[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. 10, no. 120, p. 189, col. 1-2

BAIN'S ELECTRIC COAL MINING MACHINERY.

AMONG those who have devoted considerable attention to applying the electric current in various ways to the operations carried on in coal mines is Mr. Foree Bain, of Chicago; indeed, he claims to be the pioneer of this work in this country, it being now about one year and a half ago that he installed a complete electric plant in the coal mines of the Shawnee and Iron Point Iron and Coal Company, at Shawnee, Ohio. This plant consists of a well-known coal cutting machine, which had been previously operated by compressed air, but is now driven by a Bain mining motor an electric locomotive capable of hauling a train with 25 tons of coal up a 5 per cent, grade, and a system of incandescent lamps from the same circuit, which are used to illuminate the rooms and entries of the mine.

|

| Bain's Electric Mining Machinery. |

The electric locomotive employed in the mine is capable of hauling 1,000 tons per day; one boy who is paid $2 per day to run it and another who gets $1.25 per day to couple cars and attend to switches, is all it costs for wages, and they take the place of 15 drivers and 15 mules, and, according to Mr. Hull, the superintendent, "it is an unquestioned success."

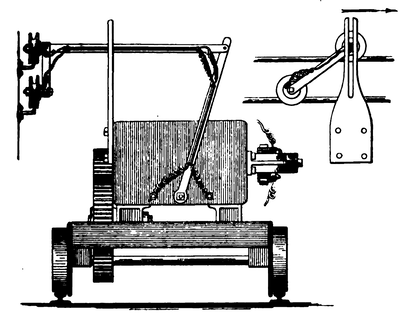

Mr. Bain has recently worked out and patented a complete system of mining coal by electrically operated machinery, which consists of an undercutting machine and an overhead drill for drilling a hole in which to place the blast. This hole is drilled at the same time the undercut is made, and is operated simultaneously by the same motor.

The undercutting machine is made in two principal parts, viz., the outside frame to which the traction wheels are removably attached and the inner frame which telescopes within the outer frame; the inner frame carries the motor and the drills. There are thirteen drill rods placed parallel and in front of the motor, and every alternate drill rod carries a special steel conveyer, stamped from sheet steel and firmly secured to the rod. The object of the conveyer is to remove the cuttings from the drills while the slot is being cut into the coal. The drills or cutting bits are removably attached to these drill rods at their extreme forward ends in such a manner that they overlap each other in their rotation to cut through intersecting planes. The drills are grooved together near their rear ends to rotate alternately in opposite directions; by this arrangement it will be evident that a continuous slot, penetrating in most cases six feet, can be cut with rotary cutters, without interference of the cutters with each other. Their relative direction of rotation is such that should any one cutter for any reason tend to lag in its work, it would be assisted by those on either side of it.

The motor, which is mounted on the inner frame, and which rotates the cutting bits, also supplies the power which gives the system a reciprocating motion to feed into the coal; a clutch immediately in front of the motor connects it with the driving and cutting mechanism, and another, located under, and at the rear of, the motor, is thrown in one direction to withdraw the system after the slot has been cut. The retrograde movement is arranged for a speed four times faster than the speed at which the bits are fed into the coal. After the cut has been made the machine is shifted and another cut parallel with the first is made in the same manner, and so on, until the room has been finished. When it is desired to remove the machine to another location or room, it may be slightly raised and traction wheels put into the studs; the cutting machine may then be disconnected by use of the front clutch lever, and the machine then becomes self propelling and can move itself around on the floor of the mine or on the tracks in the entries. For long distances it is supplied with the trolley device, illustrated in the accompanying engraving, and it may also be used as an electric locomotive for drawing a small number of cars.

In good coal the machine will cut a slot three feet wide, four inches high, and six feet under within three minutes. It is operated by a specially constructed motor of only 6 h. p., which, like all of Mr. Bain's electric mining machinery, is operated at 225 volts.