[Trade Journal]

Publication: The Purdue Engineer

Lafayette, IN, United States

vol. 33, no. 6, p. 127-128,145-146, col. 1-2,2

Builders Turn to

MOULDED GLASS

W. J. Harris Jr., Ch. E.'40

GLASS IS ONE of the oldest materials, but it has been known and used in western countries for only a relatively short time. Europe's first experience with glass came after travelers to the Orient returned with utensils and bottles made of a hard, shiny, transparent substance. Evidence that use was made of glass centuries before that time is found in Egyptian tombs. Here bottles known as tear bottles have been found, which are conservatively estimated to be five thousand years old. In ceremonies of burial, the women cried, preserved their tears in bottles, and placed them with the remains. Even after five thousand years, the glass in these bottles shows little evidence of change.

Artisans of three thousand years ago used glass for decorative purposes. Articles made of it are found in Phoenician temples and in religious buildings on the Island of Crete. When glass was finally brought to the West, Europeans found it very useful. Their artisans found it a material suitable for artistic experimentation; their alchemists found it satisfactory for making apparatus. Venice was the center of glass artistry in the Middle Ages. Techniques of glass staining were developed here that have not been matched in later years. Her workers were so jealous of their skill that they guarded their procedures closely and severely punished anyone who tried to smuggle their secret out of the city. Because of this rigorous censorship, it was not until the twelfth century that the information finally leaked out. From this secretive origin, glass has come to occupy a very important place in scientific experimentation and in civil life. All optical devices require glass. The modern chemical laboratory contains row upon row of glass containers and glass apparatus of all sizes and shapes. The electric light bulb, dishes, canned foods containers, mirrors — these and many other objects exemplify the importance of glass in modern commercial and domestic life.

| |||

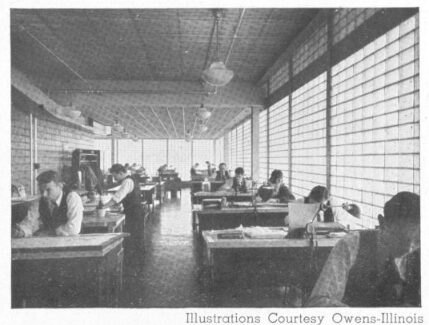

| Glass Brick Walls Aid Office Illumination |

Until very recently, glass played only one part in construction; it served as a transparent medium which would exclude the elements while it passed light. At the present time it has a great many different applications. For example, it is used as an insulator for telephone, telegraph, and power lines, as a thermal and sound insulator, as a corrective for poor acoustics, and as a decorative material. Wherever sanitation and cleanliness are paramount, glass is used.

Two new forms have been developed to satisfy certain demands, namely, fibrous glass and glass bricks.

Although fibrous glass has been made on a small scale by hand production methods for several years, only the last two years have seen its manufacture in quantities of commercial importance. Large scale procedures permit rather close tolerances to be kept on the product of today. The glass fibers are from 0.00015 inches to 0.0004 inches in diameter. Their tensile strength is equal to that of steel of the same diameter. This high strength, accompanied by the small cross-section, allows the strands to be bent without breaking. This property gives uniform space dispersion with the same density of packing. Since density of packing varies as the temperature range in which the material is to be used changes, uniform space dispersion is an essential quality of the insulator. At normal temperatures a packing of one and one-half pounds per cubic foot has a thermal conductivity of 0.28 B.t.u. per square foot per degree Fahrenheit difference in temperature per hour. At three hundred degrees the packing must be three pounds per cubic foot, and 0.42 B.t.u. per square foot per degree Fahrenheit is transferred. The upper limit of successful usage is nine hundred degrees. This temperature requires a packing of four and one-half pounds per cubic foot, which transfers 0.6 B.t.u. per square foot per degree. Fibrous glass is a sound insulator as well as a heat insulator. Tests show that it absorbs 82 percent of sound in a range from 250 to 2,000 cycles per second. In these tests one to three inch layers of padding were suspended on one and two inch wood battens. Fibrous glass has found other uses besides as insulation. Yarns woven from it have peculiar properties which make them suitable for a great many industrial applications. Fabrics made from glass yarns resist corrosion, high temperatures, weathering, rotting, shrinking, and fading. They maintain their strength under severe physical and chemical stresses and at low and high temperatures.

Fibrous glass, one of the most recent products of industrial research, is making a place for itself in the modern industrial world. Its many unique properties foreshadow a wide application in the future.

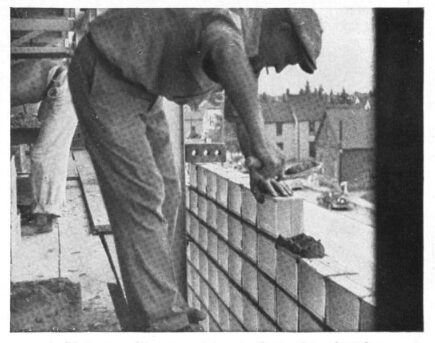

Before 1929 the saying that "people who live in glass houses shouldn't throw stones" was true. Today there is a great supply of glass blocks available for building houses which will withstand the shock of a stone thrown many times harder than the average person can throw. In private homes as well as in factories and office buildings, exterior walls, partitions, basement foundation walls, and entrances are being made of glass bricks. Cost of installation is not excessive because masons can lay them using ordinary mortar.

