[Trade Journal]

Publication: Street Railway Journal

New York, NY, United States

vol. 20, no. 2, p. 76-77, col. 1-2

The Seattle-Tacoma Interurban Railway

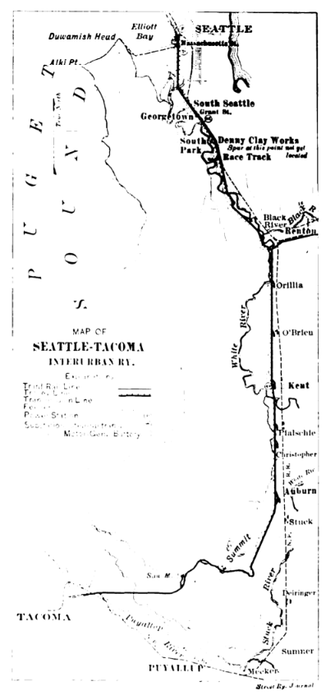

One of the most interesting high-speed electric railways now under construction in America is being built between the cities of Seattle and Tacoma, Wash. The line is about thirty-six miles long from end to end, and is to be equipped with the most modern apparatus available for quick transit.

Starting in the thickly settled part of Tacoma, the line runs easterly across the Puyalup Indian Reservation, through the valley of the Stuck River northerly to Auburn, about 14.5 miles from Tacoma, then passes to the town of Kent via Christopher and Thomas, Kent being about nineteen miles from the starting point. Thence the track extends through O'Brien, Orillia, Renton Junction, and follows the Duwarmish River through Race Track, Georgetown and South Seattle to King Street, Seattle proper, the cars to operate on the tracks of the Seattle Electric Company within the city.

The road is being built largely on a private right of way, extending between the Tacoma city line and Race Track. Current for the trains will be taken from a 100-lb. per yd. third rail on the private right of way and from a oo B. & S. trolley wire on highways. The third rail is to be supplemented by a 350,000-circ.mil cable. The track rails are 70-lb. Chase-Shawmut 500,000-circ. mil bonds will be used on the track and 750,000-circ. mil on the third-rail.

|

| Map of Seattle -Tacoma Line |

Sub-stations located at Saw Mill, Kent and Grant Streets, about 6.5, 19 and 32.4 miles from Tacoma, respectively, will serve as distributing points for the current supply. Current will probably be generated in the new Post Street power station of the Seattle Electric Company in Seattle, transmitted about one mile over a 0000 B. & S. two-phase circuit at 2,200 volts to the Massachusetts Street step-up transformer station. Here four 500-kw water-cooled General Electric transformers will raise the voltage to about 27,500 maximum and feed the high-tension transmission line with 60-cycle, 3-phase current over three No. 1 B. & S. cop-per wires as far as Race Track, where the line will change to three No. 4 B. & S. copper wires and be carried through to Saw-mill substation in this size. The step-up transformers in the Massachusetts Street sub-station are to be equipped with regulating dials giving various secondary voltages with variations in the primary between 2,000 and 2,200. Each transformer is guaranteed to regulate within 1 per cent at 100 per cent power factor, and within 3 per cent at 80 per cent power factor.

At each of the sub-stations there will be one 300-kw motor-generator set, fed by two 180-kw oil -cooled, step-down three-phase two-phase transformers. The machines consist of an eight-pole, 300-kw, 450-r. p. m., 600-volt flat-characteristic, direct-current General Electric railway generator direct-connected to a G. E. 16-pole, 450-hp, 2,200 volt, 2-phase induction motor. Each machine has a 50 per cent overload capacity for two hours. It is expected that the control of the railway current through motor generators instead of rotary converters will give an unusual flexibility in operation.

