[Trade Journal]

Publication: The Central Station

New York, NY, United States

vol. 6, no. 5, p. 437-439, col. 1-2

The Semenza Porcelain Insulator at the Milan Exhibition.

The advanced position now held by Italian engineers in the field of electric transmission is again shown, by the new porcelain insulator exhibited in the kiosk of Messrs. Richard-Ginori in the Milan Exhibition.

All insulators now manufactured must be made sufficiently large to stand the electrical and mechanical strain under all atmospheric conditions, and one of the worst of these conditions met with in practice is the case of severe rain storms.

To guard against this rain trouble, it has been usual up to the present time to make the upper petticoat with a very large diameter to enable it to protect the lower part of the insulator, whose surface, being thus kept dry, would offer the necessary resistence even during severe rain storms.

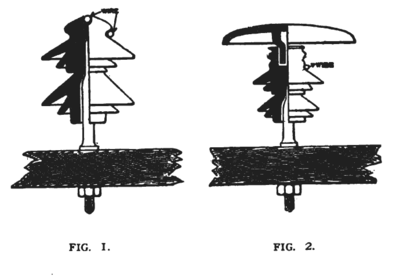

A sectional view of an ordinary insulator is shown in fig. 1, this being a type frequently used in Italy, in which the wire is fastened to a "head" forming one piece with the upper petticoat.

This necessitated making the whole of this petticoat of the same insulating material, which formed the chief part of the insulator, and it had to be made with just as much care as the lower petticoats.

The recent tendency to increase the working pressures, and the resulting greater distance which must be maintained through the air between the "live wire" and the grounded support, made it necessary to correspondingly increase the diameter of the upper petticoats, which resulted in a great increase in cost.

Signor Guido Semenza, the well-known Italian consulting engineer, and Hon. Secretary of the Italian Electrotechnical Association, devised the type of insulator, of which a section is shown in fig. 2, and the final details have been perfected by the engineers of the Societa Ceramica Richard-Ginori, after a large number of experimental trials made in the electrical testing laboratory connected with the works of the company at Doccia, near Florence.

It will be seen that in the Semenza insulator the wire is fastened below the upper petticoat. It is, therefore, unnecessary for this petticoat to be strong enough to resist perforation. It need only be watertight and sufficiently hard to resist mechanical shocks and rough usage in transportation. It is therefore, made of a form of terra cotta which is neither so costly nor so breakable as porcelain or glass.

|

| Fig. 1 and Fig. 2 |

Since the point of attachment of the wire in the Semenza type is somewhat lower than in the old type, the "strain moment" of the wire is greatly. reduced, which enables a reduction to be made in the thickness of the insulator and in the diameter and cost of the iron bolt; and since this upper petticoat or umbrella is not connected in any way with the pin, complications due to increased capacity are avoided.

| |||

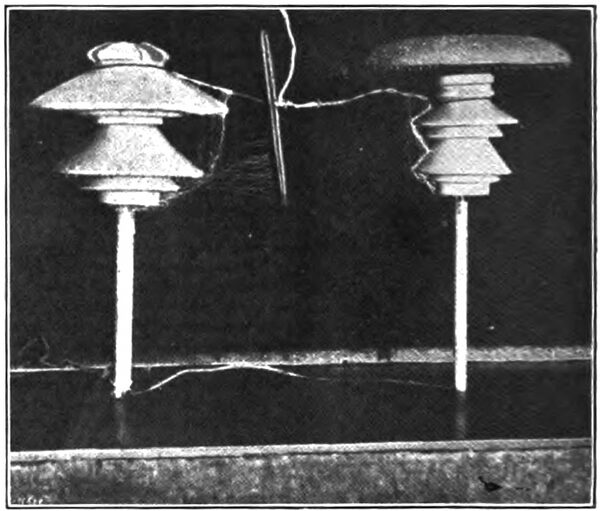

| Fig. 3 — Comparative Tests of Old Type and Semenza Patent Insulators. |

| |||

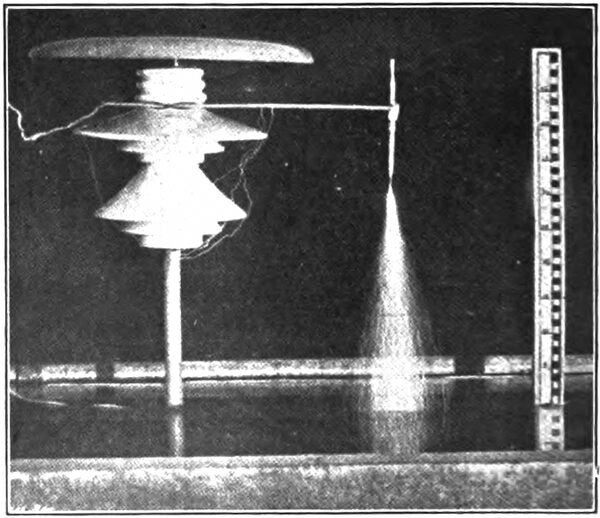

| Fig. 4 — Semenza Patent Insulator Under 122,000-Volt Test. |

The great improvement and the advance of this insulator over the old types is well illustrated in fig. 3, which shows a comparative test made between the old and the new pattern. Reference to the figure will show that a common wire connects the "heads" of the two insulators; this is led to one terminal of the transformer, the other terminal being placed in the alkali bath in which the pins are supported. The breakdown under the conditions shown above, was at 76,000 volts under a rainfall of 1,600 millimeters (62 in.) per hour. The difference in size between the two insulators for the same breakdown is very clearly shown below.

Fig. 4 shows the new Semenza insulator under an electric pressure of 122,000 volts, the test being taken with the insulator dry. The length of the discharge which takes place between the needle point and the surface of the alkaline bath is shown by the scale, which also serves to give some idea of the dimensions of the new insulator.

It is claimed that tests with a driving rain do not make any difference in the remarkable results shown by these experiments, and if such difficulty were anticipated, the size of the umbrella could be correspondingly increased with practically no difference in price.

The manufacturers state that they cannot at present give the exact dimensions of an insulator of the old style corresponding to that represented in fig. 4, as this insulator will resist a strain of t 111,000 volts under a rainfall of I,200 millimeters (46 in.) per hour, which in the old type, they claim, has not yet been manufactured. They also point out that if the difficulties of manufacturing such an insulator could be overcome, it would have at least double the price of the Semenza patent insulator.

The saving in price between the Semenza insulator and one of the old type is stated to be between 30 and 4o per cent. for an equally safe installation for working pressures between 35,000 and 50,000 volts, and for working pressures of 80,000 to 90,000 volts, a saving of 50 per cent. is claimed.

Reference to fig. 3 will show that the surface of the insulator is covered with moisture, and that drops of water actually collect there; tests, however, seem to indicate that the good results are not affected by heavy films of moisture.

Signor Semenza has stated that he considers one of the reasons for the remarkable results achieved to be that the wire is at no point in touch with a stream of water running over the surface of one of the effective petticoats of the insulator, and it might, perhaps, be said that the important effect of the insulator seems to be that the live wire and the effective surface of the upper petticoat are screened from "live water."

The shape of the umbrella might, of course, be slightly altered if necessary to cause the stream of water to run off on either side of the insulator entirely clear of the live wire.

It is interesting to note that tests so far undertaken seem to indicate that with this type of insulator the breakdown point under the heaviest rain storms is only in the neighborhood of 90 per cent. when wet, as compared with the breakdown when dry.

In conclusion, it should be stated that this insulator is now being placed on actual transmission lines, and the results obtained in practical operation should be awaited with great interest by those engaged in transmission line problems. — London Elec. Rev.