[Trade Journal]

Publication: Electrical World

New York, NY, United States

vol. 47, no. 8, p. 460-462, col. 1-2

Central Station Operation and District Supply at Hillsboro, Ill.

THE Hillsboro Electric Light & Power Company is one of the most progressive of the smaller central station companies operating in Illinois and enjoys the distinction of having constructed and put in operation the highest voltage, single-phase village-to-village transmission line yet built in that State. The station at Hillsboro now supplies the electric lighting system at Raymond, a distance of 15 miles over a single-phase, 16,000-volt transmission line.

THE CENTRAL STATION AT HILLSBORO.

Before going into the details of the transmission to Raymond, an account of the company's station and operating methods in Hillsboro will be in order. Hillsboro was credited by the census of woo with a population of 1937. From present appearances it has a population somewhere between 2,500 and 3,000. The company is fortunate in having a single uniform system of generation and distribution, this being by single-phase, 60-cycle, 1,100-volt current. With this system of distribution it handles all classes of power and lighting service. The power house has two generators, one of which is a 78-amp., 1,100-volt, 60-cycle alternator belted to a high-speed Chuse engine built at Mattoon, Ill. There is also one Westinghouse 45-amp. alternator belted to an Ideal engine. There are three horizontal return flue boilers, two of 80 rated horse-power and one of 150 hp.

| |||

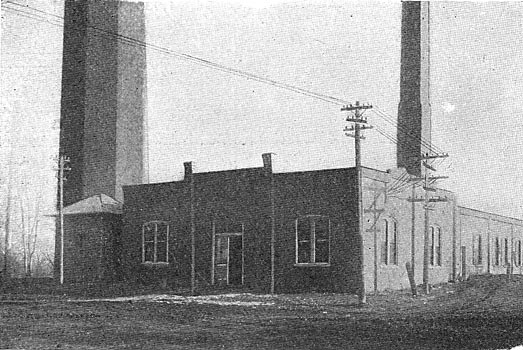

| Fig. 1. - Power Station and Sub-Station at Hillsboro. |

The exterior of the power house is shown in Fig. 1. The water tower on the adjoining lot at the left belongs to the city and has no connection with this company's work. The engine room is 40 ft. by 60 ft., the boiler room 23 ft. by 52 ft. A limited amount of exhaust steam heating is done as the station is near the business district of Hillsboro. This exhaust steam heating service will be given to more customers as additional load is put on this station by the supplying of power to surrounding towns over transmission lines. The engine room which formerly contained a store room has now been relieved of this, which reduces the fire hazard and adds greatly to the appearance of the station. The building is of brick as can be seen in Fig. 1. The engine room floor which is now of wood will be replaced with one of concrete when the capacity of the station is enlarged as it will have to be soon to take care of the load. This will make a thoroughly fire-proof station. The arc lighting is done from an 128-kw Western Electric constant-current transformer and regulator. The company has connected thirty-nine 7-amp., 70-volt, alternating-current, series enclosed arcs. There is also one series of 10 incandescent lamps for alley lighting run off the 1,100-volt bus-bars. The maximum peak load in Hillsboro, not including the power transmitted to Raymond, is about 70 amp. The maximum daylight load in Hillsboro is about 25 amp. The average is much below this. Day service has been given for about three years. The operating force in this station consists of two engineers and one fireman. The connected incandescent load in Hillsboro is equivalent to 3,800 16-cp lamps.

THE RAYMOND PLANT.

Raymond had a population of 906 in 1900 and is growing slowly. The plant in use at Raymond before the change consisted of one Chuse engine, one boiler and one alternating-current dynamo. The maximum load on the Raymond plant was about 30 amp. Two men were required to operate the plant.

THE HILLSBORO RAYMOND TRANSMISSION.

About the first of December, 1905, the Hillsboro Electric Light & Power Company, having completed the 16,500-volt single-phase transmission line between Hillsboro and Raymond, a distance of 15 miles, shut down the steam plant at Raymond and supplied that town entirely with power transmitted from Hillsboro. Figs. 2 and 3 show the transmission line near Raymond. The right of way is along the highway. Since the photographs Figs.2 and 3 were taken, the telephone poles shown on the same side of the road as the transmission line have been moved by the electric light and power company to the opposite side of the, road. There are 37 poles per mile. Cross-arms are shorter than usual, bringing the wires 18 inches apart. These were made short so as to make a substantial line construction without the use of cross arm braces. The wire is No. 8 hard-drawn copper. The insulators are the Lima Insulator Company's porcelain No. 22, 3 ins. high over all and 6 ins. in diameter. This line was built by the company at a remarkably low cost per mile, the cost of the transmission line exclusive of sub-stations and transformers being only $3,184 or $212 per mile of line.

| |||

| Fig. 2.—Transmission Line Near Raymond. |

The sub-stations in which are housed the lightning arresters and transformers at each end of this line are very substantial little buildings. The one at Hillsboro is seen adjoining the power house at the left in Fig. 1.—This is built of concrete block. The one at Raymond is of the same design but is built of brick. Figs. 4, 5 and 6 show the plan and elevations of the Raymond sub-station which occupies a ground space 10 x 18 ft. This is a thoroughly fireproof structure with plenty of room for the transformer and lightning arresters. The step-up and step-down transformers are oil-cooled Westinghouse of 50-kw capacity. The lightning arresters are also Westinghouse. Both transformers are designed for 16,500 volts on the high tension coil and 1,100 on the low tension. Each transformer has four different taps by which the ratio of transformation can be slightly varied to compensate for drop in the high tension line. As a matter of fact, the high tension line drop is so small that it has never yet been accurately determined.

