[Newspaper]

Publication: The Indianapolis News

Indianapolis, IN, United States

vol. 24, no. 30, p. 5, col. 1-5

THE CITY OF MUNCIE.

The Brilliant Story of

Delaware County's Capital.

Tremendous Industries, Wealth

And Population Increasing

And Multiplying.

Scores of Factories, Thousands of

Workmen, Millions of Capital —

A city of Fine Buildings, Electric

Lights, Water-Works,

— Organized Progress.

"Magic Muncie" is the name which inhabitants of the county seat of Delaware county have given to their city. The aptness of the title is appreciated by those who knew the Muncie of five years ago and who know the Muncie of to-day. There is so little resemblance between the two that old citizens who have lately returned to the place after an absence of a few years have gone about in perplexity, seeking familiar landmarks.

Muncie has been fortunate in attracting the favorable attention of eastern capitalists who have been seeking a location for the investment of money. The result has been that a vast amount of wealth from the East has been transferred to the Indiana town, and with in have come men of energy and resources, and the ability to handle large affairs. In the solidity and extent of the town’s development it has no superior in the gas-field.

One of the first of the large industries to come to Muncie to secure the benefits of gas is the J. H. Smith & Co. bending-works. The principal product of the establishment is carriage wood-work, annually worth $200,000. Between three and five-million feet of lumber, chiefly hickory, are consumed yearly. The company’s plant consists of a substantial brick building three stories high and several hundred feet long. Steady employment is given to 230 persons, to whom weekly wages amounting to $1,200 are paid. About one hundred thousand dollars is invested in the business.

|

| THE BENDING-WORKS |

The R. E. Hill Manufacturing Company employs 150 men in the knitting of men’s fine underwear. The concern moved to Muncie from Piqua, O., last April, and is now occupying a commodious brick building. The goods are manufactured from silk, wool and cotton, and the dying and scouring as well as the knitting are done by the company. The daily output is seventy-five dozen pieces, and the value of the annual product is about $400,000. About $50,000 is invested in the business, and $1,000 a week is paid in wages. The demand for the goods produced by this company comes from the entire country. The works run the year around.

The Muncie Casket Company employs thirty-two hands, to whom it pays $250 a week in wages; $50,000 capital is employed in the business, and the annual product is worth $100,000.

The Indiana Bridge Company is a concern which has grown from a small beginning a few years ago to large proportions. It manufactures iron and steel bridges, buildings, viaducts, roofs, etc. Its business has spread beyond Indiana into all the adjacent States, and has become so extensive that a great deal of new machinery is now being placed in the works in order to increase their capacity. The company has put $100,000 into the concern, and its annual product is $300,000. One hundred and fifty men are employed. The pay-roll is $1,800 a week.

The Muncie Architectural Iron Company manufactures building fronts, jails and radiators. The fifty-five men who are employed in the concern receive $500 a week wages. Thirty thousand dollars is used in carrying on the business.

The Gill Brothers’ Manufacturing Company produces the earthenware pots used in glass factories. This is the largest exclusive pot factory in Indiana. Thirty-five men are employed whose combined wages amount to $325 a week. The company occupies a brick building, 100x200 feet in dimensions, to which has been added an ell, 32x62 feet. Thirty thousand dollars is the amount of capital invested in the industry and the yearly product is worth about $40,000.

The Hemingray Glass Company manufactures glass specialties such as lamps, lantern globes, electrical apparatus and bottles. The trade of the concern is such that the 140 hands now employed can not produce enough goods to supply the demand. A large addition is under construction which will increase the number of employes to two hundred. The present payroll amounts to $1,500 a week. The annual product, as the factory is now operated, is worth $100,000, but after the extension is completed, this will be increased to $150,000. About $75,000 is employed in the business.

The Port glass-works manufactures jars and bottles. It gives employment to sixty hands, whose wages amount to $1,000 a week; $25,000 is invested in the business.

The Joseph Bell Stove and Range Company has just completed an immense factory with ware-rooms, and will be in operation early in the spring. From the first 250 hands will be employed. The buildings are all of brick, and the total investment will be not less than $100,000.

