[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. 22, no. 445, p. 497-498, col. 2,1

THE TESTING OF HEAVY INSULATORS.

BY NEV1L MONROE HOPKINS.

THE testing of heavy insulators designed for high tension service is of great importance before their shipment and installation. Delicate measurements of resistance would mean very little as no reliable information concerning the future behavior of the insulator when put in actual use would be gained, for leaks would develop and defects come to the surface when put under the strain of the high tensions employed in certain classes of railway work and long distance power transmission. The actual "break down" test is based on the theory that an insulator which is able to resist puncture when submitted to a tension of 30,000 volts for a period of thirty or forty minutes is capable of effectually insulating a current with a potential difference of 1,000 or 2,000 volts for an indefinite period. Is it altogether wise to submit a porcelain insulator to such an abnormal stress?

It would undoubtedly be preferable not to do so if gentler means were at hand to learn of its collapsing point. In the case of the hydraulic testing of steam boilers which are never benefited by an abnormal test pressure, the same argument may be applied. In either case heroic methods appear to be the only practical courses, and perhaps after rejecting those insulators which become at all heated during the test a reliable knowledge of their insulating qualities can be reached.

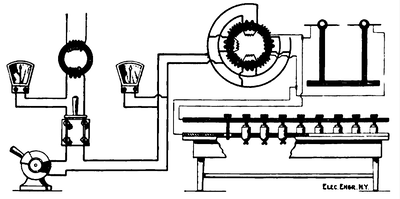

The accompanying diagram shows the arrangement of apparatus best adapted to this special test. Alternating current is received at the first transformer at 1,000 volts and it is stepped down to 100 volts before the indicating instruments are connected in and the primary of the high transformer fed. Should this step down be omitted, any accident to the high potential transformer, such as a short circuit between its primary and secondary, would put the alternator in danger. A "choking" or controlling coil is included in the circuit with the ammeter, and after crossing the terminals of a voltmeter the conductors are led directly to the high potential transformer, as shown in the diagram. Here the voltage is stepped up from 100 volts to 30,000 volts by means of the single, wire ring transformer. The table on which the insulators are placed is provided with a copper, or sheet iron top with holes punched through to receive the insulators. Wooden strips with copper covered tops carry the metal bolts that drop through and rest on the bottom of the insulator. A hard rubber or wooden stand carries copper needles which may be easily adjusted.

|

| Method of Testing Large Porcelain Insulators. |

In the present case, the needles are separated one and one-half inches and a discharge will take place across the air gap should the voltage rise above 30,000. A loud humming noise begins on closing the circuit, accompanied by a strong odor of ozone until an insulator breaks down under the stress and begins to sing at a low pitch until it cracks and heats up to a red heat in the neighborhood of the puncture. Any defects in the moulding of the clay, or any conducting mineral that may be present, immediately starts a slow leak that frequently ends in puncture.

A loss of from 8 to 10 per cent, is usual in carefully made insulators, when subjected to 30,000 volts. Insulators that contain some conducting mineral in the clay frequently begin to leak within five or ten minutes and a regular conducting passage seems to form which raises the temperature of the whole insulator without doing any apparent damage. Specimens which behave in this manner are frequently overlooked in the test, for they do not puncture and sing, and it hardly need be mentioned that they should not be passed as perfect. Those that remain cold during the thirty minutes are as near perfect as can be detected.