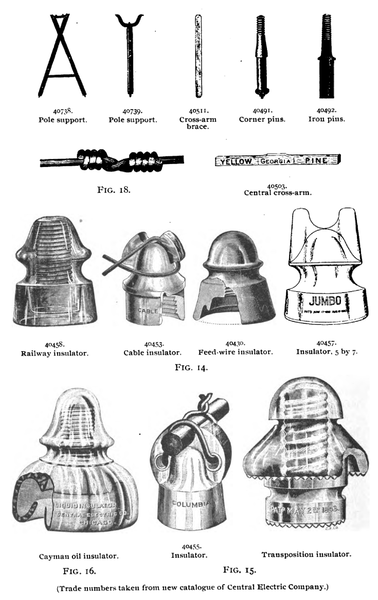

In this country very few attempts have been made to add to the life of poles by any process of preservation other than painting. In Europe, however, it is customary to treat the poles, either by creosoting, kyanizing or some similar process all of the methods of preservation aiming to coagulate the vegetable albumens contained in the sap, converting them into insoluble compounds, and by insolubility retarding the absorption of moisture from the atmosphere. The process of creosoting, most commonly adopted , involves steaming the poles in a large iron vat, from which the air and juices contained in the poles are exhausted by creating a vacuum . The tank is then filled with hot creosote oil and hydrostatic pressure applied, which is supposed to force the wood full of oil. In this country a process has been recently introduced called vulcanization, which consists in heating the pole in a closed chamber nearly to the point of carbonization. By this means it is claimed that the vegetable albumens are coagulated and the life of the pole greatly increased. This process, however, has not been in use sufficiently long to give adequate experience as to its value. As it is considerably cheaper than that of creosoting, and as the results thus far obtained seem to be exceedingly favorable, it is probable that it may in the future obtain quite a wide adoption. To sustain the wire insulators, it is customary to place upon the pole transverse pieces termed cross -arms, into which the pins that directly support the insulators are placed . This cross arm consists of a rectangular strip of oak or yellow pine, 4/4 inches deep and 3/4 inches wide. The length of the arm will vary from three to ten feet, depending upon the number of pins it is designed to support . Arms are secured by placing them in the gains or cuts in the pole and bolting them . It is now considered more advisable to secure the cross-arm by means of a single carriage bolt, extending entirely through the pole and arm, having ample washers on the outside of each. Lag bolts have been found objectionable, from the fact that the thread of the bolt destroys the fiber of the pole to such an extent that it is impracticable to replace the arms after they have been in service for a considerable period of time. In addition to the bolt, each arm is stayed by means of two braces made of strap iron, 1/4 inches in width and 14 inch in thickness, which are secured between the first and second pins, and, extending downward in a diagonal manner, are fastened to the bolt in the cross- arm directly beneath, forming an efficient lateral stay to hold the cross- arm in its place. Cross-arms should be made of carefully selected wood, truly and accurately machine, cut precisely of the dimensions specified. It is customary, around the upper surface of the arm, to afford a shed for the snow and moisture; but where the arm intersects the pole, it is left square to fit the gain. The pins usually adopted are made of locust, and are secured by dropping them into the hole drilled in the cross-arm and then driving, directly through the pin and arm, a wire nail. The upper part of the pin is threaded to fit the particular insulator to be used. Iron pins are to some extent displacing wooden ones and are found to be quite valuable, as they occupy a smaller space in the cross-arm. The objection to the iron pin is that it is very likely to bend and allow the insulator to slip off.

| |||

| Fig. 9. |

| |||

| Fig. 10. |

| |||

| Fig. 11. |

| |||

| Fig. 12. |

It has sometimes been considered advisable to place a double set of cross-arms upon poles, one on each side, thus securing the wires at each pole to the two insulators. Such a method of construction has been adopted by the Western Union Telegraph Company. Experience indicates, however, that the additional gain which is cut in the pole weakens that structure to a greater extent than the additional security obtained by the double insulator, and practice is falling into disuse, except for corner poles.

Poles are subjected to three stresses and must be designed with sufficient strength to withstand them.

First. Each pole, acting as a column, must support a weight equal to the sum of the weights of all the cross- arms, insulators, wires and cables which may be attached to it. As ordinary aėrial cables may weigh from five to ten pounds per linear foot, and as the telegraph and telephone circuits weigh from 100 to 300 pounds per mile, the dead load coming upon a heavy line pole is no in considerable amount. In the winter time this is likely to be very largely augmented by the accumulation of snow and ice.

Second: The effect of wind acting upon the wires, cross- arms and poles introduces a considerable lateral force, tending to set the pole into vibration, swaying the line to and fro and causing the poles to break at or near the surface of the ground. As the wind may come from any direction , it is exceedingly difficult to stay the pole against stresses of this kind.

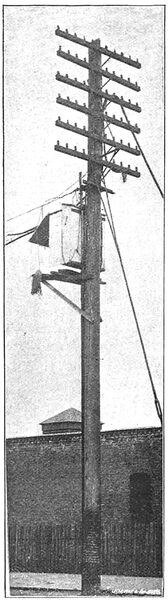

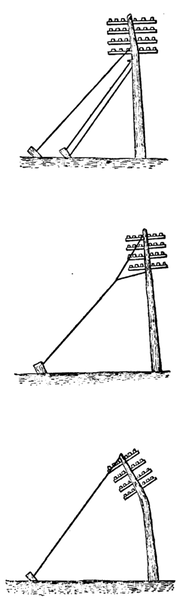

Third: Wherever the circuits upon the pole change direction , as at a corner, or wherever any of the circuits are terminated , the pole is called upon to withstand the resultant of the longitudinal tension in the lines. For telegraph and telephone work it is customary to pull up the individual wires to a tension of about one hundred and fifty pounds, while messenger strands of aėrial cables have a tension of 1,500 pounds. Thus, considering the case of Fig. 1 , there would be a tension due to all the lines and cables of 24,000 pounds, and if the circuits were all terminated on any pole, it would be subjected to this stress , giving rise to a bending moment at the base of the pole that would be greater than any wooden structure could withstand . It is necessary , therefore, for the designer to carefully study the arrangement of the circuits and note the effect of the resultant tension . To counterbalance longitudinal stresses , it is customary to resort to guying, which consists in attaching a counter- tension member to a pole stressed in this way, usually formed of iron wire or wire rope strand , which is led from the pole top to an anchor of some description inserted in the ground. In the open country there can be no objection to guying, but in city lines it is frequently difficult to find room for an expedient of this kind without occupying too great space in the streets . It is also necessary to place the guy properly in reference to the pole . Illustrations of bad guying may be seen in Fig. 2 .

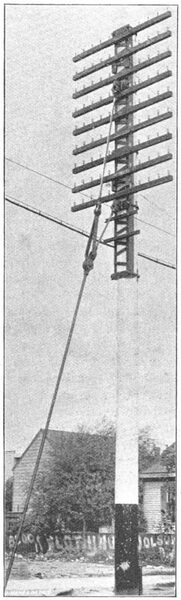

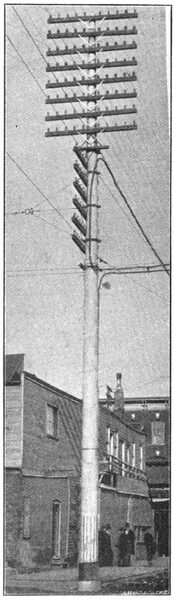

If the guy is attached to the top of the pole the tension of the circuits will pull the cross- arms longitudinally, thus causing the pole to bend at or directly beneath the lower arm . In a similar manner , if the guy be attached directly beneath the arm , a corresponding deflection of the top is the result . The best form of a single guy is that known as the Y guy , in which the strand is forked a short distance away from the pole and attached both to the pole top and also directly beneath the lower arm . No form of guying, however, of this description is entirely adequate for the purpose. In Figs. 3 and 4 will be found examples of the results of guying. In Fig. 3 it will be seen that the guy strand attached to the top of the pole has caused it to buckle and bend outward , due to the bending moment introduced in the pole by the guy . In Fig. 4 a similar result is seen , with the exception that here the expedient of trussing the guy rod by means of an iron brace to the pole has been resorted to. Unfortunately, however, this has merely exaggerated the difficulty and made the buckling of the pole still more apparent. In Fig. 5 a similar trouble is experienced . The illustration gives an example of an anchor pole terminating with four cables and fifty wires. A guy made of iron rod has been attached to the pole , directly above the cable, and in addition a truss has been arranged to support the part of the pole top carrying the cross-arms. Notwithstanding this, the tension of the cables has caused the pole to buckle outward , the greatest bending occurring at the point where the cables are attached . It is manifest that the fall of such a structure as this is only a question of time, and it is evident that very little engineering could have been exercised in its design. To meet the bending stress introduced by the termination of lines, the most satisfactory expedient is the construction of a pole built of structural iron , which is sufficiently strong to withstand the entire bending moment which can be thrown upon it . An example of this will be found in Fig. 6.

