[Trade Journal]

Publication: Electrical World

New York, NY, United States

p. 82, col. 1-2

Surface Resistance Defies Fog and Smoke

By JOHN J. TAYLOR

Development Engineer, Ohio Brass Company, Mansfield

Research showed that for satisfactory performance in districts exposed to fog or contaminating influences such as smoke, dust, cement, salt, oil spray and chemicals, a suspension insulator should have high resistance to corrosion, freedom from radio interference, long leakage distance, and high surface resistance and should provide for self-cleaning of exposed parts and for close coupling with liberal clearances between units.

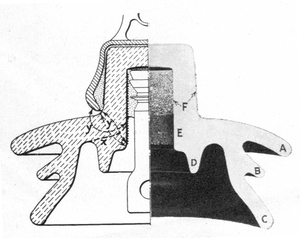

Because corrosion is likely to occur in coastal fog areas, a recessed cement level between pin and porcelain was decided upon for an improved design. With this cement terminating on a level with the cap bead, the high flux density in this zone on energized units would produce corona and radio interference. Hence, flux termination point of the cement pin mass was moved down from the zone of highest electrical stress.

Added protection against radio interference was provided by an inner petticoat-metallized in the pinhole which acts as a flux control, causing the field from the edge of the metallizing to be directed into the porcelain instead of tangential to the surface. Metallizing was extended a short distance under cement surface, with which it made electrical contact, so cement and metallizing would be at the same potential.

Exterior petticoating, similar to that used in one-piece, multi-shed pin-type insulators, was designed to offer maximum exposure to cleaning by wind and rain, to break up drip water and to permit rugged sections on parts subject to mechanical damage. Along with the deep inner petticoat, these exterior petticoats gave an overall leakage distance of 17 in., more than 40 per cent in excess of a standard 10-in. suspension. Measured as an integral along the leakage path, surface resistance was 60 per cent greater than for conventional 10-in. units.

|

| Suspension Insulator Defies Smoke and Corrosion. Wide Spacing Between Outer Petticoats (A), (B), (C) Minimizes Inter-Petticoat Sparking,, Deep Inner Petticoat (D) Acts As Flux Control, is Metallized in Pinhole (E) for Freedom From Radio Interference |

To prevent sparking from the cap of one insulator to flange immediately above it, the shell was given a 10-in. diameter and a 4-in. droop, providing liberal clearances between units spaced at 6t in. This also helps to avoid short-circuiting caused by drip water in between adjacent units near lower end of long suspension strings.

Offered under the trade name "Smogtype," the unit has a dry flashover value of 105 kv., wet flashover value of 55 kv., dry arcing distance of 9.6 in., wet arcing distance of 4.7 in . and an M. & E. rating of 15,000 lb.