R. M. Ball’s washing-machine factory employs thirty hands whose wages amount to $300 a week. The factory turns out five hundred washing-machines and one hundred wringers a week. The factory and business represent an investment of $20,000.

|

| COMMON-SENSE ENGINE-WORKS. |

One of the most prosperous industries in Muncie is that of the Common Sense Engine Company. It manufactures corn-planters, grinding mills and upright engines, and its trade throughout the West is extensive. The annual product of this company is worth 240,000. Seventy-five thousand dollars has been expended on the large brick buildings and machinery. At present seventy-five men are employed, with wages of $900 a week, but when the company, which only recently moved to Muncie, is in full operation, it will employ double that number of men. The company came to Muncie from the East, not only to get the benefits of gas, but to be nearer the center of its trade, which is chiefly in the West. The manager is authority for the statement that orders are already booked for more engines than the works can build between now and next June.

|

| THE MUNCIE PULP-WORKS. |

The Muncie pulp-works manufactures wood pulp for paper-making. The company does not manufacture paper, but sells its entire product to paper-mills. The factory is a huge brick establishment, filled with ponderous machinery, the entire plant having cost about $275,000. Twenty tons of pulp are manufactured daily and $1,000 is paid weekly in wages to the one hundred employes. The company is preparing to add to this plant next summer a paper-mill large enough to use all the pulp manufactured here. This will increase the company's investment 50 per cent or more and will double the number of employes. It is said that one of the great New York daily papers will use all the paper which this mill can produce.

The Muncie Glass Company manufactures flint glass ware. One hundred hands are employed and the weekly pay-roll amounts to $1,000. The capital invested in the business is $50,000.

One of the largest window glass factories in the gas field is that of Maring, Hart & Co., at Muncie. The factory has recently been greatly enlarged and the continuous tank system introduced. The buildings are of iron and cover several acres of ground. Two hundred and thirty hands are employed and the pay-roll amounts to $5,000 a week. The product of the concern now amounts to 2,500 boxes of window-glass a week, worth $8,000. The continuous tank system, here as elsewhere, proves to be a great improvement over the pot system. About $100,000 is invested in the plant and business.

The White River Steel Company employs 150 men, whose combined wages amount to about $2,250 a week. The capital invested by the company is about $75,000. The annual product is worth not less than$300,000. The mill is now being enlarged, and when the additions are completed its capacity and the number of men which it will employ will be greatly increased.

The Muncie nail-works was partially destroyed by fire a few weeks ago, but is being rebuilt upon a larger scale than ever. This industry was formerly located at Greencastle, Ind. Its chief proprietor is J. F. Darnall, late of Greencastle. The product of the mill is being gradually changed from nails to what is known as muck and bar iron. When rebuilt the mill will give employment to three hundred men, whose wages will amount to 4,500 a week. The annual product will be worth about $750,000, and will amount to one hundred tons a day. Two hundred thousand dollars is invested in the mill and business. When running fall-handed 250 tons of freight pass daily over the railroad switch which leads into this mill.

|

| THE MIDLAND STEEL-WORKS. |

An establishment of which Muncie is particularly proud is that of the Midland Steel Company. The extensive plant of the company is new and complete. The product which consists of high grade open hearth steel in many different forms is in great demand. The process of manufacturing steel is of interest in itself, but to the ordinary observer especially because of the ponderous machinery used in the work. As seen in the Midland steel-works, the process is as follows: The raw material used is pig iron — pure iron — first form after being reduced from the ore. This is mixed with scraps of old steel. The mixture is put into a furnace, twenty-five tons at once, and is there subjected to a heat which, in eight hours, reduces it to a molten mass. In order to manufacture high grade steel, it is of vital importance that the iron in the furnace should come to certain conditions, which can only be tested by means of a chemical analysis. Near the furnace is a small chemical laboratory, where tests of the melted iron are made at frequent intervals. The usual time for the metal to remain in the furnace is eight hours, so the furnace is filled and emptied three times a day, making the daily product of steel seventy-five tons.

When the melted iron is pronounced ready, a small opening is made near the bottom, and the fiery liquid gushes out, runs down a trough and is emptied into molds, where it stands until hard. When the molds are removed the ingot of steel formed in each weighs about 1,800 pounds. The entire process of converting iron into steel takes place in the furnace. All the succeeding operations are for the purpose of reducing ingots to merchantable forms. The ingots are first heated in another furnace white hot, then lifted by a big crane and deposited on a moveable carriage, which carries them between massive rollers. These rollers are so arranged as to press upon all four sides of the ingot, making it thinner, narrower and longer. The carriage on which the steel lies passes rapidly backward and forward beneath the rollers, the steel becoming each time longer. Soon the ingot, which at the beginning was about eight inches square and four feet long, is reduced to a ribbon of metal six inches wide, half an inch thick and eighty feet long. The machinery by which this reduction is made is of tremendous strength. The rollers are set in frames of steel, whose parts are as large as forest trees, and the engine which drives these rollers has the power of many hundreds of horses.

