[Trade Journal]

Publication: Transactions of the American Institute of Electrical Engineers

New York, NY, United States

vol. 30, no. 2, p. 1391-1456, col. 1

ELECTRIFICATION ANALYZED, AND ITS PRACTICAL APPLICATION TO TRUNK LINE ROADS, INCLUSIVE OF FREIGHT AND PASSENGER OPERATION

BY WILLIAM S. MURRAY

·

·

·

·

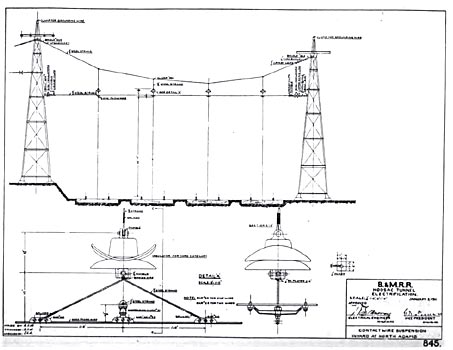

General Catenary Construction

In the simultaneous authorization of the electrification of the six-track Harlem River Branch for freight and passenger operation, the New York Westchester & Boston and the Hoosac Tunnel, it naturally made it imperative for the engineers of the New Haven Road to prepare a very extensive set of plans to cover completely these three constructions. Illustrative of the flexibility and adaptability to standardization of the single-phase system, while the Harlem River six-track work required a longer and stronger bridge than the four track New York Westchester & Boston railroad, the general design of both, however, are the same; and notwithstanding the difference in number of tracks, the wire plans for the overhead catenary system of the four-track were applicable to the six-track, the simple addition of two tracks merely meaning an additional 50 per cent increase of material and an equal percentage of weights and stresses for the bridges to sustain.

Space does not permit a lengthy discussion of the general drawings and plans that have been presented in this paper. Owing to the necessary reduction, in reproducing the tracings, the figures on the illustrations and particularly those of the strain and deflection tables, have been reduced to sizes which are difficult to read, without the aid of a glass. However, in including these drawings, my thought was that they would be an epitome of the extensiveness of the work under way, and give some idea of the methods involved in its general specification.

It will be of interest, no doubt, to state that in all the New Haven electrification drawings, it has been the attempt to make each one, while descriptive of the construction desired, at the same time a specification of procedure in erection.

In the case of the New York Westchester & Boston and the Harlem River electrifications we were able to assign to this work Mr. P. J. Kearny and Mr. L. S. Boggs, respectively, who had had previous catenary construction experience with the New Haven, and who were in touch with the methods pursued in its electrification work.

In the case of the Hoosac Tunnel electrification, coming at the same time as the two previous works referred to, and finding ourselves lacking the necessary engineer for this work, Mr. L. B. Stillwell, of New York, was offered and accepted the position as engineer in charge of this work, reporting to the engineering department of the New Haven road, of which Mr. E. H. McHenry is vice-president. As indicated in the prints included in this paper, covering the Hoosac Tunnel catenary construction, it is to be noted that these all bear a similar appearance to those relating to the two other electrifications previously referred to. While the electrification of the tunnel and its approaches is not yet complete, it is rapidly nearing this stage. Electric locomotive operation for instruction of engineers has already started on the North Adams approach of the tunnel in anticipation of regular service.

The Hoosac Tunnel electrification is characteristic for its simplicity. In the case of its power house, two turbo-generators each of 3000 kw. capacity were installed, with a provision for a third generator of similar capacity. The New Haven company was able to utilize the plans as developed for its recently installed Waterbury station, certain adjustments and additions, however, being required to be made to these plans due to difference of location and size of two of the generating units and switching arrangements necessary to the Hoosac Tunnel single phase conditions. The locomotives have been referred to before; they are characteristic for their simplicity, the cabs being roomy, the control apparatus being centrally arranged and most accessible to inspection.

