[Trade Journal]

Publication: Cassier's Magazine

New York, NY, United States

vol. 21, no. 3, p. 179-205, col. 1-2

NIAGARA FALLS POWER

THE ORGANISATION OF THE OPERATING DEPARTMENT OF THE NIAGARA

FALLS POWER COMPANY

By Philip P. Barton, Superintendent of the Operating Department

One of the many new problems encountered in the prosecution of the great work undertaken by the Niagara Falls Power Company was the selection and organisation of a force to operate and maintain a power plant capable of delivering continuously electrical energy to the amount of 50,000 H. P. In comparison with the magnitude of the output of this plant, the number of operatives required to handle it, as will be shown later, is astonishingly small, and their organisation is less complicated than that required for conducting the operation of any one of many long established plants for the development and distribution of electrical energy for light and power in large cities. Whatever interest the solution of the problem may possess is due, therefore, not to the overcoming of any peculiar inherent, or unprecedented difficulties, but rather to the magnitude and novelty of the plant, and to the importance, variety, and extent of the interests involved.

It is difficult in a few words to convey a realizing sense of the measure in which the safety, comfort, and prosperity of almost the entire population of the northwestern corner of New York State has come to be dependent upon the revolutions of the mighty wheels of the great power house at Niagara. It supplies the energy for every arc and incandescent light in four cities, having a combined population of nearly 500,000 persons. It furnishes the motive power for every street car moving in and between these cities over 350 miles of track. The Pan-American Exposition realized its crowning beauty in 200,000 glow lamps fed by Niagara power. In Buffalo, the Tonawandas, Lockport, and Niagara Falls are fifty large and important manufacturing establishments, representing an investment upwards of $100,000,000, whose successful operation depends absolutely on the continuous supply of power from this plant. In many of these industries the processes are such that an interruption of power service, even of short duration, means great loss of product, disarrangement of process, and, in some cases, costly damage to plant. Since the power plant is the sole source of the energy which vitalizes interests of such moment, the responsibilities imposed upon the men to whom are committed the operation of the plant and its maintenance are evidently of no mean order, and the question of their selection and systematic organisation is worthy of the most careful thought and study.

| |||

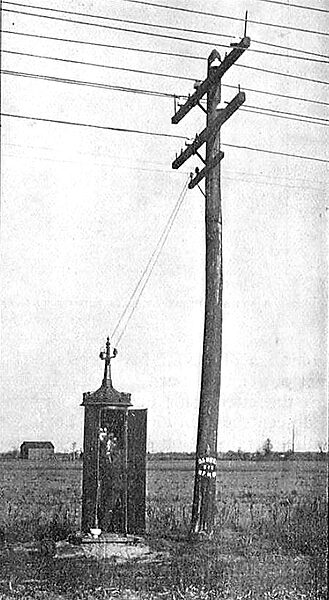

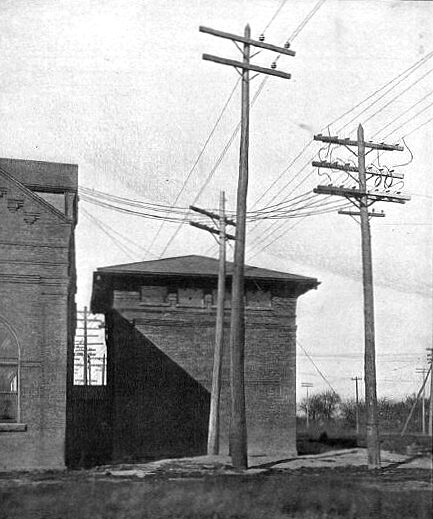

| One of the Patrol Boxes on the Transmission Line |

In March, 1898, Mr. L. B. Stillwell, then electrical director of the company, was commissioned to organize and take charge of a force for the operation and maintenance of the entire power plant. At that time three 5000 H. P. generating units were in commercial operation, and the installation of five others was rapidly approaching completion. Two additional units were contracted for in the fall of 1898, and the organisation established in January, 1899, was designed to take care of the present completed plant, comprising the ten 5000 H. P. generating units in Power House No. 1, together with the necessary local and long-distance distributing systems, and various sub-stations for performing required transformations of the energy delivered to them.

In laying out the organisation, the objects aimed at were: —

1.—To insure the continuous and uniform supply to each tenant of the full amount of power to which he is entitled; 2.—To provide for the constant maintenance of every part of the plant in the best possible condition; 3.—To provide for the immediate repair of any part of the plant damaged by accident or otherwise; 4.—To limit the annual expenditure for operating expense to the lowest amount compatible with the complete attainment of these results.

| |||

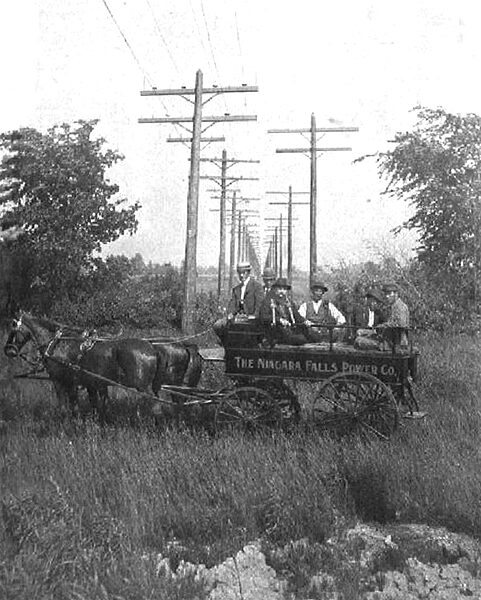

| A Straight-Away Stretch of the Transmission Lines. Emergency Wagon and Crew in Foreground |

