[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. 22, no. 426, p. 5-7, col. 2,1-2

POWER TRANSMISSION.

THE 35-MILE ELECTRIC POWER TRANSMISSION AT FRESNO, CAL.

FRESNO, the principal town of the great San Joaquin Valley, in California, was, during the last days of May, the scene of the completion of a great work, having for result the electrical transmission commercially over the longest distance yet attempted of power generated by an artificial fall of water unique in its creation and height.

|

The city of Fresno stands in the valley of the San Joaquin River, in California, and was founded in 1872, when the Southern Pacific Railroad was first built in the valley. For thirteen years its growth was extremely slow, but in 1885 it received an impetus, and in the last ten years its population has risen to 15,000 persons. Its natural advantages are many: It is the center of a fertile agricultural region, over-spread with a network of canals and ditches for irrigation purposes, and has other vast mineral resources as yet undeveloped. It is the commercial center of the San Joaquin Valley and would have become a manufacturing city had its aspirations in this direction not been subdued by the extremely high price of fuel and consequent heavy cost of power for manufacturing purposes. This handicap was felt severely by the city as a check upon its growth. All manufactured articles had to be purchased in the East, and when to their cost were added the freight charges, prices on arrival at Fresno became almost prohibitive. The utilization of the difference of level of the San Joaquin River had been mooted, but not until the successful solution of the problem of long distance power transmission had been reached did the utilization of the San Joaquin become possible. A company was formed, the San Joaquin Electric Company, to carry out the work, and the General Electric Company's project and three-phase system of transmission, by which power had already been successfully transmitted from Folsom to Sacramento, a distance of twenty- four miles, was solution of the problem of long distance power transmission had been reached did the utilization of the San Joaquin become possible. A company was formed, the San Joaquin Electric Company, to carry out the work, and the General Electric Company's project and three-phase system of transmission, by which power had already been successfully transmitted from Folsom to Sacramento, a distance of twenty- four miles, was adopted. The work, lacking a few details, is now complete and Fresno is on a par with any city of the East, so far as the cost of power and light is concerned.

THE HYDRAULIC PLANT.

The source of the water power is the North Fork of the San Joaquin, which at the point of diversion runs through a narrow canyon with solid rock walls. The minimum low- water flow of the stream at this point is fifty cubic feet per second, which at the head used, will develop over 7,000 horse-power at the water wheels.

From the point of diversion, a flume has been built and a canal excavated and carried along the slopes of a hill for a distance of seven miles. They run along a right of way cleared of all obstructions for a width of 150 feet. The grade is 5.28 feet to the mile, and the lower bank forms a roadway for the inspection wagons. The entire system of headworks and canal is below frost line.

| |||

| Pipe Line Descending Hill to Power House. |

At the end of the canal is a natural basin several acres in ex tent, surrounded for about three-quarters of its distance by a dyke of rock, which for an expenditure of less than $3,000 has been continued in an embankment for the remaining distance and a reservoir for storage water formed which at a maximum depth of only ten feet, will be sufficient to operate the plant at full load for several days consecutively. This provision will allow of the ditch and flume being shut off in case of repair or changes.

The reservoir is located at the top of a high hill, the river being some 1,600 feet below. From the pressure box in the reservoir the pipe line, 4,100 feet long, is brought down the mountain side and in this distance the difference in level between the water in the canal and the water in the river below is over 1,400 feet. For the first 400 feet the pipe is steel riveted; the balance is lap welded pipe, with lock joints, and at the lower end is 5/8 inch thick by 22 inches in diameter.

At the power house the pipe enters a receiver 57 feet long by 30 inches in diameter, of 3/4-inch steel, with joints of the butt strap type. This receiver is designed to stand a working pressure of 800 lbs. to the square inch.

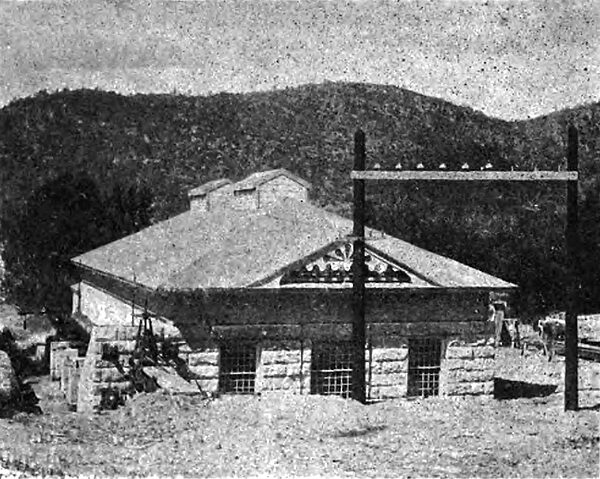

THE POWER HOUSE.

The power house at the bottom of the hill is built of native granite, with a wooden roof. It is 75 feet long by 30 feet wide and is built on solid bedrock. The receiver and water wheels are outside the main power house, the shafts passing through a heavy granite wall, which effectually keeps all water and moisture out of the dynamo room.

| |||

| The Fresno Electric Transmission Power House. |

The water wheels are of the Pelton type, 57 inches in diameter, each capable of developing 500 horse-power at 600 revolutions per minute under an effective head of 1,410 feet, said to be the highest head ever used for power transmission purposes. The wheels are constructed with steel plate centers and bronze buckets and are fitted with flywheels, five feet in diameter. Separate wheels are provided for the exciters. The wheels which drive the generators are provided with Pelton differential governors.