The ribbon of steel slides on rollers to a shearing machine, which snips it into two foot pieces as a child cuts paper with scissors. These are put into a furnace and heated white, then rolled, passing from one pair of rollers to another until each piece becomes a sheet of steel about eight feet long and two and a-half feet wide, and almost as thin as paper. When cold the sheets are rolled again, this cold-rolling giving them a high gloss, such as is seen on the finest quality of Russia iron used in stoves, stove-pipes, etc. In this form the sheets are ready for market. They go to other manufactories, which convert them into finished products of various kinds.

When all the machinery in the Midland steel-works is running, the noise is terrific. This is especially true of the mill which reduces the ingots. Every time the ingot rushes into the narrowing jaws of the rollers, there is a miniature explosion, which throws out a cloud of sparks. The loud clank of the gearing, the rumble of the engine which changes its direction and reverses motion of the ponderous driving wheel every moment, and the sight of the hurrying men with the glare of the hot metal on their faces, make an impression not soon forgotten. The Midland company employs 450 men, whose wages amount to $5,000 a week. The product of the mill is 20,000 tons of steel a year, worth $800,000; In the plant $200,000 is invested.

OTHER INDUSTRIES.

The Tappan Shoe Manufacturing Company occupies a brick building 40x100 feet, and three stories high. The company uses $75,000 in the conduct of its business, and gives employment to eighty hands. The weekly pay-roll is about $700. Ladies’ and misses’ shoes form the product, the annual value of which is about $85,000. James Boyce, one of the men to whom Muncie’e prosperity is greatly due is at the head of this company.

Another important industry, of which Mr. Boyce is the head, occupies an extensive series of brick buildings, and embraces, in fact, three distinct industries, baskets, rivets and D-handles. The company has $50,000 invested, and the seventy-five hands employed receive $250 a week in wages.

Ball Bro’s. Glass Manufacturing Company operates one of the largest glass factories in the country in its special line of business — the manufacture of glass jars and bottles of all kinds. Its buildings occupy many acres of ground and are almost constantly being enlarged At present 700 persons are employed; when extensions now under way are completed the number will be increased to 1,000. Wages now paid amount to $7,000 a week; after the increase they will amount to $10,000 a week. The company is capitalized at $250,000; the value of its annual product exceeds $1,000,000.

The John A. McVoy Company manufactures corrugated and galvanized steel from sheet steel produced by the Midland Steel Company. The two concerns are near together and a part of the Midland Company’s product is transferred to the McVoy works as rapidly as it is completed. The use of corrugated steel sheets for the walls and roofs of buildings is becoming so general that the business of manufacturing them has grown to large proportions. The galvanized sheets are used in the manufacture of sinks, buckets and other vessels and objects which it is desirable to have constructed from material which will not rust The McVoy company employs fifty hands, whose wages amount to $400 a week. The amount of capital invested in the business is $20,000.

The Burdette Organ and Piano Company gives employment to fifty hands, whose weekly wages amount to $500. The capital invested is $25,000.

The Boyer & Kandel Carriage Company employs twenty-five men, whose combined weekly pay-roll is about $250. About $35,000 is invested in the business.

The Muncie Wheel Company does a flourishing business, which requires the employment of fifty hands. The weekly pay-roll amounts to $500. The capital invested by the company is about $40,000.

The C. H. Over Window-Glass Company employs 100 persons, to whom is paid weekly $2,500 wages. The capital invested in the business is about $75,000. The annual product is worth about $150,000.

The Muncie Hard Wood Manufacturing Company employs twenty-five hands, to whom is paid $200 a week in wages. The capital is about $25,000.

The Muncie Skewer Company manufactures butchers’ skewers and other small wood novelties, including trunk slats, doing in all lines an extensive business. Forty hands are employed, and the weekly payroll is $350. The capital is $10,000.

One of the greatest industries in the city of Muncie is the Indiana Iron Company. The works occupy a number of iron and brick buildings, some of which are of these dimensions: One building 40x250 feet, one 40x70 feet, two each 50x250 feet, one 60x272 feet, one 80x100 feet, one 40x208 feet, one 100x200 feet and two each 60x200 feet. Altogether the buildings cover ten acres of ground. The concern manufactures merchant bar iron, and steel bolts and nuts. The bolt and nut department is not yet in operation, but the brick buildings which it will occupy are finished, and operations will begin in a few weeks. The rolling mil part of the plant is already in full operation. When the whole establishment is running it will require the services of 750 men, who will be paid every week $7,000 in wages. The annual product of the company will amount to about $2,000,000 The capital invested in the business is $300,000. Of the annual product the merchant bar iron will amount to 35,000 tons, while 90,000,000 bolts and nuts will be turned out.

