[Trade Journal]

Publication: Street Railway Journal

New York, NY, United States

vol. 20, no. 23, p. 887-895, col. 1-2

THE WORCESTER & SOUTHBRIDGE STREET RAILWAY

For several years Worcester has been the most active center of street railway construction in the Eastern States. The amalgamation of nearly all the lines in and about the city into the Worcester Consolidated Street Railway Company gave the opportunity to increase greatly the facilities for local traffic and improved the suburban and interurban service of many of the roads brought under the control of the general management; yet, in spite of the fact that the Consolidated operated a large number of lines extending to adjoining towns, there were left many routes. which offered tempting inducements to the promoters of interurban railway enterprises. The most recent of these, the Boston & Worcester, was described in these pages two months ago. Another road which was opened this year, and which has just closed a most successful summer season, is that operated by the Worcester & Southbridge Street Railway Company, and forming the subject of this article.

| |||

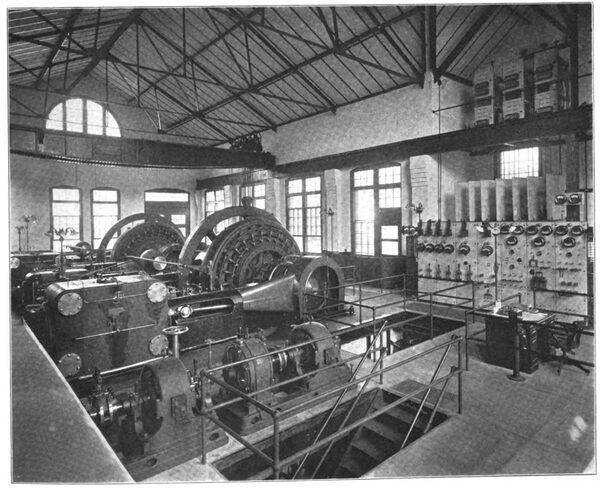

| Engine Room in Charlton Power House |

Massachusetts has been conservative in the matter of its street railways, as in other things, and the managements of its two principal systems, the Boston Elevated and Worcester Consolidated, have adhered to simple direct-current distribution. The necessities of the newer roads, however, have prevented this policy from being made general throughout the State, and some of the finest examples of high-tension distribution work for long railways are now to be found there. Second to none in excellence of construction and operation is the Worcester & Southbridge. This road runs from Worcester to Southbridge, a distance of about 20 miles, owns more than half its right of way, and controls the Southbridge & Sturbridge Street Railway Company, over whose tracks it has entrance to the center of Southbridge. It also controls the Worcester, Rockdale & Charlton Depot Street Railway Company, the connecting link between the Auburn & Worcester line and the tracks of the Worcester Consolidated, and by arrangement with the latter road can bring its cars directly to the City Hall Square, the heart of all the radiating lines. The following towns act as feeders: Southbridge, Sturbridge, Brimfield, Wales, Charlton, Brookfield, Oxford , Webster, Dudley, Leicester, Auburn and Worcester.

| |||

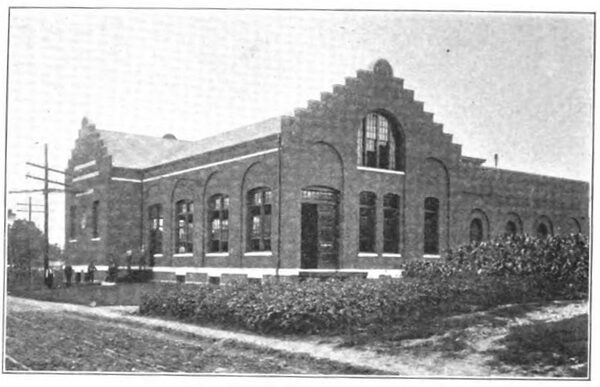

| Power House at Charlton, Mass. |

The prospects are very bright for the extension of the road and the building of branches. Already material is on the ground for the building of a branch from North Oxford to Rockdale and Leicester. The capacity of the power station is ample to accommodate much larger loads than is at present required of it, but should an increase be necessary the building can readily be enlarged and one or more additional generators be installed. The transmission is at 11,000 volts, so that the line might be considerably lengthened without changing the type of central station or sub-station equipment. That such extension will be made in the near future in the direction of Hartford is practically assured, and, when completed, this system will provide a direct and almost straight line from Worcester to Hartford, a distance of about 62 miles.