It was realized that these objects could be attained only by an organisation thoroughly systematized throughout, having a responsible head on duty at all times, and in which the respective authority and responsibilities of the various employees must be perfectly definite and clearly understood by all concerned. Considerations to be mentioned later led to the establishment of an eight-hour day for the operating force proper, and this force was accordingly divided into three equal eight-hour crews, or shifts, each comprising a completely organized body of men, with a responsible head reporting directly to the superintendent. The maintenance and repair force divided itself naturally into three departments,—one for the care of the hydraulic or motive power plant; one for the care of the electrical plant, including the underground distributing system and the local substations; and one for the overhead long-distance distributing system.

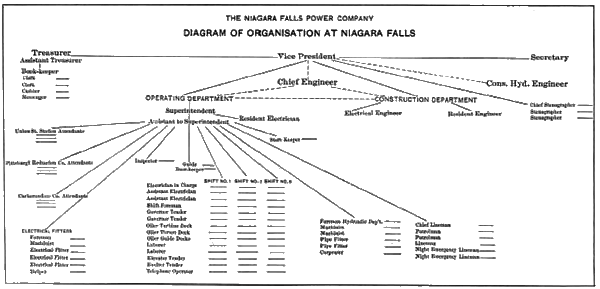

Experience in the operation of the three-machine plant was sufficient to indicate the number and general duties of the employees required for the completed plant, and the light of this knowledge and with the foregoing considerations in mind, a complete skeleton organisation was laid out, as shown in the diagram on page 12. The first appointments to the various positions were made with the utmost care, and a continuous process of judicious selection and elimination was inaugurated, which, combined with the effect of daily training and experience, constantly tends to lift the force to a higher level of efficiency. An experience of three years of actual working has failed to indicate any point in which the general plan of organisation could be changed to advantage.

| |||

| Replacing A Defective Insulator on A 22,000-Volt Line |

In a power plant whose load curve presents no great variation (i.e., whose output throughout the twenty-four hours is substantially uniform), and which, therefore, requires the same number of operatives at all times, there are only two practicable schemes of organisation for the operating force. It may be divided into two twelve-hour shifts, or into three eight-hour shifts. The latter plan has advantages over the former in every respect save that of cost. Its adaption in the present case was made practically obligatory by two considerations:—

1.—The importance of the service demands that every employee on duty shall be always on the alert to detect conditions that might result in accident, and that he shall be at all times in condition to make the best use of all his faculties to meet any emergency that may arise. Under the heavy and nerve-trying responsibilities attaching to some of the positions men cannot be expected to keep available for a prolonged period the requisite mental and nervous energy for more than eight hours daily. 2.—The special knowledge and ability required for the proper performance of the duties of each position can be acquired only by actual experience in that position. The eight-hour plan is the only economical one whereby, in case of the temporary absence or sudden removal of an employee, his place can be filled immediately by an experienced hand. This is done by allowing each of the two other men in the same position to work twelve hours daily until the absentee returns or until a new man can be broken in.

The watches of the respective shifts begin at midnight, 8 o’clock A. M., and 4 o’clock P. M. The shifts rotate each week on Saturday, when the men relieved at 8 o’clock A. M. report again for duty at 4 o’clock P. M., and the men relieved at 4 o’clock report again at midnight. The third shift is thus relieved from duty from midnight Friday until 8 o’clock A. M. on Sunday. Each many, therefore, once every third week has thirty-two consecutive hours off duty to compensate him for working two eight-hour watches (with eight hours rest between them) on each of the two intervening Saturdays. Reference to the diagram on page 12 shows that each shift of the operating force consists of fourteen men in the power station and one in each of the three outside local sub-stations.

| |||

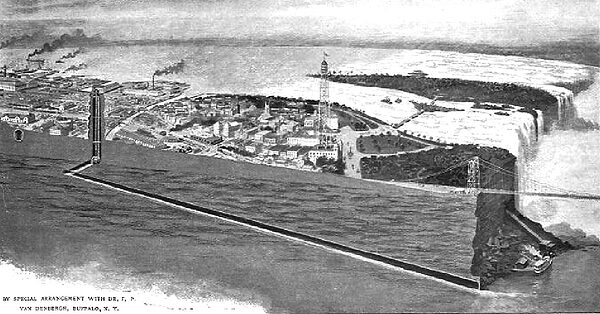

| A Bird's-Eye View and Section of the Niagara Installation. the Distance From the Beginning of the Tunnel at the Wheel Pit to the Point of Discharge Into Niagara River Below the Falls is About One Mile |