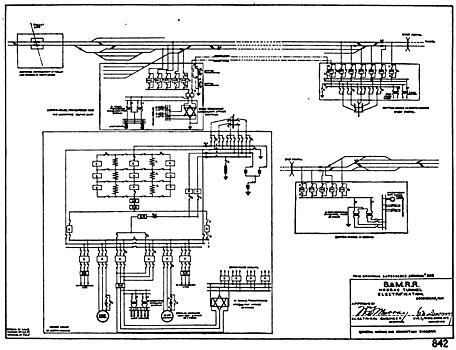

The power house is located 2.4 miles from the track catenaries, and Fig. 43 shows the general wiring diagram of the complete system. Again space does not permit an extensive description of this electrification. Naturally the most interesting part of it is the tunnel itself. The introduction of 11,000 volts into this tunnel, with the close overhead clearance that the doubletrack arrangement requires, afforded an interesting problem in the location and placing of insulators which would insure against any breakdowns between the electrified wires and ground.

| |||

| Fig. 43. - Hoosac Tunnel General Wiring Diagram |

| |||

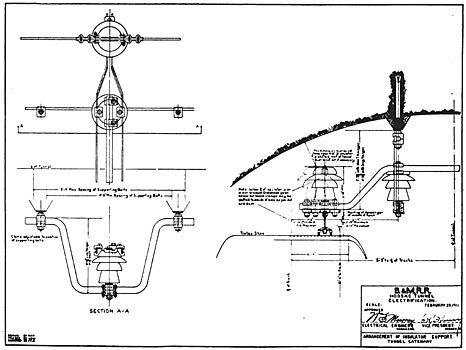

| Fig. 44. - Hoosac Tunnel Catenary Bracket |

From the crown of the tunnel is suspended a bracket, as shown in Fig. 44. Four insulators, each capable of resisting 150,000 volts to ground, are installed on this bracket. Two of these insulators apply to each track. Their arrangement of support is such as to place them in series, thus giving them a combined dielectric strength of 300,000 volts. The outside insulator holds the track messenger, to which is pendent the contact wires below. Some criticism might be offered in using a 150,000 volt insulator, where 40,000 might have sufficed. By the expenditure of $1 more per insulator, there was secured practically eight times the insurance from breakdown. The tunnel is five miles long—an unhandy place to come to a full stop. There are 1000 insulators; hence $1000 has been spent to secure eight times the protection.

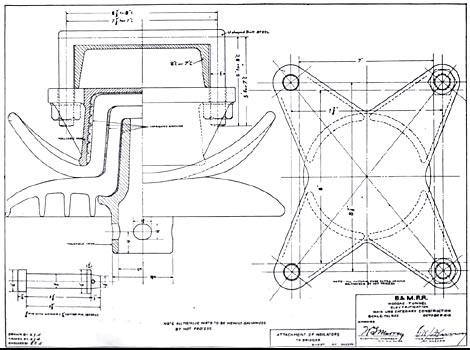

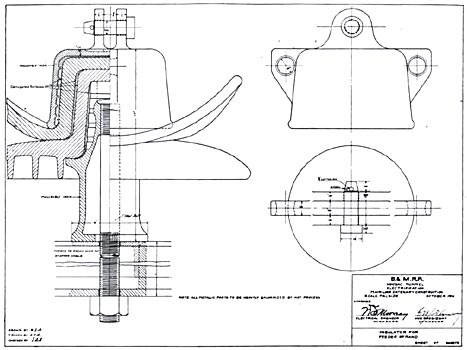

On the approaches to the tunnel, insulators of the design as shown in Figs. 45 and 46 are used. The opportunity here seemed an excellent one to secure immunity from trouble; 50 cents extra per insulator secured practically three times the protection offered by an ordinary 40,000-volt insulator. The outside insulators before erection are all required to withstand a dry voltage test of 110,000 volts.

| |||

| Fig. 45. - B. & M. Main Line Insulator |

| |||

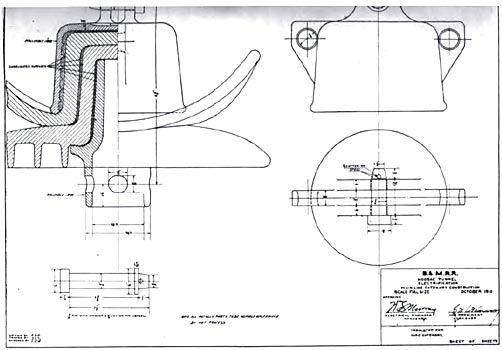

| Fig. 46. - Hoosac Tunnel. Insulator for Yard Catenary |

It has been forcibly impressed upon the writer that it is good engineering to spend money on insulation. All of the insulators purchased for the Hoosac Tunnel electrification, inclusive of the tunnel itself and its outside approaches, did not total one half of one per cent of the total expenditure. Insulation is of all things the one most important thing to be right, in order to secure continuity of service. It pays a handsome dividend every year. It has been said by our electrical superintendent, Mr. H. Gilliam, that the emergency train service on the New Haven electrified lines would practically cease if line failures were eliminated. This means that mechanically everything is fit. There is no reason why the electrical condition cannot be made identical.

