[Trade Journal]

Publication: Cassier's Magazine

New York, NY, United States

vol. 25, no. 2, p. 103-115, col. 1-2

RECENT DEVELOPMENTS IN NIAGARA POWER

By H. W. Buck, Electrical Engineer of the Niagara Falls Power Co.

| |||

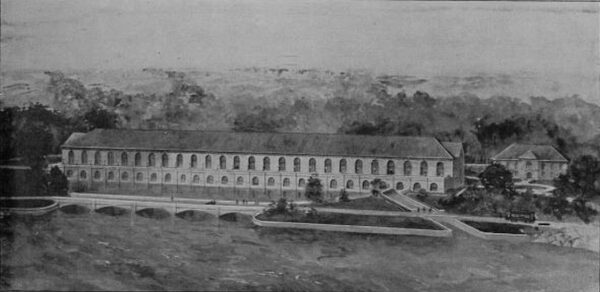

| This Will Be Appearance, When Completed, of the Power House of the Canadian Niagara Power Company. Capacity, 110,000 H. P. |

WHEN the first power house at Niagara Falls was proposed for a capacity of 50,000 H. P, with an ultimate tunnel capacity of 100,000 H. P., many people wondered how it would be possible to dispose commercially of such a large amount of electric power. Central station managers who, after a strenuous canvass for new customers, had been accustomed to increasing the output of their plants by the addition of a 150 KW Edison bipolar machine, were staggered by the magnitude of the quantities involved in this new proposition. Skeptical opinions were expressed based upon industrial and electrical conditions then existing, and these opinions at that time were, in the main, correct.

Since that time, however, great developments have taken place in the electrical arts which have made possible the present realisation of such a demand for power. The developments which have created this demand have been, first of all, in electro-chemistry, though the output of the Niagara plant is not confined to electro-chemical applications, as is generally supposed. Large blocks of its power are in use for electric railway propulsion, electric lighting, and mechanical power application. One of the most recent and important factors in the growth of this power system has been the introduction of the electric motor drive for factor), appliances. The evolution of economical methods in power transmission has made the delivery of Niagara power commercially possible to a widely scattered market.

|

As a result of these developments in the application of electrical energy the first power house has reached the limit of its capacity of 50,000 H. P. ; the second plant, having a capacity of 55,000 H. P., is well along towards its limit, and a third power house of 110,000 H. P. is being constructed on the Canadian side of the river to operate in conjunction with the first two, thus making a total of 215,000 H. P.