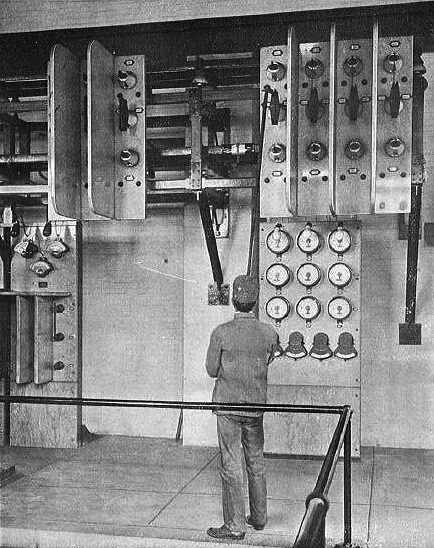

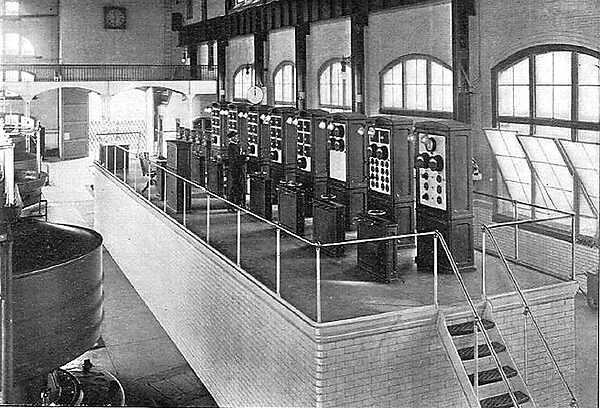

At the head of the each shift is the electrician-in-charge, who has entire charge of the plant and is directly responsible to the superintendent during his eight-hour watch, (1) for the successful operation of the plant; (2) for its maintenance and cleanliness; (3) for the conduct of the men; and (4) for the delivery of the plant in the best possible condition to his successor at the end of his watch. His specific duty is the operation of the two main switchboards, and his post, the captain’s bridge of the plant, is Switchboard No. 1, although he usually directs in person all important switching on Switchboard No. 2.

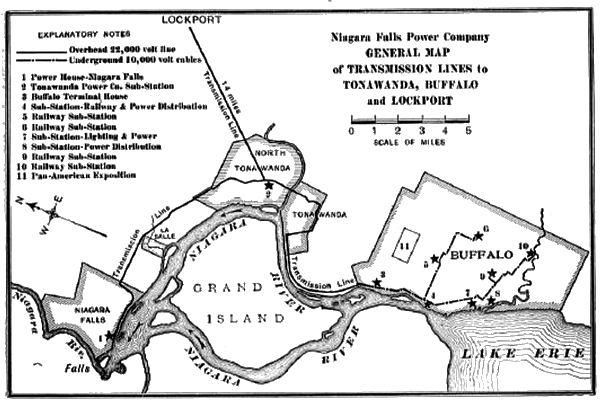

|

| This Map is Reprinted From An Article on Niagara Falls Power Applications in "Cassier's Magazine" for May, 1901, by Permission of H. W. Buck |

The switchboards are the main nerve centers of the plant from which its various functions are directed and controlled. To each of them is brought the entire output of five generators, and from each of them are distributed into varied channels of usefulness 25,000 H. P. in electrical energy. Upon them are located instruments and appliances by means of which the attendant is always informed as to the output and voltage of the various generators and which indicate instantly the nature, and, within certain limits, the location of any disturbance in any part of the system, whether in an alternator a few feet away, or in an underground cable in Buffalo, thirty-two miles distant. In front of the attendant are half a hundred levers controlling pneumatically the great dynamo and feeder switches and auxiliary switches by means of which any desired combination of alternators, feeders, and auxiliary circuits can be made. Here, by a crook of the finger, the attendant can, at will, cut off instantly the entire supply of power or any portion of it.

The successful occupant of the position of electrician-in-charge must possess an unusual combination of qualities. To a considerable theoretical knowledge and ripe experience must be added sound judgment, nerve that cannot be shaken by most trying emergency, the ability to form quick, accurate judgements, and the decision of character and courage often required to act instantly on judgments thus formed. A keen sense of the responsibilities resting on him, and the constant consciousness on the disastrous results that may follow the slightest mistake on this part, must interfere in no wise with prompt and fearless action when required. He must possess a thorough and minute knowledge of the entire plant, from the point where the water enters the inlet canal to the transforming apparatus in the most distant sub-station. He must study carefully the various emergencies that may arise, and since in many of these emergencies instantaneous action is imperative, he not only must predetermine his line of action, but must mentally rehearse it so thoroughly that the time required for forming judgments and arriving at decisions will be eliminated, and the arrival of the emergency will produce automatically the proper action on his part.

One of the assistant electricians is stations at Switchboard No. 2, where his routine duties, like those of the electrician-in-charge, are mainly to take and inscribe in books provided for the purpose half-hourly readings of the various indicating instruments upon his switchboard. Ordinarily his responsibilities are limited to the faithful and accurate carrying out of general and special instructions issued to him by the superintendent of the electrician-in-charge. Since all switching on No. 2 switchboard is usually done by the electrician-in-charge, or under his personal supervision, the attendant at No. 2 board, except in unusual emergencies, has little opportunity to act on his own initiative. While the position apparently demands no very high order of ability, it is important as a school for the development and training of candidates for the position of electrician-in-charge, and the performance of the men at this post, under the circumstances affording any opportunity for the display of special qualifications, is carefully noted. The other assistant electrician is responsible for the cleanliness and good order of the alternators, the main and auxiliary switchboards and other electrical apparatus in the power house. He also has charge of the local sub-station known as the Street Railway Plant, which is located in the north end of the main power house, and consists of three 375 KW, 550-volt converts with their transformers and auxiliary apparatus supplying power to the local trolley lines. He inspects periodically the apparatus in the step-up transformer plant to see that the motor-driven blowers are working properly, and to adjust the water supply to the oil-insulated, water-cooled transformers. He also attends to all switching in the step-up transformer plant by means of which rearrangements are made when required in the connections of the long-distance transmission circuits and the step-up transformers supplying them. These changes are made by means of 22,000-volt switches, and the work, for which specific instructions are issued in each case by the electrician-in-charge, demands the utmost care and precision in its execution. Both of the assistant electricians report directly to the electrician-in-charge.

