[Trade Journal]

Publication: 18th Annual Report of the Illinois Society of Engineers and Surveyors

Champaign, IL, United States

vol. 18, p. 108-119, col. 1

THE AURORA, ELGIN & CHICAGO THIRD-RAIL ELECTRIC

RAILWAY: AND OTHER THIRD-RAIL

INTERURBAN RAILWAYS.

BY E. E. R. TRATMAN.

One of the most modern features of the development of the railway transportation system is the development of electric railways as long-distance high-speed lines. These interurban railways form a distinct class of their own, between the steam railway and the city or suburban "street railway," which latter is in these days generally operated by electric power.

The city of Aurora, in which our Society holds its annual meeting for 1903, has the distinction of being connected with Chicago not only by steam railways, but also by an electric railway of the latest type of what are classed as interurban railways. It is built along its private right-of-way, is double track for nearly half its length, and is operated on the third-rail system instead of on the trolley system. In addition, it is designed for high- speed service, but it is as yet for passenger service only. As railways of this class are becoming so numerous, and are offering almost a new field for engineers, a general description of the road will no doubt be of interest, and the following particulars are compiled in part from personal acquaintance with the road and partly from an article in "Engineering News."

The railway is owned by the Aurora, Elgin & Chicago Ry. Co. of Chicago. The Chief Engineer is Mr. Charles Jones, Mr. E. H. Arnold was Construction Engineer, and Mr. E. Gonzenbach was Electrical Engineer. The headquarters of the engineer and for the operation of the line are at Wheaton, Ill.

The road has about 56 miles of main line, of which 21½ miles are double track. The side tracks bring the total track length up to 80 miles. The distance from Chicago (52d Ave. and Harrison St.) through Wheaton to Aurora is 33.3 miles; the line from Wheaton to Elgin 16.5 Miles; and the Batavia branch, 6 miles. The same interests own the Elgin, Aurora & Southern Traction Co., running north and south and connecting the two western terminals of the other line. This has 70 miles of track, of which 37 miles comprise the interurban line between Carpentersville and Yorkville, while the balance consists of city or street lines in Aurora and Elgin.

The line is operated partly by trains and partly by single cars, the multiple-unit system being adopted, in which each car has its own motive power, but all the motors are controlled from the head of the train. There are trains in both directions every half hour. The run between Aurora and Chicago or Elgin and Chicago is to be made in 45 minutes as soon as everything is in good running order. This will give an average speed of about 45 miles an hour from start to finish, which, with the stops, will necessitate actual running speeds of 50 to 60 miles an hour. The traffic is handled by the telephone train dispatching system, the head dispatcher at Wheaton communicating with the men at the sub-stations, or with the conductors, who report at these stations. The cars are equipped with portable telephones, and means for connecting these with the telephone wires are provided at all turnouts and crossovers; while at intervals along the road the wires are brought down the poles so that the telephones can be attached.

|

The maximum grade is one of 1.8 per cent. a mile in length, entering the Fox River valley, but on the rest of the system the aim has been to limit all grades to I per cent. The ordinary curves connecting long tangents are of 1 and 2 degrees, and the maximum on high speed portions of the line is 4 degrees. Near Chicago, however, there are some very sharp curves, including two reverse curves of 16 degrees, with a short tangent between. The superelevation on curves is about 1 in. per degree, with a maximum elevation of 5 ins.

The width of roadbed is 16 ft . for single track (13 ft. over toe of ballast) , and 28 ft. for double track (26 ft. over ballast). The track is laid with 80-lb rails of the Am. Soc. C. E. section, 60 ft. in length, and having about 0.6 per cent. of carbon. They are laid with broken joints and spliced with angle bars and four 1-in. bolts. There are 32 oak and cedar ties to a 60- foot rail, and the ballast is of gravel, with a depth of 9 ins. under the ties. The rail joints are fitted with two 12- inch electric bonds to each joint. The rails are cross-bonded at intervals of 500 ft. Split switches are used with 15-foot reinforced switch rails; and No. 10 spring- rail frogs are used for main track turnouts. On double track, the tracks are 13 ft. c. to c., and are connected by crossovers at intervals of three or four miles. On single track there are passing sidings at similar intervals; these sidings are 700 ft. to a mile in length, long sidings being provided at curves so as to provide practically double track, and thus give greater safety for high speed running at some points.

