[Newspaper]

Publication: Poughkeepsie Sunday New Yorker

Poughkeepsie, NY, United States

vol. 71, no. 269, p. 4A, col. 1-8

Glass Blowing Boomed Early in Century Here;

Workers Recall High Pay Scale, Friendly Bosses

BY HELEN MYERS

If you get a glass splinter in your finger this is the best way to take it out. First wet your finger. Then lightly touch the splinter with a bit of hot glass, molten glass. Hot glass is sticky stuff, so it will pull the splinter right out.

Around the turn of the century, when the old Poughkeepsie Glass works was running full tilt, many a glass splinter was removed that way. Working around all that glass, a man was bound to get a lot of splinters in his hands.

That was a minor penalty to pay for a very good job. There wasn't a more up-to-date glass factory in the country at the time. The management was friendly and reasonable. A man was expected to do his work, of course, but he wasn't hurried.

And the pay was wonderful. Old timers all remember the Glass works as the highest paying industry that Poughkeepsie ever had. Blowers averaged $5 or $6 a day, averaged that during a year, although the plant was always closed throughout July and August. Men working in a Jericho shop sometimes made as much as $10 or $12 in a single day. And that was in the period when other skilled mechanics were getting from $1.75 to $2.50 a day.

Of course, not all the workers were blowers, and not all the blowers worked in a Jericho shop where the big bottles, the battery jars and the demijohns were made. That was the top spot.

A man who was a blower in 1900 had usually begun work as a carrying boy, carrying finished bottles to the leer or annealing oven where they were tempered. After that he was probably a mold boy, one who closed a mold on a bottle as it was being blown.

* * *

FROM MOLD BOY he usually progressed to snapping up boy who prepared blown bottles for the gaffer or finisher After that he might do any sort of work on the floor for a year or so before he went to the blowers' bench as in apprentice. He worked as an apprentice for five years before he became a Journeyman blower, and then blew small bottles before he blew the big ones in a Jericho shop.

In 1900 the Glass works plant was spread out from a short distance south of the foot of Dutchess avenue north to the foot of Hoffman street, on land now occupied by the Dutton Lumber Co. About 350 men and boys worked there on two nine-hour shifts. Those who worked five nights one week worked six days the next.

The plant had a day shift and a night shift because the glass always was molten in at least one of the three continuous tanks. Each of these tanks held 130 tons of melted glass, and it took nearly two weeks to heat that glass to workable temperature each autumn when the place reopened.

All glass plants closed at midnight on June 30 of each year in that period and remained closed until the day alter Labor day because a glass plant was too hot a place to work in summer. The molten glass itself threw off intense heat, and all the equipment was hot, the lear, the molds, the snappers, the blow pipes.

Each of the continuous tanks in the local plant was made of brick. From the front it looked like a great squat cylinder, but the back was actually flat. The materials from which the glass was made, sea sand, soda ash, lime and cullet or broken glass, were put in the back to be melted or fused.

* * *

AS THE GLASS FORMED, it flowed in a great hot pond to the front and sides. It was kept hot and liquid by a sheet of gas flame over the surface. The gas was made from soft coal in another building, then piped to the tanks.

Ring holes, that were similar to windows, were spaced at regular intervals around the circular section of a tank. The blowers worked on the bench, the wooden platform that went around that part of the tank. This platform was six or eight feet wide, and about three feet above the floor.

A shop or group of men and boys worked around each ring hole. There were usually two blowers, a gaffer or finisher, and three boys in a shop. A blower would go to a ring hole with his blow pipe, a hollow metal tube some three or four feet long.

|

A GROUP OF GLASS WORKS employes photographed near the office building in May, 1909. The three girls in front, Miss MARY COOSTELLO, Miss MARY MILLER and Miss ALICE KELLY, assembled wires used on the tops of fruit jars. SAMUEL HORTON in the front row. wears light suspenders over a dark shirt. The third, man from the left in the second row is WILLIAM GAHAN; the fourth, GEORGE FOSTER; the fifth, JAMES COOK; the seventh. JOHN MILLER. The fourth man from the left in the third row, the man in the light shirt, is JOHN MULVEY; the sixth, JNATHAN GOOD, superintendent; the seventh, MARTIN KELLER, EDWARD McDONALD, wearing a derby, is the third from the left in the fourth low; THOMAS ETHERIDGE, fourth, MICHAEL SENKIER, with the white tie, eighth; and JERRY BOWE, also with white tie — the 10th. GEORGE ORSBORNE and GEORGE ABEEL are first and second from the left in the back row. ALBERT WILSON is fifth; HENRY KLUMP, sixth; BARNEY McPECK, eighth; and JAMES KELLY, ninth. LEGRANDE CRIPPEN looks out of the center window, ROBERT HORSFALL from the one on the right.