The Muncie Steel and Iron Company is at present building a rolling-mill which will, when completed, give employment to 150 men. The pay-roll, basing the calculation upon the wages paid men in similar industries, will amount to about $2,000 a week. Not less than $100,000 will be invested by the company in the mill and business.

The Akron Steel and Forge Company is also constructing a large iron-working mill. The product will be heavy forgings, such as car axles, eye beams, etc. This company's works are now at Akron, O., and will be removed to Muncie as soon as the new buildings can be completed. The concern will employ one hundred men and will represent an investment of about $75,000.

|

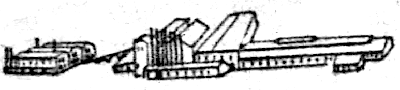

| THE WHITLEY REAPER-WORKS. |

Muncie’s largest single industry is not yet in operation, but soon will be. It is the Whitely reaper-works, which will manufacture harvesting machines of every kind under the patents of William M. Whitely, Mr. Whitely was formerly proprietor of immense reaper-works at Springfield, O., but the failure of the Fidelity Bank at Cincinnati, together with other misfortunes, ruined him financially, and since that time he has not been engaged in manufacturing. He is an inventive genius of the rarest type. It is said that since his failure another big reaper company has offered him $200,000 for his patents and a salary of $20,000 a year for ten years for his services. His patents number several hundred, and the books which contain printed descriptions of them make a large library by themselves.

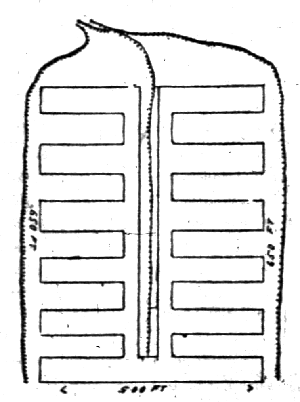

The plant which is being erected for the reaper-works at Muncie consists of one great building, composed of fourteen wings radiating from two long parallel buildings which are joined together at one end. The accompanying diagram of the ground floor plan of the structure will give a better idea of its form than words can. The building’s dimensions are 500x600 feet. Each of the fourteen wings is 45x200. The whole plant is one story high, and the floor of all is on the same level, and all on the level of the freight cars which are run along side for the loading and unloading of goods. The plan of the building is the result of Mr. Whitely’s years of experience. The raw material will be started into one end of the works and in the various stages of manufacture will move along down one side to the other end, cross over to the other side and move back in the opposite direction to the finishing and ware-rooms. There will be no loss of time by retrograde movement, hoisting and lowering.

The building is of wood, though substantial. If all of its wings were set end to end they would make a structure 45x4,000 feet. Their combined floor space is 192,000 square feet. Train toads of machinery from the old works at Springfield are being placed in the new building as fast as its wings are finished, while much new machinery is being purchased. In the building are 800 windows, each containing twenty-four panes of glass ten by twelve inches — 16,000 square feet of window glass. In a few days several hundred men will be employed in the works. When in full operation the concern will employ 2,000 men, and the wages paid will amount to about $18,000 a week. There is invested in the plant and business $500,000.

This manufactory in the suburbs of Muncie has effected a striking example of town building. The location for the works was chosen in a heavy growth of timber across the river from the town, far from dwelling houses, the ground densely covered by hazel bushes, blackberry vines and weed*. The place was not even connected with the town by a bridge, and was resorted to chiefly by rabbit-hunters, who reached it by a circuitous route. The promoters of the plan came into possession of the land August 8,1892. Two hundred men were at once put to work on it. August 23 the first lot was sold in the new suburb, Whitely.

To-day Whitely contains 168 buildings, completed or nearly so. It has good graveled streets, a first-class natural gas system; a fine steel bridge across the river is going up, and a franchise has been granted for an electric street railway connecting with the city. Ninety families already live there, and others are moving in as rapidly as their new homes are ready. The suburb also has several business houses which are already doing a brisk trade. The company which controls the land has given a beautiful part of fifteen acres to the city. It is covered with forest trees and its rolling surface makes many fine views. It is expected that before the close of next summer Whitely will have a population of several thousand.

A GRAND TOTAL.

