[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. 19, no. 362, p. 337-338, col. 1-2,1

Trade Notes and Novelties

AND MECHANICAL DEPARTMENT.

THE BILLINGS' DROP FORGED COMMUTATOR BARS, AND OVERHEAD LINE MATERIAL.

THE drop forged commutator segment known as the Billings' patent, was invented by Charles E. Billings, President of The Billings & Spencer Co., Hartford, Conn., manufacturers of machinist's tools and drop forgings. Commutator bars were made prior to November 6, 1888, the date of the Billings patent, of a single piece of brass, ordinary bronze or other electrically conductive alloy cast in specified forms. Bars were also made of two arms separately constructed and soldered, screwed or otherwise joined together. According to this method the main arm of the segment has sometimes been formed of rolled or drawn copper strips and the remaining arm, on account of the difficulty alluded to, has been formed of brass or other material cast in the desired form.

The object of Mr. Billings' invention was to produce a drop forged segment of pure copper and by so doing to avoid the disadvantages, both mechanical and electrical, which are involved in uniting two pieces of metal or in using other substances than unalloyed copper for the purpose of forming a commutator bar.

|

| Fig. 2. |

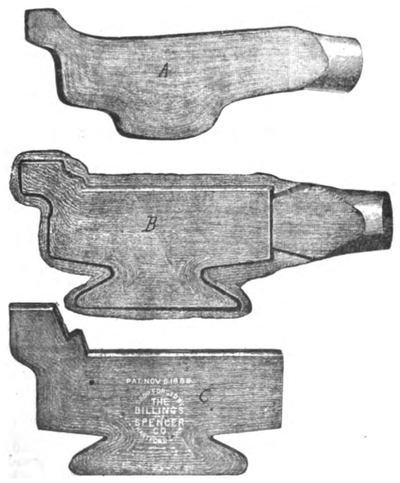

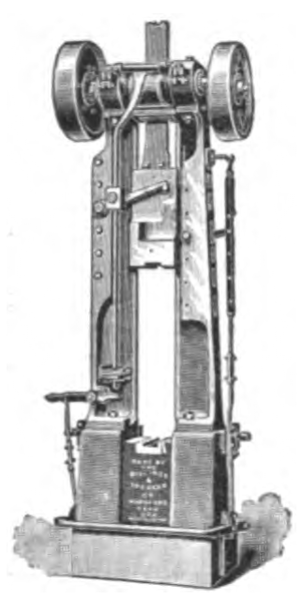

Fig. 1 A illustrates the preliminary operation of drop forging, showing a cylindrical copper rod shaped to the requisite length, heated to a malleable state. While in this condition it is subjected to the action of successive pairs of dies in a drop hammer. By the first pair of dies the so-called operation of " breaking down," the rod is ready for subsequent forging and bending of arms to the required shape to fit any special commutator.

Fig. 1 B shows the result of the "striking up " which produces a bar in an unfinished state to conform to the specified type. The bar is then treated with acid for the purpose of removing oxide. When cold, the flashed edges on the bar are trimmed in the usual manner and then the bars are subjected to a hardening process and each bar is tempered uniformly, thereby giving them all an even and durable wearing surface.

Fig, 1 C shows a finished bar ready for the No. 12 Westinghouse commutator. The most important feature of the bar lies in its being formed in one solid piece wrought from a single copper rod by the process of drop forging. It has the grain or fibre of the material always parallel to the outline of the commutator bar, no matter what shape the same may be bent to, and still be of one metal, homogeneous in molecular structure throughout

|

| Fig. 1. — Drop Forged Commutator Bar. |

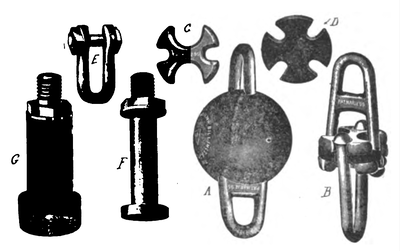

The successful adaptation of drop forged material for electrical appliances has suggested the advantages of producing wrought metal as a substitute for ordinary brass castings in the manufacture and construction of overhead trolley equipment, using Colophite insulation, and the Billings and Spencer Co. have prepared a line which will be offered to the electric railways for Spring renewals and extensions. A few of the fixtures are illustrated in Fig. 8.

|

| Fig. 3 — Colophite Overhead Line Material. |

The Colophite insulation used by the Billings & Spencer Co., is the invention of S. J. Hoggson, of the Colophite Mfg. Co., New Haven, Conn. The adhesive and elastic properties of "Colophite" are so great that it is particularly useful for an insulating compound subject to constant strains and vibrations, being unaffected by the atmosphere, and is a natural preservative, impervious to the climatic influences of oxygen, snow, ice and moisture.

In the engraving Fig. 3 A shows the Colophite insulated link strain or frog-pull-off of Tobin bronze or steel. The links shown at B are separated first by strain discs of bronze or steel C and insulated from each other by a hard rubber disc shown at D, the whole being then covered with colophite in the shape of a sphere as shown at A.

|

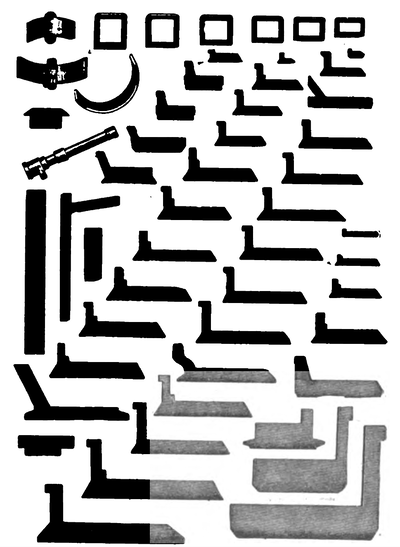

| Fig. 4 — Varieties of Drop Forged Commutator Segments. |

A series of electrical tests have been made of the Colophite insulation of the drop forged link strains, showing a resistance of 200,000 megohms, guaranteed at 575 volts. The tensile strength of the steel and Tobin bronze was from 65,000 to 80,000 pounds to the square inch; crushing strength of centre disc, 12,000 pounds. This test was made by the Pope Mfg. Co., Hartford, Ct., on an Emery testing machine.

Among the other devices for railroad work we may note the interchangeable attachment for link strain to make a frog-pulloff, shown at E, Fig. 3, made of drop forged tobin bronze or steel, and the colophite insulated stud for straight line hanger shown at G and F. Fig. 4 shows a large variety of drop forged commutator segments made by the Billings & Spencer Company.

The Pettingell-Andrews Co., of Boston are the selling agents for the Billings & Spencer Co., and Mr. Frank X. Cicott who originated the idea of using drop forgings for overhead line material has charge of the company's railway department.