Courtesy of Robert Horsfall

First he would heat the and of his pipe in the flame, then dip the hot tip into the liquid glass. He picked up the correct amount by turning his pipe. One turn would be enough if he was making a half-ounce bottle, but it would take several turns to get enough for a six or eight-ounce one.

When he had enough glass, the blower carried it on the end of pipe to his plate, a rectangular slab of stone or steel that stood on legs near the outer edge of the his bench.

He would roll the liquid glass beck and forth on the plate, blow into it to open it up a little, roll it some more, blow again, until he had a bag of glass that was approximately the correct size.

Then he dropped it, still on the end of his pipe, into a mold. Sometimes a blower closed a mold with a foot pedal, but this work was usually done by a mold boy who pulled the two halves of a mold together with the two big handles on top while the blower gave a final puff.

* * *

"A MOLD BOY HAD to see that he shut a mold just right," Michael J. Senkier of 565 Main street said. "If he caught the end of the pipe in a mold he might knock a blowers' teeth out. That's one of the things a boy had to learn."

Mr. Senkier began work there as a boy in 1898, and remained until 1909, until the trade began to go bad. During the last year and a half he was a journeyman blower. For many years afterward he was a letter carrier.

After the mold was closed, the blower broke away from the bottle, dipped his pipe in water to break off the threads of glass, and began all over again. The water took off all but a bit of glass on the end of the pipe, but that bit of glass was important. Without it a pipe won't pick glass satisfactorily.

In most of the shops, two men were blowing all the time. While one was picking up his glass, the other worked on the plate. By the time the one who was picking up glass was ready for the plate, the other had moved on to a mold.

And the work went quickly. It had to go quickly for the glass was running, and had to be handled while it was in that state. A shop would try to run about 60 beer bottles in five minutes. It would turn out from 250 to 300 dozen bottles in a day, depending on their size.

|

Courtesy of Robert Horsfall

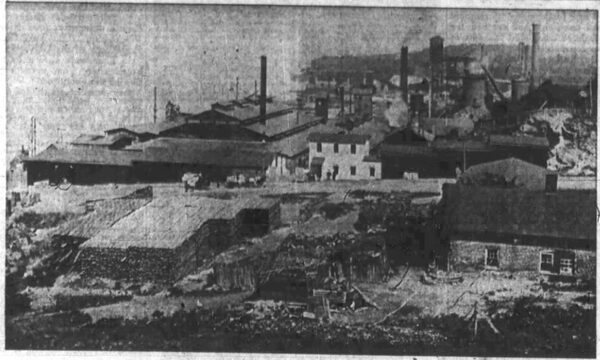

POUGHKEEPSIE GLASS WORKS (above) in its heyday around the turn of the century. Lumber in the foreground, south of the foot of Dutchess avenue, was used to crate finished ware. The main plant, with three continuous tanks, was in the big riverfront building in the center. The Tower furnace shows in the background.

Each shop had two or three molds. Besides closing the molds for the blowers, the mold boy took the bottles from the molds, always the coolest one first, and placed them on an asbestos plate.

The snapping up boy then picked up each bottle by the top with a pair of pincers and placed it in a snapper, a metal container just a little larger than the bottle. The boy turned each bottle in its snapper to rub off any rough spots on the neck, then put the bottles in their snappers on a rack in front of a glory hole.

* * *

THIS WAS AN OPENING in an oil furnace, an opening from which flame shot out just far enough to melt the bottle necks. The third man in the shop, the gaffer, took the bottle from in front of the glory holes and finished them.

The gaffer did his work in a chair on the floor, a short distance from the blowers on the bench. And about every half hour the men would change jobs. One of the blowers would become gaffer, and the gaffer would blow for a while.

