[Trade Journal]

Publication: Electrical Age

New York, NY, United States

vol. 35, no. 2, p. 137-142, col. 1-3

The Municipal Lighting Plant of the City of Seattle

by WALTER S. WHEELER

THE Washington Forest Reserve lying on both sides of the Cascade Range in the Northern part of the State of Washington comprises 5600 square miles, of which 2600 square miles lie east of the summit of the Cascade Range.

There is an abundance of water, and no irrigation would be required to cultivate the agricultural portion. The region west of the summit is composed if the spurs and slopes of the Cascades from the divide nearly down to the level country bordering Puget. Sound. The altitude of the central portion of the range varies from 5000 feet in the lowest passes to more than 11,000 feet on the highest peaks. This portion of the range is extremely rugged, containing many sharp, ragged peaks and great areas so rugged as to be without soil, and consequently without vegetation, although only a trifling portion of the range is sufficiently high to be above the limits of timber. The valleys are for the most part glacier carved, and are narrow, but gradually widen toward their lower ends.

The Cascade Range in this part of Washington is composed of granite and allied rocks. It is an old range and has suffered greatly from erosion, mainly from the action of glaciers, which in recent times have occupied all the gorges leading out of the range. The abundance of water in this region may be appreciated by the statement that not a spot has been found within the reserve where the sound of falling water was not heard. Waters navigable, however, even for canoes, arc short and detached. A climate more favourable to the growth of underbrush or to the starting of young trees would be difficult to find.

| |||

| The Pipe Line |

This short description of the Washington Forest Reserve has been given to show that water power is remarkably abundant, both on account of the quantity of water and the difference of elevation in short distances.

The headworks of the municipal lighting plant of the city of Seattle has been constructed 35 miles south of the southwest corner of this reserve on Cedar River. It is also about 10 miles south of east of the power plant at Snoqualmie Falls, a description of which was given in the ELECTRICAL AGE of April, 1904.

The city of Seattle is situated on Puget Sound, about 35 miles southwest of the southwest corner of the above mentioned reserve, and about 35 miles in a direct line from the headworks on Cedar River. We thus see that the city of Seattle, the head-works and the southwest corner of the reserve are at the corners of an equilateral triangle with sides about 35 miles in length.

Cedar River flows out of Cedar Lake, about 3 miles above the headworks. The lake is a body of water 3 miles in length and three-quarters of a mile in width. It covers 1500 acres of land, and is at an elevation of 1500 feet above mean tide. Records of the Seattle Power Company for the years 1895, 1896, 1897 and 1898 show that the flow of Cedar River at Cedar Lake varied from 200 to 4500 feet of water per second. Cedar River is also the source of Seattle's municipal water supply, and the city has purchased most of the watershed around the lake and the upper portion of Cedar River.

A timber dam has been construct. ed across the river, and this raises the water in the lake 14 feet above its original level. The water is carried through 14,000 feet of wooden stave pipe and 1000 feet of steel pipe to the power house, which is 600 feet below the surface of the lake. The wooden stave pipe is 50 inches in diameter, and is banded with iron hoops from one-half to five-eighths of an inch in diameter. The longest distance between hoops is 11 inches, and the least distance, where the pipe is subjected to a head of 343 feet, is two and three-sixteenth inches. With one exception, this is the greatest pressure used on wooden stave pipe.

The riveted steel pipe varies from one-fourth to eleven-sixteenths of an inch in thickness. It has been designed to withstand a static pressure of at least 50 pounds per square inch in excess of that due to head, without leak or fracture.

The power house is built on solid rock leveled up with concrete. It is 74 feet in length, 32 feet in width, and 40 feet in height. Two 1200-KW. generators are direct connected to Pelton water wheels capable of being operated at 50 per cent. overload. They are three-phase, revolving field alternators, running at 400 revolutions per minute, and developing 2300-volt current at 60 cycles. A Lombard governor controls each unit. The generators can be excited by either of two 75-KW., 125-volt compound-wound multipolar generators, direct connected to separate water wheels.

Nine 400-KW. transformers, three in a bank, raise the pressure to 44,000 volts for transmission. They are of the shell type, oil insulated and water cooled, and are located in a separate building from the generators. The high-tension oil-break switches are operated by remote control, there being no 2300-volt bus-bars, and only 125-volt direct-current on the switchboard.