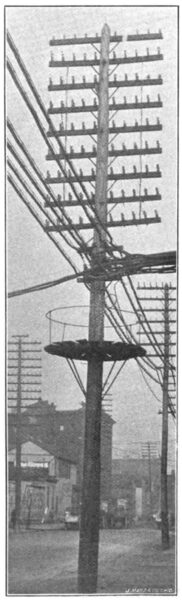

The pole here consists of four angles latticed together, forming a triangular beam . It is sustained by setting in a large block of concrete placed in the earth around the base . The cross - arms are angle iron and are riveted directly to the outer flange of the angles. By properly designing such a pole as this, an exceedingly neat, substantial and durable structure can be obtained , upon which scarcely any improvement can be expected . The objection , however, is the expense , as a pole of this description , some sixty feet in height and capable of sustaining sixty wires and five cables , would cost in the neighborhood of $800. As a compromise, a device has lately been put into practice, which consists in making a composite pole, partly of wood and partly of iron. Such a pole is seen in Fig. 7 . A lattice work of angles is designed, having sufficient strength to distribute over the entire upper part of the pole the entire bending moment due to all the wires and cables which the pole is called upon to sustain. This lattice work is planned to accurately fit the top of the pole, to which it is secured by a number of iron bands. At two or three points along the lattice work , heavy iron collars are secured to the lattice , forming points of attachment for the guy , which consists of a heavy steel rod extending from the lattice diagonally to the ground, and securely anchored at the base of the pole. The pole itself consists of a Norway pine spar, in the present instance eighteen inches in diameter at the top and twenty -six inches at the butt, being fifty feet high. The bottom of the pole is furnished with a heavy wooden shoe , consisting of 12 by 12 inch yellow pine timbers, which are bolted to the pole and which are , also , secured to the guy rod . The pole is placed in an appropriate excavation upon a bed of concrete to prevent it from sinking into the soil , and then a sufficient amount of concrete rammed about the base and heaped upon the platform formed by the timbers of the shoe , to render the pole entirely safe against turning, from the bending moment of the lines. If the iron lattice is sufficiently strong to resist the bending moment of all the lines and cables, the pole itself will only be subjected to the compressive resultant of the tension in the guy rod and the longitudinal stress in the lines, and as a consequence, if the pole be sufficiently strong to resist this compression , it will form a stable and substantial structure. The object of the entire design is to transform the bending moment of the lines into direct compression in the pole.

Cases frequently occur where lines intersect each other, indicated in Fig. 8. Here the pole carries eight cross- arms and one cable running north and south , and six arms and two cables running east and west. As the east and west cables and wires terminate on the pole , security is obtained by a guy strand calculated to compensate for the tension of the lines which end , and which is carried to an anchor in the rear of the pole . An example of heavy construction is seen in Fig. 9 , a city line intended to carry ninety wires and eleven cables.

In order to form a connection between underground and aėrial service , it is customary to arrange, at the termination of the conduits, cable poles carrying iron pipes that entered longitudinally upward along the pole from a manhole at the base , into which the underground conduits open . These iron pipes form a convenient duct through which the underground cables may be carried to the cross-arms. An example of this is seen in Figs. 5 and 6 .

To guard against the incursion of moisture in the underground cables, particular attention must be paid to the point at which the two systems join . A balcony is built at an appropriate height above the street , and upon the pole a cable box is clamped into which the cable may extend by means of a water- tight joint. This is seen in Figs. 10 and 11 .

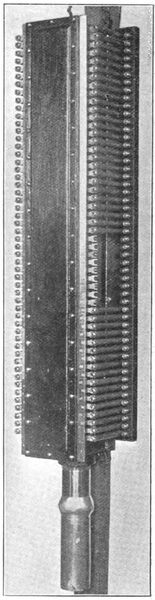

In Fig. 10 a completed cable box and balcony is indicated, the balcony forming a convenient support for the workmen in per forming their necessary avocations. From the top of the cable box, strands of okonite wire are formed up and extend the cable conductors to the cross- arms, serving as a means of distributing the cable circuits to the aėrial wires. In Fig. If the cable box is indicated as opened , showing that, by means of the outer lid and side doors , the box may be protected from the weather. To seal the cable from moisture , a cable head is provided , Fig. 12 . The head consists of a rectangular iron casing supplied at one end with a brass tube of requisite size to fit closely over the cable sheath , to which it is soldered . On the inside of the iron casing the cable is fanned out and connected to a series of binding post terminals, seen in the illustration , extending from the inside of the box through the cover, forming an opportunity by means of which the aėrial circuits may be connected directly to the cable conductors.

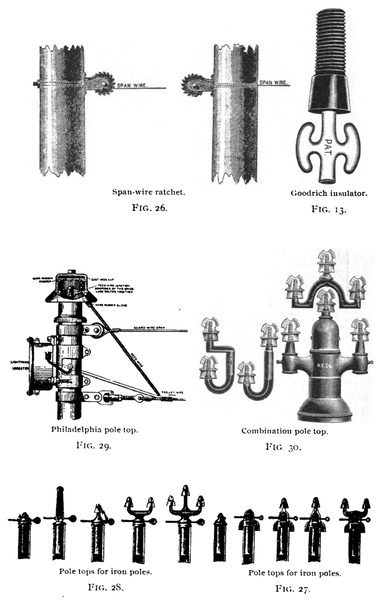

It is now necessary to see that the electrical road is thoroughly protected electrically from contact with neighboring objects, in order that the electrical energy may not be dissipated . For this purpose , insulators are provided . Insulators in this country are usually made of molded glass , cast in such forms as to be easily secured to the pins by means of screw threads on the inside. The insulator, also, carries one or more grooves upon its surface for the reception of the necessary circuits . Glass is by no means the best substance, electrically , for the purpose, for its surface is quite hydroscopic, and thereby forms an easy means of condensing a conducting film of moisture. In England and on the continent, porcelain is almost exclusively used . It has the advantage that the surface much less readily attracts moisture, but it is consider ably more expensive, and as it is opaque, cocoons are liable to collect beneath the insulator, thus forming a conducting path . For indoor work porcelain is almost exclusively used as the material for the insulators. The value of the insulator depends not upon its absolute size , but upon the ratio of the distance from the point where the wire is attached to the point where the pin touches the insulator, divided by the circumference of the insulator, for it is evident that the insulating power depends upon the amount of conducting surface which is exposed . This conducting surface is the distance from the wire to the pin , multiplied by the mean circumference of the insulator ; and of the various forms that which gives the smallest conducting surface will give the highest resistance. Grooves have been adopted to improve the insulator, but the objection is that they are likely to be filled with dust and dirt , not easily washed away by rain , thus forming a conducting medium of considerable value . By molding a series of deep grooves beneath the insulator, termed petticoats, the distance from the wire attachment to the pin is considerably increased , without at the same time increasing the main circumference. The favorite forms of French and English insulators resemble to a great extent the American types, but are heavier , more substantial and are better designed, as they present a greater length from the attachment of the wire to the pin , with a decreased circumference. A valuable though rather expensive form of insulator consists of a rubber cap, which may be mounted upon the pin , to which the wire is secured by an iron hook . Though this insulator is expensive, it is valuable for high potential work , as its insulating power may be made very great . ( Figs. 13 , 14 and 15. )

|

For high potential circuits the ordinary form of insulator is found inadequate, as it does not retain for sufficiently long periods the requisite isolation of the circuit , and recourse is had to the device of the oil insulator, as exemplified in Fig . 16. In this contrivance a trough of glass is formed beneath the insulator, which may be filled with mineral oil of high insulating properties. The inner petticoat of the insulator dips into the oil , which thus entirely surrounds the upper part of the insulator. As often as may be necessary the oil can be withdrawn and replaced with that which is fresh and clean .

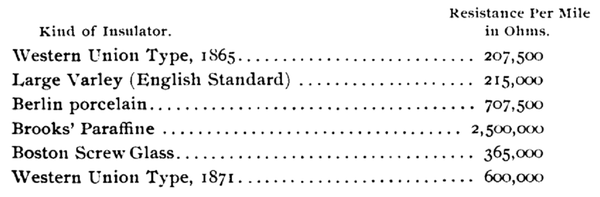

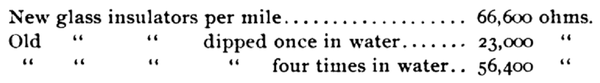

The protecting power of insulators varies so greatly with atmospheric conditions, and with exposure to the smoke and dirt of the larger cities , that it is impossible to give accurate data upon which to predict results . The lowest insulation usually occurs during a fog or mist that covers the surface of the glass with a thick , beady film of moisture . Insulation is highest directly after a hard rain , that has washed the surfaces clean and free from dirt. As double petticoat insulators dry more slowly than the more open forms, the period of low insulation lasts longer. From a number of experiments on telegraph lines, the following results have been obtained per mile of line of forty insulators :

|

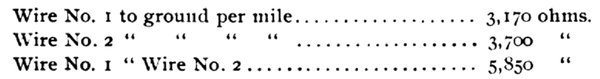

Poles and cross-arms also contribute to insulation . Thus, on a telegraph line between New York and Boston , measurements were made between two wires mounted on glass insulators placed on brackets and between each wire and the ground, with the following results :

|

Tests made on glass insulators after exposure to city air for a long period gave results as follows :