As the bottles they made were finished, the carrying boy took them to the lear lor tempering. The lear is a big flat oven, some 60 feet long. The bottles were placed in big pans that were hooked to one another on a track in the lear. By winding a chain on a wheel, men draw the pans of glassware through the lear for annealing or tempering. Each pan was in the lear about seven hours.

In any one day, if 10 shops were working around a tank, Mr. Senkier said, probably 10 different types of bottles would he produced, everything from little half-ounce medicine bottles to 10-gallon demijohns.

Everything that was made at the local glass works was utility glass, what is known in the trade as "green glass," although some of it was colorless and sometimes there was an "amber" tank in operation. The "amber" glass, actually dark brown, was used mainly for whiskey and beer bottles.

* * *

"NO DECORATIVE GLASS was made there at all," Mr. Senkier said. "It was all utility glass. They did make a lot of fruit Jars, milk bottles, soda bottles, beer bottles, whiskey bottles, pill bottles and preserve Jars. A man who could go from one size bottle to another was considered a good workman. Most of them made just one size."

Poughkeepsie Glass works was unionized, and the workers belonged to the Green Glass Bottle Blowers Association of the United States and Canada, branch 62, Charles Miller of 35 Fairview avenue said. Flint glass blowers, who made finer decorative glass, had a different union. Mr. Miller worked at the local plant for 33 years, the last 26 was a blower.

"When they started in they made light green glass," he said. "It was light green because they didn't put anything in to bleach it. After a while they found they could pick up a lot of business by making prescription ware, but it had to be light, so they put some kind of stuff in to bleach it. They used to call that transparent glass "Dutch flint."

Sometimes the blowers made glass canes and swords and chains and balls for their own amusement during their lunch period or between shifts, but there wasn't much time for that. Mr. Miller said. And if you started to make something one day, something you couldn’t finish right away, you had to hide it.

He and Mr. Senkier both remember that there used to be a lot of canes and chains in local bar rooms in the late 1890s and early 1900s. They usually were made by men who used them to get, some free drinks, Mr. Miller said.

Most of the canes and chains and swords that were made at the local plant are gone now. Since they weren't made as company projects it was hard to temper them properly. That meant that they broke easily.

* * *

ROBERT HORSFALL of 32 Corlies avenue believes that it was manganese that was put into the glass to bleach it. He worked in the plant for 13 years, first as time-keeper, than as shipping clerk.

"When you put that glass in the sun the manganese turned it pink," he said. I remember we had to replace one shipment of milks because the bottoms were pink. They had stood in the yard in the sun with the bottoms up."

Mr. Horsfall also the ingredients of each batch of glass were mixed in the batch house that was at the north end of the alley that ran between the east end of the factory building and the office building. Exactly what went into each batch was a secret, he said, but the ingredients must have varied because the glass of one batch would be very much clearer than the glass of another.

|

Courtesy of Robert Horsfall

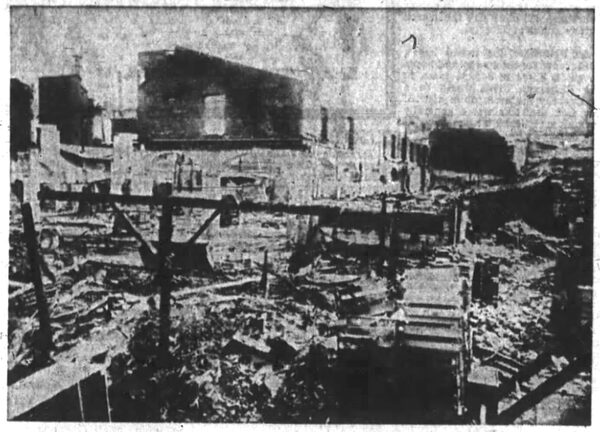

THE SECOND PLANT of the Poughkeepsie Glass works was destroyed by fire in April, 1897, Robert Good Sr., plant manager, then lived in a brick house on a bluff northeast of the plant. A bit of this house shows in the background, at the extreme right, A greatly enlarged plant was built after the fire.

"I've seen old man Good go to the back of a tank and dump in some potatoes, peel and all." he said. "That was supposed to clarify the glass. He was a big man, about six feet four, a regular John Bull of a man."