|

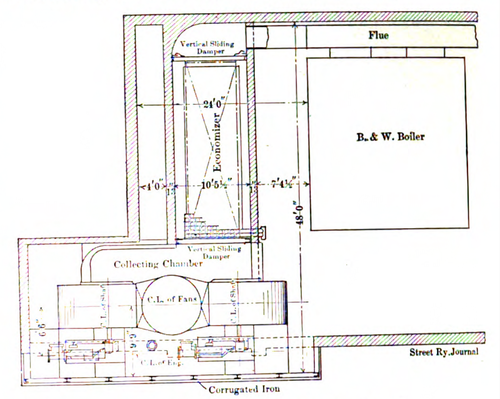

| Economizer and Mechanical Draft |

The 20 miles of road already completed run through a magnificent New England country, with fine scenery throughout the entire distance. The service which has been provided has made this route a most enjoyable pleasure and excursion run for summer trips, but the arrangement of the closed cars is such that even in the colder weather there will probably be much pleasure riding. A half-hour schedule is at present in operation, and the service is such that, although a single-track road, there is little trouble in keeping the runs up to the time-table and pre-venting delays at the turnout.

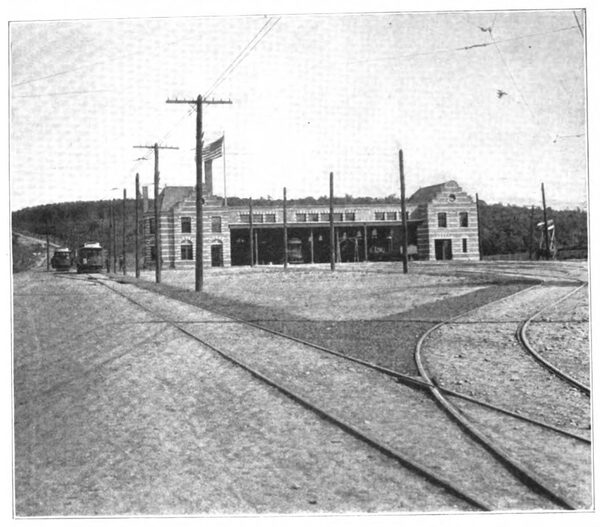

POWER STATION

The power station, which supplies the entire line, is at Charlton City, a little more than half way between Worcester and Southbridge. The site is on an old water privilege, which allows ample water for condensation for the present plant, with sufficient surplus for supplying a duplication of the apparatus now installed should occasion require such enlargement. This water is excellent for boiler feeding purposes as well.

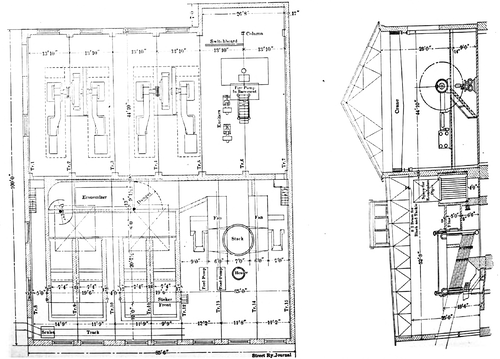

The building is a handsome brick structure with granite and terra-cotta trimmings, and is located on the banks of the stream supplying the condensing water. It has 85 ft. 8 ins. frontage by 100 ft. deep, and is subdivided by a brick wall into an engine room 44 ft. 6 ins. deep, and a boiler room. Under the floor of the engine room is a basement 9 ft. high, which is well lighted and contains the condensers, fire pumps, large transformers, some of the heavier rheostats, oil room, etc. The engine room is 23 ft. high at the sides and 45 ft. to the peak of the roof. At the end of the engine room is a shipping platform and large doors, while the entrance for ordinary usage is at the front. At the side of this entrance the front wall projects out considerably, giving accommodation for the high-tension switchboards.