The conductor or third rail is of the 100-lb. Am. Soc. C. E. section, in 33-foot lengths, and is of much softer steel than the track rails, having only about 0.1 per cent. carbon. The object of this is to give greater conductivity, but as the softer steel rusts and corrodes much more quickly than the harder steel , the third rail is painted with a cheap asphalt paint, thinned with gasoline. This rail is carried by insulating supports on the ties (every fifth tie being of extra length). At road grade crossings the third rail is cut; the last rail is dropped 2 ins. in its length and has its end fitted with an incline 24 ins. long to raise the contact shoes of the cars into place. The ends of the rails are connected by cables laid under the crossings. Single cars will drift over the crossings, but trains (and even single cars at short crossings) will have the front shoe again in contact before the rear shoe has left the rail. As all the car lamps go out when the car is going over a road crossing, experiments are to be tried with an overhead wire at the crossing and a transverse wire low above the roof of the car. There is no room for storage batteries or gas tanks on the cars. At switches and crossovers, the third rail is depressed so as to clear the shoes of cars on the turnout. If this was not done the rail would have to be cut, and cable connections used, as at road crossings, which would be inconvenient.

The right-of-way is fenced with woven wire fencing, and all highway grade crossings are fitted with cattle-guards of vitrified clay blocks. There are only four railway grade crossings with steam railways, three of which are protected by interlocking plants. There are also three crossings of street railways.

All steel bridges were designed in accordance with Cooper's specifications, with his Class E-40 loading. There is only one truss bridge, crossing the Chicago & Northwestern Ry. at Elgin, on a skew. This has a span of 158 ft. 7 ins. , with shallow floor construction, and one end rests on columns, connecting with a steel viaduct 363 ft. long. All the other steel bridges are of plate girder construction. Besides these there are a number of small openings spanned by I-beams with concrete filling. The steel bridges have open floors, but with closely spaced ties and a substantial floor system. All piers and abutments are of concrete.

There are four concrete bridges, besides a number of concrete culverts and cattle-passes. The Salt Creek bridge has two 35-foot arches (with a rise of 1 in 6); the Poplar Creek bridge at Elgin has one 30-foot arch, and another bridge over the west branch of the Du Page River, and on the Elgin branch, has two 30- foot arches (with a rise of 1 in 10). The smaller structures have arches of 10, 12 and 15- foot span, and one of these has two 15-foot spans. Old 60-lb. rails are laid in all the arches, except those of 12 and 15-foot span. They are placed about 36 ins. apart, near the center line of the arch ring, and extend into the haunches.

In one cattle-pass, concrete jack arches are turned between the I-beams, but instead of the ordinary removable wooden centering, arches of wire netting were fitted on the lower flanges and the concrete placed on these, being filled in from both sides towards the crown. The end of each I-beam rests on a vertical 60-lb. rail embedded in the abutment, and a diagonal rail is embedded in each wing wall. This arrangement enables lighter walls to be used, with an economy in concrete and a saving of about 30 per cent. in cost as compared with a structure having concrete abutments and an open I-beam floor. The Chicago terminal is a transfer station for connection with the Garfield Park line of the Metropolitan West Side Elevated Ry. The cars run between two platforms, on the outer sides of which is the terminal loop of the elevated railway, which is reached by an incline from the elevated station at 48th St. At Elgin and Batavia the line runs on its own right-of-way up the river bank to a terminal station in the center of the town. At Aurora the cars run for about half a mile along the street. There are about 30 stopping places in all, most of these having simply open platforms at road crossings. Each of the six brick sub-station buildings has a waiting room and platform for passengers, and there are a few small frame stations. The main repair shops and car sheds are at Wheaton, and are of fireproof construction throughout.

