[Trade Journal]

Publication: The Clay-Worker

Indianapolis, IN, United States

vol. 36, no. 5, p. 423-4, col. 1-2

LISBON’S NEW POTTERY.

The New Works of The Thomas China Co., at Lisbon, Ohio.

THE NEW WORKS of the above company will, when completed, make one of the neatest and most up-to-date plants in the country. The main buildings are 320 feet in length by 130 feet in width. At the north end of the plant are located the clay shops, which are two stories in height. The whole plant is built of fire brick.

The pottery, as a whole, is very well planned and is built with a view to convenience and economy in the manufacture of their ware.

In the slip house the company will have two seventy-two Chamber filter presses, with gaskets, three singled blunger mills, one double belt-power pump and one sliding motion sifter. This will comprise the machinery in this department, and when the writer visited their works, some two weeks ago, all of the machinery was going in as fast as possible. The pug mill which will be used for pugging the regular body clay is of the horizontal pattern, the company claiming that this pattern mill pugs the clay tighter and taking more of the air out of it on account of the extra worm-push outs in the curved nozzle.

| |||

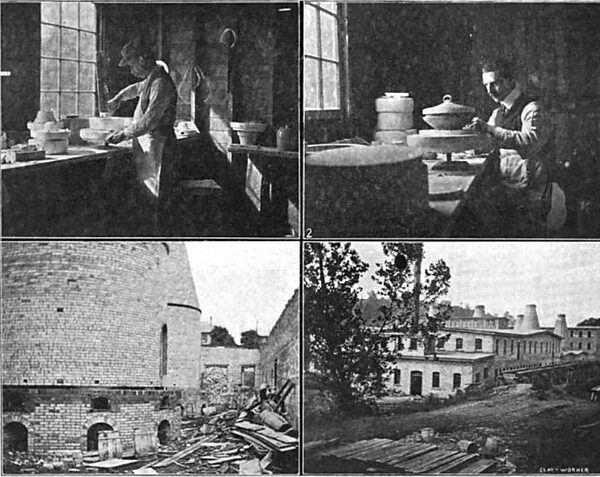

| The Thomas China Co. -- 1. Mould Maker at Work. 2. Mr. Wright Modeling A Dish Cover. 3. Glimpse of A New Kiln. 4. Part of the Plant. |

Just outside of the slip house are the fret chaser-mill and the two color mills, which grind the color for the body.

At one side of the pug mill is located the belt elevator, which conveys the clay to the workmen on the second floor.

On the first floor, and right next to the claymaking department, is located the sagger-making equipment. The machinery in this department will comprise the five-foot dry pan for grinding the broken saggers into grog and the ragger pug mill, which is used to pug the sagger clay after it has been mixed with the grog and tempered and aged.

Next to the sagger-making department is located the green room. This room is well lighted and is of large dimensions, it will be heated by steam.

Next to the green room is located the bisque kiln room. When the writer was at their works the kilns were just completed, and as the accompanying illustrations will show, the carpenters’ and bricklayers’ debris had not, as yet, been cleared away. When completed, the plant will contain three bisque and three glost kilns.

Next to the bisque kiln sheds are located the bisque warerooms, which are spacious and well lighted. After which comes the dipping house and the underglaze department, where all of the underglaze decorating will be done. It is probable that one, and, possibly, two, printing presses will be located in this department for the underglaze decoration only.

Next to the dipping rooms are located the glost kiln rooms, which contain the company’s three glost kilns, which are 16 feet 6 inches in diameter and of the up-draft pattern.

Next to the glost kiln shed is located the three-story portion of the plant, the first story of which will be used as a glost warehouse and packing rooms, the second floor for offices, sample rooms and decorating, the third floor being used for decorating also.

The company propose to operate their own electric light plant and their entire factory will be lighted by electricity. The plant will be heated by steam.

The decorating kilns will be four in number and the company expect to draw their first decorating kiln by the first of the year. They will be in full operation within a week.

All the power for the entire factory is furnished by a 100-horse-power Skinner engine and 100-horse-power Erie boiler. The company will employ, in all, about 250 people.

Regarding shapes and quality of the ware to be produced, the company say that they will have upon the market a ware that is not to be equaled in its class.

All of the modeling is being done by Mr. F. B. Wright, of England. The accompanying illustration will show Mr. Wright at work on the cover dish belonging to the dinner set called the “Regina.”

Another illustration will show the moldmaker at work on the molds for the company’s new ware.

The plant of the Thomas China Co. may be classed, in all, as a most complete and modern pottery.

The officers of the company are George W. Thomas, president; J. W. Boch, vice president; A. G. Mason, secretary and treasurer, and W. F. Keates, general manager.