So much with reference to our plans of main line electrification, in which I believe there can be recognized a general sense of inherent standardization, notwithstanding they refer to three properties with a variety of service and location.

In a previous part of the paper the electric switch engine has been referred to. Figs. 47 and 48 show two great yards on the Harlem River branch; one of them covering 20 miles, the other 42.3 miles in tracks that are being electrified, and in which the electric switch engines will work.

On account of the extremely small amount of current required per horse power developed, and on account of the excellent conductor section offered in the gridiron arrangement of the track yards, not a pound of copper is required throughout this extensive trackage, with the exception of rail bonds and these are reduced to the smaller size and only one rail is bonded, with the attendant result of an extremely low cost, compared to main line construction. Fig. 49 gives a cross section at station 22-|-81 ft. Harlem River yard, from which is to be noted the simplicity of cross catenary span for the support of the track contact wires. On this drawing is seen the same cross catenary wire split up into spans supporting contact wires over tracks, some with regular—others with irregular spacing; the irregular spacing being due to the leading in of tracks to a common ladder. By a simple system of bridles, which on the plans are to be noted require only one rigid post to hold many tracks, the overhead contact wires are held in proper alignment over the tracks they serve. The cost of yard electrification, as before stated, can vary from $1,500 to $3,000 per mile of track, depending upon the average number of tracks spanned.

Electrification Costs

The question of cost, both with reference to capital investment and operating in connection with electrified lines, is naturally the greatest factor of consideration on the part of railroad companies contemplating the application of electricity to their lines. In this department I am quite in agreement with the previously scorned adage—"Every situation is a study in itself"; for while in my opinion no trunk line electrification can be better served than by the use of single-phase current, it must be conceded that electrification costs must vary with the greatly fluctuating conditions of volume and density of traffic involved. Again, while it would be perfectly possible to state the actual cost involved in handling a train mile by electricity vs. a train mile by steam, this information as applying to the New Haven road might be extremely misleading when considered for other application. It is not to present any information not generally known, to say that power houses can be constructed, depending upon the capacity, from $90 to $110 a kilowatt; line construction for one, two, four and six tracks can be erected at costs varying respectively from $4,000 to $7,000; from $8,000 to $15,000; from $25,000 to $40,000; $40,000 to $60,000 a mile; the fluctuation in cost for these respective constructions depending entirely upon the standards elected, which are inclusive of the consideration of importance of track, in turn bringing into consideration the advisability of wood and steel post construction, cross catenary and bridge span construction, single or compound catenaries, etc., also the cost of overhead yard construction can vary from $1,500 to $3,000 a mile, depending upon number of tracks spanned and type of construction selected.

Locomotives of the passenger road and switching type, depending upon the nature of their service, can vary in cost from $25,000 to $45,000 a unit. Thus it is seen that it would be impossible, from the capital point of view, to give a useable estimate of electrification cost. Again the necessity of property acquisitions, which in one case may be nothing and in another a very large sum, all varying in accordance with the environment of the electrification in question, make such studies individual to the specific cases under consideration.

In general, from an electrical operating standpoint, it may be stated that for trunk line properties, where a very considerable density of traffic is involved, there will be shown a considerable debit in the department of " maintenance of way and structures," while in the departments of "maintenance of equipment and transportation expenses" a large credit, if the proper system is selected, may accrue. The balance between the debit and credit columns furnishes the ground upon which it may be said it is either a good or bad investment for the railroad company to electrify; and yet even though the direct returns prove unsatisfactory, it does not follow that the investment is a bad one if considered from a broader standpoint of general policy.

A most careful analysis of the relation between steam and electricity was made in connection with the lines of the New Haven road west of New Haven. I have no authority, in presenting such a paper as this, to state whether the policy of the railroad company in electrifying over 300 miles of its trunk line rails, terminals and yards was for financial gain to itself or better service to its patrons; but at least it is reasonable to assume that with an application of electricity to cover complete passenger and freight train propulsion and yard switching over the mileage above named, expending millions of dollars to effect such a service, its Directors could not have ratified the extension of the adopted system and its application over such a wide territory in all classes of service, unless the successful and uncompetitive characteristics of the system were not immediately apparent.