The cars are 47 ft. 3 ins. long over all, 8 ft. 8 ins. wide, and weigh 74,000 lbs. empty. They have steel underframes stiffened by truss rods, and steel framed trucks. The wheels are 36 ins. diameter, and the axles 6 ins. diameter, with journals 5x9 ins. Contact shoes are fitted on both sides of each truck, and there are two trolley poles on the roof for use on the short piece of street line in Aurora. The cars have transverse seats, upholstered in rattan, and have seating accommodation for 56 passengers. They are equipped with telephones, Christensen air brakes, electric heaters and electric interior lights and headlights. At one end is a smoking room. The platforms are vestibuled and have side and end doors in the vestibule, the latter allowing for access between the cars when coupled up in trains. The dimensions of the cars correspond very closely with those of the cars on the Chicago elevated railways, and the trucks are so arranged as to enable the cars to readily pass the 90-ft. curves on these lines. This is in view of the possibility of eventually running the cars over the elevated railways into the city. Each car has four motors of 125 H.P. , the gear ratio being 1.61 to 1.

The power house is at Batavia, Ill., and this also supplies current for the line from Elgin to Aurora, and for the street cars in these cities. The city service tends to equalize the load on the power station and prevent the high peaks which occur when only interurban traffic is operated. The power house is 202 x 160 ft., of steel frame construction , with walls of limestone and common pale brick, and a roof of tar and gravel composition on plank sheathing.

There are three Corliss cross-compound condensing engines of 2,200 H.P., running at 75 revolutions; cylinders 32x60 and 64x60 inches. On the middle of the shaft of each engine is a revolving-field generator of 1,500 kilowatts, and a 20-ft. 80-ton flywheel. Space is provided for a fourth engine and generator. There are also two horizontal engines of 200 H.P., each directly connected to an exciter of 160 K.W. Steam is supplied by Edge Moor water-tube boilers of 500 H.P., carrying 180 pounds of pressure.

The plant also includes Green economizers and Worthington condensers and pumps, the main circulating and feed pumps being driven by induction motors. The power station is close to the Fox River, and the water supply for the boilers and condensers is taken from the river by a conduit which passes through the building, while the waste water is discharged into a culvert which leads back to the river. The 240-foot chimney, of brick and stone, is placed at the middle of the building, and the top of its 11-foot flue is 225 ft. above the grates. Coal is delivered to a storage bin of 2,000 tons capacity, with hoppers in the bottom, from which the coal falls by gravity through gates into steel cars of I ton capacity, running on a track of 24 inches gauge, the wheels having outside flanges. From under the hopper the loaded car is run to an elevator, the floor of which is a turntable, revolving on steel balls and fitted with an automatic weighing apparatus. This elevator raises the car to a track running along over the hoppers feeding the magazines of the automatic stokers, into any of which the coal can be dumped as required. Similar cars run on a track passing under the ash pits and provide for the removal of the ashes.

The transformers are on the engine room floor, and are cooled by a current of air passing up through them.

The power plant generates an alternating current of 26,000 volts, which is sent out over the high-tension cables to the sub-stations. Stationary transformers reduce this to a 420-volt alternating current; this enters the rotary converters, which deliver a 600-volt direct current to the third rail. In the arrangement of the high-tension circuit, provision is made for alternative circuits in case of failure in emergency. Each circuit consists of three aluminum cables, arranged in a triangle, 20 ins. c. to c. These are transposed at intervals of a mile. The poles carrying the high- tension cables are 40 ft. long and 80 ft. apart, and the telephone wires are carried on the same poles, below the cables.

There are six sub- stations, approximately 10 miles apart, feeding the third rail for five miles in each direction. All these are fire-proof buildings of brick and stone, with Monier concrete steel floors; and they have waiting rooms and platforms to serve also as passenger stations. Each sub-station has six stationary air-cooled transformers, two rotary transformers, and a fan with induction motor for supplying the air blast to the transformers.

The third rail between any two sub-stations constitutes a continuous section fed by the sub-stations at each end. On the line, all the third-rail sections on the entire system are connected together through the medium of the sub-station bus-bars and feeder panels, so that there is opportunity for the sub-stations to divide the load among each other as far as the conductivity of the third rail will permit, and in case of an excessive load upon one section the substation nearest is not required to carry the whole load. On the double-track part of the road the third rails on the two parallel tracks are not connected together, but form two separate sections through the medium of the sub-station feeder panels and bus-bars, just as are any other sections, but it is proposed to tie the two third rails together through a circuit-breaker located half way between the substations, so that there will be the benefit of the two conductors in case of a blockade on one track. The use of a circuit-breaker would be necessary to avoid trouble on both third rails, as would happen in event of a short-circuit on one.