|

| Plan and Sectional View of Power House at Charlton City, Mass. |

The building has damp-proof granite underpinning extending entirely around it. The roofs are made of fire-proof material, terra-cotta slabs supported on steel trusses and evened off with cement to receive black slate for the pitched roof, and tar and gravel on the level portions. The boiler room is ventilated by two deck houses on the roof immediately above the boilers, each 12 ft. square, and fitted with pivoted sash, while sufficient ventilation is given to the engine room by the large windows extending up into the peak of the roof at the gable ends. The floor of the basement under the engine room and that of the boiler room are made of concrete cement. The engine room floor is constructed of masonry arches supported by steel girders, and consists of crushed stone and Portland cement concrete. All foundations for engines and generators are laid up in solid brickwork in Portland cement mortar and thoroughly grouted in liquid Portland cement. All visible masonry, including settings for fans, pumps, condensers, etc., and all ceilings, are coated with water fire-proof paint.

|

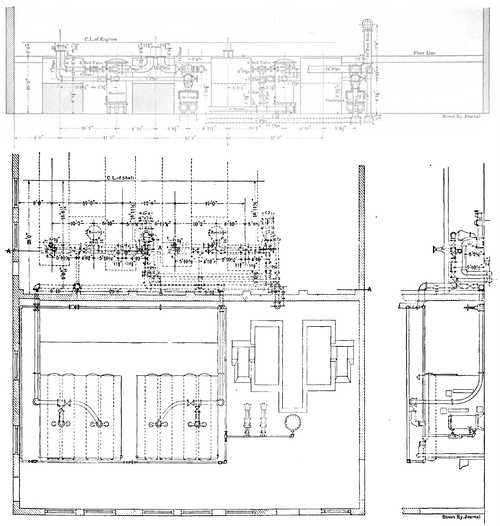

| Plan and Elevation for Steam Piping |

The boiler equipment consists of four 300-hp water-tube boilers made by the Babcock & Wilcox Company, arranged in two batteries of two boilers each. The safe working pressure for these boilers is 160 lbs. Roney mechancial [sic] mechanical stokers, operated by Westinghouse engines, are attached to each boiler. Induced draft is supplied by two engine-driven, direct-connected fans, placed at the base of the stack. This stack extends a few feet only above the roof, the mechanical draft being depended upon at all times. As each fan is large enough to operate a plant of twice the size of the one now installed, no difficulty from lack of draft is possible even should one of them become entirely disabled. Above the boilers are placed economizers made by the Green Fuel Economizer Company. The mechanical scrapers for keeping the tubes of these economizers in a clean condition are operated by shafting belted to the fan engines at the base of the stack. The feed-water is passed through a National feed-water heater supplied with steam from the auxiliaries, and is raised to a temperature of about 290 degs. F. before entering the boilers. Two Dean feed pumps, either of which is large enough to supply the four boilers, are installed. Between the engine room and the boilers is the Holly steam loop and gravity return system, which returns all water of condensation to the boilers, the steam jackets with which both the high-pressure and low-pressure cylinders of the engines are fitted being connected thereto.

| |||

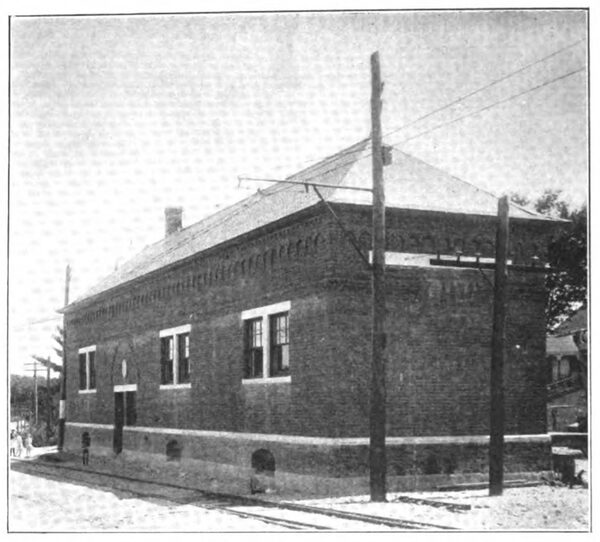

| One of the Sub-Stations |

Behind the boiler house is a well, from which ample condensing water can always be obtained, as it is supplied from the creek before mentioned. The coal pockets are also behind the building. Tracks, turntables, cars, etc., furnished by the C. W. Hunt Company, of New York, are laid so as to facilitate the handling of coal, and a weighing scale is placed at the entrance to the boiler room. The piping, which, like the rest of the plant, was designed by Westinghouse, Church, Kerr & Company, of New York, is of extra heavy pipe. No elbows are used, the pipes being bent. The pipe covering was furnished by the H. W. Johns-Manville Company, of New York. The piping between the boilers and engines is placed under the engine room floor. In the spaces between the machinery foundations are placed two Worthington jet condensers. These run at a speed of from 19 r. p.m. to 22 r. p. m. and their dimensions are 8-in. x 12-in. x 14-in. x 10-in. stroke.