One 44,000-volt, three-phase transmission line has been completed to Seattle and is in operation, and about to miles of a duplicate line have been constructed at the power house end, which will be built through to Seattle in the near future. The wire is No. 2 B. & S. gauge copper, and is the smallest that could be used at this voltage and distance without serious loss between wires on account of the conductivity of the atmosphere. Thomas porcelain insulators made up in three parts and tested at 120,000 volts in the usual manner, are used on this line.

A telephone line of No. 11 B. & S. gauge copper wire is carried on the same poles below the transmission wires.

The power and telephone wires are transposed, the telephone line being transposed every ten poles. The power wires are at the corners of an equilateral triangle whose sides are 84 inches long.

Eucalyptus pins are used to support the power insulators; a large pin 18 inches long being bolted to the top of the pole to support the upper wire. An extra large type of D. P. D. G. glass insulator is used on the telephone line, and the telephone wires are placed about 10 feet below the lower power wires. A good quality of cedar poles with a 9-inch top are used, and they are set from 100 to 132 feet apart. Where the line crosses railroad tracks, 75 and 90-foot poles are set close enough together so that a broken wire could not possibly reach the ground.

| |||

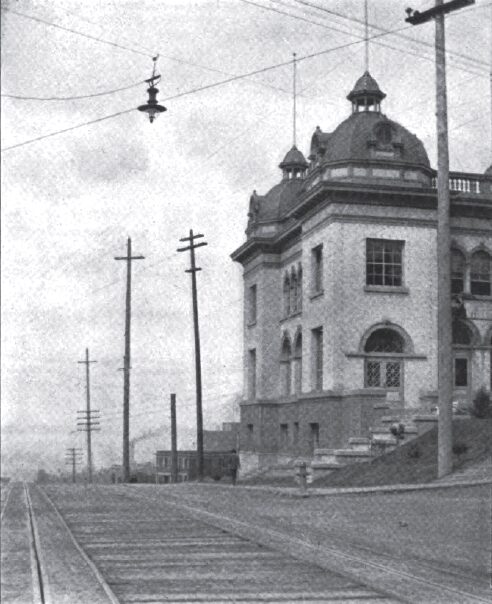

| A View of Sub-Station. One of the Street Arc Lamps is Here Shown |

The sub-station at Seattle is located at the corner of Seventh avenue and Yesler Way, and is illuminated on all sides at night with thousands of incandescent lamps. A large sign at the top of the building is made up of these lamps and reads "City Light." This sign can be seen for miles out on Elliott Bay at night, as the building stands about 200 feet above mean high tide and is unobstructed.

Five three-phase two-phase transformers used in two banks of two each, with one spare transformer to take the place of any one of the other four in emergency, step the line voltage down to 2300 volts. Seven constant current transformers regulate the voltage for fourteen series street lighting circuits. Both alternating current enclosed arc lamps and 30 candle-power incandescent lamps are placed in series on these circuits. A current of 6.6 amperes is used, the arc lamps taking about 75 volts, and the incandescent lamps about 18 volts.

Three years ago the street lighting of the city was done by a private corporation at the rate of $66.00 per year per arc lamp, and $15.00 per year per 30-candle-power incandescent lamp. In order to secure some concessions at the time, this corporation agreed to put its wires underground in a portion of the business district within three years, and in another portion within five years. The city had decided to build its own lighting plant, and in order to tear the streets up as little as possible and preserve its pavements, it agreed to build a joint conduit system with this company.

| |||

| A View of the Dam |

A new franchise granted to this company by the city required it to construct one duct free of charge for the city's wires in every conduit containing nine ducts or less, and an extra duct free of charge for every ten ducts in excess of the first nine. The manholes and handholes along these conduits have been purchased by the city at one-half of the original cost, as provided in the franchise. We thus see that the city controls the manholes, but employees of the company can enter them upon obtaining a license from the Board of Public Works.

The city began to map in all underground structures as soon as it was decided to put in this conduit system. The plans were drawn to a scale of 1 inch equals 10 feet, and sectional maps were made at street intersections and other places where it was deemed advisable to do so.