|

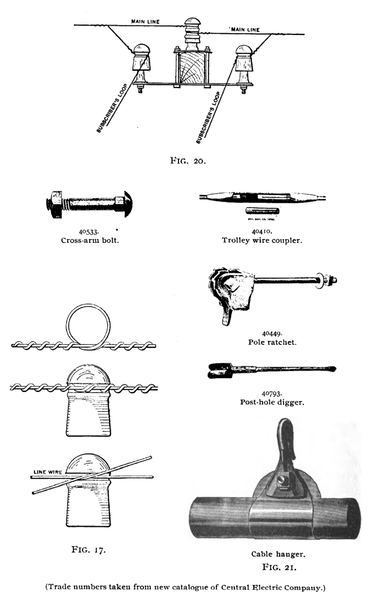

The resistance of the cross - arms when old , dirty and wet, may be as low as 2,000 ohms, and when new, clean and dry , as high as 330,000 ohms. To secure the wire to the insulators, it is customary , in this country , to run the line directly alongside of the insulator, placing it in the groove. The tie wire, as indicated in Fig. 17 , is then placed around the insulator in such a manner that one end of the tie will pass downward over the line wire, while the other end passes upward from underneath . The tie wire is then wrapped round and round the line wire , securing it firmly . In the method of tying in Europe the line wire is placed in the groove, which extends longitudinally through the top of the insulator, while directly underneath a double strand of tie wire is twisted around the insulator and then each of the strands is wrapped round and round the line wire , thus securing it firmly in its position . Innumerable methods have been devised to join successive lengths of wire . Of all , only three have survived the tests of experience : the Western Union joint, the McIntire joint, and the brazed sleeve. For iron wire , the Western Union joint ( Fig . 18 ) forms a splice which is successfully and easily made in the simplest possible manner, for the joint simply consists in twisting the two ends of the wire firmly together, wrapping them successively around each other for a great number of twists. The McIntire wire splice consists of two sleeves of copper made slightly larger than the wire to be spliced , being drawn out of a single sheet. To make the splice, the ends of the coils to be jointed are inserted into these tubes, and then by an appropriate pair of plyers the tubes are twisted on each other , serving to bind the ends so firmly as to make a joint that electrically and mechanically is nearly as strong as the wire itself.

|

To serve a customer, the circuit must be carried from the pole line into the premises of the subscriber. To avoid subjecting the pole to the stresses due to an open line, it is usual to resort to a loop bracket. Such a contrivance is indicated in Fig. 20 . Here the main line is supplied with three insulators, the center one having a double groove. The line is opened by placing one end of it in the upper groove and the other in the lower groove, carrying the ends around the insulator and twisting them around and around the line. The other two insulators of the bracket are carried upon an iron plate , which extends outward from , and is secured to , the cross - arm . The outer insulators form a means whereby an extension from the line wire may, on the one side , be carried into the subscriber's premises, and, on the other side , return to the main line.

Where a number of circuits are carried for a considerable distance , without interruption , the aėrial cable forms a most compact and sightly method . The arrangement of the circuits in the cable is considered in succeeding paragraphs, but to the pole line belongs the mechanical arrangement and suspension of the cable itself. Aėrial cables are never strong enough to be self-supporting, and it is , therefore, essential to provide them with some means of sustaining them in their proper position . This is usually accomplished by a messenger wire, which consists of a strand of 38 - inch or 58- inch wire rope extended from the poles , being secured by a short cross- arm formed of angle iron bolted to the pole . The messenger wire has sufficient strength to sustain the cable, thus relieving it entirely from its own weight. The cable is attached to the messenger wire by means of a clip of metal, designs for which are shown in Fig. 21 . As aėrial cables are usually sheathed with lead , it is important to place the supporting clips at such frequent intervals that the lead sheath may be held often enough to prevent cracking or injuring the lead. As lead is a metal which flows easily , under slight stress , if applied for a long time, it is necessary to place the supporting clips at intervals of 18 to 24 inches in order to prevent injury .

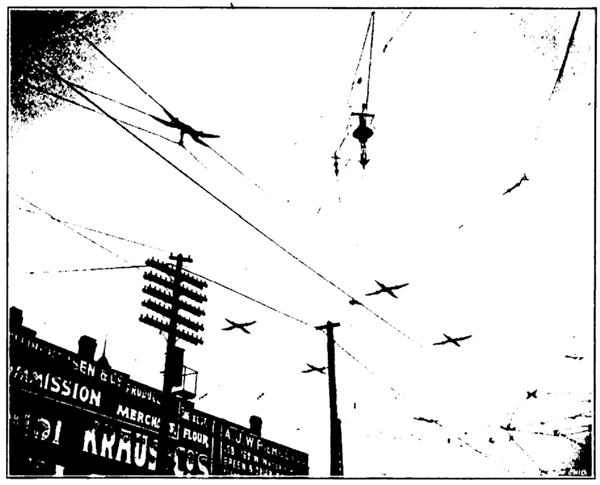

|

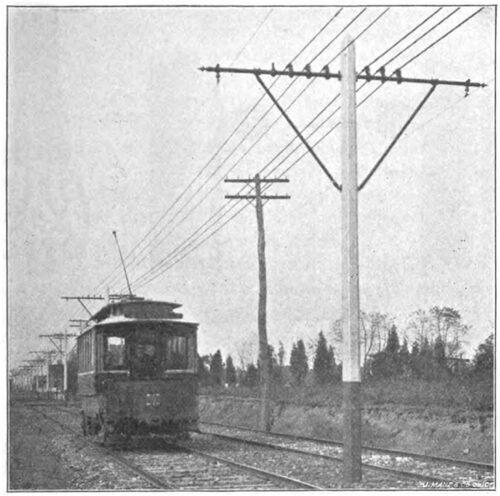

| Fig. 24. |

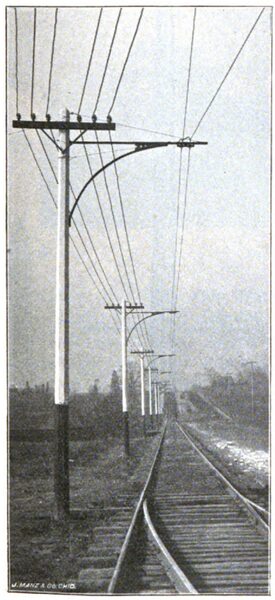

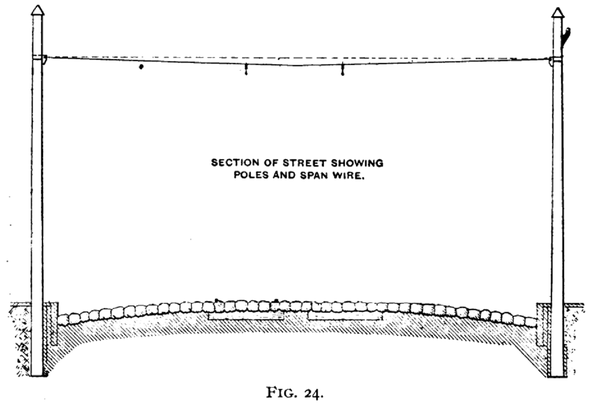

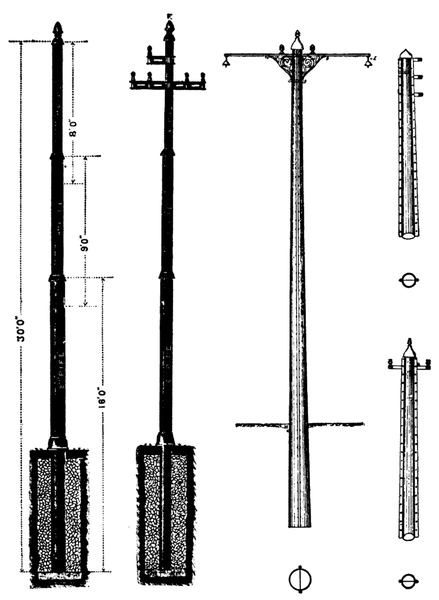

The electrical railway circuit forms a special department in aėrial transmission line construction and may be divided into two parts. First . A trolley wire for the purpose of delivering energy directly to the car motors. Second. A feeder system designed to con vey to the trolley wire the requisite amounts of energy from point to point along the line at the required potential . Necessarily , the trolley wire is a bare conductor, in order that the essential con tact between the trolley wheel and the conductor may be secured . As the trolley wire is subjected to exceedingly severe usage , due to the passing cars, the overhead construction must consequently be designed in accordance therewith . The customary potential railway circuit being 500 volts, which approaches the danger limit of electrical pressure , it is essential to pay particular attention to the insulation of the circuits . So far as the trolley wire portion of the railway circuit is concerned , but one typical form of construction has ever been put into practice , namely, the design of suspending over the center of the track the conductor. Two different designs are in common use : the center or side-pole , and the span- wire type of construction . The center or side-pole type, as exemplified in Figs. 22 and 23 , consists in a series of substantial poles , which are placed, in the case of a double -track road , in the center, between the two tracks, or, in case of a single-track , at the side of the rails in such a position as to easily clear the passing car. At the top of the pole a bracket is arranged for the purpose of supporting the trolley wire directly over the center of the track . It is customary to place the poles as near as practicable to the track , in order that the bracket may be short, yet a sufficient distance so as not to interfere with the passage of the car, or subject the passengers to undue risk owing to the proximity of the pole. Span-wire construction , Fig. 24 , is arranged by placing two poles on either side of the street , usually at the curb line, and suspending the trolley wire from a flexible cable or strand, which is stretched between the tops of the two poles. Manifestly, the center- pole construction occupies more room in the center of the street , and cannot be so well applied in crowded localities. The span-wire type has the objection that it interferes materially with the curb line , thus obstructing the property of abutters, and as it involves the erection of two poles for every trolley wire insulator, it is considerably more expensive than the other form . The span- wire construction presents a more flexible system , in so far as the overhead wiring is concerned , and from this cause is somewhat less expensive, from a maintenance standpoint. In the early days of the electrical railway , wooden poles were exclusively used . To attain a better appearance it soon became customary to machine the pole , giving it a series of chamfers, cutting the pole to an octagon . Poles which are carefully selected and machined, and subsequently adequately painted , present an excellent appearance. Wooden poles have the advantage of being good insulators, thus avoiding the difficulty of leading a current from defective line insulators to the street. No accidents have, as yet, occurred from contact with wooden poles, though there are quite a number of injuries on record due to iron poles which have become charged. The wooden pole should be set as indicated for the ordinary transmission line pole, excepting that, owing to the severity of the service to which it is subjected, it is usually essential to set the pole in a bed of concrete. This is particularly the case in span-wire construction , where the tension of the span wire constantly tends to pull the pole over toward the center of the street. Wooden railway poles should never be less than eight inches in diameter at the top and should be about thirty feet in height. Typical illustrations of wooden side- pole and center-pole construction will be found in Figs. 22 and 23 .