| |||

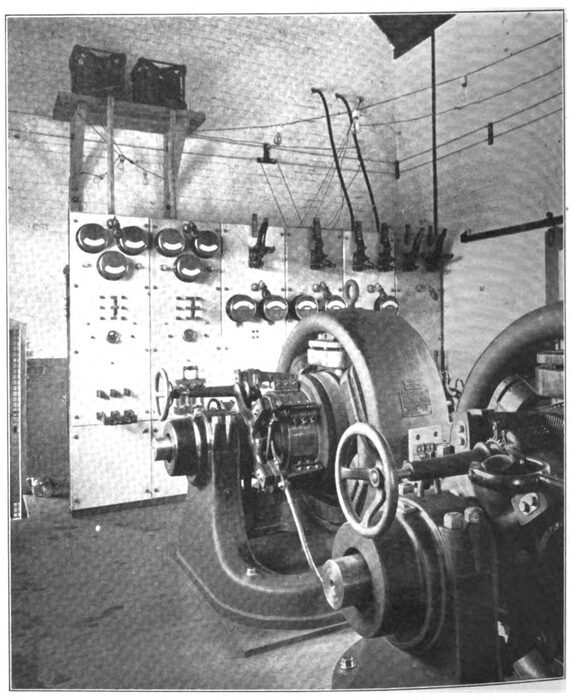

| Rotary Converter in Sub-Station |

The two engines are of the cross-compound type, 16-in. and 32-in. by 42-in. stroke. They represent the latest form of the well-known Rice & Sargent design, and were built by the Providence Engineering Works. Both high-pressure and low-pressure cylinders are jacketed with live steam, and between the two cylinders, underneath the floor, is a superheating receiver. The rated capacity of each engine is 600 hp. Wright governors are used, and the Monarch engine stop has been installed on the engine throttles and on the condensers.

The generators are double-current machines with both the direct-current commutator and alternating collector rings at the same end of the armature. They have a capacity of 400 kw each, and the entire load can be taken from the machine as either direct current or alternating current. This is a great advantage in a railway system of this type, as the traffic at times is extremely heavy near the end of the road, while at others it is quite evenly distributed throughout the entire length. The direct-current voltage is 550 volts, the alternations are 3000 per minute, and the speed 115 r. p.m. The generators are separately excited, but have a compound winding from the direct-current side. On account of the alternating-current regulation they are not over compounded. Arrangements are made at the switchboard so that the shunt winding can be excited from the direct-current side of the machine if desirable, but in general the induction-motor exciter sets are used on the field.

| |||

| Interior of Car House |

The generators are separately excited by two direct-connected motor-driven exciters. The motors are Westinghouse Type C induction motors, 20 hp, 335 volts and 720 r. p.m. They take current directly from the alternating end of the double-current generators without transformation. In starting, the "auto-starter" is used. This consists of a resistance box on which is placed a double-throw switch. In one position the right connections and combinations of resistance are made for starting the induction motor, and when up to speed it is put directly into circuit by throwing over the switch. The motors are connected by a flexible coupling to 550-volt direct-connected generators of 15-kw capacity. Either one of the exciter sets can furnish enough current for both generators.

The transformers which convert the generator current at 335 volts to the line current at 11,000 volts are placed in the basement. The floor above them is open, so that at all times they are ready for inspection. There are three transformers of 200 kw each and of the oil-cooled type.

The switchboard apparatus is all of Westinghouse standard make. The low-tension board, containing the 550-volt trolley current and the 335-volt alternating current from the generators, sets out into the room, leaving considerable space behind it. This space is increased by the extension forward of the front wall, and a roomy alcove is made for the high-tension apparatus. The low-tension board and a high wire fence at each end prevent access to this part of the station. There are seven panels of blue Vermont marble on the low-tension board, three being used for alternating current and four for direct current. Alternating current is used for lighting the power station and car house, auxiliary switchboards being placed in both buildings for this purpose. A storage battery is provided, and, by means of throw-over switches on the lighting boards, the circuits can be connected to this source of current when the plant is shut down.

| |||

| Car House of Worcester & Southbridge Railway |

There is a traveling crane running the entire length of the engine room. This crane has a capacity of 20 tons, and was built by the Whiting Foundry Equipment Company. A steam-driven Westinghouse air compressor is installed in the basement which furnishes compressed air for blowing dust out of the generators, etc. This compressed air is also used in connection with the automatic oiling system. The oil is circulated by means of gravity and is forced to the upper tank by the compressed air.

be placed in it directly from a car on an adjacent track. In the basement is also a Worthington fire pump having a capacity of 1000 gals. per minute, or four good 11-in. smooth-nozzle streams.