In his 33 years at the Glass works, Mr. Miller progressed from carrying in boy, a boy who put the completed bottles in the ovens, to a Jericho shop worker. "They advanced you all the time," he said. "They started a blower on small bottles. When they saw that you could advance, they put you on bigger ones.

"The biggest I made were two-gallon demijohns. They did make 10-gallon ones there, but I never did that. It’s harder to make the big ones. There’s more glass to handle. I used to make six-by-eight battery jars. There was no necks on them. They were just straight up and down. The company used to sell a lot of them to the New York Central railroad. They used them for the batteries that changed the signals.

"To make a battery jar you had to handle 64 ounces of glass. That's four pounds. And remember, it was hot and it was running. You had to work the glass before you could blow into it at all. It was a Jericho shop where I made those battery jars.

"It was a Jericho shop where you made any of the big ware, big soda bottles, packers' bottles, battery jars, demijohns. When you worked in a Jericho shop there were only two men, and you had a gathering boy. He just gathered the glass and brought it to you.

* * *

"IF YOU WERE USING anything under 30 ounces of glass you were supposed to gather your own. Battery jars weren't the heaviest things they made at the Glass works, some of those big demijohns took 10 pounds of glass.

"One man did the blowing while in a Jericho shop. You'd blow it up to a pretty good size, then put it in the mould. After half an hour of blowing you’d go into the chair to finish while the other man blew."

Glass blowing and finishing were all piece work in the local plant, and a shop was paid for the work it did, paid as a shop. This money was divided between the three men in a regular shop or the two in a Jericho shop, but not immediately.

At the end of each week the Journeymen blowers each received $20, or "market money." They could collect the remainder that was due at the end of each month, or they could wait until "the end of the fire" and collect the extra for an entire year just before they began their two-month vacation.

Mr. Senkier, Mr. Miller and Mr. Horsfall agree that the Poughkeepsie Glass works paid the workers well, but they disagree about just how much that amounted to. It was easy to make $7 or $8 a day, Mr. Senkier says, and the fellows who were making the big demijohns sometimes made as much as $12 or $14 in a single day.

* * *

I NEVER HEARD of anyone making $14 a day in this glass works," Mr. Miller said. "The fellows who blew the big demijohns, may have made $10 or $12, but not all the time. When you averaged it up through the year, it might come to $6 a day. I don't think that anyone made $2,000 a year.

"You worked only 10 months. Maybe the plant didn’t open up right away in the fall, so it was nine instead of 10. When there was high tide water would get in the flues and shut off the gas. Maybe they'd run out of material, so you'd be off a day or two more. It added up to a lot of time when you weren't working.

"Of course, an average of $5 or $6 a day was good then. The average going wage for a laborer was $1.25 a day, $1.35 in summer. That's what they were paying on the New York Central. If a skilled mechanic got $2 a day that was big."

Mr. Horsfall is certain that some of the blowers collected as much as $2,000 or $2,500 at the end of the fire. As timekeeper he saw the money, he said.

Most of the blowers lived in the First ward, and there were families of glass blowers at the time, the Kellys, the Cooks, the Grays, the Hendersons, the Dows, the Groves, and, of course, the Goods. Robert Good Sr. had three sons, Robert Jr., Jonathan and Isaac, who all began their career as glass blowers in the local plant.

The Poughkeepsie Glass works was established as the result of the mistaken belief that slag from the Tower Iron furnace could be used to make a superior grade of strong green glass.

In the 1870s a method of using slag in glass making was perfected in England. A group of men from Clyde and Rochester purchased the controlling interest in the American patent for this process, then looked for a place to use it.

The old Whale dock property in Poughkeepsie seemed ideal. It was directly south of the Tower furnace, and the furnace was only too glad to dispose of its slag, especially at a profit.

* * *

THE TOWER FURNACE had been at the foot of Union street originally. The federal government eventually prohibited the furnace from throwing any more slag into that section of the river, which was one reason why the new furnace had been built north of the foot of Hoffman street.

In July 1879, the men who owned the American rights to use slag in glass making purchased the north part of the Whale dock property, the section at the foot of Hoffman street, from the Farmers' and Manufacturers' bank, and then sent representatives to England to find a man who could operate the plant they had in mind.

The man they selected was Robert Good Sr., then 38. He had worked in glass all of his life, and was then the manager of a glass factory in Northamptonshire, England. This factory was making a very strong, very attractive olive green glass by throwing hot iron slag into the tank with the basic materials.

