[Trade Journal]

Publication: Street Railway Review

New York, NY, United States

vol. 15, no. 4, p. 231-232, col. 2,1-2

Third-Rail Insulators.

The recent developments in heavy electric traction work and more particularly the equipping of the New York terminals of the great steam railway systems with electric locomotives are being watched with keen interest by many persons, both from an engineering and from a traffic manager's point of view. The heavy electric traction work in and about New York City will he used as an example in much similar work which is sure to follow both in the East and other parts of the country. The several systems which have been equipped for excessively heavy traffic, all have been fitted with the third-rail as their working conductor. It therefore seems appropriate to enter into a close study of this part of the distribution system and its essential details.

|

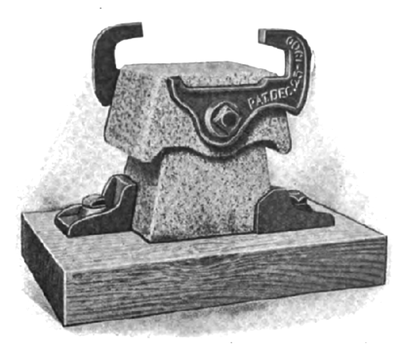

| Courtnay Type of Insulator. |

After having chosen the form of conductor rail which is best suited to meet the conditions under consideration and after having detailed the plans for the cable work which will connect the different sections of this rail, there remains the choosing of a suitable support for the conductor rail.

A third-rail insulator in order to serve its purpose well must have certain essential characteristics: It must be a mechanically strong column that it may safely hold a heavy rail to proper gage and elevation; it must have a sufficiently large creepage surface of well sheltered insulation to furnish an insulation resistance so high that there will be practically no leakage between the third-rail and the tie; it most furnish a strong seat which will retain the rail from any lateral movement yet allow it to move freely along its longitudinal axis, and it must be provided with an ample base by which it can he so securely fastened to the tie that any local movement of the tie or rail will not disturb the relative position of the third-rail and track rails. These general requirements are approached by all the successful third-rail insulators on the market.

|

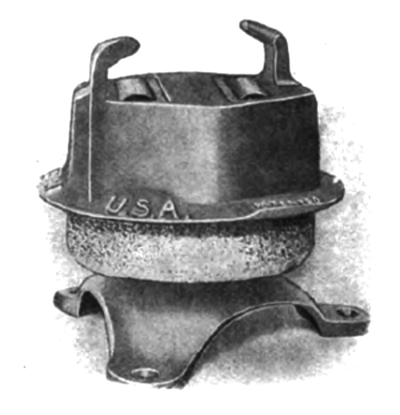

| Interborough Rapid Transit Co. Third-Rail Insulator. |

Reconstructed granite is a material which has found much favor as an insulating medium for third-rail insulators and which in its several different forms is now used by a large percentage of the third-rail roads, both in this country and abroad. For making insulators a class of granite is selected which has crystals of a very uniform shape and size. This granite is pulverized and molded into the desired form under heavy pressure and then fused into a solid mass at a temperature approximating 3,000° F. When used for insulating purposes reconstructed granite is highly glazed to prevent any accumulation of dirt. This glazing process insures a long life for the high resistance qualities of the block. The reconstructed granite differs from natural stone in many important respects, namely:

1. Being vitreous it does not contain or absorb moisture, hence, it can be heated red hot and dropped into water without cracking.

2. It is of unlimited durability, not being affected by heat or any commercial acids.

3. It is exceedingly strong, its crushing strength ranging from 12,000 to 15,000 lb. per sq. in. and its tensile strength from 800 to 1,000 lb. per sq. in. of cross section.

4. It possesses high ohmic resistance. These essential properties of an insulating medium have after many years of severe tests in all sorts of climatic conditions placed it in high regard as an ideal material for third-rail insulators and similarly constructed articles. The accompanying illustrations show several types of the product of the Reconstructed Granite Co., of No. 14 Dey St., New York City.

The Courtenay type of insulator is one which because of its simple, substantial design and high insulating qualities combined with low cost has been installed on many miles of the more important third-rail systems. All parts of this insulator are easily separated and can easily be removed from the track without disturbing the third-rail. The same body can be used to support contact rails of varying widths of base by merely changing the size of rail clips.

|

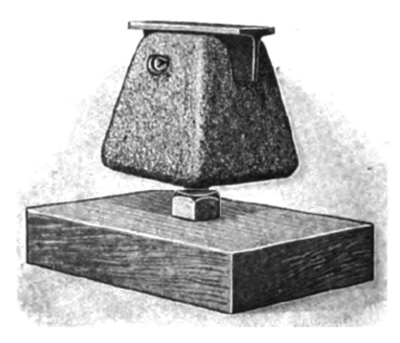

| Special Design Insulator for T-Bar Sections. |

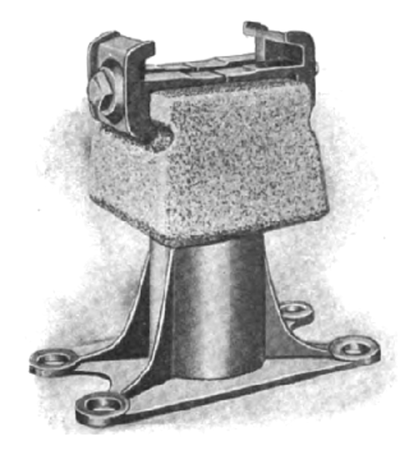

The General Electric Co's. standard type third-rail insulator with reconstructed granite insulation consists of three parts. A cap protects the insulating block and has cast upon it lugs for holding the rail in place and bosses which lessen any friction due to the sliding of the third-rail from the cause of expansion or contraction. The reconstructed granite block and its protecting cap of this insulator are mounted upon a three-footed malleable iron pedestal by means of which the insulator is bolted to the tic.

The type of insulator used throughout the Brooklyn elevated system is known as the Martin patent type, the general design of which is similar to the General Electric type, except that no bosses are provided to lessen the friction. 1 he retaining lugs on the malleable iron cap are designed for being bent over the base of- the rail. This cap is loose from the rest of the insulator which permits vertical play to accommodate the motion of the track under wheel loads.

|

| General Electric Type. |

The reconstructed granite third-rail insulators which were furnished the Interborough Rapid Transit Co. in connection with the New York subway consist of a broad four-footed malleable base, upon which is mounted a rectangular block of reconstructed granite, but differing from the other insulators which have just been described; these subway insulators have no protecting cap, because the entire track is underground and is not subject to the effects of weather. The insulating block of this insulator is surmounted by a pair of malleable iron clamps, which bolt together and tightly clamp the base of the rail to the top of the reconstructed granite block.

For "pony" feed rails, which are used for signal systems, traveling cranes, scenic railways, etc., a reconstructed granite block is made in the form shown in the accompanying illustration. This block is so arranged that it provides a secure scat for T-bars of sections, and is of such proportion and so designed that it may be placed either vertically or horizontally.