SUB-STATIONS

There are two sub-stations, one at North Oxford, on the road to Worcester, and the other near the Southbridge terminus. Each of these stations is equipped with six 75-kw oil-cooled step-down transformers, and two200-kw rotary converters. The switch-boards consist of two alternating-current panels, two direct-current panels and a double feeder panel. There are also high-tension alternating lightning arresters and circuit breakers. Besides being built with large waiting rooms for passengers, the sub-stations will form an important adjunct in the development of the freight and ex-press business contemplated by the company.

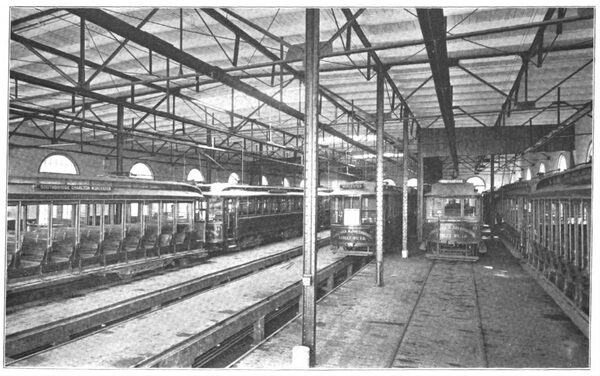

CAR HOUSE

The main car house is situated at Charlton City, near the power station. It is directly on the railway, and contains the operating offices of the company. The dimensions of the main building are 90 ft. 8ins. wide by 191 ft. 8 ins. deep, and there is an addition on one side used as a supply house, etc., 22 ft. by 42 ft. The capacity for storage is twenty-eight cars of the largest type. On one side two tracks are partitioned off from the main room, making a paint shop 104 ft. in depth, and on the other side a repair shop 62 ft. in depth is made by enclosing two tracks. The car house is built of brick with granite foundations and sandstone window ledges and trimmings. The roof is supported on steel trusses and columns, and is covered with tar and gravel on flat portions and black slate on the pitched roofs. The doors extending across the entire front of the car house, as well as those closing the paint shop and repair shop, are of the steel rolling type, made and erected by the Kinnear Manufacturing Company, of Columbus, Ohio. The interior is lighted by large windows in the exterior walls, and by 8-ft. x 22-ft. sky-lights placed in the roof.

| |||

| An Elevated Crossing |

The ground floor of the supply house offers accommodation for repair wagons, two stalls for horses, and a fireproof oil room. The second floor is utilized for storing supplies of a costly or delicate nature; there is also provided a room having a capacity of 1500 cu. ft. for sand, which feeds by gravity to an outlet at the floor level of the car house. The entire surface of the main floor has been excavated to the depth of 4 ft. and concreted and so graded as to drain to a given point.

At the corner of the main building is a two-story addition used for office purposes, etc. On the first floor is the employees' lobby, or lounging room, 16 ft. by 22 ft., containing a fireplace, reading table and lockers. The locker room proper adjoins this room, as do also bath and toilet rooms. The second floor contains the general office, superintendent's The finish private office, supply room, lavatory, etc. of this portion of the building is red oak, with floors of Southern rift pine. The windows are provided with screens, outside awnings and shades, making a very pleasant interior. In the basement of the office is a low-pressure 60-hp tubular boiler, used for heating the entire car house. There is also a hot-water heater for supplying the bath fixtures. Two standpipes are located in the car house, each fitted with 100 ft. of 2 1/2-in. linen hose, and out-side are five two-way hydrants. These are all connected with the fire pump in the power station. In addition chemical fire pails are distributed throughout the entire building.

