[Trade Journal]

Publication: Electrical World

New York, NY, United States

p. 47, col. 1-2

Fogbowl Keeps Contaminants Out

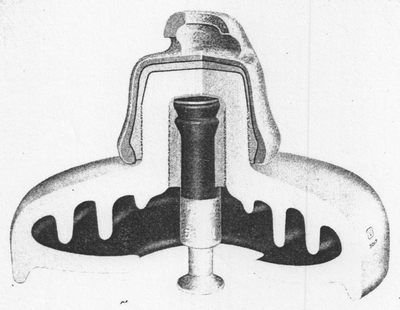

Protection against contamination on the underside of the unit is designed into a new Fogbowl suspension insulator by the Victor Insulators Division of I-T-E Circuit Breaker Co. This new concept provides an insulator for use in areas subject to salt fog or industrial contamination.

It features a specially designed bowl ceramically welded to a standard 10-in. suspension unit that creates a dead air space within the insulator.

This dead space almost completely eliminates contamination inside the insulator and should negate the need for periodic washing or replacement. The new insulator has a guaranteed minimum impact rating of 75-in.-ol, which is 36.4% greater than the rating for a standard suspension insulator.

|

| Porcelain Bowl is Welded Ceramically to the Inside of A Standard 10-In. Suspension Insulator to Create A Dead Air Space. |

To verify the design of the Fogbowl insulator, two West Coast utilities and a West Coast university have been testing about 400 new units and a number of standard fog suspension units for about five years.

These conclusions then were drawn from the tests: "Lowering of the wet flashover voltage by contamination for the No. 961 Fogbowl type was less than one-half that for comparable fog-type suspensions; the unit also has lower surge and leakage current values." Also observed was "the almost complete absence of contamination on the inside of the Fogbowl type" which was subjected to a highly contaminated salt spray.