| |||

| Fig. 22. |

With improvement in electrical railroading, the wooden pole is gradually disappearing, its place being taken up by an iron pole made either from wrought pipe or from rolled shapes . The iron pole is by far to be preferred from all considerations, excepting that of insulation, as it is stronger, more durable and is much more slightly.

The earliest forms of iron pole were those constructed of wrought pipe, by taking three or more lengths of different sizes and shrinking them together at the joints. Typical forms of iron poles are given in Fig. 25 . In selecting pipe poles great care should be taken to see that they are sufficiently substantial , for commonly they gradually bend under the weight of the circuits , or the tension of the span wire, thus allowing the whole line to fall out of shape. The joint between the successive pieces of pipe forming the pole is made by heating the tubes and shrinking them together. This is a point of frequent weakness, and to the joints especial inspection should be given to see that they are solidly and securely made, and that the separate tubes extend far enough in side of each other to insure permanency . The method of erection , including the placing of the concrete and the arrangement of the cross arms for the purpose of sup porting the feeder circuits, clearly illustrated in Fig. 25 .

|

| Fig. 25. Central Electric Steel Poles. |

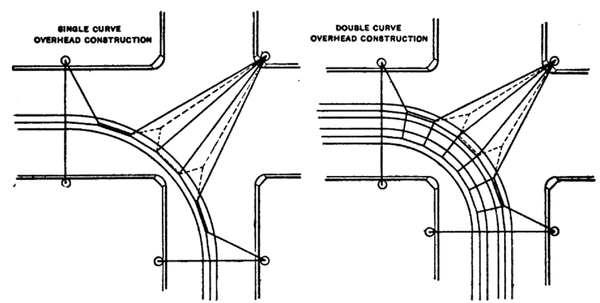

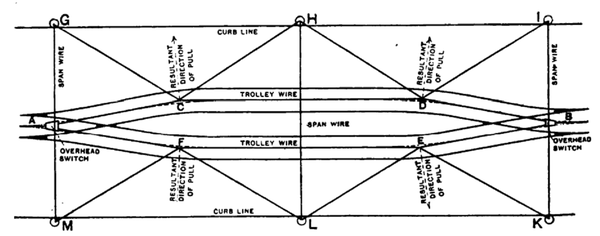

The structural iron pole in various forms is also a favorite method of giving a lighter and at the same time a more solid and substantial form of construction . The difficulty with the iron pole, however, has always been the unwise attempt at economy which has resulted in giving a pole not substantial enough to stand the necessary stresses . An exceedingly valuable form of structural iron pole is seen in Fig . 25 , showing a pole consisting of drawn steel tube made by riveting two semicircular plates together , stiffened by the introduction of a center plate between the two halves of the column. The appropriate brackets for the trolley wire and insulators for the feed wires are indicated also. Such a pole as this is the lightest and best form of street-railway construction , though probably the most expensive . In the case of wooden poles it is customary to provide for the necessary adjustability in the span wire by placing on the pole a ratchet to which the span wire is attached . This method is indicated in Fig. 26. By means of the ratchet the span wire can , at any time , be shifted, and the position of the insulator carrying the trolley wire, with reference to the track , be altered at pleasure. In iron-pole construction , devices for accomplishing a similar result are indicated in Figs. 27 and 28. Fig. 27 indicates a series of pole tops above the insulator, and non-insulated , which may be supplied with bolts for the purpose of securing the span wire. In Fig. 29 is indicated the method of construction adopted by the Philadelphia Traction Company. Here the feeder circuit is underground construction and is brought up through the center of the pole into a cast - iron cap , carrying a hard - rubber insulator. From this cap the feed wire extends to the span wire that serves as a means of connection between the feeder and the trolley circuit . The span wire itself is attached to the pole by means of a collar and insulated turn -buckle which serves the purpose of adjustability and insulator at the same time. Directly above the span wire an appropriate lightning arrester is placed ,, and above this a second collar for carrying the guard wire is attached . In Fig. 30 a combination adjustable pole top is indicated , by means of which anywhere from one to seven insulators may be placed upon the pole for the purpose of carrying the feeder circuits . The electrical railway circuit is peculiar in that it must afford not only a path for the electrical current but the trolley wire must also serve as a mechanical conductor to guide the trolley wheel. If railway circuits were straight lines little difficulty would be experienced, but, on the other hand, provision must be made for corners, for intersection with other lines and for the necessary switches and turn-outs where one line departs in direction from another . Wherever changes of direction occur in the trolley circuit it is necessary to provide special arrangements for sustaining the wire in its proper position above the track . The methods of laying out curves are indicated in Fig. 31. The general plan to be adopted consists in placing two heavy span-wire poles at the ends of the tangents on either side of every curve or turn- out . These heavy poles form the base from which the curve is to be constructed. In the case of curves an anchor pole is placed on a line bisecting the arc of the curve , usually upon the street corner . This pole must be sufficiently strong and substantial to sustain the entire tension of the aėrial circuit. By means of a series of insulators, the trolley wire is attached to stranded cables which form pull-offs, which being attached to the curve pole , serve to sustain the wiring in its proper position . The appropriate design for turn outs is indicated in Fig. 32 , attention being specially directed to the necessity of anchoring the tangents in both directions, as is shown at G H I. Here, from the guy poles G M and H L, anchor wires, consisting of wire rope strand, are extended to the trolley wire in such a way as to anchor it in both directions . In case of rupture , either in the tangent or curve , the anchors serve to hold the remainder of the line in proper position , thus pre venting the interruption which would occur to traffic if large sections of the overhead construction should fall to the ground.

| |||

| Fig. 23. |

|

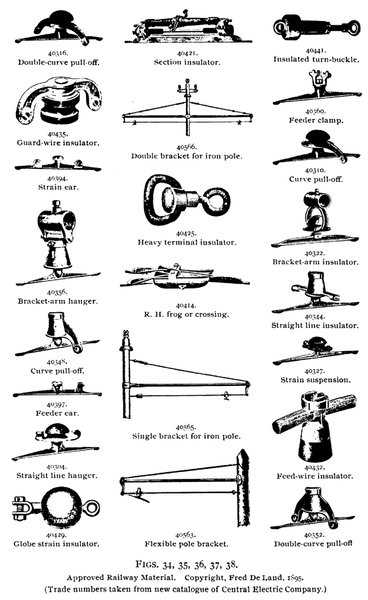

For switches and cross - overs in the trolley wire , special appliances are necessary. Fig. 34 represents the typical forms of cross overs, which are arrangements to be placed in the trolley wire to afford paths for the trolley wheels of two intersecting lines. The method of wiring the cross- overs is indicated in Fig. 33 , in which several lines , intersecting both at right and oblique angles, are shown. The cross-over is introduced in the two intersecting circuits and held in place with the appropriate guy wires and strain insulators. Unfortunately , all appliances of this kind have as yet been found to be open to considerable objection . They are very rarely successful in guiding the trolley wheel in its proper path , and as they afford a sensible obstruction , they form points at which the wear upon the overhead system is particularly concentrated , and where particular attention must be given to careful maintenance. Overhead switches are constructed in a similar manner to the cross- overs and are placed in the wirework at the points of intersection of diverging lines . Considerable skill is necessary to locate the overhead switch in such a manner as to cause the trolley wheel to follow its appropriate path with any degree of certainty . The general appearance of an overhead curve with the proper location of the switch in reference to the path of the car is indicated in Fig. 33 .