ROLLING STOCK

The equipment consists at present of twenty long, double-truck cars, eight closed and twelve open. These were all built by the Osgood Bradley Car Works, of Worcester, and are equipped with Laconia trucks and Westinghouse No. 49 (35-hp) motors. The closed cars are 42 ft. 4 ins. over all, with 32-ft. car bodies. The width is 7 ft. 10 ins., height inside 8 ft., and height from head of rail to top of roof 11 ft. 4 1/2 ins. The cars are finished in cherry, with plate-glass double windows, 24 ins. x 26 ins. and 10 ins. x 26 ins., fitted with spring-rolling Pantasote curtains on Hartshorn rollers, and equipped with fixtures made by the Curtain Supply Company, Chicago. The cars are of the straight-sided type, with vestibules 4 ft. 8ins. at each end. Folding doors are used at the sides of the vestibules, and single sliding doors at the end of the cars. The vestibule shades for these latter doors are on vertical rollers at the side of the jamb, and unroll as the door is closed. They were supplied by the Trolley Vestibule Shade Company. The capacity is forty-eight passengers, and the seating arrangement is similar to that originated in Worcester some years ago and found to be very satisfactory where the traffic is made up of mixed local and long-distance riders. At the center of the car are five walk-over seats on each side, and at the ends. are longitudinal seats. The seats are covered with red plush, and were furnished by the Heywood Brothers and Wakefield Company, of Wakefield, Mass. The walk-over seats are of the well-known Wheeler pattern, with grab handles at the upper corner. At the ends of the cars hold-straps are provided for standing passengers. The cars are painted a handsome olive green with neat gold lettering.

The open cars are 44 ft. 9 ins. over all, 7 ft. 1 in. wide at the sills, and 7 ft. 6 ins. wide at the seat rail. They are 7 ft. 6 ins. high inside, and the distance from head of rail to top of roof is 11 ft. The cars have bulkheads fitted with plate-glass windows, but no vestibules. The roofs are of the steam-car type. There are fifteen benches, eleven of which have reversible backs. The finish is of ash with solid bronze trimmings. Pantasote side curtains which can be pulled down to the floor of the car in bad weather are placed between the side posts.

The trucks for both open and closed cars are of a type perfected especially for this class of service, and built by the Laconia Car Company Works, of Boston. They have a wheel-base of 5 ft. 4 ins., and the diameter of the wheel is 33 ins. A 3-in. flange is used. Each truck carries two of the 35-hp motors, making a total of 140 hp per car. The gear ratio is 18 to 64. The other electrical equipment comprises two trolleys, two controllers, two circuit-breaker switches, fuses, lightning arresters, etc. headlights are used made by the Dayton Manufacturing Company, of Dayton, Ohio. Both open and closed cars are equipped with the Standard Traction Brake Company's system of motor-driven compressors and air brakes, and are supplied with whistles, as well as gongs.

| |||

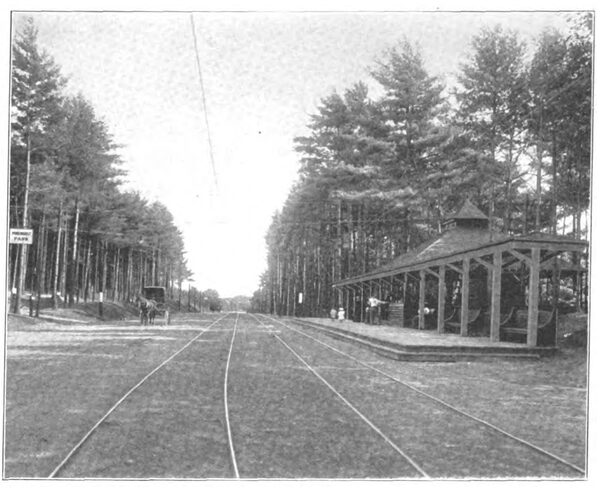

| Station at Pinehurst Park |

There is also operated a parlor car, which can be used as a directors ' car or leased to private parties. This car is very handsomely fitted up with mirrors, buffet, writing desk, etc., and is equipped with wicker easy chairs, instead of fixed seats. The buffet is supplied with glasses, plates and silverware, every article being marked with the name of the car, "Huguenot." There are smoking and toilet rooms and every convenience ordinarily found on the steam roads. Arrangements are being made with connecting lines so that this car can be operated on any road in the State, and it has already become so popular with excursion, theater, wedding and special parties that engagements are booked for months ahead.