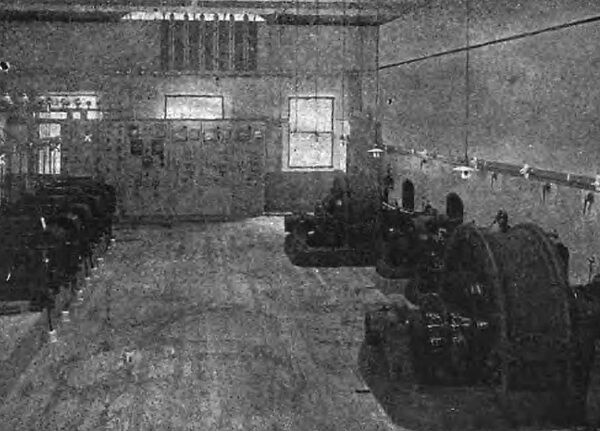

THE ELECTRIC PLANT.

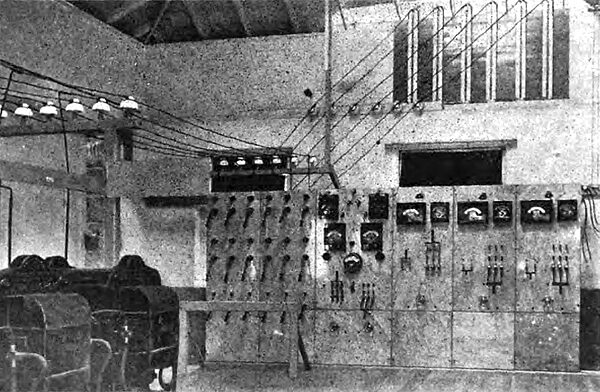

The electric plant consists of three General Electric three- phase generators, each of 350 kilowatts capacity, at a speed of 600 revolutions. The armatures are directly connected to the water wheels by insulated flange couplings. The exciters used are of the slow speed multipolar type. The current from the generators is delivered to six 125 kilowatt step-up transformers of the G. E. air blast type with secondaries wound for 11,200 volts, to which pressure the current in the transmission line is raised. Provision is left in the generator room for three more transformers of similar capacity. From the transformers the current passes to the switchboard, which is of Vermont marble highly polished, as are all the other switchboards used in the installation. The switchboard consists of six panels, three of which are generator panels, one exciter panel and the other two operate the combination of the six transformers and carry special high tension line switches.

THE TRANSMISSION LINE.

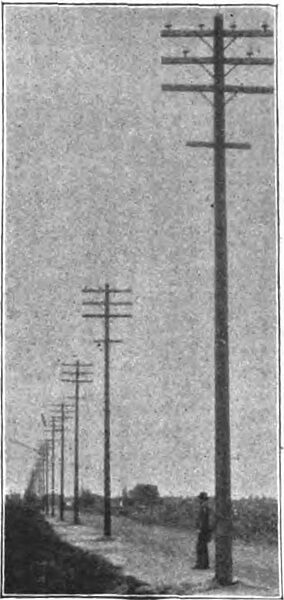

The 11,200-volt circuit, consisting of six bare c copper wires, leaves the power house at the upper end, runs up the stream a few hundred feet, crosses the San Joaquin River, with a wide span of 275 feet, and is then led up the mountain for a distance of about 2,000 feet. The line continues for about ten miles through a rolling, hilly country, easy of access and at all times below the snow line; the rest of the line runs over a flat country and near Fresno passes through wheat fields and vineyards and follows a special right of way and wagon road for the entire distance.

| |||

| Generator and Transformer Room. |

The total length of the transmission line from the power house to the substation is little short of thirty-five miles, and is thus the longest commercial electric power transmission in the world.

The line is strung on special high-tension porcelain insulators made in the porcelain works of the General Electric Company, tested under 27,000 volts alternating before shipment. The poles are square redwood thirty-five feet long, set six feet into the ground and fitted with three heavy cross arms and one small cross arm for telephone wires. As a model of pole line construction, the Fresno transmission line can compare favorably with any pole line work done in the country.

THE SUBSTATION AT FRESNO.

The substation at Fresno is almost in the center of the business portion of the city, and is a brick structure 55 feet by 45 feet. The high pressure circuits entering the house are brought to nine step-down transformers, also of the air blast type. Three of these are 125 kilowatt capacity and reduce the pressure to 200 volts, three of 75 kilowatt capacity with secondaries of 1,000 volts, and three are of 40 kilowatt capacity, reducing the pressure to 3,000 volts. In addition to these trans formers, the station also contains two 80-light Brush arc machines directly driven by two 60 horse-power, three-phase induction motors.

| |||

| Switchboard in Fresno Electric Transmission Power House. |

The system of distribution from the substation is divided up into three networks. The first a 200-volt, four-wire, low-tension network which covers the business portion of the town and having an initial capacity of 6,000 16 candle-power incandescent lamps. The second, a 1,000-volt, three-phase system covering the residence districts of the town and having an initial capacity of 4,000 16 candle-power incandescent lamps. The third, a 3,000-volt, three-phase circuit designed to furnish current to the numerous vineyards and wineries within a radius of ten miles from the substation for both lighting and power purposes. Motors will also be furnished with current from both the 200-volt and 1,000-volt systems. The policy of the operating company is of a broad gauge character, the end in view being the stimulation of the use of electric power. To effect this end prices are made which com- pare favorably with those charged for power where steam coal costs only $2 per ton. The result of this is that the demand has already taxed the resources of the company, although the plant has scarcely been running for one month.