|

| Fig. 31. |

|

| Fig. 32. |

|

| Fig. 33. |

The vital point in street-railway construction is the suspension of the trolley wire in a manner to be both electrically and mechanically secure, and experience has indicated that it is essential to sustain it as often as every 100 or 125 feet. Usually the trolley wire consists of No. 0 hard-drawn copper wire. The method of suspension must be such as to afford electrical immunity from leakage , and must have sufficient mechanical strength to withstand the wear and tear of the frequent passage of the trolley wheel. Numberless forms of insulators have been devised to attain this result , a typical form , consisting of a bell , formed of some insulating substance, such as hard rubber, vulcabeston, molded mica , or similar compound, that is sustained by a metal ear secured to the top and which carries on the underside a hemispherical clip capable of embracing and holding the wire. A legion of different forms have been placed on the market for best accomplishing this result . Unfortunately the perfect insulator has yet to be devised , as all the devices which have so far been produced fail sooner or later , owing to the severe mechanical usage to which they are subjected. Fig. 35 indicates an insulator which has met with good success. Two designs are shown , one a double pull - off insulator, valuable on curves , and the other a plan for supporting two trolley wires , which may be used on either a double trolley wire road , or upon the two parts of the trolley wire with which it is now customary to equip a single-track road in order to avoid switches that are otherwise necessary at the turn-outs . One of the best insulators has a metal casing so arranged as to receive a heavy iron bolt which may be thoroughly coated with insulating material. The cap is modeled after the ordinary form of glass insulator, thus affording a complete protection from weather to the insulating material which surrounds the bolt . The trolley wire is placed along the clip or ear , that is secured to the threaded portion of the bolt , where it leaves the insulator. A valuable form of wooden pole bracket has this trolley wire insulator sustained upon a bit of wire cable placed in a loop at the end of the bracket in such a way as to afford flexibility in the trolley line. For all span and pull-off wires , it is essential to introduce a contrivance termed a strain insulator, which is an arrangement for interrupting the metallic continuity, thus protecting the circuit from contact with the ground . Approved forms of such strain insulators are given in Fig. 36. They consist of blocks of wood or other insulating compound which are molded and forced into metal eyes, preferably of bronze, at either end. A similar contrivance is obtained in the iron strap insulator, which consists of two bars of sheet iron that carry two porcelain insulators secured at either end by means of bolts . (See also Figs . 37 and 38 for approved material.)

|

It is found advisable in all street railway construction to divide the line into a number of separate sections which may be supplied with energy from the station by independent feeders. The object of this is to avoid a complete paralysis of traffic throughout the entire line in case of a short circuit at any point. It is necessary to preserve the mechanical continuity of the trolley wire in order that , as the cars pass from one section to another, the wheel may not leave the circuit. To provide for this, section insulators are introduced at the end of each division along the line, one form being illustrated in Fig . 39. The section insulator consists of two ears into which the trolley wire may be securely fastened and separated with an insulating section , either of wood , vulcabeston, molded mica or other material so arranged as to present sufficient mechanical strength to stand the tension of the line. It is advisable to introduce these section insulators quite frequently in order to confine interruption to the traffic to as small a section of the line as possible.

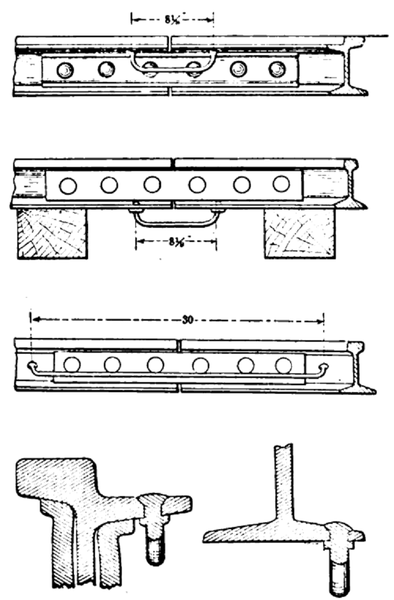

In the early roads it was customary to rely entirely upon the ground as a return circuit, simply depending upon the rail to dis tribute the energy received by the car motor. For small roads in damp locations such a practice may not be amiss , but for large lines where hundreds of amperes are transmitted it is found that the ground circuit is not sufficient as a return path . Upon leaving the rail the current immediately seeks lines of least resistance, usually finding them in the water pipes, gas pipes and other subterranean metallic structures. As a result , exceedingly destructive electrolytic action is introduced . Such a ground return will , also , offer so large a resistance to currents of magnitude as to consume in the return path an undue amount of energy. The rail section of ordinary roads, even considering the difference in conductance between iron and copper, is greatly in excess of that of the feeder section as usually installed . It thus becomes perfectly practicable to use the rails as convenient return circuit , provided the electrical continuity throughout the rail system is adequately secured . Early attempts in this direction consisted simply in uniting the ends of the rails with either a small iron or copper wire. Such a provision as this is entirely inadequate to carry the current needed by large roads. The early rail bonds, too, were made so long as to offer a very appreciable resistance in each mile of track . Great difficulty was also experienced in obtaining an adequate contact between the rail bond and the rail. Attempts have been made to improve the return circuit by electrically welding the rails similar result has been sought for by casting a joint around the end of successive rails by means of a portable furnace carried through the streets. While both of these expedients would certainly afford an admirable electrical circuit , it seems probable that the rail ends would be injured by any process of this kind, sufficiently to cause them to fail by breaking or cracking. These experiments, however, have not as yet had sufficient time to afford reliable data as to the results. The surest , and at the same time probably the most economical, method now to be adopted is indicated in Fig. 40 . The rail bond consists of a short, heavy copper rod , not exceeding eight inches or there abouts in length , which is Q arranged to span the joint in the rails . Bonds of this kind should not be less than one half- inch rod . They should be secured to the rails by die-forging a head on the end of the bond which should be passed through a hole drilled in the rail , and then thoroughly soldered into place. After the soldering is complete the head of the bond should be riveted over the rail in a most careful and substantial manner and then again soldered . The object of the soldering is to make a joint between the rail and the bond which shall always be water-tight in every respect and which shall in the future prevent any corrosive action between the rail and the bond.