Several express, baggage and mail cars have been ordered from the Wason Manufacturing Company, of Springfield. These will be used for the freight and express business, as well as for carrying the mails. A special compartment in each car for the use of the mail clerks will be fitted up

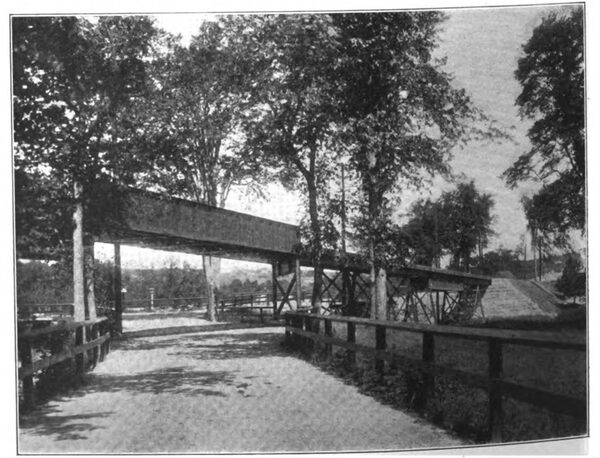

THE ROAD

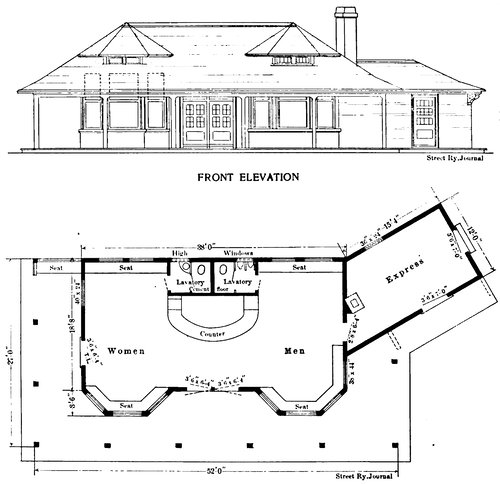

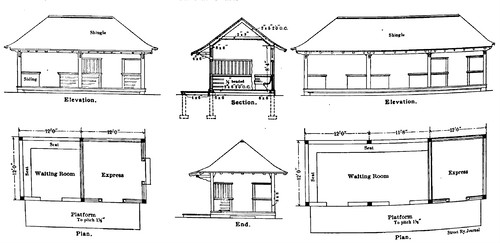

No expense has been spared in making the permanent way, overhead construction, waiting stations, etc., of the Worcester & Southbridge Railway up to the best standards of electric road building in the country. The larger portion of the line runs on the company's own right of way, and about half of the entire line is rock ballasted, the remainder being gravel. The rail is a 70-lb.T, A. S. C. E. section, laid in 60-ft. lengths on 6-in. chestnut ties placed 20 ins. center to center. The overhead material was manufactured by the Albert & J. M. Anderson Manufacturing Company, of Boston . Mr. John P. Coghlin, of the Page Electric Company, Worcester, was the road's electrical engineer, and in addition to the laying out of the powerplant also erected for the company all the overhead work. Plain iron brackets attached to wooden poles spaced 70 ft. apart support the trolley wire. Double trolley wires are used, obviating the necessity of overhead switches at the turn-outs, as well as giving sufficient carrying capacity to dispense with other feed-wires from the main and sub-stations. The trolley wire is of the grooved type, held firmly in screwed clips without soldering. No. 0000 B. & S. gage is used. The 11,000-volt three-phase transmission lines are carried at the top of the poles on heavy porcelain insulators with extra wide petticoats, supplied by C. S. Knowles, of Boston. A feature of interest is the placing of signboards bearing the names of the stops along the line. These are suspended from brackets on the poles, and are painted white with black lettering. Eight waiting stations have been erected at points along the line. A portion of each station is adapted to handling the express business, while the remainder is devoted to the accommodation of the road's patrons. These stations will be open in the summer time, but in winter glazed sash are placed around them. The accompanying illustrations show the general types placed along the road, and the more pretentious one built at Charlton City.

|

| Ground Plan of Waiting Station at Charlton City, Mass |

Besides five instruments connected with the exchanges of the New England Telegraph & Telephone Company at different points of the line, the road has a private tele-phone system of its own, and a private exchange with switchboard at the company's office in Charlton City, and is used as a despatcher station. Each car is provided with a portable tele-phone outfit, and connection to the line wires can be made at any place by means of a jointed pole carried in the car and equipped with contacts at the end. There are also telephones at the turnouts, sub-stations, etc., all connected to a main switch-board in the general office. All despatching is done by telephone. The road is also thoroughly protected against accident by an automatic block signal system put up by the United States Electric Signal Com-Company, West Newton, Mass.

|

| Combination Passenger and Express Stations |

The entire electrical equipment of the power plant, sub-stations and rolling stock was furnished by the Westinghouse Electric & Manufacturing Company.

