[Trade Journal]

Publication: Electrical Review

New York, NY, United States

vol. 47, no. 8, p. 267-271, col. 1-3

The Use of Steel Towers and Wooden Poles.

By Alton D. Adams.

STEEL towers are rapidly coming into use for the support of electric transmission lines that deliver large units of energy at high voltages to long distances from water powers.

One case of this sort is the seventy-five mile transmission of 40,000-horse-power at 60,000 volts from Niagara Falls to Toronto, for which a line with steel towers is now nearing completion. Another example may be seen in the seventy-five mile line of steel towers which carries transmission circuits of 60,000 volts to Winnipeg. Guanajuato, Mexico, which is said to have produced more silver than any other city in the world, receives some 3,300 electric horse-power over a 60,000volt transmission line 100 miles long on steel towers. Between Niagara Falls and Lockport the electric circuits now being erected are supported on steel towers. On a transmission line eighty miles long in northern New York, for which plans are now being made, steel towers are to support electric conductors that carry current at 60,000 volts.

|

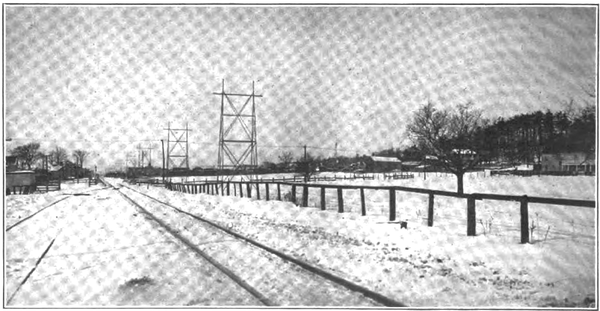

| Steel Towers for the Niagara Falls and Toronto Transmission Line. |

For the elevations above ground at which it is common to support the conductors of transmission lines, that is from thirty to fifty feet, a steel tower will cost from five to twenty times as much as a wooden pole in various parts of the United States and Canada. It follows at once from this fact that there must be cogent reasons, apart from the matter of first cost, if the general substitution of steel towers for wooden poles on transmission lines is to be justified on economic grounds. During fifteen years the electric transmission of energy from distant water powers to important centres of population has grown from the most humble beginnings to the delivery of hundreds of thousands of horse-power in the service of millions of people, and the lines for this work are supported with very few exceptions- on wooden poles. Among the transmissions of large powers over long distances at very high voltages that have been in successful operation during at least several years with wooden pole lines are the following: the 60,000 volt circuit that transmits some 13,000 horse-power from Electra station across the state of California to San Francisco, a distance of 147 miles, is supported by wooden poles. In the same state the transmission line is 142 miles long between Colgate power-house and Oakland, at 60,000 volts and with a capacity of about 15,000 horse-power, hangs on wooden poles, save at the span nearly a mile long over the straits of Carquinez.

Wood is used to carry the two 55,000-volt circuits that run sixty-five miles from the 10,000-horse-power station at Canon Ferry on the Missouri river to Butte. Between Shawinigan Falls and Montreal, a distance of eighty-three miles, the conductors that deliver at least 6,000 horse-power are carried on wooden poles. Electrical supply in Buffalo to the amount of 30,000 horse-power depends entirely on circuits from Niagara Falls that operate at 22,000 volts and are supported on lines of wooden poles. +

| |||

| Profile of Niagara Falls and Toronto Transmission Line at Welland Canal. |

In the operation of these and many other high-voltage transmissions during various parts of the past decade some difficulties have been met with, but they have not been so serious as to prevent satisfactory service. Nevertheless it is now being urged that certain impediments that are met in the operation of transmission systems would be much reduced by the substitution of steel towers for wooden poles, and it is even suggested that perhaps the first cost, and probably the last cost, of a transmission line would be less with steel than with wood for supports. The argument for steel in the matter of costs is that while a tower requires a larger investment than a pole, yet the smaller number of towers as compared with that of poles may reduce the entire outlay for the former to about that for the latter. More than this, it is said that the lower depreciation and maintenance charges on steel supports will make their final cost no greater than that of wooden poles.