In order to get these maps as accurate as possible, all the old records of gas mains, water pipes, steam heating mains, telephone conduits and other underground structures, were looked up with great care, and special attention was given to all openings being made in the pavements at that time. About one year after the map making began, construction was commenced on the conduits. On account of having these maps, thousands of dollars were saved in not having to open up the street unnecessarily, and much annoyance was saved the traveling public.

In addition to the ducts that the company was required to furnish the city free of charge by the terms of its franchise, the city decided to purchase at actual cost, from one to eight extra ducts in all conduit laid under brick-paved streets. In these locations the conduit varies in size from four to sixty-four ducts, the average-sized conduit containing thirty-four ducts. Vitrified terracotta, mostly of the four duct multiple type, 36 inches long, and laid with broken joints was used in this conduit. The duct was joined together with 4-inch iron dowel pins, and each joint was wrapped with burlap dipped in oil, and then cemented over.

The ducts are encased in concrete from three and one-half to four inches thick. The concrete was mixed in the proportions of one part by measure of Portland cement, three parts sand and five parts gravel. All mortar used was mixed in the proportion of one part Portland cement to three parts sand. The concrete on the sides was tamped between the duct and a form of one inch lumber placed three and one-half inches from the duct. This lumber was left in place after the conduit was completed.

The manholes and handholes varied in size from 5 feet by 5 feet and 4 feet deep, to 9 feet by 9 feet and 10 feet deep. They were built with double brick walls and concrete bottoms. Eighty-eight manholes and handholes, and 191,948 duct feet of vitrified terra-cotta conduit were laid tinder brick pavement having a 6-inch concrete foundation.

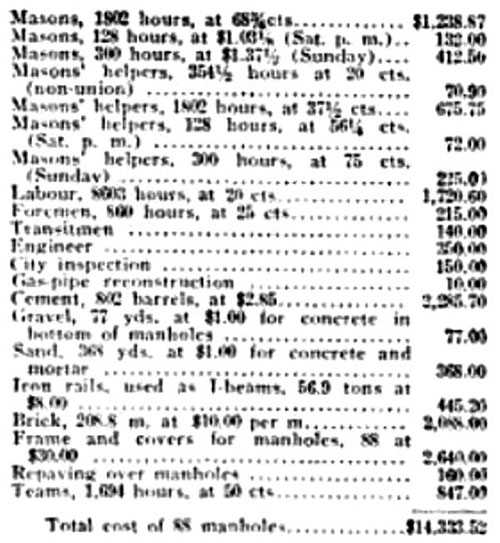

The cost of this underground construction was preserved in detail, the cost of the conduit being kept separate from that of the manholes and handholes. These costs were as follows:-

|

This does not include connections to sewers, as the manholes were not connected at first. Those that collected water were afterward connected. The average size of these was 7 feet by 7 feet by 7 feet.

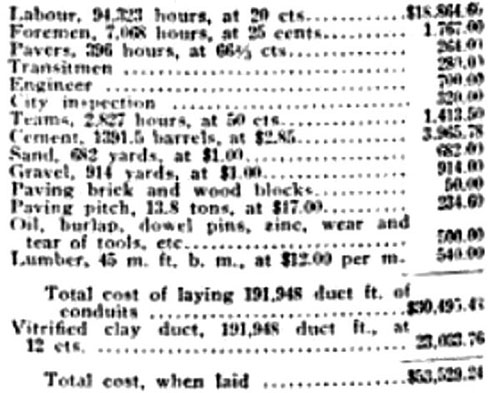

The rails had outlived their usefulness as rails, and were obtained at a very low figure. Their greatest cost was the cutting of them into the right lengths. They were laid close enough together to allow the laying of brick between them in cement mortar. The cost of laying the ducts was as follows:�

|

This would be an average of about 28 cents per duct foot for a conduit, laid under a brick pavement with a 6-inch concrete foundation. The high cost of the duct itself (12 cents per foot) was due to the cost of transportation from the East, and breakage in transportation. Much of the duct that was not too badly broken, was used toward the last, zinc strips being put around the broken portion. The conduit contained from four to sixty-four ducts, the average being thirty-four ducts.

The contract between the city and the company doing the street lighting before the municipal plant was put in operation, provided that the city could purchase the street lighting circuits at the time that the contract expired, if it so desired. The city took advantage of this provision and purchased the wire in place, lamps, tub transformers, arc lighting switchboard and other miscellaneous apparatus. The city pays the company 25 cents per wire per pole per annum, for supporting these lighting wires. However, many of the poles arc being maintained under franchises that require the company to reserve space for the street lighting wires free of charge, which reduces this rental considerably.