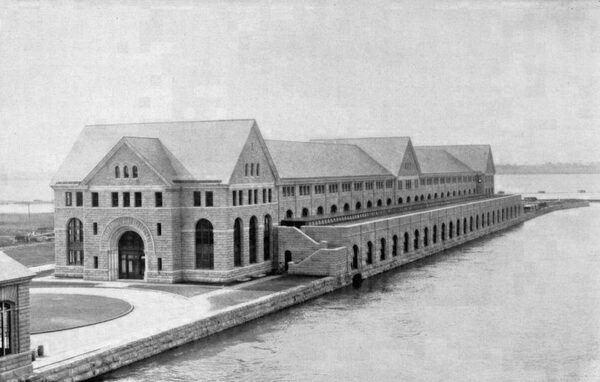

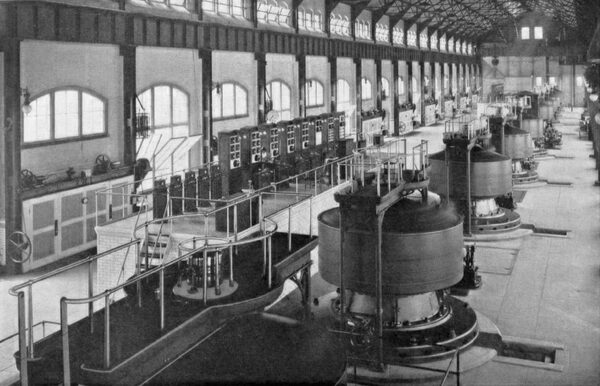

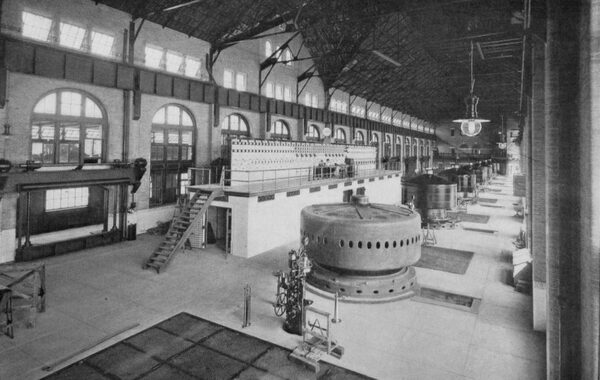

The second plant on the American side, known as Power House No. 2, is constructed near the first power house, but on the opposite side of the inlet canal, and its turbines discharge their water into the original tunnel through a short branch connection. Its equipment consists of eleven 5000 H. P., vertical shaft, 2200-volt, 25-cycle, two-phase generators of the same speed as those in the first plant, viz., 250 revolutions per minute. The first six machines of the installation are of the external revolving field or umbrella type; the last five generators have internal revolving fields with outside stationary armatures, the speed remaining the same. The general appearance of this latter generator is well shown in the illustration on page 107, and a marked contrast will be noted between it and those of the external field design. This internal revolving field construction affords many advantages of simplicity and accessibility to the various parts of the machine.

The general construction of Power House No. 2 is the same as that of the older plant, with which almost everyone is familiar. The changes introduced have been principally along the line of improvements in detail which have been the result of the evolution which has taken place in engineering methods since the first plant was installed. The turbines were built by the I. P. Morris Company, of Philadelphia, from designs of Escher, Wyss & Co., of Zurich, and the electrical equipment was manufactured by the General Electric Company, of New York. The output of this plant is used for local service to customers on the lands of the Niagara Falls Power Company, the Union Carbide Company alone taking a block of 15,000 H. P. Seven generating units are now in operation, and by January I, 1904, the plant will be entirely completed with eleven 5000 H. P. units.

As stated above, a third power house is being constructed on the Canadian side of the river, which will serve to supply the demand for power in both Canada and the United States when all the power from the two American plants is taken up. The work is being carried on by the Canadian Niagara Power Company, a Canadian corporation controlled by the Niagara Falls Power Company. The capacity of this plant, when completed, will be 110,000 H. P. In general, its hydraulic development will be similar to that of the American plants. The power house is situated in the Queen Victoria Niagara Falls Park, about half a mile above the horseshoe Falls. The water is taken in from the river through a short canal and fore-bay, discharged through penstocks into turbines near the bottom of a wheelpit, and carried away to the lower river through a tunnel about 1,700 feet in length.

| |||

| Power House No. 2 of the Niagara Falls Power Company. |

| |||

| One of the Internal Revolving Field Generators for Power House No. 2. |

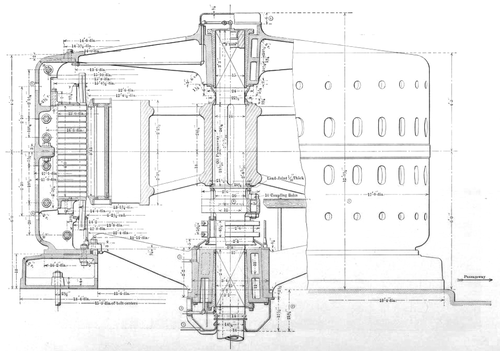

The most distinctive feature of this plant is the size of the generating units, each of which is to have a capacity of 10,000 H. P.,--the largest machines which have thus far been constructed. The plant, when completed, will Comprise eleven of these generators. A unit of this size was adopted for reasons of economy in hydraulic development and in electrical equipment. These 10,000 H. P. units occupy but little more space than those of 5000 H. P. Thus results a great reduction in length of wheelpit and power house for a given horse-power output. Furthermore, the generators cost considerably less per horse-power than those of 5000 H. P. capacity.