|

| Fig. 40. |

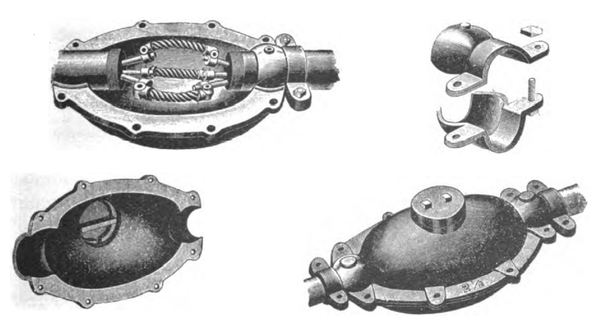

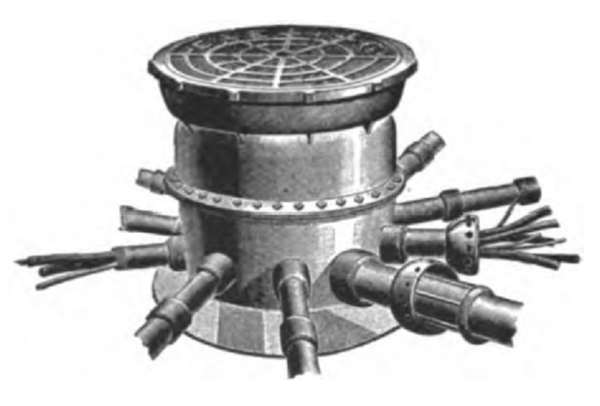

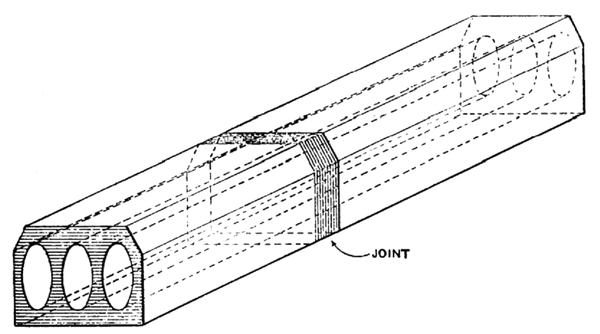

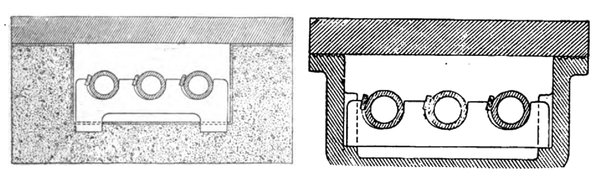

The rapid multiplication of overhead lines , especially in the larger towns, soon gave rise to situations in which the complexity of aėrial wires has become an unbearable nuisance, and some means must, therefore, be provided to free the streets . The earliest attempts in this direction consisted simply in excavating a trench , either in the footway or in the street , and simply burying a sufficient cable having the requisite insulating protection directly beneath the street pavement. Installations of this description, however, proved too short-lived for commercial work . Every sub sequent street excavation inevitably resulted in the injury of the cable , due to the destruction of the insulation by the tools of the workmen , or such a serious disturbance of the circuits as to put the lines hors de combat. Circuits thus laid could not be changed or rearranged , except with exceeding difficulty. It became essential , therefore, to provide some means whereby the conductors could be protected from outside interference, and at the same time would permit sufficient mutability so that from time to time the circuits could be rearranged , increased or diminished as changes in the business might require. The earliest form of conduit was probably that introduced by Valentine, which consisted in a series of pigeonhole - like boxes, made of creosoted yellow pine, each box consisting of a series of rectangular wooden ducts . The sections were made in lengths of ten to fifteen feet, and were introduced by excavating an appropriate trench underneath the pavement level , and introducing the boxes composing the ducts and making the joints by carefully battening the end of each section . Manholes or cavities in the street were provided at requisite intervals, into which the ducts opened. The cables were subsequently introduced by pulling them through the separate partitions in the box.. Conduits of this style were exceedingly cheap to construct, but soon presented serious difficulties . Unequal settlement of the street caused the successive sections to separate from each other, as the wooden box did not present sufficient mechanical strength to withstand the inequalities produced by the frost . An inevitable decay soon manifested itself, notwithstanding the creosoting, which soon threatened the life not only of the box but also generated sufficient acetic acid to completely destroy the lead sheaths with which the cables were surrounded. The Valentine conduit , therefore, is now rarely introduced, excepting for work of the most temporary character . The Brooks system became the next expedient. This device consisted in placing beneath the street a wrought-iron pipe into which the necessary conductors were drawn. At frequent intervals boxes were provided consisting of rectangular cast - iron troughs opening into the pipe and affording convenient access for the workmen to perform the necessary avocations for the introduction of the cables. The conductors consisted of the requisite number of copper wires, either solid or stranded , loosely separated from each other by layers of jute. After being introduced into the pipe the whole structure was filled with boiling resin oil , the expectation being that as oil is a magnificent insulator, it would entirely surround the conductors and preserve their electrical integrity. This was partly realized , and had it been feasible to mechanically provide for expansion and contraction of the pipe, and at the same time to insure the absolute tightness of the joints, it is probable that the Brooks cable would have been a success . The inevitable oil leakage and the poor quality of the fibrous insulation surrounding the conductors has been sufficient, in most of these plants, to cause the lines to cross and ruin the insulators. The Edison tube system became a favorite method of construction , and from the superior class of workmanship exhibited in its manufacture this form of transmission line has, probably, at the present time the largest introduction of any in the world . The Edison system consists of a series of wrought- iron tubes from eight to twelve feet in length , forming the outer casing or protection for the conductors. The circuits consist of copper rods of appropriate size , which are separated from each other by several layers of jute or other fibrous material , and then introduced into the iron pipe , which is afterward filled with insulating compound which , when melted , can be poured into the tube , thus completely filling all of the interstices between the conductors and the pipe, retaining the copper rods in the appropriate position with relation to each other. As the melting point of this compound is high, no ordinary summer temperature causes it to soften , and thus the conductors are irremovably fixed . Any length of line can thus be constructed by joining successive sections of tube. The general appearance of the tubes is shown in Fig. 43. The joining of the successive sections is effected by placing around the end of each an egg-shaped cast iron box. The tubes open into these boxes through a water-tight sleeve at either end. Each conductor is spliced to the next succeeding one by a piece of copper rope which is carefully soldered to the respective ends of the conductors. When the soldering is completed the cover of the egg-shaped box is placed in position, secured by bolts, and the whole joint is sealed and completed by pouring the box full of composition . At the street corners, or at any desired intervals, the tubes are arranged to open into junction boxes, consisting of iron castings into which the tubes enter by means of water- tight sleeves, the interior of the box being arranged with appropriate terminals which allow of any desired combination of the various circuits. The details of this construction may be seen in Fig. 44. To afford a service connection an egg- shaped box with three openings is placed at a junction between the two sections of tube , thus affording means of running a lateral from the main through the cellar walls of the customer. The location of a service connection and the arrangement of the junction box is also shown in Figs . 41 , 42 , 43 and 44 .

| |||

| Fig. 42. |

|

| Fig. 41. |

|

| Fig. 43. |

|

| Fig. 44. |

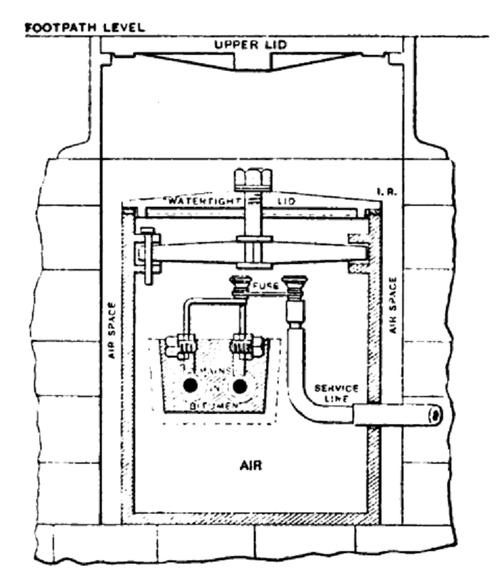

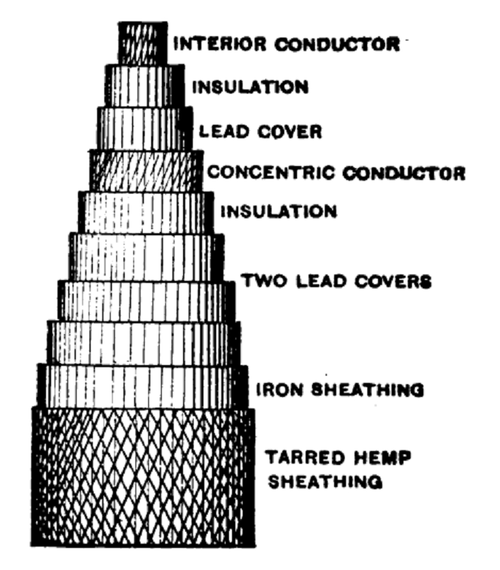

In England a somewhat similar arrangement is presented in the Callendar solid system . This system is made by laying cast iron troughs in the street that are provided with bridge-shaped porcelain insulators, set at sufficiently frequent intervals to support the conductors, which are laid directly upon the porcelain . The conductors may be either insulated cable or bare wire mains. As soon as the conductors are in place the cast- iron trough is filled with melted asphalt, thus retaining the conductors in their appropriate position . Such a method has given excellent service in some of the London installations , and were it not for the expense of the iron construction it would seem an exceedingly feasible solution of the underground problem . To afford service connections and access to the conduit, it is necessary to construct a man hole, as indicated in Fig. 45. The appropriate chamber is built beneath the street level , and in the space thus afforded a cast-iron box of sufficient size is introduced into which the conduit pierces by means of a water-tight joint. The service line is connected with the appropriate mains and then carried through the wall of the iron chamber by means of a sleeve and flange. The chamber is further provided with a lid that is forced into place on top of an india-rubber gasket , hermetically sealing the interior. Sufficient space is left around the iron chamber to afford room for street drainage, and is further connected with the sewer to provide an outlet for the surface water. As a more economical expedient than that presented by the Callendar solid system , an installation has been recently introduced in the city of Cologne. The conduit consists of a yellow pine box into which concentric cable is placed (46A) , the cable being supported by iron hooks placed every two or three feet. After the cable is in position, the box is filled with asphalt, thus accomplishing the protection and insulation of the cable . The details of the system are shown in the cross- section of the conduit with the cable in position, and also a detail of the cable itself is given in 46B . A similar construction has also been adopted in this country in two or three instances for the purpose of laying street - railway feeders. Wooden troughs are placed between the tracks into which bare wire mains are placed , being supported in insulators, boxes being subsequently filled with some one of the appropriate compounds. Such devices are reported as giving exceedingly good satisfaction .

|

| Fig. 45. |

| |||

| Fig. 46a. |

|

| Fig. 46b. |

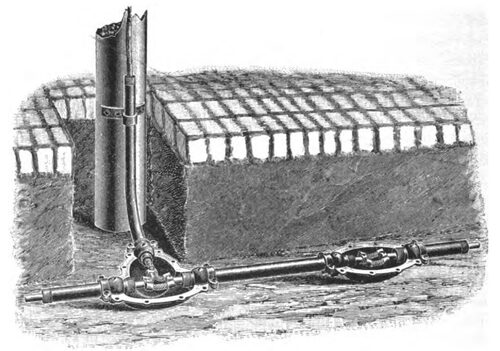

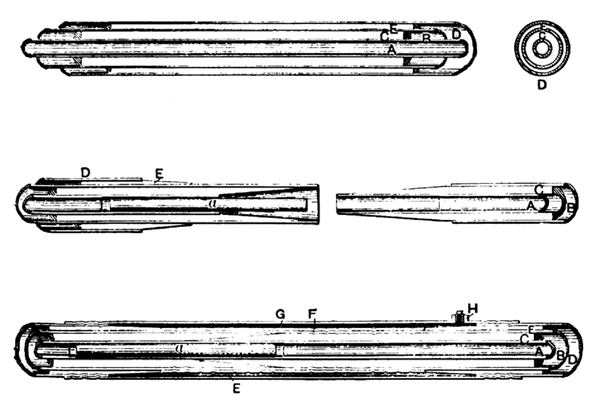

The Ferranti mains form another illustration of a similar method of installation , and are remarkable for the size and amount of energy which they are intended to carry and the high potential under which the mains work. As indicated in Fig.. 47 , the mains. consist of concentric cables formed of an exterior wrought- iron pipe D , into which two conductors, A and B , are placed . These conductors consist of copper tubes, it being impracticable to use solid conductors for the high frequency proposed for the Ferranti distribution. The two conductors are separated from each other and are insulated from the sur rounding iron sheath by means of several thick layers of paper saturated with mixture of india-rubber and pitch. Like the Edison mains, the Ferranti tubes are made of lengths of ten to twelve feet. The joints are accomplished in an entirely different manner from that adopted in the Edison conduit. In the Ferranti mains the splice is accomplished by stripping away the surrounding iron sheath and insulation and then by tapering each of the tubular conductors, forming a male and female joint . The inner conductors are spliced by inserting in the tube a solid copper rod , a . The mechanical electrical contact is secured by forcing the mains into proximity by hydraulic jack and the tubes are then firmly corrugated together. (Figs. 47 , 48 , 49.)

|

| Figs. 47, 48, 49. |

A series of underground installations have been very success fully carried out in England, involving the use of bare wire conductors set in an appropriate tube formed of cement or other similar material. The conduit is prepared by excavating the necessary trench in the street ; the bottom of this trench is then lined with a layer of six inches of good cement concrete made of hydraulic cement one part , sand two to three parts , and broken stone three to five parts. As soon as this bed has set , an appropriate wooden mold is placed upon the bottom and concrete rammed around the mold . Upon the withdrawal of the mold a rectangular trough is formed . The installation may be completed by laying an insulated cable and filling the trough with asphalt or other pitch compound. A cover of flagstone finishes the work .

