[Trade Journal]

Publication: Street Railway Journal

New York, NY, United States

vol. 21, no. 12, p. 455, col. 1-2

A NEW THIRD-RAIL INSULATOR

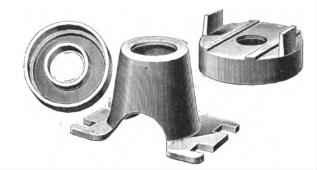

A simple, reliable and satisfactory insulating support for the contact-rail on third-rail roads is one of the details in construction work that has attracted the attention of engineers engaged in that line of railway construction. Several devices of this kind have been described in these columns, but no extended particulars have been published of the insulator designed for the Aurora, Elgin & Chicago Railway Company by Ernest Gonzenbach, constructing electrical engineer of that line, and which is a radical departure from all previous efforts. Illustrations of this device are shown in this article, and it will be noted that it embodies several new features.

It consists of but three pieces, which are not fastened together in any manner, but they are kept in their relative position by the weight of the contact-rail. For an insulation Mr. Gonzenbach employs a standard compound, which is practically the same as that used on regular overhead trolley fixtures. The principal difference in this compound is that it is much tougher and of greater tensile strength, due to the introduction of a specially prepared fibrous material. This insulation, which is in the form of a ring or inverted cup, is so placed that it is out of reach of all mechanical injury, shocks or strains. The shape of this insulating ring is such that there can beno shearing strain on any of the insulation, and the only strain it is subjected to is that due to the weight of the rail, which does not exceed 50 lbs. per square inch even with the heaviest rail.

|

| Third-Rail Insulator |

In view of the fact that com-pound insulations of this character are used in overhead work under constant strains of about 1000 lbs. per square inch and over, the margin of safety is very large in this third rail support. The base casting and the insulating ring, being both of considerable diameter and extending over almost the entire surface of the rail base, it will be seen that movement of the rail over this support, due to expansion and contraction, cannot exert any leverage or strain tending to break the insulation, as is the case in other types of supports. As the three parts of the device are entirely separate and not held together by anything but the weight of the rail, there is no tendency for the contact rail to drop with any slight sinking of the ties as the car passes . The result is that there is no corresponding strain upon the insulating support, as the metallic rail-cap holds fast to the rail and the under portion of the support follows the sinking motion of the tie. Provision is made in the insulator for a 2-in. movement of this character, and this can be made even greater if desirable. The top cap has the usual lugs, which are bent over the heel of the rail with sufficient clearance to allow the rail to move without straining the cap longitudinally. The base shell and the rail cap are made of malleable iron.

|

| Parts of Third-Rail Insulator |

The arrangements of skirts or petticoats on the insulating portion, as well as the rail cap, is one of the most important features of this device, producing, as it does, a third-rail support that is absolutely impervious to salt or lime commonly used to cut sleet and ice from the contact-rail during the winter season. That the insulator is not affected by this was shown during the winter just past on the Aurora, Elgin & Chicago Railway, where these insulators are now in use in large quantities, there being no trouble whatever on this road on account of salt or lime applied to the rail. This insulator is being manufactured and sold by the Mayer & Englund Company, Philadelphia, and will be known as the "Keystone" third-rail insulator.