| |||

| Niagara Falls and Toronto Transmission Line. |

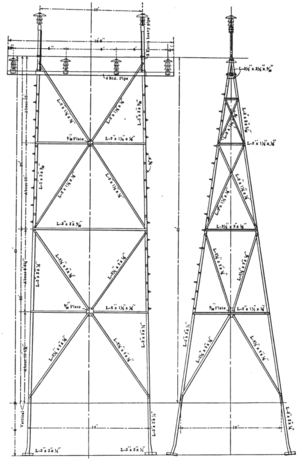

In the present state of the market, steel towers can be had at from three to three and one-half cents per pound, and the cost of a steel tower or pole will vary nearly as its weight. During the first halt of 1904 the quotations on tubular steel poles to the Southside Suburban Railway Company, of Chicago, were between the limits just stated. That company ordered some poles built up of steel sections about that time at a trifle less than three cents per pound. Each of these poles was thirty feet long and weighed 616 pounds, so that its cost was about eighteen dollars (xxi, A. I. E. E., 754). For a forty-five-foot steel pole to carry a pair of 11,000-volt, three-phase circuits along the New York Central electric road the estimated cost was eighty dollars in the year last named (xxi, A. I. E. E., 753). On the 100-mile line to Guanajuato, Mexico, above mentioned, the steel towers were built up of 3" x 3" x 3/16" angles for legs, and were stayed with smaller angle sections and rods. Each of these towers has four legs that come together near the top, is forty feet high, weighs about 1,500 pounds, and carries a single circuit composed of three No. 1 B. & S. gauge hard-drawn copper cables. The weight of each of these cables is 1,340 pounds per mile, and the forty-foot towers are spaced 440 feet apart, or twelve per mile, over nearly the entire length of line. At three cents per pound, the lowest figure at which these towers could probably be secured for use in the United States, the approximate cost of each would be forty-five dollars. Between Niagara Falls and Lockport each of the steel towers that is to carry a single three-phase transmission circuit has three legs built up of tubing that tapers from two and one-half inches to smaller sizes, and is braced at frequent intervals. The height of these towers is forty-nine feet, and the weight of each is 2,800 pounds. At three cents per pound the cost of each tower amounts to eighty-four dollars. For a long transmission line in northern New York bids were recently had on towers forty-five feet high to carry six wires, and the resulting prices were $100 to $125 each for a tower weighing about 3,000 pounds. On the seventy-five-mile line between Niagara Falls and Toronto the standard height of steel towers is forty feet from the ground level to the point where the two legs of each side join, and to this must be added a length of six feet that goes into the ground, and about three feet of pipe that run up from the junction of each pair of legs at the top, giving a total length of forty-nine feet exclusive of insulator pins. Except as to a cross-arm of standard four-inch steel pipe, and the two uprights of extra heavy three-inch pipe at the top, this tower is built up almost entirely of L sections that vary from 3" x 3" x ¼" to 2" x 1 ½" x 1/8". The weight of this tower is very close to 2,360 pounds, and its cost at three cents per pound would amount to about seventy dollars. On the line of these towers there are strung six hard-drawn copper cables with a cross-section of 190,000 circular mils each. Between these standard towers the maximum spacing is 400 feet, but this length of span is much reduced on curves and where the ground is uneven, so that about 1,400 towers are used on the seventy-five-mile line, which gives an average spacing of 283 feet.

| |||

| Steel Tower on Niagara Falls and Toronto Transmission Line. |

In January, 1902, four steel towers were purchased to support transmission circuits for two spans of 132 feet each over the Chambly canal, near Chambly Canton, Quebec. Each pair of these towers was required to support eleven No. 2/0 B. & S. gauge bare copper wires with the span of 132 feet between them. The vertical height of each of these four towers is 144 feet above the foundation, and they were designed for a maximum stress in any member of not more than one-fourth of its ultimate strength, with wires coated to a diameter of one inch with ice and under wind pressure. For these four steel towers erected on foundations supplied by the purchasers the price was $4,670, and the contract called for a weight in the four towers of not less than 121,000 pounds. On the basis of this weight the cost of the towers erected on foundations was 3.86 cents per pound.