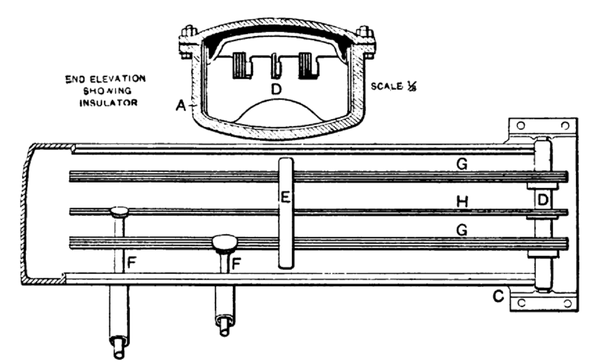

With bare wire mains it is essential to install the conductors in such a way as to prevent them from ever touching the sides of the conduit. The Kennedy system and the Crompton system are of this form of construction . In the St. James system a series of porcelain insulators is set in the concrete forming the bottom of the trough. On both sides a ledge is provided, upon which a wheeled carriage will travel. This carriage consists of two iron strips mounted upon rollers , to which the circuits are attached and which are introduced by drawing the carriage through the conduit, depositing the strips in the insulators at the same operation . The conductors consist of bare copper, usually from one inch to one and one-half inches in width and from one eighth to one-half inch in thickness, depending upon the cross section required. As the carriage travels along through the duct , the copper ribbon is unrolled from the reels placed at the commencement of the subway and falls into its appropriate niches in the insulators. When the carriage reaches the end of the duct the strips are drawn up to their appropriate position and secured in place. In the Crompton system , a very similar construction is exemplified . The conduit is formed in a similar way , hand holes being placed over each of the insulators, which are set about fifty feet apart, being so arranged as to fall directly opposite the front of every second house . The insulators are porcelain sup ports that rest upon solid oak blocks set in the cement. The method of construction is indicated in Fig. 50 a half section through the conduit, and showing the arrangement of supporting the strips at the manholes, which occur every two or three hundred feet. In the manholes, a special insulator is provided, having two heavy oak strips set transversely across the ducts. Each piece carries a heavy porcelain insulator upon which is placed a brass yoke containing two heavy set - screws. The mains of bare copper strips are introduced in a manner similar to that indicated for the St. James system , with the exception that , instead of providing a carriage to travel through the conduit, a small dog is trained to run between the manholes having a string attached to its collar . By this means a rope is drawn through the conduit, which enables the workmen to pull the strips in , one after the other , and place them in their appropriate insulators . When the conductors are located , by means of a hydraulic jack they are drawn tightly into position and secured with set - screws.

|

| Fig. 50. |

|

| Figs. 51, 52. |

A similar construction is exemplified in Figs. 51 , 52 , in the Kennedy system . Here , a cast-iron trough is provided into which a series of bridge-shaped insulators are placed . The conductors are bare wire strips and are stretched in a slot in the insulators and held in place by suitable wedges. The installation is completed by bolting a cover tightly upon the trough , making a water - tight joint. As the cast - iron trough is considerably more expensive than a cement duct and presents no special further attraction , the Crompton system has seemed on the whole to be preferable. The reports from the English bare wire main installations indicate that they have met with almost unqualified success , and it seems strange that practice in this country has not tended in this direction in the slightest degree , for by the use of bare wire mains, considerable expense , in the shape of cable insulation , could be avoided and an exceedingly compact and durable subway cheaply secured .

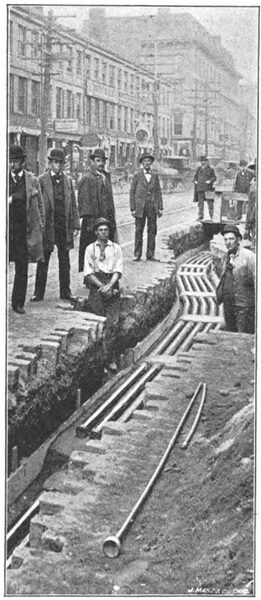

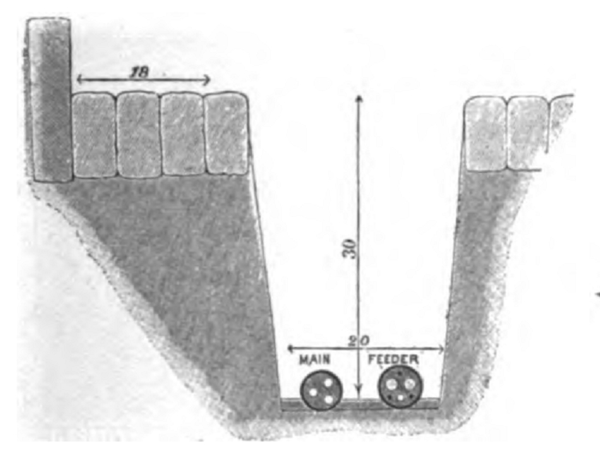

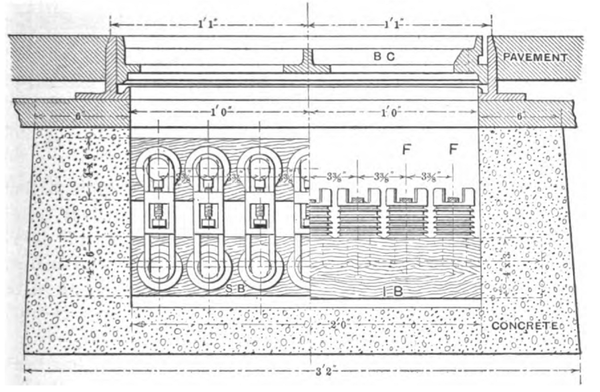

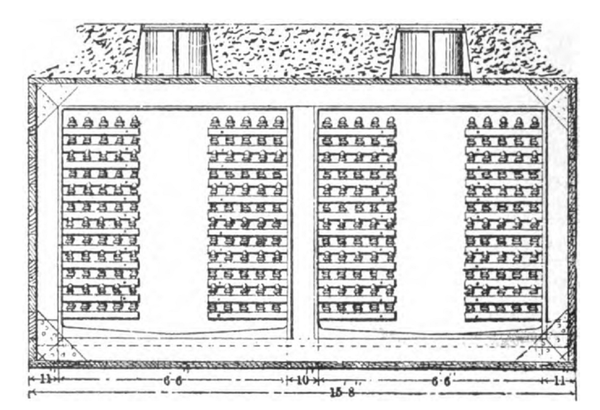

In America the practice for underground circuits has been entirely in the direction of providing a series of tubes in the ground into which insulated cables could , from time to time , be introduced. An example of this form of construction is seen in Fig. 53 , which consists of a series of blocks made, either of cement concrete, asphalt concrete or similar mixtures, which were molded into pieces about three feet in length , containing two or more tubes extending entirely through the block . It was proposed to lay these in a suitable excavation in the street, abutting the ends and forming a joint, either with cement or with melted pitch . Unfortunately, conduits of this description had the same ephemeral qualities exhibited by the Valentine ducts and exhibited insufficient strength to withstand the service requirements. The next stop was the construction , in New York , of large amounts of wrought- iron subways. In all probability the New York subways form the largest and probably the best system of underground construction now in existence. The general design is indicated in Fig . 54. The method of construction consisted in excavating the appropriate trench in the street and lining same with a good layer of good hydraulic cement concrete. Upon this a layer of wrought- iron tubes , from 272 to 4 inches in diameter, depending upon the size of the cables to be introduced, was placed . When the tubes were laid , additional concrete was rammed around them , thus filling all the interstices between the tubes and providing a bed for the next layer. Thus, layer after layer could be placed , making a subway of any desired capacity . At frequent intervals, manholes were located, into which the iron tubes opened , being secured by a water-tight joint . It was considered that , possibly , in the course of time , the iron pipe might be corroded away , in which event there would be a clean , smooth hole left in the concrete , which would be equally efficacious to protect the inclosed cable . As the iron pipe is exceedingly flexible, it could be threaded in and around the other structures within city streets, such as gas and water pipes, in a way which left little to be desired . This form of conduit has been eminently successful in every respect , and were it not for the expense of the iron pipe, engineers would not be compelled to look further for the appropriate conduit structure .

|

| Fig. 53. |

As an attempt to economize to some extent upon the wrought iron subway , the Johnstone system came into existence . A series of cast- iron troughs were made, containing rectangular partitions, thus forming an indestructible subway very much after the plan of the Valentine system . Under this plan a subway of any desired capacity could be built , containing any number of ducts and affording room for cables of all descriptions. As in the iron pipe subway , the objection to this form chiefly lay in the attend ant expense.