The shift foreman is responsible to the electrician-in-charge for the operation for the operation of the entire motive power plant, from the point where the water enters the inlets up to and including the bearings in the main generators. He is stationed on the power house floor, and gives his personal attention to the governors and the alternator bearings in which work he is assisted by two helpers on the power house floor. Under his immediate supervision are the oilers, elevator tender, and labourers. The position is one of no small responsibility, and demands considerable knowledge of machinery, a thorough acquaintance with the plant, and experience in its operation. The success of the electrician-in-charge in operating the plant is largely dependent on the effective co-operation and efficiency of the shift foreman.

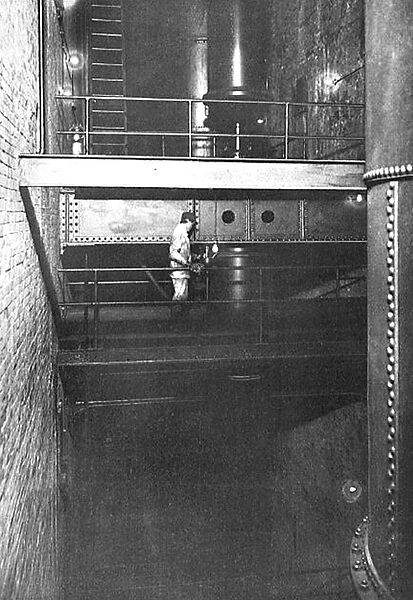

| |||

| In the Wheel Pit. Observing the Temperature of A Guide Bearing on One of the Main Shafts |

The three oilers are located in the wheelpit. One of them is stationed on the lowest, or turbine, deck, where he sees that the turbine bearings are continuously supplied with oil, and looks after the oil-filtering and pumping plant, by means of which the oil, after it has passed through the bearings, is purified and returned to the reservoirs under the roof of the power house, whence it again passes to the bearings under gravity pressure. He also has charge of the two air compressors which supply air for the operation of the pneumatic switches and for other purposes. The second oiler is located on the first deck below the power house floor, known as the thrust deck. He looks after all the thrust bearings located on this deck and the governor-driving mechanism immediately beneath the power house floor. To the third oiler is entrused the care of the main guide bearings of which there are two on each main shaft, and the numerous guide bearings of the four small exciter shafts. Every main bearing is examined at least once each half hour, when its temperature is taken and transmitted to the shift foreman, who records it in a book kept for the purpose, and is thus continuously informed as to the performance of each bearing.

| |||

| Bi-Weekly Inspection. Removing Small Stones and Other Obstructions From the Ports of One of the Turbines |

| |||

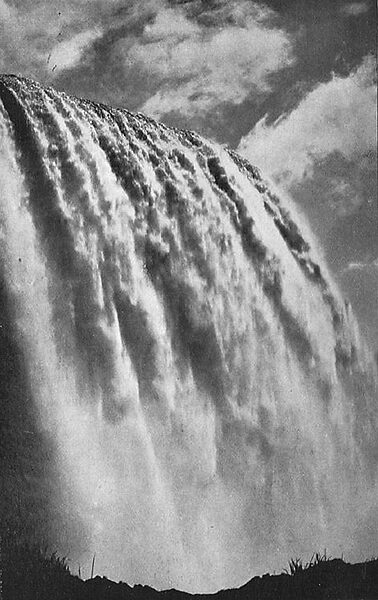

| The Falls of Niagara |

| |||

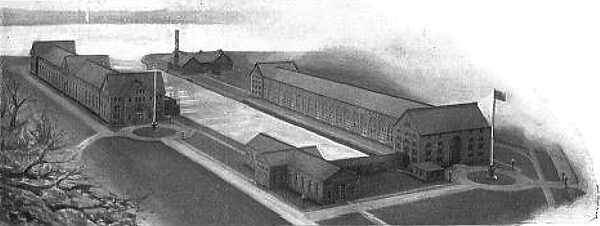

| Bird's-Eye View of the Power Plant As It Will Appear After Completion of Power House No. 2 |

|

| Diagram of the Local Organisation of the Niagara Falls Power Company in October, 1901. the Dotted Lines Indicate Consulting Relations |

The elevator tender has charge of the hydraulic elevator at the middle of the power house, which affords quick communication between the power house floor and every part of the wheelpit. At the north end of the wheelpit is an electric elevator held in reserve for use in case the hydraulic elevator should be, for any reason, temporarily out of service.

| |||

| Removing Eel Grass From the Inlet Racks at the Power House |

| |||

| Preparing for Submarine Repairs to the Inlet Racks |

| |||

| Removing A Section of the Inlet Racks by Means of A Locomotive Crane to Allow Anchor Ice to Pass Through |

The primary duties of the labourers are the removal of eel grass, ice, and other drift material from the inlet racks. When their attention at this point is not needed they are employed in general cleaning about the plant. During the winter months, at times when the river is filled with anchor ice, it is necessary to remove temporarily many sections of the inlet rack to allow the anchor ice to pass through. A steam-driven locomotive crane is utilized to aid in this operation which must be performed with great rapidity. For this work, and to remove the heavy drift ice which sometimes accumulates in the forebay, an extra force of labourers is required. At night this force is in charge of a special foreman who is responsible to the shift foreman for keeping the water at the proper level in the inlets. During the daylight hours, when the regular maintenance crews are on duty and can be called on for emergency work of this character, the foreman of the hydraulic department can conveniently look after it. It involves, at times, keeping an open channel several hundred feet long though the solid ice which forms in the rive at the head of the canal.

