[Trade Journal]

Publication: The Journal of Electricity

San Francisco, CA, United States

vol. 2, no. 1, p. 16-17, col. 2,1

HIGH GRADE PORCELAIN EQUIPMENTS.

In no department of engineering has it been so fully or so frequently demonstrated that good work and good materials pay, as in the field of electrical transmission and application of power. Cheap devices, like cheap labor, particularly in the field of electrical transmission, not only means a constantly increasing repair account, but create the probability of failure until such time as the cheaper materials have been replaced by those of the highest quality. An increasing repair account almost invariably forms an unnecessarily large item of expense that makes serious inroads into the dividends of the operating company.

| |||

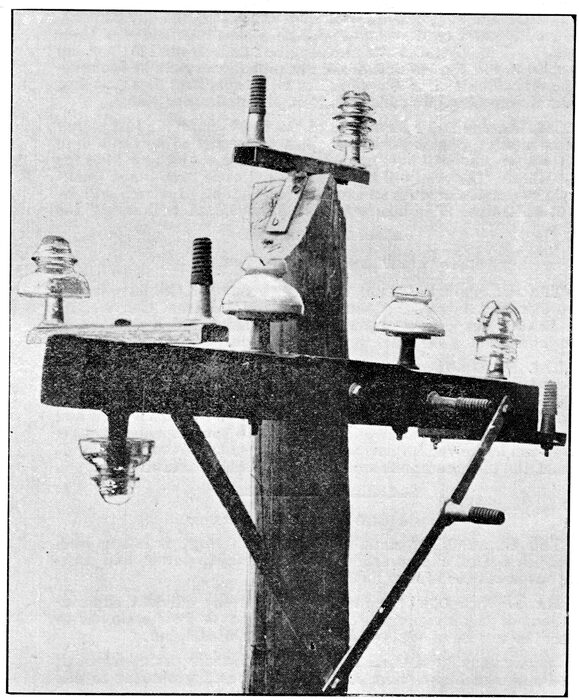

| Some of Fred M. Locke's Line Specialties. |

A full appreciation of the fact that the transmission circuits of electrical plants, whether used for the distribution of light or power over long or short distances, form at once the most vulnerable portions of an installation because of their exposure to many trying influences, led Mr. Fred. M. Locke, of Victor, New York, to make special inquiry into the manufacture of strictly high grade appliances, such as pins, brake arms, side brackets, cross arms, special glass and porcelain insulators and other fittings used in pole line construction.

This being a day of specialists, it cannot but be admitted that Mr. Locke has brought out a quality of line materials that are unsurpassed. The Locke indestructable steel pin is one that stays where you put it. It does not rot or rust, it is practicably impossible to break it, and it costs but $1.60 per mile of line more than wooden pins.

Then there is the Locke triple petticoat China insulator so extensively used in high potential power transmission circuits. A noteworthy example of the use of this insulator in California is in the Nevada county power transmission at Nevada City and Grass Valley. The insulator measures 5-1/4 inches in diameter, is 4 inches in height, and, having over twelve inches of surface between the wire contact and the supporting pin, and ten inches of which surface is on the under or dry side, it has been found by repeated practical tests to successfully withstand puncture from a potential of 85,000 volts. The body and glaze of these insulators are of simple earths only, fused together into a vitrious homogeneous mass at the greatest heat, and as no lead or other metallic oxide is used in the making, the glaze is not a conductor. The insulators do not craze or crackle on the surface, as insulators made of inferior material do when subjected to variations of temperature, and, in brief, the superior quality of the materials and workmanship used renders the insulators proof against severe tensile strains or heavy blows, against cracking or chipping from the effects of high potentials, and against the actions of heat, cold, dampness, acids, alkalis or other substances or forces. Being the very best it is the cheapest, though yet inexpensive. Triple petticoat glass insulators designed for currents of 5,000 volts or less, together with special transposition insulators used for the purpose of transposing telephone wires to overcome the effects of induction, are also manufactured, as are railway deep-groove double petticoat insulators, and other insulators of all sizes and designs.

The accompanying illustration shows a few of the many high-grade pole line specialties brought out by Fred M. Locke, and among which may be enumerated indestructable steel pins, brake arms, side brackets, glass and porcelain insulators, braces and pole fittings for all classes of line work.