To cheapen subway construction , devices have arisen that consist in supplying pipe made of terra cotta or cement. The first of these is the cement-lined iron pipe , underground system . A very thin wrought- iron tube is selected , made by winding a special iron ribbon , something after the fashion of a stovepipe. This pipe is then filled with a layer of about one inch of cement. After the cement has solidified, a long straight smooth cement tube is obtained, which is consider ably cheaper than wrought iron pipe. The method of laying the cement-lined pipe is precisely the same as that adopted for the wrought- iron tube and is fully illustrated in Fig. 54.

| |||

| Fig. 54. |

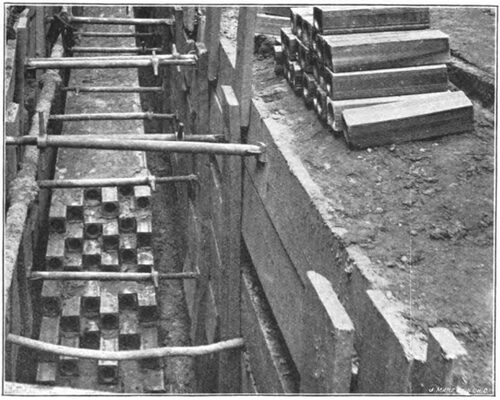

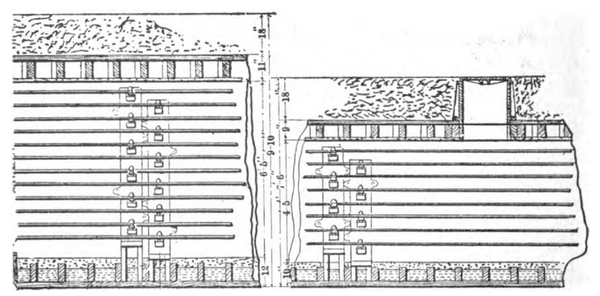

To still further cheapen subway construction the 10 by 10 inch terra cotta pipe made in lengths of about four feet and divided through the center by a partition has been largely used . These rectangular blocks are laid by excavating the appropriate trench in the street, lining same with cement, and laying the requisite number of terra cotta pipe upon the foundation thus provided . The joints are effected by wrapping successive sections of the pipe with a number of layers of jute saturated with asphalt . It has been found by experience that this makes a solid joint a certainty, provided the cement foundation of the trench is adequate to resist street settlement. Care must be exercised , however, to see that the asphalt is thoroughly applied at a low temperature. If the asphalt is not sufficiently hot , it will not saturate the jute , which will subsequently rot . If the asphalt is too hot the jute will inevitably be burned and the joint destroyed. The objection to the 10 by 10 terra cotta duct lies in the fact that it provides a single duct into which several cables must be introduced. If ordinary lead - covered cable be used, no difficulty at all is experienced in the introduction of at least three cables into each duct ; but while the cables may be readily introduced, it is found impracticable, after they have been in position some months, to withdraw them without entirely stripping the lead sheath . Lead is a metal which flows under the least provocation , and it seems as if the slight weight of the adjacent cables, pressing against each other, in the duct , was sufficient to cause the lead sheaths to drawn. While this form of conduit is exceedingly cheap - probably the most economical one known as it is impossible to with draw lead- covered cable with any certainty of success, the system becomes an expensive one to adopt . As a remedy for this difficulty, a conduit, consisting of a number of sections of terra cotta tile eighteen inches long and five inches square on the outside, each pierced with a round hole three and one- half inches in diameter, has been introduced . To construct the subway, the necessary trench is excavated in the street and provided with the concrete foundation, as in other forms of the terra cotta tile , cemented with mortar in the same way the ordinary house wall is constructed, extending between adjacent manholes, the terra cotta tile forming a series of straight, smooth, cylindrical tubes, each one adapted to the reception of a single cable . On the completion of the conduit , by pulling a scraper through the ducts and then washing them out with a stream of water, a clean and polished tube remains. Subways of this kind are completed by ramming, on either side of the ducts, a layer of concrete some six inches in thickness ; and covering the entire structure is a similar layer of concrete, which is then protected by planks to ward off the offensive pick of the street re --paver. Subways of this kind can be quite cheaply constructed , and form, on the whole, probably the most durable and valuable form of conduit now known. ( Fig . 55.)

| |||

| Fig. 55. |

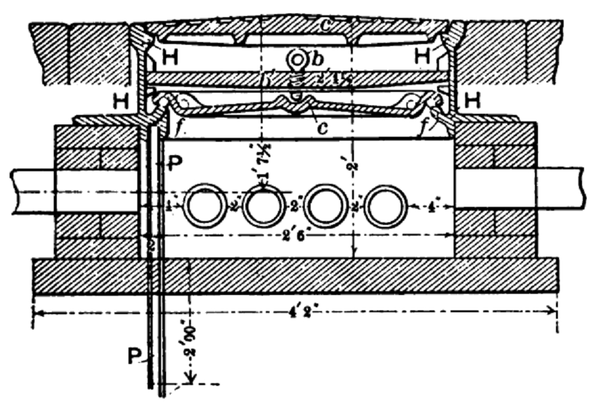

To afford accessibility to the inclosed circuits, it is necessary to provide the subways with manholes at appropriate intervals. It is considered advisable to locate manholes at each street corner ; as here one or more ducts intersect , and at such points it may be necessary to change the direction of the circuits. It is necessary to here afford means of introducing the new cables and drawing out the old ones, which may in time become defective. The man hole usually consists of a chamber constructed either of brick or concrete, and should be made as large and roomy as possible , for while large manholes cost proportionally more than small ones, the ease with which the workmen can in the future perform necessary avocations is much facilitated and the maintenance expense proportionally decreased . Manholes should be from 4-1/2 feet to 5 feet in height inside, and from 4 feet to 7 feet in width , being from 6 feet to 8 feet in length . It is customary to pave the bottom with either cement or brick , connecting same with the nearest sewer, with an appropriate trap to provide for surface drainage, thus keeping the manhole dry . In the earlier subways considerable difficulty was experienced by the incursion of illuminating gas into the manholes. It has been found that illuminating gas companies usually fail to account for from eight to fifteen per cent of the gas manufactured by them , excepting on the theory that, either through the cast- iron pipes which are used for distribution, or from sundry leaks in defective joints, the gas escapes into the soil of the street . Manholes afford convenient places into which gas can easily accumulate, thus giving rise to an atmosphere which may either asphyxiate the workmen or may mix the requisite portions with the air to form an explosive mixture which may be ignited by the lantern of the unsuspicious workman . In the early subway days in New York , a number of disastrous explosions were traced to this cause . As a cure, it was considered essential to provide the employes entering the manholes with a blower, whereby the gas could be dispelled before the entrance of the workman and afford a means of supplying fresh air. To provide against the incursion of gas, two methods are employed in the cities where the leakage of illuminating gas is excessive. One plan involves the placing of an air pipe along the side of the sub way, which may be connected to a blowing plant located at the central station . By means of this plant air pressure is maintained constantly in the blowing pipes which open into the manholes, from which the air flows into the subway. It is found that if the pressure in the subway is slightly in excess of that in the atmosphere, the tendency is to force the gas away from and prevent it from accumulating in the ducts and manholes. To carry out this system , it is essential to provide the manholes with air-tight covers. Such an arrangement is quite expensive, as it is necessary to install and constantly operate a blowing plant of sufficient magnitude to keep the subways free from gas.

In locations in which gas is not exceedingly prevalent, a cheaper and equally efficacious device may be put into practice, consisting in grading the subways between successive manholes so that every alternate manhole forms a low point , while the others form relatively high points. By then providing the manholes with perforated covers, allowing ample access to the atmosphere, it is found that the gas leakage will not accumulate in the subways to any disastrous extent. As the illuminating gas is slightly lighter than the air , if the subways are appropriately graded , the illuminating gas tends always to rise to the highest manhole , and thus pass through the perforated cover into the air , its place being supplied at the lower manhole by the incursion of a corresponding amount of the atmosphere.

|

| Fig. 56. |

|

| Fig. 57: English Tile Conduits. |

To protect the iron pipe subways from leakage from street drainage much care has been taken in the construction of man holes, which consist of a brick chamber into which the ducts open through joints which are cemented solidly into the brick wall . The cover for the manhole is an iron casing provided with two covers , an inner and an outer one, as shown at H and c , Fig. 56 . The outer cover fits loosely into the cast-iron ring set in the pavement, simply serving to preserve the continuity of the street . The inner cover is placed upon a rubber gasket at F, that is supported upon a circular ledge surrounding the inside of the man - hole frame. This cover is forced tightly into place, thus . hermetically sealing the manhole across bar B and heavy plate B. The ledge supporting the gasket also serves as a trough to collect any drainage which may leak through the upper cover, and con duct it to the sewer , by means of pipe P.