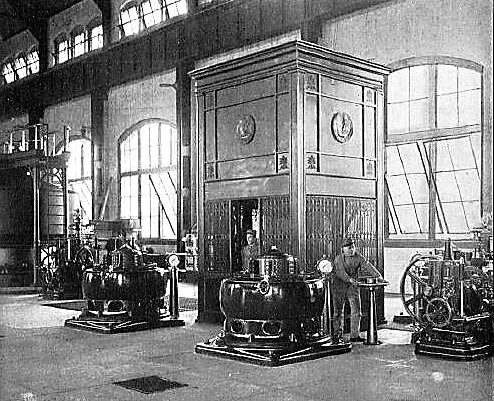

The exciter attendant is stations on the power house floor and has charge of the four 125-KW exciter dynamos located in the vicinity of the hydraulic elevator, each being driven by its own turbine through a vertical shaft. The attendant regulates the speed of the several exciters as directed by the switchboard attendants.

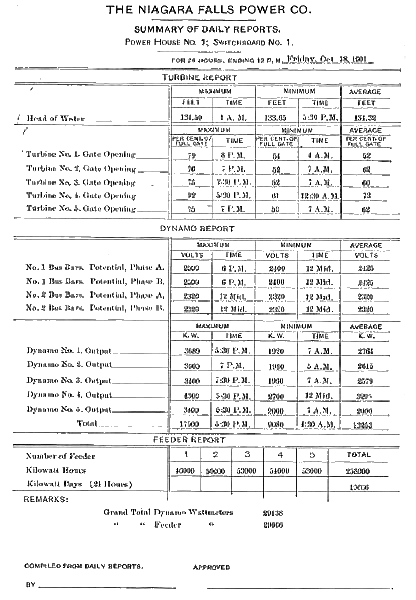

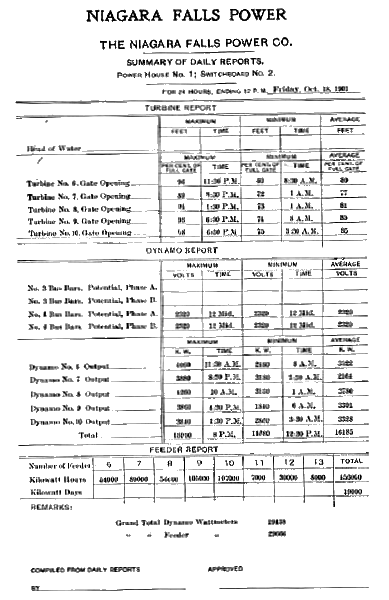

The telephone operator has charge of the private branch telephone exchange located in the office building, whence he has direct communication with the main switchboards, all the local sub-stations, the transformer stations of the various power tenants, the several offices of the power company, and, through a private telephone line, with all the long-distance sub-stations in Buffalo, Tonawanda, and Lockport. The last-mentioned stations can also be reached by a special telephone line strung on the poles of the overhead transmission line. The position of telephone operator is one of considerable responsibility, and requires intelligence, quickness, accuracy in the transmission of messages, and close attention to duty. At times of emergency, when concerted action is necessary between the power house and several sub-stations, much depends on the efficiency and reliability of the attendant at this post. During the night watches the operator uses his spare time in making up from the records of the switchboard attendants and the shift foremen a summary report of the operation of the plant for the preceding day. This report shows, at a glance, the maximum, minimum, and average output of each generator, corresponding data in regard to the gate opening of each turbine, the available head of water, the temperature of the various bearings, the potential of each set of bus-bars, the total output of the plant, and also the total number of kilowatt-hours delivered to each feeder. By comparing the last-mentioned figures with those obtained from the switchboard readings, a useful check on the accuracy of the meters is obtained. A continued discrepancy of more than one per cent, results in a recalibration of all of the dynamo and feeder watt-meters.

| |||

| Connecting No. 2 Transmission Line With the High-Potential Bus Bars by Means of the 22,000-Volt Switches in the Step-Up Transformer Plant |

The guide and doorkeeper are on duty between the hours of 9 A. M. and 5:30 P. M. on week days, and from 10 A. M. to 4 P. M. on Sundays for the accommodation of the numerous visitors who desire to inspect the plant. The public interests in the power house is so great that it was found necessary to appoint a guide in order to relieve the officers and employees of the company from constant demands on their time in conducting interested visitors through the establishment. In order to defray the cost of the guide and to keep the number of visitors within reasonable limits, a small admission fee is charged. The net proceeds of the fund thus created are devoted to the endowment of beds in the Niagara Falls Memorial Hospital for the benefit of employees of the company who may be disabled by sickness or accident.

