[Trade Journal]

Publication: Electric Railway Journal

New York, NY, United States

vol. 42, no. 25, p. 1298, col. 1

NEW PORCELAIN STRAIN INSULATORS

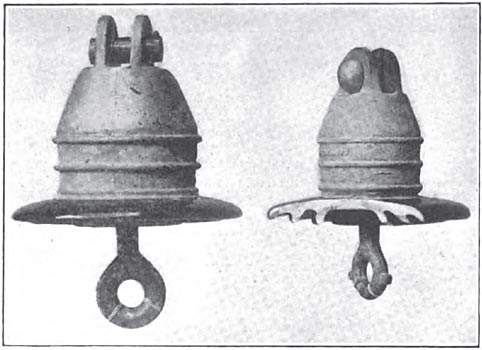

To meet the severe requirements due to the increasing weight of overhead construction two new types of porcelain strain insulators have been developed by the Westinghouse Electric & Manufacturing Company. These are a combination of a metal cap to give the necessary strength and a porcelain skirt to furnish the required dielectric strength. The metal parts of these insulators consist of a malleable-iron cap, a drop-forged steel eye bolt, and a malleable iron sleeve by which the eye bolt is securely fastened. The metal and porcelain parts are cemented together with a high-grade Portland cement. The cemented surfaces are provided with carefully determined corrugations which prevent failure, except by the actual shearing of the cement. The skirt of the porcelain is provided with corrugations on the under side to give additional creepage surface.

|

| Application of Porcelain Strain Insulators to Section Insulator |

Two types of these insulators are made, the PK and the PK-I. The metal parts of the type PK insulator are sherardized and those of the larger size, types PK-I, are hot galvanized. The type PK insulator is especially used for insulating cables when the working load does not exceed 1600 lb. As they are tested at 5000 lb., both types are generally used for heavy service, such as dead-ending high-strength steel messenger cables, with a working load of 4000 lb. and 8000 lb. respectively. The drop-forged eye bolt of the type PK-I has side projections so that if two or more insulators are used in series they cannot swing more than a few degrees, thus avoiding the danger of breaking the porcelain skirt because of striking the cap of the adjacent insulator.

| |||

| New Types of Porcelain Strain Insulators |