Supplementing the motor generators and taking up the fluctuations which the trains will superimpose upon each sub-station will be three storage batteries, made by the Electric Storage Battery Company, of Philadelphia. The Grant Street and Kent sub-stations will each contain 288 cells with Type G17 plates, each battery having a capacity of discharging 640 amps. at the hour rate, and the Saw Mill battery will be 288 cells of Type G15, all plates in the three batteries, however, being in Type G23 tanks to allow for future growth. These batteries will be charged and discharged through differential boosters, General Electric Type MP 6-pole, 35-kw, 600-r. p. m. 50-volt to 110-volt generators direct connected to General Electric Type MP 4-pole, 53-hp, 600-volt motors.

These boosters will be designed to bring an average load upon the motor-generator sets. When the line current becomes great the booster's series ampere turns overpower the shunt turns ,generating a voltage in the booster armature coincident in direction with the battery voltage, so that the battery discharges, taking up the fluctuations. At times of extremely light load, the shunt field overpowers the series, giving a voltage in opposition to the battery, and charging it from the generator. At average load the shunt and series fields just balance and the battery floats on the bus-bars, inactive, with the load coming on the generator. The batteries can also be operated without boosters by giving the motor-generators a falling voltage characteristic as the load comes on.

On the Seattle power station current will be derived from two 1600-kw Westinghouse 2,200-volt, 60-cycle alternators. The local cars in Seattle depending primarily on this station will be supplied through 500-kw rotary converters connected to step-down transformers.

The Seattle Electric Company has also at present a connection with the lines of the Snoqualmie Falls Power Company, which transmits power from the Falls thirty-one miles to Seattle and forty-four miles to Tacoma over a 30,000-volt, 3-phase line, using aluminum wire. A recent test on this line made by sending current from the Falls to Seattle, back to the Falls, then to Tacoma and back to the Falls, 153 miles in all, gave, with a line resistance of 241 ohms, 13½ per cent power loss at 60-cycles. The insulation resistance was 70,000 ohms, and the charging power 112 kw.

The interurban transmission line will be made up on red cedar poles 40 ft . to 45 ft. long . spaced 110 ft. to 120 ft. apart. The upper transmission cross-arms will be 8 ft. 6 ins. long by 6 ins. square at the ends, with two pins 7 ft. on centres. The lower arms will be 12 ft . long, 6 ins. x 6 ins. at the ends, with four pins 3 ft. 6 ins. on centres. Thus the transmission wires will be spaced on a 42-in. eqilateral [sic] equilateral triangle. The telephone arm will be at least4 ft. below the transmission arm and standard in size. The railway feeders will be run on standard 4-pin arms. Pins are of eucalyptus, insulators are of the Locke type, with porcelain petticoats and glass supports, designed for a working pressure of 60,000 volts. Lighting arresters will be used in the sub-stations.

The passenger motor cars are to be combination smoking and baggage type, length over end panels 32 ft. 6 ins. and 41 ft. 6 in over vestibules, equipped with Van Dorn automatic couplers, Ham sand boxes, and Hale and Kilburn walkover seats. They are mounted on Brill "27E" trucks. There are also similar cars without compartment to operate both as motor and trail cars. The multiple unit system of control will be used, each motorcar having four G. E.-66 motors mounted on its trucks, giving a rated capacity per car, on the hour basis, of 500 hp. The equipment will probably attain a maximum speed of 60 miles per hour with a 30-ton motor car hauling a 20-ton trailer. G. E. Type M control is to be used on the cars. There will also be two 4-motor G. E.-66 freight equipments in operation, capable of hauling a trailing load of 275 tons behind a 35-ton locomotive at twelve miles per hour. The passenger gear ratio is 1.55, and the freight, 3.95. Two of the motors of each freight equipment are connected permanently in series.

The schedule time and train service of the road has not yet been given out, but the speed capabilities of the equipment and favorable characteristics of the right of way, as regards alignment and grade, except between Saw Mill and Auburn, where 2 percent grades and sharp curves abound, should ultimately cut down the running time to within an hour and a half under favorable circumstances and perhaps better it. Boston capital, principally, is backing the enterprise.