To carry on work of maintenance and repair which cannot be performed by the regular operating force without neglect of proper attention to the running of the plant, a maintenance force was established. This force ordinarily works ten hours daily, but in case of emergency it is expected to remain on duty as long as circumstances may require. If urgent repairs, requiring several days for completion, are in hand, the force is augmented, if necessary, and is divided into relays so that the work may proceed continuously. The maintenance force is divided into three general groups, though the men are sometimes shifted from one group to another as may be found expedient to facilitate the execution of work in progress.

| |||

| Store House and Lineman’S Headquarters in North Tonawanda |

The foreman of the hydraulic department, assisted by two machinists, a carpenter, and two pipe-fitters, attends to the maintenance and repair of the machinery comprising the hydraulic or motive power plant and the buildings in which the main power plant and sub-stations are housed. This force, with occasional extra help, has proved itself capable of handling all work required to maintain the plant in good condition and to repair damage caused by accidents, besides accomplishing a large amount of work in making the minor alterations and improvements which are constantly suggested by experience in the operation of such a plant.

| |||

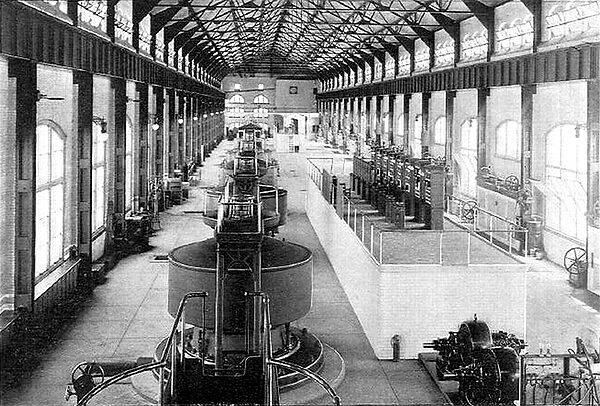

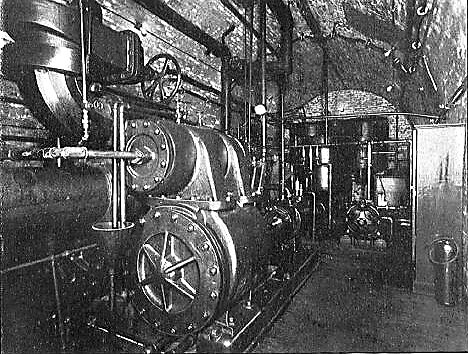

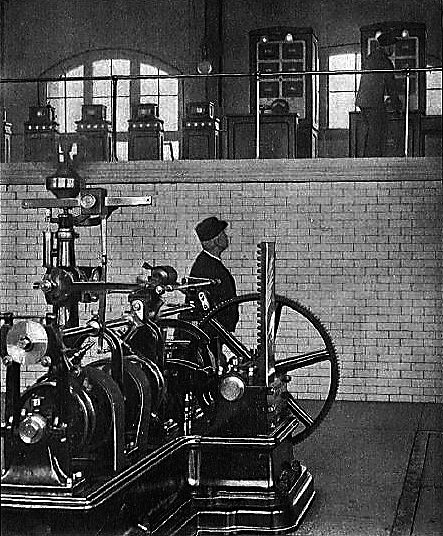

| A Recent Interior View of Power House No. 1 the Equipment Comprises Ten Electric Generators, Each of 5000 Horse-Power |

| |||

| Switchboard No. 1. Electrician in Charge Taking Readings of the Instruments |

|

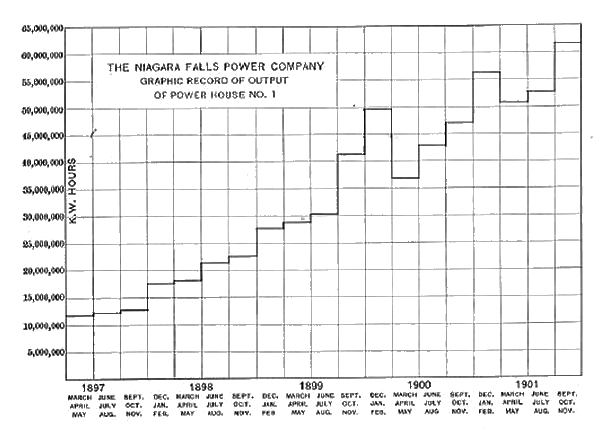

| Diagram Showing the Output of the Plant in Kilowatt Hours for Each Quarter Since March, 1897 |

|

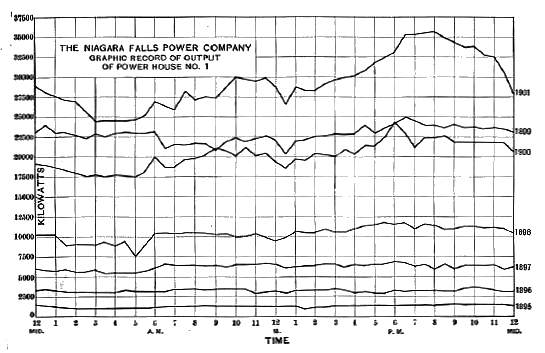

| Diagram Showing Growth of Output by Means of A Load Curve for the Same Day (October 18) in Each Year Since the Plant Was Installed |

The group of electrical fitters comprises a foreman, a skilled machinist and instrument maker, and three or more electrical fitters. A wide variety of work falls to the share of this group, which looks after all the electrical apparatus in the main power plant and the local sub-stations, and also the under-ground cables transmitting power to the local tenants. It is liable to be called on the undertake, at a moment’s notice, any kind of electrical work, from the replacement of an armature winding on one of the main generators, or the reconstruction of a burnt-out transformer, to the building of a delicate measuring instrument.

| |||

| The Exciter Plant and Elevator Enclosure. Governor of Unit No. 5 on the Right |

In addition to ordinary repairs and a large amount of construction work in the installation and rearrangement of apparatus incident to the growth of the plant, it has performed in the building of special appliances and in the alteration of auxiliary apparatus much work of a kind that is usually undertaken only by well-equipped manufacturing establishments. Under the direction of the resident electrician, this force has also carried out many elaborate tests and a considerable amount of original experimental work resulting in useful additions to scientific knowledge and in the development of electrical appliances of practical value in the operation of the plant.

