[Trade Journal]

Publication: Street Railway Review

Chicago, IL, United States

vol. 10, no. 3, p. 171, col. 1

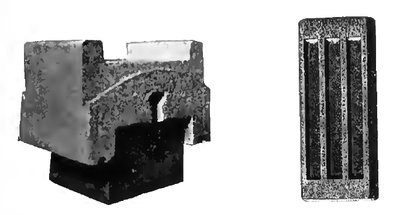

INSULATING FORMS FOR THIRD RAIL INSULATORS, RHEOSTAT BLOCKS, ETC.

The illustrations herewith show forms of insulators for various special purposes which are made of reconstructed granite, a material that is a good insulator and is strong both in tension and compression. This material is a high grade of Maine granite, which in the process of manufacture, is pulverized, mixed with a bonding clay, molded into the desired form and vitrified in kilns at a high temperature. The material undergoes important chemical changes, so that the product when put upon the market has such insulating qualities that the designs for third rail work have stood up under test made at Niagara Falls to a voltage of 36,000 even after being soaked in water. The product is not only fireproof, but is not injured or affected by heating to a high temperature and then suddenly cooling. Neither is it affected by the lowest temperature that can be produced by liquid air. It resists acids and alkalies, does not contain or absorb moisture, and has a crushing strength of 14,565 lbs. And a tensile strength of from 680 to 700 lb. Per sq. in. The material is not only adopted for third-rail insulation, but is now being employed for a general line of insulators for electric railway purposes.

|

| Fig. 1. Fig. 2. |

Fig. 2 illustrates a three-channel rheostat block. These are made in three or six channel sizes or in any desired size. The material is specially valuable for rheostat and controller blocks, as it will not receive or hold an electrolytic deposit of copper upon its surface, a feature that causes short circuits with some other materials. It is also a good arc blow-out, and is designed as an arc arrester for street car controllers. Reconstructed granite can be as readily molded into switch bases, lamp sockets or other form of insulating blocks as well as porcelain material. These blocks have been employed on a number of elevated railways for insulating the third rails, and have sustained all the claims made for them. For this use the style shown in Fig. 1 is mounted on a wooden block and attached by means of strips of metal or fibre, as in the illustration; each wooden block is provided with a lag screw by means of which the device is firmly attached to the end of the tie.

The works of the Reconstructed Granite Co. are located at Norristown, Pa., where they occupy large buildings with an area of seven acres of ground. The New York office is at 17 Dey St., and is under the management of Mr. W. Courtenay, president of the company, who will gladly furnish information desired.