[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. 26, no. 533, p. 49-51, col. 1-2

A Fourteen Mile Transmission at Barton, Vt; With Monocyclic Apparatus.

FOR the past two years the village of Barton, Vt. , has been enjoying the benefits of cheap electricity brought to it by the Barton Electric Light and Power Association, from a water power situated fifteen miles distant at Charleston, Vt. Within recent years Barton has been undergoing a steady process of growth, incident to the location within its limits of several large manufacturing concerns, and the increase of population which these have brought in their train. About two years ago it was felt that the town had reached the condition in which electric lighting had become a necessity, and the project took form by the appointment, by the townspeople, of a committee to investigate the matter and report. The question was very thoroughly examined and discussed, and every system canvassed. One mile east of West Charleston village on the Clyde River, is a water power known as Plunkett's Falls. This seemed to the committee a very suitable source of power which might be utilized in connection with the electric lighting project, and it was secured at a reasonable figure. At the next village meeting it was voted to build a plant and to locate it at Plunkett's Falls. The trustees were empowered to bond the town in accordance with an act of the Legislature and to proceed with the work.

| |||

| Stone Dam and Wooden Tube, Plunkett's Falls, Vt. |

The power site is admirably suited to electric generation purposes. The stream is large, the flow comparatively uniform and with only ordinary precaution little danger of shut down is likely to occur from ice or freshets. The entire fall of water, 76 feet, is utilized.

A masonry dam 75 feet long was thrown across the river at Plunkett's Falls and from this to the power house forebay a flume or wooden pipe line, 1,000 feet long, was laid, 700 feet of which is laid upon a rock ledge along the Clyde gorge above the stream. The wooden pipe is built of heavy planking tongued and grooved and held together by heavy iron bands. The hydraulic work was carried out by G. W. Buzzell. The system of generation and transmission adopted is the monocylic system of the General Electric Company. The use of this system for a transmission of power over so great a distance is extraordinary and this is the only instance in which it has been employed. It has, however, been successfully operated without accident or difficulty since the day the plant was started.

| |||

| Generating Station, Plunkett's Falls, Clyde River, Vt. |

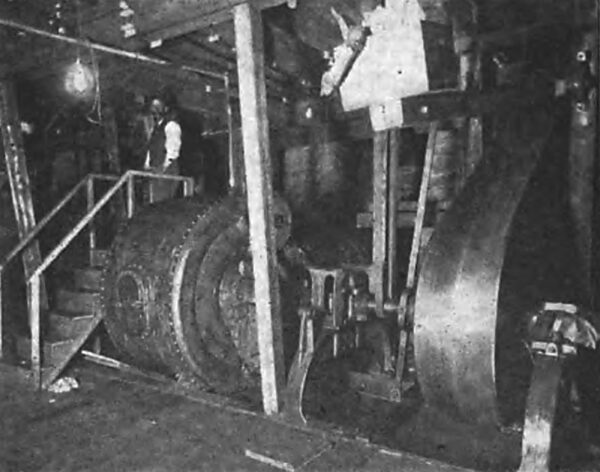

The power house is a frame building standing on a rock ledge near the stream, about one mile from Charleston village. It is divided into three parts, the lower or turbine chamber, the dynamo and switchboard room and the living room of the station attendant above the dynamo room. The turbine is from the works of the James Leffel Co., of Springfield, O. It runs at 350 revolutions per minute and is rated at 500 h. p. The discharge water passes into a tail race 200 feet long below the power house. The turbine is belted to two General Electric monocyclic alternators set up on the first floor. These are eight-pole machines, each of 100 kilowatt capacity, delivering current at 1,040 volts at a speed of 900 revolutions per minute.

| |||

| Leffel Wheel, Generating Station, Charlestown, Plunkett's Falls. |

| |||

| Generating Plant, Charlestown, Plunkett's Falls. |

These alternators are simple single-phase generators differing slightly from the standard single-phase type, in the armature, which is provided with a small additional winding known as a "teaser" coil. By means of this coil an out-of-phase electro motive force is furnished for the purpose of starting motors. The monocyclic system is, however, essentially a single-phase system and practically all the energy is carried over two wires. From these the lighting system is supplied in the usual manner. The induction motors require a third or "power wire," but this is run only to points where motors are to be installed. Thus the lights are operated on a single-phase system, while the motors operate as on a multiphase system. In the mono cyclic system unbalancing is impossible.