|

| Fac-Simile of A Typical Daily Report, Giving A Resume of the Operation of the Plant for October 18, 1901 |

|

| Fac-Simile of A Corresponding Report Blank, Filled Out, for Switchboard No. 2 for the Same Day |

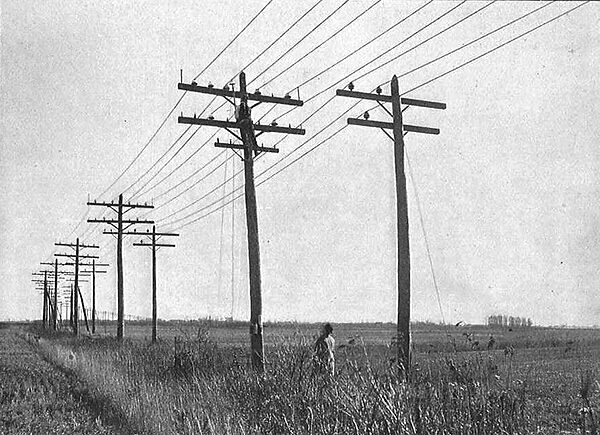

The long-distance distributing plant, by means of which power is delivered to Buffalo, the Tonawandas, and Lockport, consists of three tri-phase, 22,000-volt circuits carried on two separate pole lines, each approximately twenty-two miles long. In North Tonawanda, midway between the power house and the terminal house in which the current is reduced to a pressure of 11,000 volts for underground distribution in Buffalo, is a sub-station where the lines are tapped to supply the Tonawanda Power Company, and where a fifteen-mile branch transmission line, delivering power to Lockport tenants, is supplied with energy. The care of the over-head transmission lines is entrusted to a chief lineman living in North Tonawanda. His force consists of two patrolmen and an emergency lineman stationed at the main power house at night, and a night emergency lineman living at La Salle, about five miles from the power house. The lines are inspected daily by the two patrolmen, each taking half of the line, while the emergency man at Tonawanda remains on duty at the Tonawanda station. In case of trouble on the line at night, two men start from Tonawanda,— one towards Buffalo, the other towards the power house. A man is sent from the terminal house at Buffalo to meet the man from Tonawanda, and the emergency lineman at La Salle follows the line until he meets the other man from Tonawanda. The lineman from the power house proceeds along the line to La Salle and reports from there. In this way the entire line can be covered in a very short time. Reports from the men are received by means of telephones located in patrol boxes at various points along the line.

An emergency wagon, with a complete equipment of all the appliances and material required for every kinds of line repair, is stationed at Niagara Falls, in a stable whose proprietor is under contract to have the wagon horsed and delivered at the power house, ready for a quick trip to any part of the line, at any hour of the night or day, within fifteen minutes after receipt of notice. Another wagon, similarly equipped, is stationed at Tonawanda under the same arrangement.

The night emergency lineman at the power house has been ordered out for the purpose for which he was appointed only once in more than two years of service, and in order to keep him occupied he is made responsible for the cleanliness of the step-up transformer plant and the cable subways in the power house. The emergency lineman at La Salle has also had a sinecure so far as night work is concerned, but is employed by day as one of the electric fitters. The maintenance of a line of this character demands constant watchfulness, and the sometimes dangerous work of remedying defects requires intelligence, nerve, and good judgment.

| |||

| Unfinished Section of House Adjoining the Tonawanda Sub-Station. It Will Contain Switches by Means of Which Any Conductor of the Transmission Lines May Be Divided, to Facilitate Location of A Defect |

A record of more than thirteen consecutive months without interruption of service due to line troubles, in a region infested with mischievous, kite-flying, stone-throwing boys, and hunters, to whom an insulator is shining mark, is the best evidence of the care and vigilance with which the work has been performed. Among the tasks which the line force has been called upon to perform are the replacement of a broken insulator on a “live line,” and the removal and replacement of a pole on the line while in service. Both of these feats were repeatedly performed with conductors charged to a potential of 11,000 volts, and each of them has recently been accomplished without accident or interruption of service with lines in operation at 22,000 volts.

In connection with the organisation of the operating force the questions of storeroom administration and keeping account of operating expenses were given much attention. These questions, while not directly connected with the organisation of a force of operatives, are, nevertheless, important factors in the administration of the operating department, and have a vital bearing on the successful accomplishment of the purpose for which the operating force was established.

|

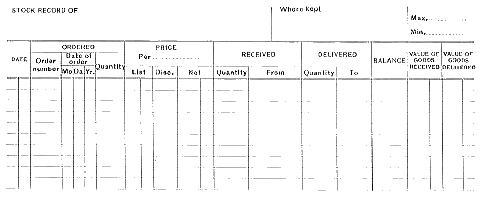

| Fac-Simile of One of the Store Room Cards on Which the Stock Ledger is Kept |

For the successful operation of the plant and the prompt execution of repairs it is necessary to have constantly available not only an ample supply of materials used in routine operation, but also a complete assortment of spare parts of apparatus from which quick replacements or renewals can be made when required. In order to keep the storeroom properly stocked, an accurate list of its contents must be available at all times, and means must be provided to insure the replenishment of the supply of the needed article before the stock has become exhausted. To accomplish these objects, the well-known card system of stock ledger was adopted. Under this system each article carried in the storeroom has a card showing the amount purchased and from whom, the price, the amount issued from the storeroom from time to time, to whom it was issued, to what account it was chargeable, and the amount remaining in stock. The maximum and minimum quantities of the article to be kept in stock are indicated on the card, and when the balance shown approaches the minimum, the storekeeper must make requisition for additional supplies. A complete set of forms was developed for making requisitions, orders for material, and reports, which has proved extremely satisfactory, and by means of this any desired information as to the condition of material in the storeroom and goods on order from the manufacturers can be readily obtained.