The city can also take advantage of provisions in the franchise of another company, which allows the city to string wires on this company's poles for distributing light and power to private consumers at a rental to be agreed upon between the two parties, and which rental is to be submitted to arbitration in case such an agreement cannot be arrived at.

| |||

| An Air Vent on the Pipe Line |

Although the city has been lighting its streets and public buildings for several months, it is just starting into the private lighting and power business. New poles are being set, and the street lighting which took less than 500 H. P. before the municipal plant was put into operation, will soon be increased to 1000 H. P. on account of new extensions.

Allowing for loss of power in transformers, transmission and distributing lines, and assuming a reasonable power factor for different kinds of load, 1600 H. P. remains that can be sold for light and power purposes. This would not overload the generators, and as much as 2200 H. P. could be sold for a short time during the peak of the load. In the daytime, when city lights will not he needed, then about 2600 H. P. will be available for sale. These estimates as to power are to be considered as taken at the consumers' meters after allowance has been made for all losses between generators and meters.

The "all-night, every night schedule" is used in Seattle for street lighting, and this schedule is commonly called 4000 hours for the year. Much more power can he developed by building a larger dam and putting in more generators, and the plant was designed with this point in view. Leaving out the distributing lines in the city and the cost of land purchased around Cedar Lake, the development, including the transmission line, was made at a cost of about $500,000. Much additional power can be developed for a few thousand dollars.

Before the municipal plant was constructed, the small consumer paid 20 cents per kilowatt-hour for his light. He is now purchasing it at 12 cents per kilowatt-hour, and a still further reduction is looked for in the near future. The rapid growth of Seattle, which is increasing the electrical output from 25 to 30 per cent, per annum, renders the problem of construction of both generating and distributing apparatus, quite complex.

The current available at the substation is two-phase alternating current of a periodicity of 60 cycles per second, and at a normal pressure of 2300 volts. It now becomes necessary to transform this current into the various forms needed in different parts of the service. Briefly, these forms will be as follows:— 2300-volt, two-phase, for power purposes; 2300-volt, single-phase, for lighting service in residence district; 250-volt, direct current, for lighting service in business district; 6.6 ampere, alternating current, for municipal street lighting service. For the 2300-volt, two-phase power, the current may pass out with the intervention of controlling and recording apparatus; the single-phase lighting circuits may be operated directly from the main bus-bars; the direct current service will be obtained through a rotary converter. The sub-station is connected by means of two-phase, 2300-volt circuits, with the sub-station of the Seattle-Tacoma Power Company, two blocks away, so that current may be obtained in case anything happens to the transmission line or other apparatus of the city. All of the wire in the distributing lines is insulated copper.

The municipal street lighting wires are of No. 6 copper, this being considered the smallest wire that could be used with safety on account of mechanical strength.

In the generating station, the switchboard is elevated at one end of the building. It is of Vermont marble and contains two panels for the generators and two for the exciters. Although polyphase instruments would have been much cheaper, and less space would have been taken up on the switchboard, three ammeters were installed on each generator panel, so that errors of instrument and unbalancing of circuits will be indicated at once.

The plant is controlled entirely from the switchboard gallery. A space of 4 feet has been left between the wall and the switchboard, and the wiring passes down the back of the board, under the floor and through the wall to an annex, where all switchboard transformers, shunts, rheostats, etc., are kept.

A wire passageway carries the leads to the transformer house. The transformer house is of stone, and is divided into three fire-proof compartments, each containing a bank of transformers all of which are placed in a single row. A path 4 feet wide, and a concrete pit runs the entire length of the building.

The oil and water pipes are carried in this pit, and it can also be used to drain off burning oil in case of fire.

A separate building has been erected for high-tension switching. It is of stone and concrete and is divided into eight compartments by concrete walls. Six of these compartments contain six triple-pole, 45,000-volt oil switches. Lightning arresters have been placed in the two end compartments, and disconnecting switches have been placed between the oil switches and the line.

The operation of the plant has been very satisfactory since the first of the year, when the street lighting load was transferred to it, and it is to be hoped that it will be just as satisfactory when the private lighting and power load is increased from time to time.