[Trade Journal]

Publication: Electrical World and Engineer

New York, NY, United States

vol. 39, no. 10, p. 434-435, col. 1-2

District Electrical Supply

For some years past a practice has grown up on the Continent of Europe whereby, instead of there being a number of separate central stations in near-by towns, a large central generating plant furnishes the energy for all of the towns within a considerable territory. With the voltages now practicable, it is entirely feasible to supply in this manner a large territory, and one of the developments to be expected in the near future is a considerable extension of this practice in this country, involving in many cases the consolidation of the companies operating plants in neighboring towns.

An example of such a central plant is one recently erected by the Central Electric Company at Metuchen, N. J., for the supply of current to Metuchen, Highland Park, New Brunswick, Perth Amboy, Rahway, Woodbridge, Bound Brook and Dunellen. This company is a consolidation of the Middlesex Electric Company, Edison Electric Illuminating Company of New Brunswick, Raritan Electric Light & Power Company, of Perth Amboy; Rahway Electric Company, of Rahway, and Bound Brook Electric Light, Heat & Power Company, of Bound Brook.

| |||

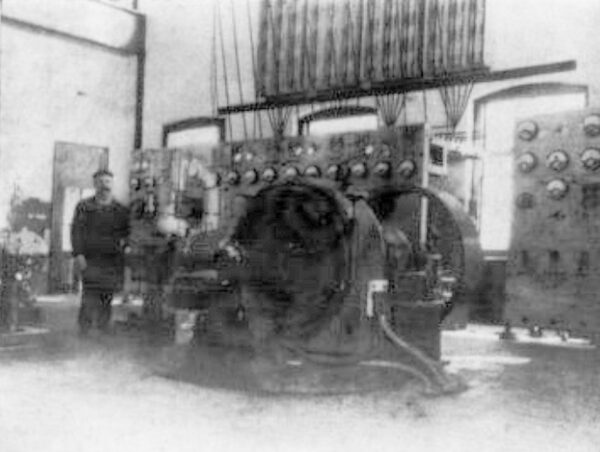

| Fig. 1.—Metuchen Plant. |

The equipment of the generating stations replaced by the new central plant was as follows: Edison Electric Illuminating Company at New Brunswick, Edison bipolar machines belted from counter- shaft driven by belt from simple Corliss type engines. The Raritan Electric Light & Power Company’s plant at Perth Amboy was equipped with 1100-volt single-phase alternators and American arc machines belted from a countershaft driven by belt from a simple high-speed engines. The apparatus at the Rahway Electric Company’s plant at Rahway consisted of single-phase, 2200-volt, 125-cycle alternators and 500-volt railway generators, all belted from high-speed engines. The Bound Brook Electric Light & Power Company at Bound Brook was operating an 1100-volt, two-phase alternator, belt-driven from a Corliss engine. The location of all of these plants made it necessary to cart all coal used at a cost of 28 to 40 cents per ton, and in every case except at Bound Brook, to purchase water for boiler supply.

The main units in the engine room are two horizontal cross com an oil filter, which in turn discharges into a tank, from which the oil is pumped again into the receiving tank of the system.

The condenser is of the elevated central condensing type, supplied by Henry R. Worthington, who also supplied the compound circulating pump and the rotative dry vacuum pump. Condensing water is obtained from three brooks, which supply an artificial lake, and to which lake the discharge from hot well may be returned in case of scarcity of water. The piping is also arranged that water may be drawn from three artesian wells for condensing purposes, and although this source would not be sufficient in itself, the low temperature of the water obtained from these wells considerably reduces the surface water required.

| |||

| Fig. 2.—Perth Amboy Sub-Station. |

The generators supply alternating current at the transmission pressure of 6600 volts. All of the high-tension switches on the switchboard, which was supplied by the Stanley Company, are of the oil type and of double the carrying capacity required for either the generators or circuits. The main switchboard now consists of two main generator panels and five circuit panels. The mains from one of the circuit panels lead to another part of the building to a set of Stanley three to two-phase step-down transformers having a ratio of 6600 to 2300 two-phase, at which pressure the current is distributed for local lighting. The high-tension leads from the other four panels are carried through lightning protection devices to sub-stations at New Brunswick, Perth Amboy, Rahway and Lincoln, which latter supplies the Bound Brook district. General Electric short-gap arresters with Stanley dischargers are used on all feeders.

The line is of the most substantial construction throughout, the insulators used being 10,000-volt Hemingray glass. The feeders vary in length from 4-1/2 to 9-1/2 miles, and are given two transpositions at respectively one-third and two-thirds of the distance covered by each particular feeder. All feeders are carried overhead their entire distance, except those to New Brunswick, which are carried on the stone-work of a bridge over the Raritan River, then down through a triple-conductor, steel-armored submarine Okonite cable under the Delaware & Raritan Canal, which parallels the Raritan River at this point. On the opposite bank of the canal the line is carried underground through Okonite single-conductor lead-covered cable, each drawn in a separate conduit to the sub-station about 550 ft. distant. The whole underground and underwater system is provided with oil switches and is in duplicate, thus making it possible to carry the whole load on either set entirely independent of the other in case of accident.

The present installation of the New Brunswick sub-station includes one 100-kw set of step-down transformers for lighting, and one 200-kw, 240-volt Westinghouse rotary converter for supplying the Edison three-wire system, space, however, being reserved for double this equipment, which will probably be required in the very near future.

At the Perth Amboy sub-station there are at present installed two 100-kw Stanley step-down transformers, 6000-volt three-phase, to 2300 volts two-phase; and three General Electric constant-current transformers for street lighting, each having capacity of 50 6.6-ampere enclosed arc lamps, the primaries of which will take the current directly from the three-phase transmission, working three to two-phase, or straight single-phase, as desired. The three transformers now installed are connected in single-phase, but with the addition of the fourth one, the three to two-phase connection will be used, thereby obtaining a balance of the transmission independent of the number of transformers installed.

The equipment of the Rahway sub-station is similar to the one at Perth Amboy, but lacking the constant-current transformers, and with the addition of one 200-kw Westinghouse rotary converter, 550 volts, supplying current to the street railway company.

The present installation at the Lincoln sub-station comprises one 100-kw set of Stanley step-down transformers similar to the others, and three reactive-coil General Electric series regulators for the incandescent street lighting system.

The main generating plant at Metuchen was designed, as a whole, by Mr. Paul C. Oscanyan. The operating force of the company consists of Dudley Farrand, general manager; H. C. Richardson, general superintendent; S. D. Sprong, chief engineer; W. A. Belcher, superintendent Perth Amboy & Rahway divisions; R. P. Bache, superintendent Bound Brook division.