The road is laid out for six sub-stations. The transmission is by 26,000-volt, three-phase alternating current. The high-tension lines are carried on cross-arms, with insulators 30 inches between centers on the cross-arms, and the cross-arms are 24 inches apart. The telephone lines are on cross- arms 7 ft. below the lower transmission cross-arms. There are two telephone circuits, one for general business and the other for dispatching. The telephone lines are transposed every fourth pole and the high-tension lines every mile. The telephone wires are transposed by tying both to a single wide petticoat transposition insulator every fourth pole.

The erection of 650 30-foot, 4,250 40-foot, and 150 50-foot poles was not an easy task. The greater part of the poles were hauled from the nearest railway stations by wagons, and as the right-of-way was minus bridges and only partially graded, three or four 40-foot poles made a big load for one team.

The holes for 40-foot poles were put down 6 ft., and many were blasted with dynamite, a two-inch hole being bored six feet deep and a stick of 40 per cent. dynamite tamped in the bottom. Then the hole would be half filled and another stick put on top of this and tamped, both being set off with a magneto generator. This made the hole the same diameter all the way up, and as the sod is cut the size of the hole intended, there was no tearing up of the ground. No direct-current overhead feeders are needed, as the third rail has sufficient capacity to conduct all the current from the sub-stations to the trains. The overhead pole line has only to carry two telephone circuits, and the 26,000-volt, three-phase, high-tension feeders which supply the sub-stations. The high-tension feeders are of standard aluminum cable. Poles carrying these lines are 40 feet long, placed 80 feet apart.

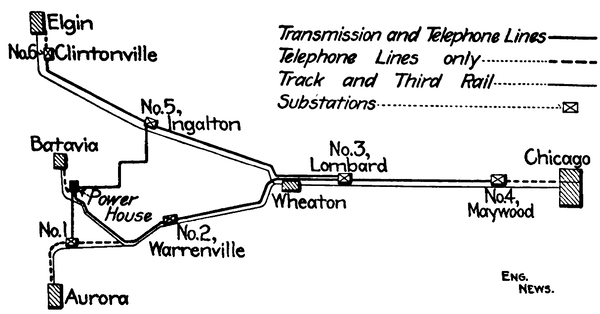

The system of high-tension distribution is arranged to secure freedom from interruptions of service due to short-circuits or breakages on any one transmission line. Three high-tension feeder lines leave the power house at Batavia. A line runs directly across the country to sub-station No. 1, near Aurora. Another high-tension pole line follows the railway, supplying sub-stations Nos. 2 and 3, and extending to Maywood. The third line from the power house is built directly across the country to sub-station No. 5 on the Elgin branch, and along the right-of-way from this sub-station to Wheaton, at which point it joins the pole line from the Aurora branch, and the two three-phase circuits run on the same poles to sub-station No. 3, with one circuit from there to No. 4. Sub-station No. 6 is supplied by a line running from sub-station No. 5.

The regular sub-station equipment for all the sub-stations comprises two 1,500- kilowatt rotary converters with a bank of three transformers each. The sub-stations have air-tight bus-wire compartments, in which air is kept under pressure by the blower for cooling the transformer and the reactive coils. The top of the coil and transformer cases have openings by which the amount of air passing may be regulated.

At the Warrenville, Lombard and Ingalton sub-stations there is another panel devoted to the out-going line to the next station. The principal object of this is to make it possible to cut off the line beyond in case of short-circuit or line trouble. After passing the lightning arresters, the incoming line goes through the current transformers which supply current for an indicating ammeter, and the current coil of a reversal relay. This reversal relay is the same as that on the power house generator panels, and will act to open the oil switch on the incoming feeder in case the sub-station attempts to give current to line instead of receiving it.