With these examples of the cost of steel towers a fair idea may be got of the relative cost of wooden poles. For poles of cedar or other desirable wood thirty-five feet long and with eight-inch tops fitted with either one or two cross-arms an estimated cost of five dollars each is ample to cover delivery at railway points over a great part of the United States and Canada. This size of pole has been much used on the long, high-voltage transmission systems that involve large power units and use heavy conductors. Examples of lines where such poles are used may be seen between Niagara Falls and Buffalo, between Colgate power-house and Oakland, and between Canon Ferry and Butte. Of course some longer poles were used in special locations, like the crossing of steam railways, but it is also true that on the lines supported by steel towers such locations make exceptionally high towers necessary. The thirty-five-foot poles will hold the electric lines about as high above the ground level as the forty-nine-foot towers on the Niagara Falls and Toronto transmission, because the former will be set so much closer together. On the line just named the regular minimum distance of the electric cables above the ground level at the centres of spans is twenty-five feet. The standard towers on this line carry the lower electric cables forty feet above the ground at the insulators, and it was thought desirable to allow a sag of fifteen feet at the centres of the regular spans of 400 feet each. On these towers the conductors that form each three-phase circuit are six feet apart, and the lines drawn between the three cables form the sides of an equilateral triangle. With a pin fourteen and three-fourths inches long like that used on these steel towers, and one conductor at the top of a thirty-five foot pole, where the other two are supported by a cross-arm five feet three inches below, giving six feet between cables, the lower cables are held by their insulators twenty-six feet above the ground, when the poles are set five feet deep. Between thirty-five-foot poles 100 feet is a very moderate span, and one that is exceeded in a number of instances. Thus on the 142-mile line from Colgate power-house to Oakland the thirty-five-foot poles are 132 feet apart, and one line of these poles carries three conductors of 133,000-circular-mil copper, while the other pole line has three aluminum cables of 168,000 circular mils. On the later transmission line from Niagara Falls to Buffalo, which has one three-phase circuit of 500,000-circular-mil cable, the regular distance between the thirty-five-foot poles is 140 feet.