| |||

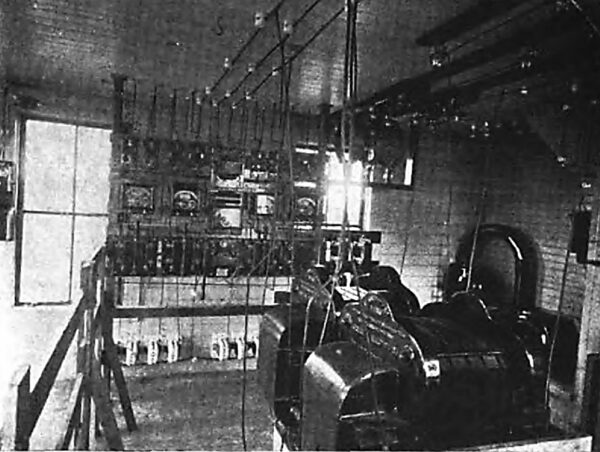

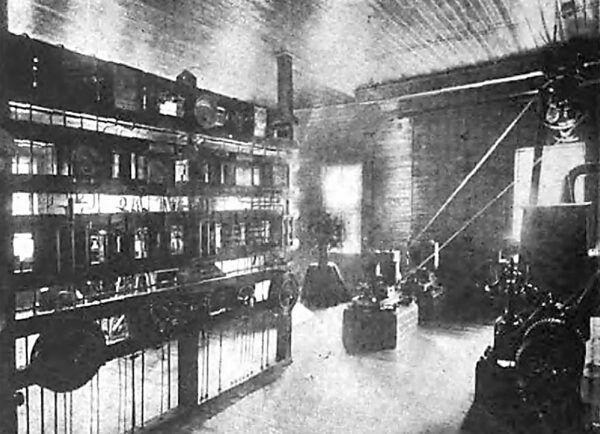

| Interior of Sub- Station, Barton, Vt. |

The armatures of these machines are of the ironclad type and the coils are formed and insulated before application to the core. They are held in place by insulating blocks and no binding wires are used. The armature is thoroughly ventilated, and built up of thin sheets of steel of high magnetic permeability. The frame is in two parts, the lower being the base lower magnet yoke and the pillow blocks; the upper part being the upper magnet yoke. The pole pieces are made up of steel laminations cast into the yoke, and the field coils are wound on insulated removable spools. The machines run cool and regulate automatically. Each machine occupies a space of 6 ft. 8 in. long by 6 ft. 2 in. wide.