After passing the current transformers the incoming line is taken to the three-pole motor-operated oil switch. The switch is also controlled by a hand switch on the feeder panel. From the oil switch the incoming feeder goes directly to the bus-bars. The panel for the outgoing line and controlling apparatus connected therewith are similar to the incoming, except that the motor-operated oil switch is controlled by an overload relay instead of a reversal relay, and there is an ammeter in each leg of the circuit. The potential transformer for the reversal relay on the incoming panel is connected directly to the alternating-current bus-bars. Current for the operation of the motor-operated switches is supplied by a small storage battery located in the cabinet in the sub-station.

Each rotary converter has its bank of three transformers controlled by a motor-operated oil switch. The alternating-current panel is to all intents and purposes a high-tension panel, although there are no high-tension wires upon it. After passing the main switch the high- tension lines go through current transformers for the switchboard instruments. The converter panel contains a power-factor meter, ammeter, voltmeter, overload relay and controlling switch. The machines may be started on direct- current from the third rail or by alternating-current, and can be started alternating-current from rest and put into service in 30 seconds. When starting on alternating-current the three- pole, double-throw switch located on top of the reactive coil is first thrown up, giving only half voltage until considerable speed has been attained, when this switch is thrown down and the rotary given full alternating- current pressure through the reactive coil.

THIRD-RAIL ELECTRIC RAILWAYS.

The third rail conductor was invented in the very early days of electric railways, but it was first used in practical service in 1903, on the Intramural Elevated Railway at the Columbian Exhibition in Chicago. It was next adopted for the new Metropolitan electric elevated railway of Chicago, in order to avoid the unsightly appearance of poles and wires on the elevated structure. It is now used on elevated roads in various cities and also on underground lines. Its first application to practical surface work was on the Nantasket Beach branch of the New York, New Haven & Hartford Ry., and this road afterwards used it on some local lines. The third rail is about 20 to 27 inches from the track rail , and its head is usually 6 inches above that of the latter. It is supported by an insulator on every fourth or fifth tie, these ties being made of extra length. The value of an ordinary steel rail as a conductor, as compared with copper, is about 10 to 1 or 12 to 1, with the additional disadvantage of frequent joints and bonds in the rail. But with second-class rails at $20 per ton and copper at $360 per ton, an ample amount of steel can be provided and still leave a considerable saving. On one new English electric railway, the third rail conductor is used, and there is a fourth rail to carry the current back to the power house, instead of using the track rails for the return circuit. The third-rail system cannot, of course, be used for lines built on the public roads .

There are as yet very few third rail interurban railways, the overhead trolley wire system being more generally used. Besides the Aurora and Chicago line, there is a line at Muskegon, Mich.; another between Wilkesbarre and Scranton, Pa., and another from Albany to Hudson, N. Y.; while the New York, New Haven & Hartford R. R. has this system on some local lines.

The Grand Rapids, Grand Haven & Muskegon Railway is 35 miles long, laid out to avoid grade crossings, all railways being crossed by steel bridges with earthwork approaches of easy grade. The track is laid with 70-pound rails. The third-rail system is used, except that short sections of overhead wires (not more than 2,500 feet in all) are used through towns and cities. The third rail weighs 65 pounds per yard. The power house has four boilers of 250 H.P. each and six Westinghouse generators directly connected to vertical engines. Two of these generate direct-current at 650 volts. The others generate alternating-current at 390 volts, which is transformed to 16,600 volts for transmission to the two sub-stations at Coopersville and Walker. These are 12 and 27 miles from the power station at Fruitport. The district near the power house is supplied direct from two 650-volt direct-current generators at that house. The sub-station rotary converters supply the other parts of the line. The passenger cars are 52 feet long, and each has two motors of 150 H.P. There are also 40-foot express cars. The service is controlled by telephone from Fruitport, and the cars are run every half hour, making an average speed of 35 miles per hour, including stops.

The Lackawanna & Wyoming Valley Ry. runs from Wilkesbarre to Pittston and Scranton, Pa., 20 miles, and is being extended to Carbondale, making 36 miles in all. The line is substantially built, with maximum grades of 2 per cent., and maximum curves of 4 degrees, except one of 12 degrees near a station. The line is double track, laid with 75-lb. and 90-lb. rails, and having a 75-lb. third rail conductor. The main power plant has two Westinghouse 2,000 H. P. engines directly connected to two double current generators. These supply direct-current at 650 volts, which is delivered to the third rail, and alternating-current of 390 volts. This latter is stepped up to 22,000 volts for transmission to the sub-station, where it is stepped down and converted into direct-current at 650 volts. The equipment includes passenger cars, freight cars and combination passenger and baggage cars, all about 52 ft. long. The front truck has 33-in. wheels and no motors, while the rear truck has two motors of 150 H.P. each. The fast trains average 40 miles an hour.