| |||

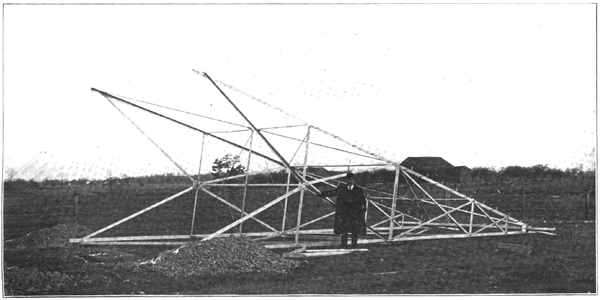

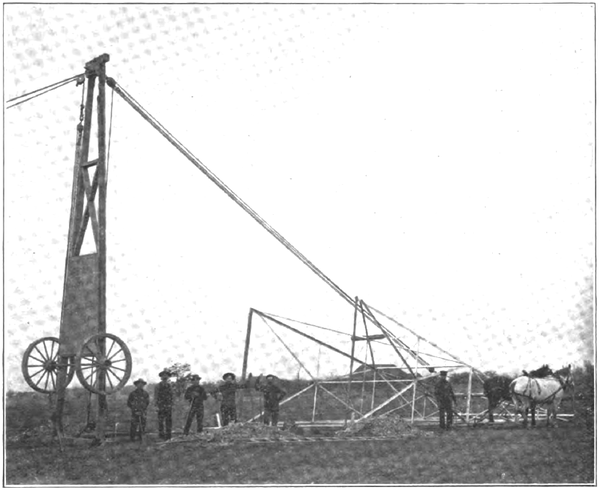

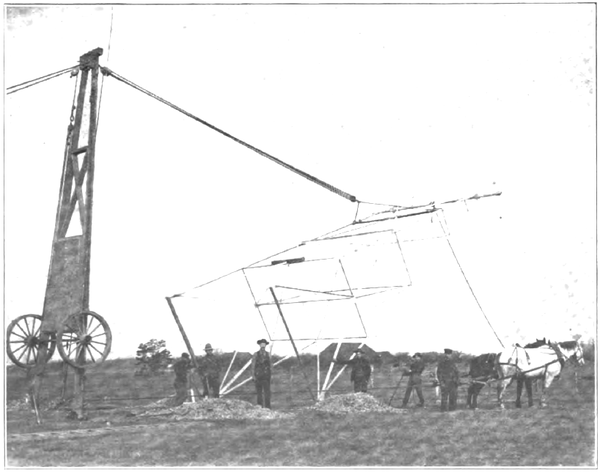

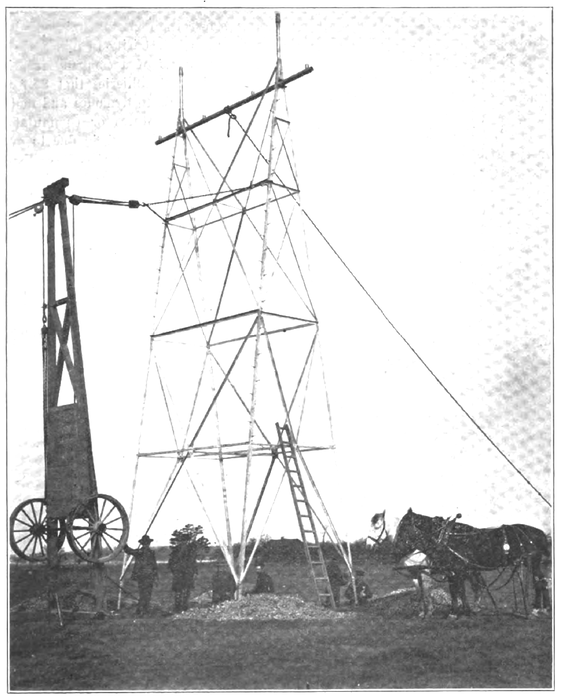

| Ready to Raise A Tower With the Derrick Wagon, Niagara Falls and Toronto Transmission Line. |

| |||

| Raising A Tower With Derrick Wagon, Niagara Falls and Toronto Transmission Line. |

A maximum sag of twenty-four inches between poles 100 feet apart under the conditions named above brings the lowest points of the electric cables twenty-four feet above the ground. The steel towers on the line to Guanajuato being only forty feet in length, and spaced 440 feet apart, it seems that the distance of conductors from the ground at the centres of spans is probably less than that just named. Particular attention is called to this point because it has been suggested that the use of steel towers would carry cables so high that wires and sticks could not be thrown onto them. It thus appears that thirty-five-foot wooden poles set 100 feet apart will allow as much distance between conductors, and still keep their lowest points as far above the ground, as will forty to forty-nine-foot towers placed 400 feet or more apart. The two lines that have their conductors further apart perhaps than any others in the world are the one from Canon Ferry to Butte, on thirty-five-foot wooden poles, and the one to Guanajuato, on steel towers. In each of these cases the cables are seventy-eight inches apart at the corners of an equilateral triangle. With steel towers 400 feet or wooden poles 100 feet apart, four of the latter must be used to one of the former. At $5 per pole this requires an investment of $20 in poles as compared with at least $45 for a tower like those on the Guanajuato line, $84 for a tower like those on the line from Niagara Falls to Lockport, or $60 for one of the towers on the Niagara and Toronto line. Each of the towers on the line to Toronto carries two three-phase circuits, and the least distance between cables is six feet. To reach the same result as the distance between conductors with the two circuits on poles, it would be desirable to have two pole lines, so that $40 would represent the investment in the poles to displace one tower for two circuits. The older pole line between Niagara Falls and Buffalo carries two three-phase circuits on two cross-arms, and the 350,000-circular-mil copper cables of each circuit are at the angles of an equilateral triangle whose sides are each three feet long. In this case, however, the electric pressure is only 22,000 volts.

| |||

| Tower Just Up, Niagara Falls and Toronto Transmission Line. |

The costs above named for poles and towers include nothing for erection. Each tower has at least three legs and more commonly four, and owing to the heights of towers and to the long spans they support, it is the usual practice to give each leg a footing of cement concrete. It thus seems that the number of holes to be dug for a line of towers is nearly or quite as great as that for a line of poles, and considering the concrete footings the cost of erecting the towers is probably greater than that for the poles. With wooden poles about four times as many pins and insulators are required as with steel towers, or say twelve pins and insulators on poles instead of three on a tower. For circuits of 50,000 to 60,000 volts the approximate cost of each insulator with a steel pin may be taken at $1.50, so that the saving per tower reaches not more than $13.50 in this respect. In the labor of erecting circuits there may be a small advantage in favor of the towers, but the weight of the long spans probably offsets to a large extent any gain of time due to fewer points of support.