| |||

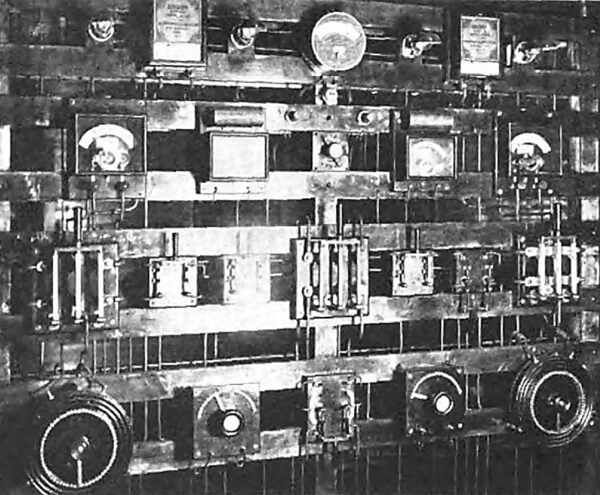

| Main Switchboard, Generating Plant. |

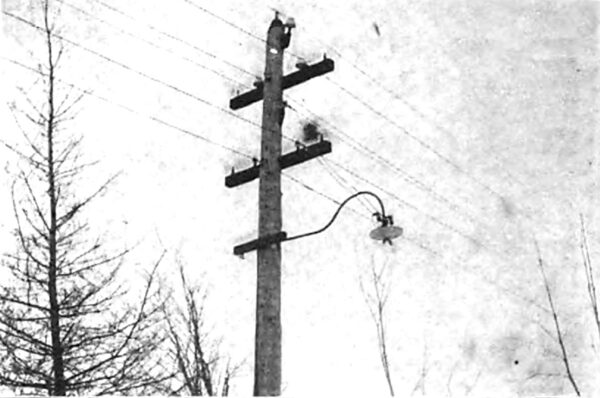

The switchboard is of the wooden skeleton type and all wires to and from it are carried underneath the floor. The step- up transformers are of the air-blast type and are four in number each of 40 kilowatt capacity. In these the initial pressure is raised, and the current passes to the transmission lines at 5,720 volts. One illustration shows a pole head near the entrance of the line into Barton. The topmost insulator supports an iron barbed wire grounded at intervals and acting as a lightning arrester. The next three insulators arranged in a triangle are of the porcelain double petticoated type, and carry the three main transmission wires of No. 4 B. & S. gauge. The next three are of glass and carry the secondary mains from the substation. The two lowest carry the telephone wires.

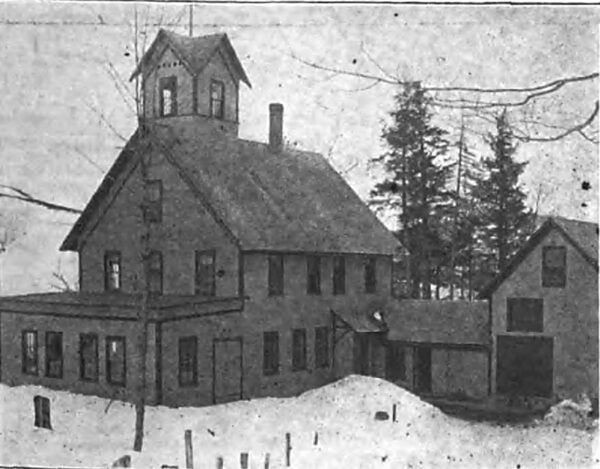

The substation at Barton is a small frame building carrying a tower into which the main transmission lines are brought and connected through G. E. alternating current lightning arresters to step-down transformers, each of 40 kilowatt capacity, also of the air-blast type. These are cooled by two 12-in. Sturtevant blowers-one coupled directly to an overshot water motor driven by water from the Barton water system, the other coupled directly to a 1 h. p. induction motor served from the long distance transmission lines. There are thus two methods of ventilating the transformers, but ordinarily the water motor only is in use, the electric motor being called upon in case of emergency. The transformers reduce the pressure of the current to 1,040 volts, at which pressure it is distributed over a system of feeders to smaller transformers, in which the pressure is again reduced to 113 volts.

| |||

| Pole Line, Entering Town of Barton. |

| |||

| Sub- Station, Barton, Vt. |

The service network is laid out on the Edison three-wire system, and all current is supplied to customers through Thomson recording wattmeters. The lighting of the streets is effected by groups of two 16 candle power incandescent lamps, under a small reflector hood, located at short intervals along the streets and highways. They are directly connected to the secondary, three-wire Edison, network, This system of lighting was adopted because it allowed the use of one type of lamp only for all lighting purposes in Barton. Furthermore, the chance of both lamps failing is very greatly reduced, and as a matter of fact inspection of the street lamps is made once a week only. The number of 16 candle power lamps wired for residential and street lighting is 2,000.

| |||

| Exciters and Water Wheel Governor, Charlestown. |

The cost of operating this plant is, we are assured, exceedingly low, while the service rendered is highly satisfactory. The transmission line is carried also to the town of Island Pond, Vt., 12 miles away, where about 800 lights are supplied with the necessary current. The committee under which the project was started was made up of Messrs. C. P. Percival, Geo. H. Davis and J. W. Murkland. The general superintendency of the work was vested in the town trustees E. G. Colliston, H. T. Seaver and E. F. Dutton. The resident engineer, who superintended the details of the work, was Mr. Ernst Gonzenbach.