Not until the electrical system of the New Haven road is a unit in itself, rather than a mixed service of steam and electricity, can its true economies of electrical traction be discussed. Suffice it to say that the two great departments of economy lie in the saving of fuel and repairs to rolling equipment.

I regret that my contribution in this paper to the many times repeated question as to the cost of electrification cannot bring a definite reply to each request. The electrification of railroads will not await the reply of an impossible inquiry. The practical answer, and substitute for this inquiry, is: As electrification of trunk lines is now practically at hand, what is the correct system for all? Our experience with the single-phase system as applied to the New Haven Road to over 300 miles of its track, with the necessary extension to follow to New Haven, adding 150 more— making a total system, with yards, of nearly 500 miles, may offer a strong suggestion in this direction.

Recommendations. As in the early days when alternating current application forced its way into the acceptance by its very opposers, so has the force of its application to the trunk line railroad problem impressed the writer that he has not felt it necessary to make any plea for its acceptance. When railroads consider trunk line electrification, all important will be the matter of freight movement and with it the cost and convenience of operation of their yards. The ratio of the mileage of yards in the division run between Harlem River and New Haven to the main line tracks, is over 55 per cent; and while the New Haven road may be considered to have a high ratio of yard mileage to main line mileage, this condition is ever true throughout the railroads of the Atlantic Coast territory. In fact, such a condition is naturally true of any territory including cities and towns of close proximity to each other. In writing this paper, it has been my effort to avoid a discrimination between systems. I wish, however, to state very plainly that I am not at all in sympathy with the attitude on the part of some who claim some recognition in the field of railroad engineering, when they suggest the advisability of not advocating any particular system of electrification. To discuss electricity vs. steam without a recommendation of system in the specific cases of trunk line work, in my judgment, is to launch a ship upon a rough and windy sea without a rudder. I plead guilty to a considerable effort in trying to lay before the Institute the facts presented in this paper. I have endeavored to deal with nouns and not adjectives. An extremely important matter would be omitted if I did not say that my experience with the single-phase system vs. other competitive systems, affords me the sincere conviction that, under practically all conditions of trunk line consideration where the traffic is of the .same amount and character, or indeed much less than that which is comprehended in the mileage that this paper covers, its first cost is at the greatest not more than 85 per cent of its next best competitor, and its operating costs less than the above percentage.

The above statements should not be taken to mean that all trunk line railroads, considering electrification, can electrify and save money; indeed its general application is prohibitive. There are, however, roads that must and will electrify. To such railroads it is my hope that the information compiled will be of value.

It has been suggested by some not altogether friendly even now to the single-phase system, that if this paper be made inclusive of specific recommendations as to system to be applied for trunk line properties, inclusive of suburban and terminal territory, that it might confuse the mind of the railroad man, due to diversity of opinion among electrical engineers on this subject. I wish to say, with reference to this matter, that my opinion of and respect for the railroad man, born of the past six years of intimate association with him, be he an executive of finance, transportation, operation or engineering, is that he is not of the caliber to be confused by a discussion of this subject. I have invariably found rudders on their ships; why not one to ours? And let me assure those who are contrary to this opinion that railroad men can intelligently analyze any argument that is to be advanced—pro or con—on this highly necessary and near decision. The paper, however, is not presented to precipitate an argument; nor is it an argument for the single-phase system. Statistical records of the first cost and operating expense make such a course unnecessary. It has been written with the purpose of placing in the hands of those interested in the electrification of railroads the facts concerning the application of single-phase current to nearly 500 miles of trunk line property and to make a specific recommendation that for the sake of simplicity and economy it be the adopted system for other trunk line properties which the future will see electrified.

I wish to here acknowledge the able services of Mr. Paul Real, my principal assistant, in connection with the preparation of this paper.

APPENDIX

The following illustrations (Figs. 50 to 76) include the detailed drawings pertaining to the overhead catenary construction for:

1. New York, New Haven & Hartford Harlem River Branch.

2. New York Westchester & Boston Railroad.

3. Hoosac Tunnel Electrification.

| |||

| Fig. 66. - Hoosac Tunnel Yard Construction |

| |||

| Fig. 75. - Insulator for Feeder Strand, Hoosac Tunnel |