OPERATION

By a twenty-five-year traffic arrangement with the Worcester Consolidated, the Worcester & South-bridge can carry its passengers directly to City Hall Square, in the heart of the trolley systems of central Massachusetts, where transfers are given to the other lines. At a point just outside of Worcester, when leaving the city, conductors and registers are changed, and on approaching the city a Worcester Consolidated conductor and register are put on at New Worcester, where the companies' tracks connect. The rush to Pinehurst Park and Prospect Park, on the Southbridge road, in the town of Auburn, last season taxed the facilities of the road to the utmost, and far exceeded the most sanguine hopes of the officers. Arrangement are now being made for the building of a thoroughly up-to-date theater at Pinehurst Park. These are two of the most picturesque pleasure grounds near the city of Worcester, and the company's business last season shows how highly they are appreciated by the people. To provide for the increased traffic expected for next year additional turnouts and tracks are being provided between the parks and the city and additional open cars. Two other resorts are being fitted up farther down the line, which will, it is hoped, divert some of the attendance from the present resorts.

The present schedule provides for a half-hour headway. It is intended to shorten this next season, probably at least 15 minutes. The distance of about 20 miles between Worcester and Southbridge is made in 75 minutes. The steam railroad time-table makes the time between the two stations from 70 minutes to 120 minutes.

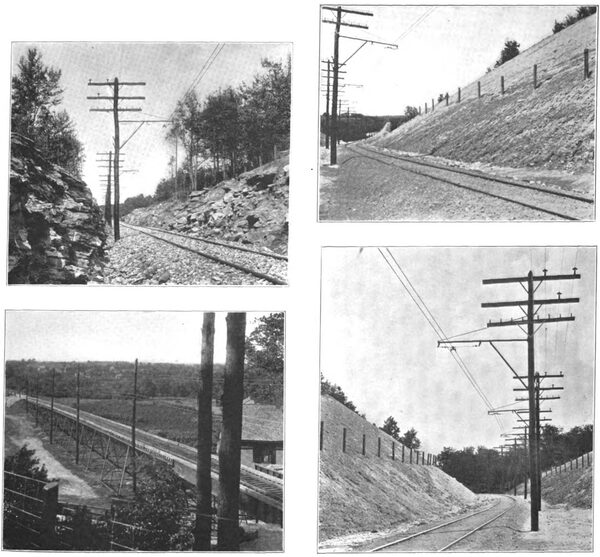

| |||

| Typical Views Along the Roadway |

The handling of freight and express matter is to be made a special feature by the management. The waiting stations described, together with special accommodations and arrangements at the terminals, among which is the securing of a large terminal near the Boston & Albany Railroad station in Worcester, give excellent facilities for competing with the old express service. It will be possible for the storekeepers in Southbridge to use the private telephone line of the railway company in ordering goods in Worcester and receive them within a few hours, while shopkeepers in both Southbridge and Worcester can send goods to the respective terminal and have them delivered to all parts of the system. Deliveries are made several times a day. Stamps sold by the railway will be used to prepay express charges, greatly simplifying the clerical work. The express cars will also carry United States mail.

ORGANIZATION

The officers of the Worcester & Southbridge syndicate are: Fred Thayer, president; Wilford A. Bailey, secretary, treasurer and general manager; George W. Wells, vice-president, and E. L. Parker, auditor. O. Willis Rugg, of Worcester, is engineer, and George M. Thompson, of Wakefield, Mass., consulting engineer and appraiser. The board of directors consists of Fred Thayer, Wilford A. Bailey, Edmund L. Parker, Samuel H. Colton, Frank D. Perry, Calvin D. Paige, George W. Wells and Albert B. Wells. The direct supervision of the road is under the superintendent, Leavenworth Wheeler, whose office is at Charlton City. H. W. Culver is chief engineer of the power station, and C. F. Harding, electrical engineer.