Many years of experimentation were necessary to perfect a size and shape of brick as well as a method of large-scale production. The present bricks are made in many designs, but in only three standard sizes. Of course, special sizes can be fabricated on demand. The multitude of designs serves two purposes: first, it permits unusually attractive panels to be made; and second, it makes possible regulation of the amount of light transferred. Some designs pass four times as much light as others. The transmission of light by glass bricks is one of their most important properties because it allows great savings in the amount of artificial light necessary, and it gives pleasing illuminative effects. From fifteen percent to eighty-five percent of the total light falling on the brick is transmitted, as compared to ninety percent transmitted by plate glass. However, the light is only one-eighth as bright. Since the light is more diffused, no sharp shadows are thrown. Objects are not visible through the bricks because fluting and designs on the sides obstruct the vision.

The hollow bricks are made in halves in presses. Thus the cross-section area can be controlled within rather close limits. After the halves are formed, and before they can cool appreciably, they are either heated and fused together or dipped into some alloy and welded on the edges. Since this operation is carried on while the bricks are at a temperature of well over one thousand degrees, there is little water vapor present in the trapped air, and there is only a small amount of air. On cooling, a vacuum of at least fifteen inches of mercury is formed inside the bricks.

| |||

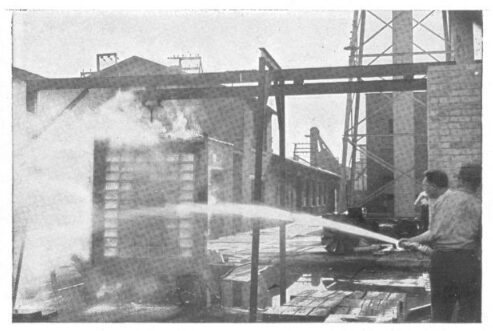

| Quick Temperature Change Test for Glass Brick |

This vacuum gives rise to the second important property of glass bricks, namely, their insulating ability. Tests show that their heat transfer value is from 0.3 to 0.5 B.t.u. per sq. ft. per hour per degree F. This value compares favorably with that of an eight inch clay brick wall. The brick used in the test was of standard thickness, three and seven-eighths inches. Not only are glass bricks heat insulators, but also they are sound insulators. In a frequency range from one hundred twenty to thirty-five hundred cycles per second, an average of thirty-five decibels was lost in the passage of sound through a panel of bricks. A partition of these bricks would effectively screen office workers from factory or traffic noise, making possible more efficient office work.

A question in many people’s minds is, "Is glass strong enough to be used as a structural material?" Tests have been carried out which show that glass bricks, either singly or in panels, exceed the strength of granite, concrete, or brick in compressive resistance. A layer one brick thick would support the five hundred fifty-five foot granite shaft of the Washington Monument. A panel of bricks three blocks by four blocks withstood one thousand pounds per square inch compressive pressure. Their tensile strength is about ten thousand pounds per square inch. These values have adequately answered all queries about the strength of glass bricks. The blocks have been approved by various safety councils in the country as being safe for use as a material for the construction of non-bearing walls.

A question of great importance, though not immediately obvious, is that of the bricks' fire resistance. Everyone is familiar with occasions when dishes break because they have been subjected to sudden changes in temperature. What, then, would happen to a panel of glass bricks when a fire is playing against its internal wall and a jet of water is streaming against its external surface? The American Society for Testing Materials and the New York Labor Department have standard tests through which the bricks were put. The first test requires that the material being tested be heated to eighteen hundred fifty degrees F. in one hundred minutes, while the second test requires that the material be heated to sixteen hundred degrees in thirty minutes and that this temperature be maintained for forty-five minutes. In both cases, following the heating, the panel undergoing the test is withdrawn from the furnace and placed under a stream of water shooting from a fire hose under standard pressure. The glass bricks successfully withstood the sudden change in temperature and subsequently were approved as fireproof windows by the New York Labor Department.

| |||

| Using Ordinary Mortar to Lay Glass Bricks |

Glass bricks possess other advantages that are not often recognized. Although a great percentage of the light that strikes their surface is transmitted into the room, heat rays are not transmitted. This property will be a great help to ventilating engineers who have as one of their most difficult tasks the problem of keeping buildings cool in the summer. While the bricks exclude heat rays, they permit ultra-violet rays to penetrate. This should improve the health of workers who must stay indoors in the day time. It will give them an opportunity to be exposed to the rays of the sun which cause the formation of vitamin D, the vitamin which helps the body resist infections. No longer will it be necessary for one to go to the seashore to get a sun tan in the winter. All he will need to do is retire to his bedroom and open the shutters on the glass brick skylights.

In the past public schools have been poorly lighted and poorly ventilated. A school building should have more natural light in the halls and class rooms, a means of admitting more light without allowing more heat loss, a proper ventilation system no longer subject to the whims of the class room master, and a more extensive elimination of dust, dirt, and noise. To a large extent glass bricks have satisfied these needs. More window space in the form of glass panels admits more light to corridors and rooms. The insulating properties of glass bricks have resulted in smaller heat losses. An improvement in ventilation has come about through the installation of a mechanical ventilating system in the ground floor of the school with automatic controls to regulate temperature and humidity. This takes the responsibility of keeping these factors controlled from the individual school teacher. Proper filters and electrical precipitators have greatly reduced the dust content of the air, and windows can no longer be opened to let more dusty air into the building. As a final improvement, glass bricks have reduced outside noises to such a degree that they have lost much of their distracting power. Because of the many advantages which come from the use of glass bricks they are certain to find wide usage in the construction of new school buildings.

A few years ago it was stated that glass had the makings of a revolutionary material because it is harder, smoother, more colorless, and cleaner than any other mass material. Glass is living up to expectations. Radically different designs have been developed by architects who are trying to make possible more complete utilization of the unique properties of glass. New uses to which it is being put are truly revolutionary. From Egyptian tear bottles to walls of buildings in the past — what will the future of glass be?