The following discussion of the third-rail and trolley-wire systems for interurban electric railways is taken from "Engineering News:"

THE THIRD-RAIL AND TROLLEY-WIRE SYSTEMS FOR INTERURBAN ELECTRIC RAILWAYS.

In the development of the long-distance and high-speed electric railways, which are becoming such an important feature in local transportation, there has as yet been but a limited adoption of the third-rail system of current conductor. Partly on account of the fact that these railways are a development of the street electric railway, the natural tendency has been to continue the use of the overhead trolley wire. But besides this there are certain objections to the third-rail system, in which the "live" rail is readily accessible, and is therefore more dangerous than the overhead wire. The third-rail system is used only on lines having their own right of way, which is closely fenced in, and the rail is broken at level crossings, connection being made by an underground cable. Yet fences and cattleguards are not sure preventatives against trespassing, especially on the part of curious or mischievous persons, and it remains to be seen how much serious danger there is in the use of the third rail.

One of the reasons given for the use of this system is that the trolley wire system is not so well adapted for high-speed service, but as a matter of fact many high-speed trolley lines are in operation and experience little trouble from the trolley leaving the wire; in fact, probably no more trouble than is experienced on city lines. On the lines of the United Traction Co. of Indiana (154 miles) the trolley system is used exclusively, and the cars are run at schedule speeds of 40 to 45 miles an hour, while speeds of 50 to 60 miles an hour are not infrequently attained. Yet the trolley very rarely leaves the wire. On the other hand, the third-rail system is considered as a general improvement upon the trolley-wire system for railways of this class, and the cost of maintenance will probably be very much less than for the overhead construction required to support the trolley wire, especially where there are numerous curves, switches, etc., which require a more or less complicated overhead special construction.

The Albany & Hudson Railway & Power Co. operates a line between Albany and Hudson, N. Y., a distance of 38 miles. Through the cities the trolley system is used, but outside of the cities (where the line is laid on a private right of way) the third-rail system is used. The business resembles that of a steam railway, and all classes of steam railway cars are hauled over the line. The reason for the adoption of the third-rail system in this case was the very crooked condition of the line, and it was feared that a high speed could not be maintained with an overhead trolley wire. The traffic is also very heavy at times, and the third rail is said to have proved a much better conductor than the trolley. A current of 550 volts is carried in the third rail.

The cars are operated at an ordinary speed of about 25 miles per hour, but a speed of 60 miles an hour is often attained, and even a higher rate of speed than this is occasionally made on straight and level track. The line is fenced with a woven- wire fence the entire distance. At highway crossings, cattleguards are placed to prevent animals and persons from getting on the right of way ; and a sign is also placed on each side of the highway, reading, "This railroad is operated by an electric rail; walking upon the track or other trespassing is forbidden." At all farm crossings, cattleguards are used to prevent stock from getting upon the right of way when being driven across the tracks at such points.

Since the road began operations, two persons have met their death by coming in contact with the third rail. The first case was that of an old man, who was in very feeble health, and it was shown that he had fallen down several times during the day on the streets of Albany and that he was not in a physical condition to withstand any shock. It is considered an open question whether he met his death by coming in contact with the third rail or whether he had fallen in a fit and was found dead on the rail. The next case was that of one of the car conductors, a man about 60 years of age, who was cut in a thunder shower, his clothing being thoroughly soaked. While performing his work he slipped and fell backwards, striking the back of his head on the third rail, his body lying across the main track rail. In this case it was a question if the blow on the back of his head did not have more to do with his death than the shock from the third rail. A few animals have been killed by coming in contact with the third rail. This record would seem to show that the third-rail system is not so dangerous as is sometimes supposed.

At first there was a little trouble from boys and others tampering with the third rail, by short circuiting it with short pieces of wire and other pieces of metal. This trouble was very slight. On one occasion the third rail was short-circuited by some mischievous person placing a splice bar from the third rail to the main track rail; this caused a temporary shut-down of about 30 minutes. Aside from this, there has been no trouble from this source.

