[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. 18, no. 328, p. 137,139, col. 1,2

TRADE NOTES AND NOVELTIES

AND MECHANICAL DEPARTMENT.

·

·

THE OHIO TROLLEY.

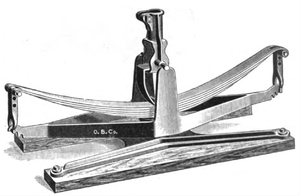

The Ohio Trolley, manufactured by the Ohio Brass Co., of Mansfield, seems to be one of the simplest and most effective on the market. It is made up of less than a dozen pieces, any of which can be easily duplicated. The spring is of the regular flat leaf style, such as any manufacturer of carriage springs keeps in stock. The working parts of the trolley are made of steel and malleable and wrought iron, and in consequence are not easily broken. The base and stand are three feet long, and eight inches wide, and, when the trolley-pole is in a horizontal position, but thirteen inches high. The trolley-pole can be swung either forward or backward or in a complete circle, and the pressure against the trolley wire diminishes as the pole assumes more nearly a horizontal position.

|

| The Ohio Trolley. |

The trolley can be assembled or dismantled in a few minutes' time without the aid of tools. It is very easy and flexible in action, and will follow the variation of the trolley wire quickly and surely. These trolleys have been given a practical and thorough test, and are in use on many roads.

In fitting these trolleys out complete, the Ohio Brass Co. use their special carbonized steel trolley-pole. This pole is drawn cold through a die and is made of the best Norway iron. It is then carbonized to the proper degree to give it sufficient elasticity. It is seamless and endless, and formed to a perfect taper. The claim made on this pole is that it is lighter, more flexible and stronger than the regular style trolley-pole. It will not break, and if bent out of shape can be straightened cold without injury.

This pole is one of the specialties of the Ohio Brass Co. which they are now pushing into the market.

·

·