[Trade Journal]

Publication: Electric Railway Journal

New York, NY, United States

vol. 55, no. 25, p. 1267, col. 1-2

New Porcelain Feeder Insulator

Porcelain Insulator Is Now Being Tried in Brooklyn for Supporting 500,000 Circ. mil Direct-Current Feeders

BY G. H. MCKELWAY

Engineer of Distribution Brooklyn (N. Y.) Rapid Transit Company

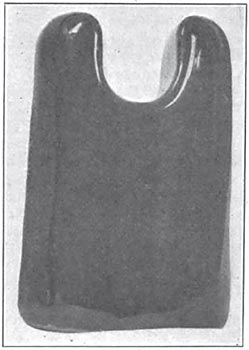

THE accompanying illustration shows a porcelain feeder insulator which is being used on the lines of the Brooklyn Rapid Transit system. Insulators of this type support the 550-volt direct-current feeders of 500,000-circ.mil. section and, so far as the writer knows, are the first porcelain insulators to be designed for such service. They are made of wet-process porcelain and are of approximately the same dimensions as the ordinary composition tree-top insulators used for similar work. They are 5 1/2 in. high, with a diameter at the base of 3 3/4 in. and at the top of 3 3/8 in. At the bottom a single petticoat extends down 1 in., while the pinhole has a drawn steep thimble of the Hubbard type cemented into it and is large enough to take the 1-in. tapered steel pin which is standard on the lines of the Brooklyn Rapid Transit system. The outside of the insulator is covered with a brown glaze.

The reason for the decision to try out the new type of insulator was that it was believed it would last longer than the composition type, would be just as satisfactory, if not better, and would certainly be no more and probably be less expensive in first cost. Some composition insulators have been found not to "weather" well and to deteriorate quite rapidly, especially in hot weather. With such insulators the threads in the composition often become soft, causing the insulator to "freeze" to the pin, from which it can be removed only with considerable labor and by damaging the insulator so much as to render it valueless for reinstallation.

| |||

| Porcelain Feeder Insulator |

Another point in which this insulator would appear to have an advantage over the ordinary type of feeder insulator is that the prongs which hold the wire in place are of porcelain and integral with the rest of the insulator. This does away with the metal saddle used with most of the composition insulators, which is a factor of danger to unskilled men working near such insulators owing to the fact that the saddle may be alive due to the movement of the wire, causing the insulation to be worn through at the point where it rubs against the saddle. This is of very little importance where the feeders are installed on poles, as there the only men working near them are linemen, who are accustomed to the risks of their trade and who are taught to consider no insulation as affording complete safety. Where the wires are hung from bridges or elevated structures there are, on the contrary, painters or iron workers often working near the wires, and they are apt to consider anything but a bare wire as being safe to touch. Such men are occasionally shocked or burned by coming into contact with or letting their tools touch live parts that are normally safe.

So far as cost is concerned there is very little difference at present between the two types of insulators, but the porcelain insulators should be cheaper if there is ever a demand for them sufficient to warrant the makers turning them out in large quantities, especially after the development charges have been absorbed.