The most recent case of the adoption of the third-rail system is the line of the Aurora, Elgin & Chicago Electric Ry., about 80 miles; and on this road the third rail is laid through several towns along the route. It has its own right of way entirely, but crosses numerous streets and roads at grade, and there is some anxiety in these places as to the liability of accident, especially to children. This road is intended for high-speed service. The third-rail system is also used on a part of the New York, New Haven & Hartford R. R. On the elevated railways of Chicago and New York the same system is used, and accidents have occurred to men working on the lines, but of course these tracks are inaccessible to the public.

Reference has been made to the use of the third-rail system on the electrically-operated lines of the New York, New Haven & Hartford R. R., and information as to the practical working of this system has been obtained from Mr. N. H. Heft, Chief of the Electrical Department of that road.

The company was led to experiment with the third- rail system through a desire to obtain the simplest and least expensive method of transmitting power. The cost of installing the third-rail system was found to be very much less than the overhead system, and the comparative cost of maintaining the third-rail and overhead systems has been found to be very much in favor of the former. Practically the only item of expense in connection with the maintenance of the third-rail system is the renewal of underground cables at crossings. From experience gained with the present installation, Mr. Heft hopes to be able to place cables under the crossings in such a manner that there will be practically no deterioration. When this has been accomplished, the only expense will be an occasional tightening of the bolts at the joints of the rails, which will amount to very little.

The third-rail system is in use between Hartford and Bristol (18 miles), and between Berlin and New Britain (3 miles) in Connecticut; and between Braintree and Cohasset, in Massachusetts (11.5 miles). The average speed maintained in operation under the regular schedule is about 35 miles per hour. The right of way is fenced, and at grade crossings the ordinary surface cattle-guards are in use. The voltage carried by the third rail is from 550 to 650 volts.

One of the great obstacles that has been encountered in introducing this system, which presents so many advantages, is the fear of liability of persons being killed or injured by coming in contact with the third rail, and also the fear of trouble caused by persons tampering with the rail. The experience on the Albany & Hudson Ry. , above referred to, and on the New York, New Haven & Hartford R. R., appears to indicate that the danger of the third rail has been exaggerated, and that the objections to it on this score have not been well-founded. The right of way should, of course, be fenced in, and provided with cattleguards at road crossings; then if people persist in trespassing they must be held responsible if they receive injury. As to the matter of tampering with the rail and short circuiting the current, the strength of the current will usually soon burn out and destroy any small connection such as a wire, and if the railway companies take prompt action and have the offenders arrested, the publicity and punishment will soon have a deterrent effect upon mischievous persons. This course of action has been taken by the Aurora, Elgin & Chicago Ry., whose line was recently opened, and several boys have already got into trouble. Probably in a few months the railway will be so familiar that it will not suggest itself as an outlet for mischievous tendencies, and will not be tampered with any more than the steam railways. In regard to the experience in these directions on the New York, New Haven & Hartford R. R., we give Mr. Heft's statement in his own words, as follows:

"We have had very few accidents due to the location of the current conductor. A few persons have come in contact with the rail, and have received slight burns. Two persons have been found dead on the track, but in both cases there has been reasonable doubt as to the cause of death. One (a man) was subject to epileptic fits, and was known to have been under the influence of liquor the night before he was found. The other (a boy) was also known to be subjects to fits, and it is thought he may have been taken with one while walking along the track, and that, while in an unconscious condition, he remained in contact with the third and service rails a sufficient length of time to be killed. With these exceptions, we have had practically no serious accidents on account of the location of the third rail."

A few dogs and one horse have been killed by coming in contact with the third rail. The horse was running away and took to our roadway at a grade crossing. We have also had several dogs so seriously shocked while loitering about our tracks, that they have thereafter religiously avoided the vicinity of the railway in general, and the third-rail track in particular.

"We have experienced trouble on our Hartford & Bristol line from boys and mischievous persons causing short circuits by throwing metallic substances across the third and service rails. We have succeeded in bringing one or two such persons into court, and the result has been that we now have practically no trouble from this source."