[Trade Journal]

Publication: Business Week

New York, NY, United States

p. 12-14, col. 2-3,1-3,1-2

The House That Glass Built

Owens-lllinois puts up plant for itself, made all of glass

blocks and without windows. And thread and air-fillers

can now be made of glass.

THE Owens Illinois Glass Co. has built at Toledo an all glass, window less building, occupied by the company’s packaging research laboratory.

The 39-room, two-story building, with 20,000 feet of floor space, is made of 80,000 hollow glass blocks, translucent but not transparent.

Weighing less than four pounds each, the blocks were laid by ordinary brick masons and are a product of the Owens-Illinois industrial materials plant at Muncie, Ind. The building is completely air-conditioned.

Glass blocks offer many advantages in light transmission, insulation against heat and cold, light diffusion, and sanitation. They are said to resist fire, moisture, vermin, and acids, and to prevent passage of air and gases.

In Milwaukee the J. C. Penney Co. has built a retail store of them; in West Virginia an electric power plant has been built with them; and several cities are building schools of glass blocks.

Owens-Illinois, having excessive plant capacity as a result of the depression, set out to discover new products which automatically would create markets for themselves. It spent courageously on research. One result is glass blocks. Another is fibrous glass.

This is produced in three different forms: (1) in a fluffy mass commercially available as insulation for homes; (2) in the size of broom straw assembled into mats, about two inches thick for use as air-filters; (3) in fiber 20 times less in diameter than human hair, this thread being employed as insulation for electric wire and large cables.

The usual ingredients for glass — sand, soda ash, lime, and certain costly chemicals — and the ordinary type of glass furnaces are used to make fiber glass by a secret process in the Owens-Illinois industrial materials division at Newark, Ohio. It has been made in Europe for years at a relatively high cost.

Insulating 15,000 Houses

Owens-Illinois insulating glass "wool" is distributed by the United States Gypsum Co. and has been sold as insulation for 15,000 houses in the past year.

It weighs only one and a half pounds per cu. ft., takes a two-ton load off the ceiling of the average house compared with other materials on the market, and can be installed in homes already built, by reducing the packs to tiny pellets and forcing them between walls with a blowing machine inserted in a small hole cut in one wall.

| |||

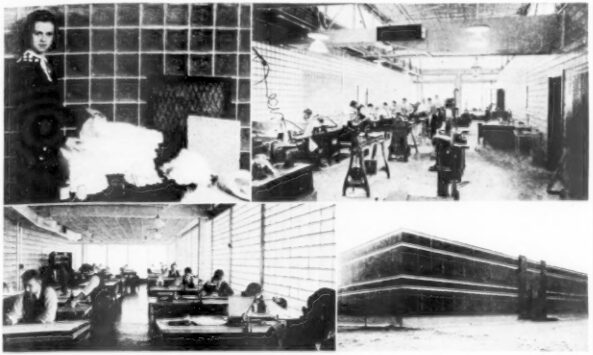

| 100% Glass — Owens-Lllinois Glass Co. Has Built at Toledo An All-Glass Windowless Building, for Its Own Use. Plenty of Day Light is Admitted Through the Translucent Blocks. There Are 39 Large Rooms, One of Which (Top Right) is Occupied by the Men Who Make Wood Models for Glass Containers, Another (Lower Left) Houses the Container Designers. the Girl Above Holds Fluffy Glass, Used for Insulation, Fibrous Glass Can Also Make Thread, Yard, Rugs, and Air Filters. |

Insulation glass has uncommon acoustical properties and has attracted the interest of moving-picture sound people, because it softens sound and also is fireproof. It is being made into metal mesh blankets to wrap around boilers, steam and hot-water pipes, and hot-air ducts. One type withstands temperatures up to 1,000 deg., the other type up to 200 deg.

Use of Glass Filters

Glass air-filters can be used not only to clean air from warm-air furnaces in homes and stores, but also to protect internal combustion engines from abrasive dusts.

Fiber glass may become an accepted thread, alongside wool, cotton, and silk. Fifty textile companies are experimenting with it. and the Owens-Illinois laboratory at Newark is trying to make it in colors (thus far white, blue, black, and red fiber have been produced).

Owens-Illinois has licensed a glass company at Duesseldorf, Germany, to make fiber glass, and has shipped special machinery from Newark It has also granted a license to the Corning Glass Works, of Corning, N. Y.

Glass blocks and fiber glass are still only offshoots of the Owens Illinois main business, which is the manufacture of containers. It also owns the Closure Service Co., of Toledo, which makes metal and synthetic caps and other closures.

Recently Owens-Illinois invaded the can-making industry. Some declare it was provoked by the competition of the American Can Co., but Owens-Illinois says it wants to round out its packaging service — glass, metal, and paper containers.

It has bought the Tin Decorating Co., of Baltimore, subsidiary of the American Tobacco Co., and the Enterprise Can Co., of McKees Rocks, Pa., and is reported to be negotiating for two or three other can companies, all to be operated as the Owens Illinois Can Co.

Can-Making Activities

Tin Decorating Co. has facilities for lithographing metal, and makes and sells decorated metal containers. Enterprise Can has a general line of tin products.

F. A. Prahl, former vice president of Continental Can, is a chief executive in the Owens-Illinois can-making activities (which is not expected to include making beer cans, since the company does not believe cans are a suitable container for beer).

Further expanding its glass container business, the firm has acquired the Libbey Glass Mfg., Co. of Toledo, which makes glass stem ware.

Owens-Ilinois is the result of a merger in 1929 of the Owens Bottle Co. and the Illinois Glass Co. Most of the executives are relatively young men. It is headed by W. E. (Bill) Levis, youngish grandson of the Edward Levis who helped to establish Illinois Glass in 1873 at Alton, Ill.

C. B. Belknap is executive vice-president and for years has had charge of the legal work. Harold Boeschenstein is vice-president and general manager.

The company has two main divisions — container and industrial materials. In the container division are 11 sales managers, each in charge of sales in a separate market, reporting to General Sales Manager F. J. Solon. The industrial materials division is under Mr. Belknap and Vice-President Benjamin F. Hazelton, with W. C. Davis as director of merchandising.