In addition to the industries which have already been mentioned, Muncie has many smaller factories. Among these are five planing-mills, four grain-mills,two roofing-works, four brickyards, two coil-hoop factories, two carriage factories, two saw-mills, three washing-machine factories, two saw-mills, many machine-shops, novelty brass-works, cigar factories, bub and spoke-works, stave and heading factories, and so on. These minor industries give employment to 500 persons at the lowest computation, to whom is paid not less than $5,000 a week in wages. In the aggregate the capital invested in these concerns is not less than $250,000.

A summary of the foregoing statement of Muncie's manufacturing industries shows that there are now employed in those industries 4,732 persons, who are paid wages amounting to $52,325 every week, or about $2,517,000 every year. The amount of capital invested in these industries is approximately $2,800,000. Add to these totals the statistics of the nine industries which will begin operations within a few months and the grand totals are: Number of employes. 7,232; weekly wages, $75,775, and capital invested, $3,400,000.

All other material interests are enjoying the greatest prosperity because of the activity of the manufacturing industries. There is a bustle and stir in the streets. Stores and shops are crowded with customers. Hotels are crowded; the most substantial and gratifying conditions prevail in the banking houses. The December statement of the banks show that at that time they held deposits amounting to $983,146.12.

The progressive spirit of the community is also seen in its excellent fire department, its handsome school houses in which fifty teachers are employed, its City Hall, its imposing court-house, and the substantial character of its business blocks. There is hardly a finer business block in Indiana than the Anthony Block in Muncie. In the City Hall is a free public library of nearly 20,000 volumes. Connected with it is a reading-room supplied with the leading periodicals. At present, Muncie’s street-car system is not satisfactory to the public, as it is equipped with steam motors which throw out clouds of steam and scare the horses. They do not run at regular intervals, and for this reason are inconvenient. It is probable that the steam motors will give place to electric cars within a few months. An excellent system of water-works supplies the city with water for public and domestic uses. This belongs to a company, but the electric lighting of the city is in the hands of the city itself. A great many thousand dollars have been expended upon the electric light plant, and 102 arc lights are now in use in the streets. This number is increased as the city grows.

In its newspapers, Muncie is fortunate in being well served. There are three daily papers. All are able and progressive newspapers and are said to be valuable business investments.

The Daily Times is an evening paper, Republican in politics and aggressive in all things. Its editors and proprietors are John F. Wildman and James H. and Charles T. McClung.

The Democratic daily is the Herald, also an evening paper. Although the prevailing party in Muncie and Delaware county is the Republican, the Herald wears an air of prosperity. Thomas McKillip and F. G. Haimbaugh are the editors.

The third daily paper is the News — independent in politics. For several years the News was an evening paper, and as the field for papers of that class was already well filled, it did not prosper financially. A year or so ago it was changed to a morning paper, and since that time, being the only morning daily in the city, it has flourished greatly, and is now considered one of the leading papers of the city. Charles F. W. Neely is the-editor and proprietor of the News.

POPULATION AND PROGRESS.

At the presidential election in November of this year 3,966 votes were cast in Muncie. It is estimated that at that time fully five hundred men were in the city who had not lived there long enough to vote. This number added to the number of votes east and the whole multiplied by four (upon the conservative theory that the population of a city is equal to four times the number of voters at any general election) gives the population of Muncie at the time of the November election as 17,864. Fully five hundred persons have been added to the population since the election, thus making the population at the beginning of the year 1893, according to conservative estimates, 18,364. A city directory, which is almost completed, will, it is said, credit Muncie with a population of over twenty thousand. There is not lacking enthusiastic citizens of the place who claim 22,000. Multiplying the vote of last November by five, and carrying out the remainder of the calculation as above, would give a population of 22,830.

A year or more ago a fund of $216,000 was raised by private subscriptions within the city limits, to be used in inducing manufacturers to locate there. Land companies which control large tracts of territory adjoining the city agreed to give $1 for every dollar subscribed in the city. Thus there was raised a fund of $432,000, to be used in securing manufactories. Several of the largest industries now in Muncie have been brought there through the influence of this fund, although, as yet, not a quarter of it has been expended. It is in the hands of men of recognized ability and loyalty to the city’s interest, and it is confidently predicted by those most interested that by the time the fund is exhausted Muncie’s population will be doubled.

In every way the city shows unmistakable signs of prosperity and rapid development. The building operations can scarcely keep up with the increase of population. A costly school-house is built every year. The first steps in the direction of paving principal business streets have been taken. The manufactories now in operation are in many instances yielding great profits. Probably two-thirds of them are being enlarged or will be enlarged during the coming season. In numerous instances they are running night and day. Everywhere is life, and activity, and development. If these conditions continue for a few years, Muncie will become one of the largest and wealthiest cities in Indiana.