[Newspaper]

Publication: The Anacortes American

Anacortes, WA, United States

vol. 21, no. 52, p. 1,10, col. 2-5

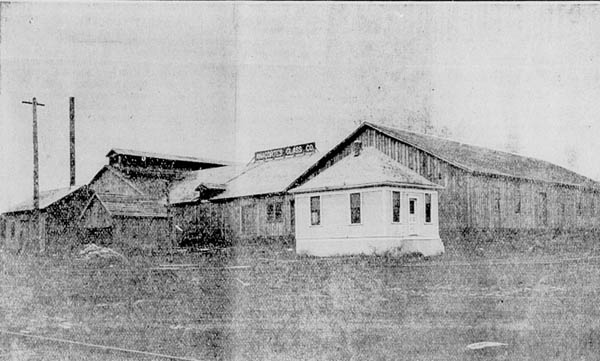

Anacortes Glass Company Plant Now in Operation

|

GLASS FACTORY

NOW OPERATING

SPLENDID EQUIPMENT AND ONLY

EXPERTS EMPLOYED

ORDERS BOOKED FOR SEVERAL

MONTHS' FUTURE DELIVERY

Work at the Anacortes Glass company's plant is humming merrily on as the machinery of the large plant is kept in motion, giving employment to fifty men, while the heat is kept at a steady temperature day and night and never allowed to go out. N. Jerns is president of the company with E. A. MacKay as secretary and manager. Construction on this plant was first begun June 15, 1907, and after the plant was fully finished Manager MacKay was kept busy traveling about the country seeking the best of help and making other necessary arrangements, so that when the plant would once begin manufacturing, it could continue to do so. The floor space of the plant covers 25,700 feet of ground, while the plant is valued at $50,000, and has a capacity of 15 tons of finished product per day. The highest wages paid are from ten to twelve dollars per day, while the lowest wage is five dollars, the monthly payroll for the fifty employes being $7,500. They manufacture fruit jars, bottle of all kinds and telephone insulators. The materials from which the glass is manufactured is a local product, the silica being brought from Orcas island, while the lime rock comes from Roche Harbor and is brought in on scows. The material used has been pronounced by experts as being of the very best obtainable anywhere in the world. The soda ash is brought from Seattle. The big tank in which the material is melted is 12 x 12 x 3 feet deep and is lined inside with 4 inches of hard baked glass, being the only material to withstand the intense heat, which is 2,700 degrees. It took ten days, at the rate of twenty-four hours per day to line it. As this tank is emptied by the glass makers at one end, it is filled with the raw material at the other, in consequence of which it is in constant use all the time, and thus the heat is never allowed to go down. Bottles, fruit jars and insulators are not made by glass blowers, but in specially tempered steel moulds, on a machine very similar to a topping machine at a cannery. The three men operating this machine are experts and are working at top speed from the moment they start the machine until they stop, turning out in one hour's time 400 to 550 separate pieces. The slightest mistake on the part of any one of the three men in handling the boiling glass would mean death or serious injury to one or all. The men wear as little clothing as possible

·

·

[Missing text]

·

·