[Newspaper]

Publication: The Hartford Courant

Hartford, CT, United States

p. 6

Oldest Plastics Plant to Get "New Look"

| |||

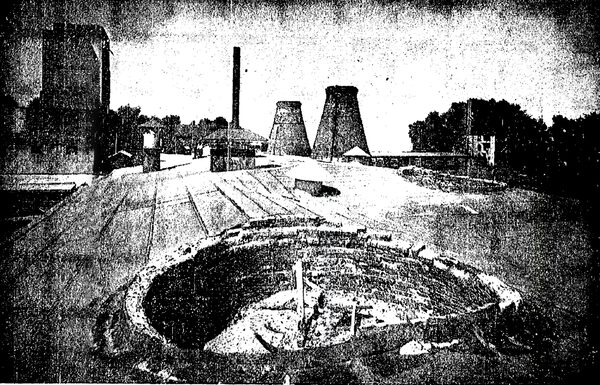

| In the background of this roof view are two conical chimneys that once belched flame 40 feet high to make porcelain in big beehive ovens. in the foreground is one partly dismantled with a draft control in the center. Oven temperature used to be gauged by noting the color of flame over a 25 to 65-Hours period. If heat varied more than 20 degrees, the "charge" (load of porcelain products being processed in the kilns) would be spoiled. This plant, owned by the Hartford Faience Corporation, once operated 10 kilns. Old giant hand-Fed, coal-Burning oven had been in use since 1894 when the firm was established. |

| |||

| Six big beehive kilns that once fired clay products at the Hartford Faience Corporation are coming down to make way for modern equipment used in vitrifying porcelain fixtures, chiefly electrical insulators and textile items. Replacing them will be a new tunnel kiln which will make better products more cheaply because its temperature can be controlled more easily. |

| |||

| The 53-Years-Old business, operated at the Hamilton Street plant, represents one of the oldest divisions of the plastics industry. It is owned by the Rankin family of Hartford whose members recall the active days of the picturesque old kilns -- days when the plant's 10 ovens, fired at once, would redden the sky with their glow and people unfamiliar with the phenomenon would get excited enough to call the fire department. |