[Newspaper]

Publication: The Anacortes American

Anacortes, WA, United States

vol. 23, no. 37, p. 1, col. 1-6

DISCOVERY MAY CHANGE CANNING INDUSTRY

PATENTED GLASS JAR

MAY DISPLACE CAN IN

SALMON PACKING FIELD

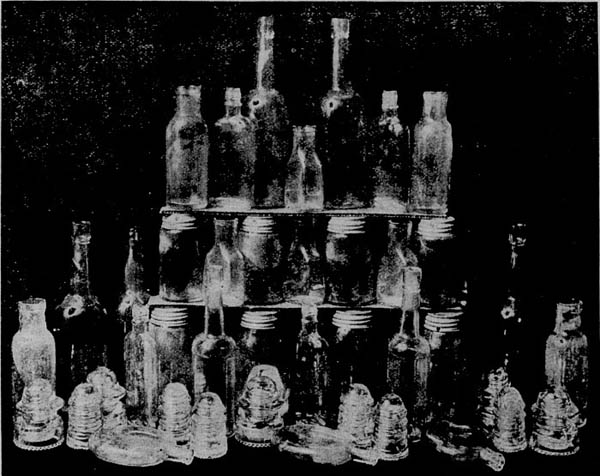

Samples of Receptacles Which Inventors Claim

Will Revolutionize a Feature of Fishing

Industry, Are Being Made at Local Plant

of the Anacortes Glass Company

-- Will Stand Cooking

Tin cans as a method of packing salmon may be a thing of the past in the near future if experiments being conducted at the plant of the Anacortes Glass Company prove successful. . . . [illegible text] . . . a patented process, a firm of Seattle men are having samples of glass salmon jars turned out at the local plant and if they meet all the requirements, the glass receptacles will at once come into great demand and the use of salmon cans will be gradually done away with in Anacortes and elsewhere.

The glass is made be a new process which makes it more durable than the ordinary product and the men behind the invention declare that it will stand the cooking process, in which salmon is cooked after is is . . . [illegible text] . . ., without breaking. It will stand the required amount of heat, and cannot be easily broken under any conditions, they declare.

The advantage of glass jars for cooking salmon is easily seen and this method will at once appeal to all. Glass jars would prove to be the best standard of sanitation and could do away with the possibility of the action of acids which sometimes spoils the contents of cans.

The promoters of the new salmon jars declare that if it comes up to expectations, local cannery men have promised to use a million of the jars in the course of the coming season. The manufacture of glass salmon jars would then become an important . . . [illegible text] . . . of the canning industry and the Anacortes Glass Company would obtain a big field for operation in supplying the local demand.

Exhibits of Work Done by Anacortes

Glass Company Which Is Now Working

Night and Day to Turn Out Orders

|

VARIED PRODUCTS OF LOCAL GLASS PLANT

One thing is sure and that is if the new jar is practical and can stand the heat of cooking, salmon packed by this method will have a vast advantage over the canned product. This will make it necessary for all canneries to adopt the new method.

The samples being made at the local glass plant will hold a pound of salmon. The cover will be put on and hermetically sealed by a patented method which will insure absolute cleanliness and sanitation. Moulds for the new glass jar are being perfected and the samples will be completed and ready for a test by cannery men in a few days.

The Anacortes Glass Company is working two shifts at its plant and prospects are that there will be no chance to shut down to increase the plant's capacity until fall.

The plant is engaged in turning out a big order of brandy bottles for a big wholesale liquor house of Seattle. Two carloads of beer bottles were shipped to Olympia during the past week and the Crescent Manufacturing Company has placed a big order for Mapeline [sic] Mapleine bottles which is being filled on contract time.

If the new salmon jar proves successful, the plant of the Anacortes Glass Company will probably have to be increased, with several cycles devoted exclusively to the manufacture of this product alone.