[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. 19, no. 367, p. 431, col. 1-2

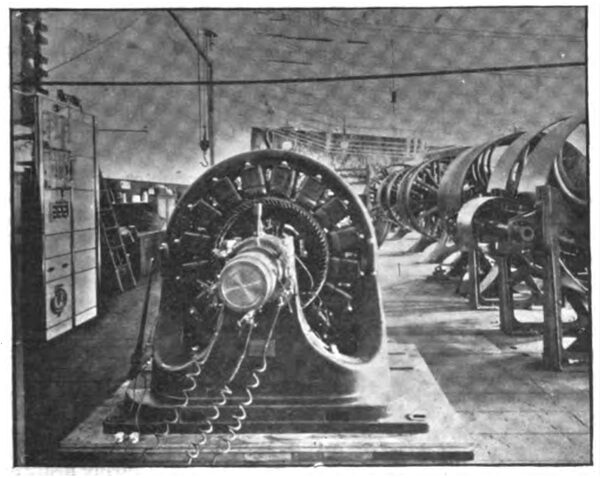

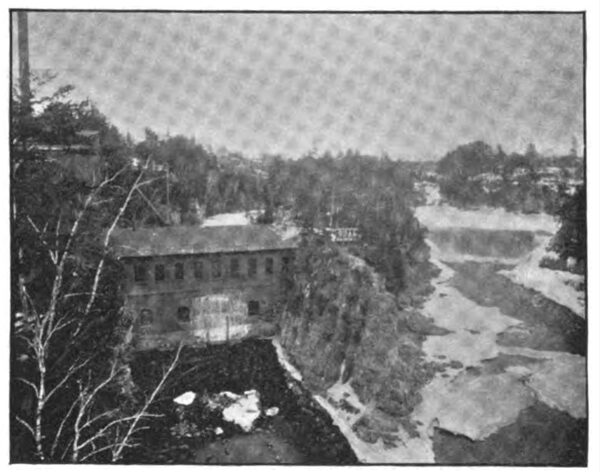

THE THREE-PHASE PLANT OF THE VERMONT

ELECTRIC COMPANY AT WINOOSKI, VT.

THE Westinghouse three-phase power plant which has been installed for the Vermont Electric Co., Winooski, Vt., for supplying the city of Burlington with electric power, presents many points of interest.

The electrical equipment of the power house consists of a Westinghouse generator, rated at 46 amperes at 2500 volts, running at 450 revolutions per minute, and having a periodicity of 7200 alternations. The machine overcompounds 10 per cent, at full load. It has 16 poles, with drum wound slotted armature, and triangle construction for three-phase work. It can be belted direct from a turbine, or from a counter shaft, which is in turn driven either by a turbine or steam engine. The exciter is driven from the shaft of the generator.

The transmission line, which is 2 1/2 miles long, consists of No. 0 weather-proof insulated wire. There is also, covering the principal business part of the city, a secondary network of No. 0 wire. The primaries are run on white-glass insulators; the secondaries on green glass.

The secondary mains are fed by two banks of transformers in parallel, each bank consisting of two 18f K. W. transformers installed in a brick vault. One vault, out of doors, has a removable tin-covered roof, and is provided with a trap door from which all the fuses may be reached. There are fuses on both the primary and secondary side of this vault. The second vault, which is located in the basement, is similar to the first, except that it has the primary fuses on a pole outside of the building. Both vaults are perfectly ventilated, and each has space for a third transformer when the load shall require it.

| |||

| Fig. 1. — Three-Phase Dynamo Room, Burlington, Vt. |

The motors are three-phase, with "cage" wound revolving secondary, and distributed primary windings. They are driving printing presses, elevators, and various manufacturing machinery. The service is excellent and the demand for power is rapidly increasing. A large number of small industries in Winooski rely entirely on the electric power supply, and more than 100 H. P. in small motors is already connected to the set of secondary mains. Many motors in distant parts of the city have individual transformers. At present the transformation is effected by two instead of three transformers in a bank. Each motor has a fuse cut-out, a three-jaw switch, and a Shallenberger recording watt meter. The local company and consumers have arranged to install a meter at each motor, even when several motors are used by the same customer. It is proposed to equip another set of secondary mains in different district of the city before long.

| |||

| Fig. 2. — Three-Phase Water Power Plant, Burlington, Vt. |

The work of the installation has been carried on under the direction of the manager, Dr. W. S. Vincent. Mr. A. E. Richardson is president of the Company, and Capt. Smith S. Leach, U. S. A., consulting engineer.