SAVING BY THE TRANSMISSION.

The point of most interest to other companies thinking of shutting down steam operated electric light plants in neighboring towns and supplying them over transmission lines is the economy of the proposition. Previous articles in this paper have given data on some of the other district supply systems in Illnois, but in the cases before described the distance of transmission has not been as great.

| |||

| Fig. 3.—Transmission Line, Hillsboro. |

The cost of the transmission line and sub-stations was $4,852 divided as follows:

Transmission line ............................... $3,184

Transformers and lightning arresters .....$1,268

Sub-station buildings ............................. $400

Total ................................................. $4,852

The cost of the Raymond steam plant which, of course, was purchased along with the distributing system in Raymond, is estimated at $3,000. Of this about $1,000 is estimated as being lost entirely by the discontinuance of the plant, leaving an estimated value of the equipment in the plant of $1,650 and $350 for the buildings and plant."

|

| Figs. 4, 5 and 6.—End and Side Elevations and Plan of Raymond Sub-Station. |

In December, 1904, the Raymond plant burned $81 worth of coal at $1.75 per ton and the Hillsboro plant $146 worth of coal at from 70 cents to 85 cents per ton. The first month of operation of the transmission plant the Hillsboro plant burned approximately $152 worth of coal, carrying both the Hillsboro and the Raymond loads. Facilities were not at hand for making accurate determination of the amount of coal burned in a month at the Hillsboro plant on account of the condition of the coal bins. It is believed, however, that it did not take at most over $15 worth more of coal to carry the Raymond load than would have been required had the Raymond system not been connected. There is, therefore, a saving of nearly $67 per month in fuel by supplying the two towns from one station. As to labor, two men were formerly kept at Raymond to run the plant there. Now one man is sufficient at Raymond and, in fact, it would be possible to operate without any man at the Raymond sub-station. One man is being kept there, however, at the present time. As it is, a saving of $40 per month on labor at Raymond is being made. The saving made is, therefore, at least $107 per month which is amply sufficient to justify the investment in the transmission line. The additional load placed upon the Hillsboro power station comes at a most economical point on the engines. All of the fixed engine and boiler room losses were taken care of before the Raymond load was added, hence the low cost of fuel to carry the Raymond load. There are a number of other villages within transmission distance from Hillsboro which may some day be supplied from the Hillsboro plant.

MISCELLANEOUS POINTS OF INTEREST.

In order to stimulate the fan business, the company keeps a stock of fans which it rents at $1 per month during the fan season. These are placed in store room during the winter months. The customer of course pays for what current he uses at the regular rates. Electric flat irons are rented at 50 cents per month. Four or five Emerson sewing machine motors are in use in Hillsboro. An interesting installation which offers a steady revenue is the electric lighting of the signal lamps at an interlocking switch plant of the Big Four Railroad at Hillsboro. There are 27 2-cp lamps located on switches and signals scattered over a distance one mile each way from the interlocking tower. The wire is placed in iron pipe conduit with a woven fabric lining. The signal lights are operated off the same transformer as the supervisor's office and depot. The Westinghouse meter has been adopted by the company as its standard. Meters are checked for accuracy by comparison with a Wagner indicating wattmeter. This wattmeter is sent to St. Louis for calibration four times a year and is also used to check station instruments. This meter has a series transformer for use in checking meters of over 5 amperes capacity.

The rates are as follows:

Fifteen cents per kw-hour until the consumer has used 20 kw-hours; 10 cents per kw-hour for all over and above 20 kw-hours.

A meter rental of 25 cents per month is charged and no bill for current is less than 25 cents. This practically makes the minimum bill 50 cents per month. The meter rental is added to the amount charged for power until this amount reaches $2.50.

The gross income from Hillsboro and Raymond last year was about $23,500. This is remarkably good considering the population served, which is probably less than 4,500 and possibly will not be over 4,000. The total investment which the company has made to date amounts to approximately $48,000. Extensions and improvements - since the plant was first built have been paid for out of the earnings rather than by increases in the capital stock, the owners preferring to invest the money in that way rather than take it out in the shape of dividends. The company is owned entirely in Hillsboro by a number of business men there. The management is under Mr. J. J. Frey, and the electrical and mechanical work is under the supervision of Mr. John T. Kester, superintendent. The Company appears to have the nucleus for a valuable and substantial property and offers a good example for other companies operating in small towns to follow. It is Mr. Frey's general idea to extend the company's system to other villages and to add to the power house new and more economical apparatus from time to time, thus constantly improving the character of the investment and the economy of production and making it possible to employ the services of specialists in the various departments to a greater extent than is possible in the ordinary small country plant.