An approximate conclusion from the above facts seems to be that a line of steel towers will probably cost from 1.5 to twice as much as a line or lines of wooden poles to support the same number of conductors the same distance apart, even when the saving of pins and insulators is credited to the towers. This conclusion applies to construction over a large part of the United States and Canada. It is known that wooden poles of good quality retain enough strength to make them reliable as supports during ten or fifteen years, and it is doubtful whether steel towers will show enough longer life to more than offset their greater first cost. It may be noted here that any saving in the cost of insulators or other advantage that there may be in spans 400 feet or more long can be as readily secured with wooden as with steel supports. With these long spans the requirements are greater height and strength in the line supports, and these can readily be obtained in structures, each of which is formed of three or four poles with cross-braces. Such wooden structures have long been in use at certain points on transmission lines where special long spans were necessary, or where there were large angular changes of direction. In those special cases where structures 75 to 150 or more feet in height are necessary to carry a span across a waterway, as at the Chambly canal above mentioned, steel is generally more desirable than wood because poles of such lengths are not readily obtainable. Neither present proposals nor practice, however, contemplates the use of steel towers having a length of more than forty to fifty feet on regular spans.

Much the strongest argument in favor of steel towers for transmission lines is that these towers give a greater reliability of operation than do wooden poles. It is said that towers will act as lightning-rods and thus protect line conductors and station apparatus. As to static and inductive influences from lightning it is evident that steel towers can give no protection. If each tower has an especial ground connection it will probably protect the line to some extent against direct lightning strokes, but there is no reason to think that this protection will be any greater than that given by well grounded guard wires, or even by a wire run from a ground plate to the top of each pole or wooden tower. If a direct lightning stroke passes from the line conductors to a wooden support it frequently breaks the insulator on that support, and the Pole is often shattered or burned. Such a result does not necessarily interrupt the transmission service, however, as the near-by poles can easily carry the additional strain of the line until a new pole can be set. Quite a different result might be reached if lightning or some other cause broke an insulator on a steel tower, and thus allowed one of the electric cables to come into contact with the metal structure, as the conductor would then probably be burned in two. To repair a heavy cable thus severed where the spans were as much as 400 feet long would certainly require some little time. Where a conductor in circuits operating at 20,000 to 35,000 volts has in many cases dropped onto a wooden cross-arm, it has often remained there without damage until discovered by the line inspector, but no such result could be expected with steel towers and cross-arms (xxi, A. I. E. E., 760). Where steel towers are employed it would seem to be safer to use wooden cross-arms, for the reasons just stated. This is, in fact, the practice on the steel towers before named, that support 25,000-volt circuits over the Chambly canal, and also on the steel towers that carry the 60,000-volt circuits from Colgate power-house over the mile-wide straits of Carquinez.

On the 40,000-volt transmission line between Gromo and Nembro, Italy, where timber is scarce and steel is cheap, both the poles and cross-arms are of wood. It is thought that the comparatively small number of insulators used where a line is supported at points about 400 feet apart should contribute to reliability in operation, but insulators now give less trouble than any other part of the line, and the leakage of energy over their surfaces is very small in amount, as was shown in the Telluride tests. Whatever benefits are to be had from long spans are as available with wooden as with steel supports, and at less cost.

One advantage of steel towers over wooden poles or structures is that the former will not burn, and are probably not subject to destruction by lightning. Where a long line passes over a territory where there is much brush or timber the fact that steel towers will not burn may make their choice desirable. In tropical countries where insects rapidly destroy wooden poles the use of steel towers might be highly desirable even at much greater cost, and such a case was perhaps presented on the line to Guanajuato, Mexico.

Mechanical failures of wooden insulator pins have been far more common than those of poles, both as a direct result of the line strains, and because such pins are often charred and weakened by the leakage of energy from the conductors. For these reasons the general use of iron or steel pins for the insulators of long lines operating at high voltages seems desirable. Such pins are now used to support the insulators on a number of lines with wooden poles and cross-arms, among which may be mentioned the forty-mile, 30,000-volt transmission between Spier Falls and Albany, and the forty-five mile 28,000-volt line from Bear river to Ogden, Utah. Iron or steel pins add very little to the cost of a line, and materially increase its reliability. One of the cheapest and best forms of steel pins is that swaged from a steel pipe, and having a straight shank and tapering stem with no shoulder. A pin of this sort for the 400-foot spans of 190,000-circular-mil copper cable on the line from Niagara Falls to Toronto measures three and one-quarter inches long in the shank, eleven and one-half inches in the taper, and has diameters of two and three-eighths inches at the larger and one and one-eighth inches at the smaller end.

On long transmission lines where the amount of power involved is very large, the additional reliability to be had with steel towers is probably great enough to justify their use. For the great majority of power transmissions, however, it seems probable that wooden poles or structures will long continue to be much the cheaper and more practicable form of support.