[Trade Journal]

Publication: The Electrical Engineer

New York, NY, United States

vol. 10, no. 129, p. 444, col. 1-2

THE EMMET TROLLEY AND LINE INSULATOR.

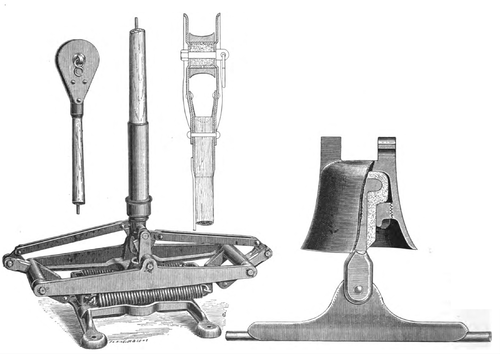

ALTHOUGH the trolley illustrated in the accompanying engraving may be new to many electric railway men, it has been in use for about a year on a few roads, during which time every detail has been thoroughly standardized. The general mechanism of the base can be readily understood from the engraving. There is a battery of four springs suspended between the lower extremities of a pair of rocking levers which are pivoted at opposite extremities of the main frame. The springs are attached to swivelling blocks with screw bolts so that the tension may be adjusted from both ends. The levers are fitted with lugs which control their motion so that one holds fast while the other rocks, thus admitting of the same battery of springs being used for motions of the pole in both directions. This obviates the necessity of always bending the pole one way and makes it possible to keep a light wooden pole quite straight.

|

| Figs. 1 and 2. — the Emmet Trolley Arm and Trolley Wire Insulator. |

The rocking levers are connected to the pole base by links. The positions of the various centres, and the lengths of these links, etc., are so arranged that the upward pressure of the pole is accurately graded to the conditions of service, and the springs are never subjected to excessive strains. The pole may be tied down flat to the car roof for an indefinite period. The highest point of the apparatus when the pole is down is nine inches above the car roof.

The contact roller and head illustrated in the same engraving have some novel and very convenient features. The guiding flanges, it will be noticed, are stationary, and the sheave runs between them. The shaft or spindle is a 1 1/4 inch brass tube, which acts at the same time as an oil reservoir, being packed with felt and oiled through a hole in one flange. The advantages of this head are its extreme lightness, sure lubrication, minimum injury to wires, and minimum cost of maintenance in repair. The sheave contains about a half pound of brass. It can be changed from the rear platform of a car in one minute and its life has been in some cases over three months, one having actually made 10,000 miles. The same firm also manufacture a wheel trolley, which weighs only a trifle more than the one illustrated; it has the same method of lubrication. These wheel heads are furnished in aluminum if desired, at a slight additional cost. The wheel head is used with the same pole and spring device. The bell trolley line insulator, illustrated in Fig. 2, is an economical and thoroughly serviceable device. It is made of iron and has a malleable iron stem with a button; this is encased in semi-vulcanized rubber, and is held firmly in place by a ring which screws into the interior of the bell. The insulation is protected from the weather; it is tough and elastic, and the whole device is practicably indestructible. It attaches to the span wire in a particularly convenient and secure manner, which, however, is not shown in the cut. The span wire lies in grooves in the lugs on top of the insulator, and is firmly held there by a piece of wire, which passes through holes in the same lugs and is attached to the span wire on each side by a half connection. These devices and many others covering the whole field of overhead railway work are manufactured by Messrs. Emmet Bros., of this city.