The economical operation of any power plant requires that its accounts shall be so kept that the cost of any department for a given period can be readily ascertained, in order that comparisons may be made that will call attention to undue expenditures and thus lead to their elimination. For the purposes of cost keeping, general ledger accounts were established by the treasurer’s department, as here given:—

Motive Power Plant

Electric Generating Plant

Local Distributing Plant (Cables, Conduits and Meters)

Long-Distance Distributing Plant

Step-up Transformer Plant

Railway Plant

Pittsburg Reduction Co. Plant

Pittsburg Reduction Co. Transformer House

Carborundum Company Plant

Carborundum Company Transformer House

Union Street Transformer Plant

Union Street Transformer House

Laboratory and Testing Apparatus

Power House and Office Building

Telephone Line on Transmission Pole Line

Private Telephone Line to Sub-stations — Rental

Telephone Connection to City Exchange — Rental and Tolls

Machine Shop

General Expenses

Sewers and Roadways

Docks

Sidewalks

Lawns and Grounds

Farm Buildings

Farm Lands

Taxes

Insurance

Each of these general accounts was again divided into the following sub-accounts, or as many as were applicable:—

Operation—Labour

Operation—Material

Maintenance—Labour

Maintenance—Material

Maintenance—Contracted for

Repairs—Labour

Repairs—Material

Repairs—Made under Contract

Inspection and Testing

Oil for Lubrication

Lighting—Incandescent

Lighting—Arc

Improvements and Betterments

All items of cost, whether for labour or material, are thus readily distributed, each into its own proper account. A book containing a complete list of all the accounts is kept in which the expenditures for each month are brought together in parallel columns, so that the cost of any department for a given month can be compared with the cost for the corresponding month of any other year, or with the cost for any other month. These comparisons are of the greatest assistance in the economical administration of the operating department, and the system of accounts furnishes, in minute detail, ready information as to the cost of operation, maintenance, or repair of any department or of the plant as a whole.

| |||

| Oil Pumping and Filtering Plant and Water-Driven Air Compressor Located in Chamber Adjoining the Turbine Deck, 150 Feet Below the Power House Floor |

To what extent has the organisation herein described accomplished the objects aimed at in its creation? It is obvious that the efficiency of the organisation and that of its personnel must be judged by the record of the operating plant for the period of nearly three years which has elapsed since the organisation was established. During this time the supply of power has suffered total interruption on only one occasion, when a temporary failure of the water supply, caused by an ice jam in the river, necessitated an eighteen-minute shutdown. During the year 1900 general interruptions of service to the local power tenants amounted to only thirty-seven minutes in the aggregate. Between November 7, 1900, and October 25, 1901, there were only two general interruptions of the local service, aggregating thirty minutes in duration. The long-distance service, depending, as it does, on a system of overhead lines exposed to lightning and the wanton interference of mischief-makers, delivering power to an extensive installation of underground cables working under very high voltages, has necessarily been subjected to occasional interruption, which, however, have rarely exceeded five minutes in duration. As stated by Mr. L. B. Stillwell, in a paper on the Niagara plant recently read before the American Institute of Electrical Engineers, “of the various troubles that have occurred in operation, those due to mistakes or lack of vigilance constitute a proportion quite insignificant.”

|

| Synchronising A 5000 Horse-Power Alternator. the Governor Attendant Adjusts the Speed, As Shown by An Indicator at the Extreme Right, Not Seen in the Engraving, Until the Machine is “In Step” Then the Switchboard Attendant Closes the Switch, Parallelling the Machine With the Others |

In the opinion of the writer, the record warrants the conclusion that the first object of the organisation has been as nearly attained as has been possible under the conditions imposed. Each department of the maintenance force has earned for itself a well-established reputation for thorough, conscientious, energetic work. The present condition of the plant and the fact that on more than one occasion anticipated complaints from tenants on account of temporary partial suspension of power service have been turned into expressions of gratified surprise at the celerity with which required repairs have been made, testify to the thorough accomplishment of the second and third aims of the organisation.

| |||

| Working Model of Power House No. 1, Shown the Pan-American Exhibition at Buffalo |

In respect to the fourth object, which relates to annual cost, experience has shown that the operating force is not larger than is required to handle effectively the emergencies that sometimes arise. The maintenance force for the care of the hydraulic plant and the electrical plant is somewhat larger than is necessary for the execution of ordinary repairs, but since the spare time of this force is always profitably utilized in construction work, the surplus labour does not add to the maintenance charges, yet is always available for cases of emergency. The employment of patrolmen for the daily minute inspection of the long-distance transmission lines, and of emergency linemen, is amply justified by the importance of the service and the consequent necessity for prevention of accidents and for the prompt location and repair of any defect that may develop in any part of the system. The broad-minded policy that has been consistently adhered to demands that no reasonable outlay tending to secure continuity of service shall be withheld, and in view of this policy the force employed, while ample for the purpose, is not larger than is required for the complete attainment of the aims of the organisation.

The broad view taken in the adoption of liberal factors of safety in the working of the organisation has been made possible by the gentlemen composing the board of directors of the company, to whose provision of ample means for its creation and maintenance the success of the organisation is largely due.