The English factory that Robert Good managed had another glass-making innovation, a continuous tank in which the raw materials were melted into glass 24 hours a day. That tank had been built by a man who had been hired to come from Germany just to build it. In other glass factories, the materials were then melted in clay pots during the night, and the glass was worked the next day.

The purchasers of the Whale dock property hired Robert Good on a six-month contract. During that six months he was to build a glass factory with a continuous tank and begin operation

* * *

"I CAN REMEMBER old man Good during that period," Mr. Miller said, "He was a regular Englishman with a short jacket. He boarded with Mrs. Hooker in Dutchess avenue. We lived at Dutchess avenue and North Water street."

The plant began operation in March, 1880, with the first successful continuous tank in this country. When Mr. Good's contract ran out, he remained to manage the factory, which was a disappointment in one way. Slag from the Tower furnace just didn't make good glass.

"There's too much difference in slag." Mr. Miller said. "It rises to the top. Sometimes it's light. Sometimes it's dark. It's dirt. I remember one company was going to make paving stones of it. That didn't work either. The machinery for that lay around for a long time."

Although the slag was a disappointment, the Poughkeepsie Glass works prospered until December, 1881, when the factory was destroyed by fire and a large quantity of finished ware was destroyed.

But the tank was not seriously injured. That was repaired and a new tank was built in the new plant. That also was destroyed by fire in April, 1897. "A tank burst," Mr. Miller said. "That's what usually started a glass works fire. The hot glass went all over and started it all.

Fortunately, it happened between shifts, when no one was blowing. If anyone had been blowing, he would have been burned up. I don't remember the first fire, but the second, one was bad. It took the whole business."

Mr. and kin. Robert Good Sr., and their family then lived in a brick house on a bluff northeast of the plant but quite near it. Mrs. Ralph C. Overacker of 46 Smith street, a daughter, was then a little girl. She doesn't remember the fire, because she slept through it, but she does remember hearing that her mother packed while the blaze was at its height because she was afraid that it would spread to the large wooden porch of the house.

* * *

AFTER THAT 1897 FIRE the company bought more land, south to Dutchess avenue and a lot south of that. New iron and brick buildings that were then considered models for glass works were constructed. The new plant had three tanks, and the output was increased from about 30,000 gross to 130,000 gross a year.

It was a wonderful plant, Mr. Senkler said, and it was doing wonderful business. Everyone thought it would last forever. Both he and Mr. Miller believe that machines that did the work of men caused it to close, but Mr. Horsfall thinks that unwise concentration of orders is responsible.

In any case, Robert Good Jr., worked for two years, from 1899 to 1901, at the local plant to perfect a machine designed to make bottles. Eventually he discovered many ways to speed up glass making while he worked for the Hazel Atlas Glass Co. in Washington, Pa.

|

Courtesy of Mrs. Ralph Overacker

ROBERT GOODE [sic] GOOD SR., above, built the Poughkeepsie Glass works on the old Whale dock property in 1879 and '80, and was its general manager until it closed in 1912. CHARLES MILLER, top right, worked at the Glass works for 33 years, for the last 26 as a blower. ROBERT HORSFALL, center right, was first a timekeeper, then a shipping clerk. MICHAEL J. SENKIER, lower right, was at the Glass works 11 years, for the last year and a half as a blower.

|

During the early 1900s the Poughkeepsie Glass works had four semi-automatic machines that made bottles. A man gathered the glass and put it in molds, where it was blown by compressed air. Then the man cut the top with a pair of scissors. Those machines weren't nearly as fast as modern equipment, but they were much faster than hand blowing.

As the years passed, the summer layoffs grew longer. Sometimes the plant was closed three or four months instead of two. Sometimes only one of the three tanks was in operation when the plant was open.

Just before Christmas on 1912 the men who worked there were told that the plant would be closed for a week. It never reopened.

"This was an elegant glass works," Mr. Miller said. "It wasn't so large, but it was a good place to work. They wanted a man to work as fast as he could, but not to hurry.

"Glass blowing was an elegant trade. I don't think there's any hand blowing now. Even little glass pill bottles are made by machines. Machines killed everything. Eventually the whole thing here, tools, molds and everything, was sold as junk. All was taken away on a barge."