|

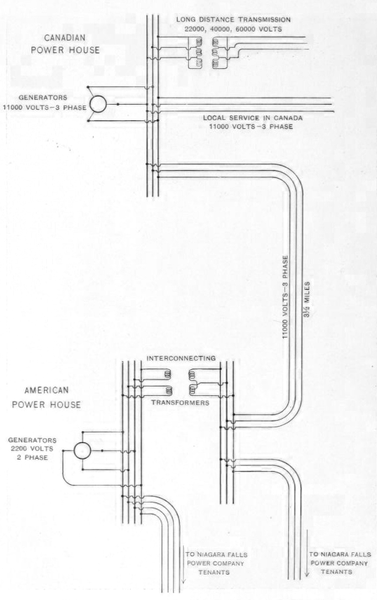

| Method of Interconnecting the American and Canadian Systems. |

The generators will have vertical shafts, and their general design is well shown in the illustration on page 122. They are wound for three-phase current, 11,000 volts, 25 cycles at 250 revolutions per minute. This high generated voltage was selected not for long-distance transmission, but for economy in local distribution of power. The cost of distributing underground at 11,000 volts, three-phase, is about one-fifth that required for a 2200-volt, two-phase system. For long- distance transmission step-up transformers will be used to raise the voltage to 22,000, 40,000, or 60,000 volts, depending upon the distance of transmission. Three-phase was decided upon rather than two-phase for the reason that one less conductor is required, which simplifies cable connections, and because the three-phase system requires 25 per cent. less copper for transmission than one of two-phase for the same voltage. Power from this plant will he distributed by means of No. 000 B. & S. triple conductor, lead-covered cables laid in ducts underground.

The first installation in the Canadian plant will consist of five such I0,000 H. P. generators, which are being built by the General Electric Company. The turbines, of like capacity, have been designed by Escher, Wyss & Co., and are under construction at that company's factory at Zurich. It is the intention to have cable connections so that this Canadian power house can operate, if desired, in parallel with either or both of the American plants. The method of accomplishing this is shown in the diagram opposite, the cables being carried across Niagara river by way of the upper steel arch bridge, a total distance of about three and one-half miles. The 11,000 volts, three-phase, will be changed to 2,200 volts, two-phase, for paralleling, by means of step-down transformers, as shown in the illustration, or delivered direct to tenants on the lands of the Niagara Falls Power Company. This plant will be in operation by July I, 1904. Its output will be used for Canadian industries in the province of Ontario within transmission distance of the power house, or for American consumers, as the demand may be. A part of its output may be sent to Buffalo by a transmission line to be built on the Canadian side of the Niagara river.

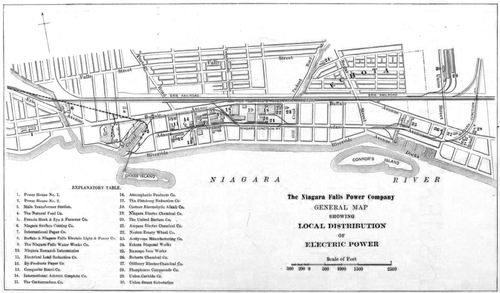

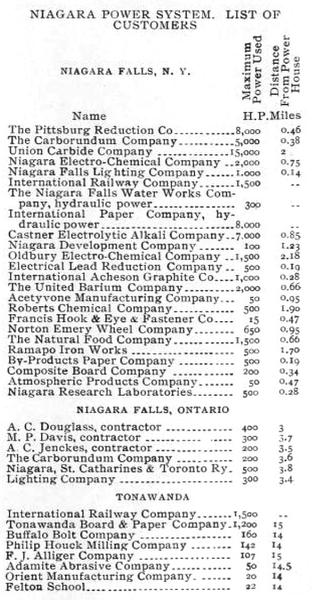

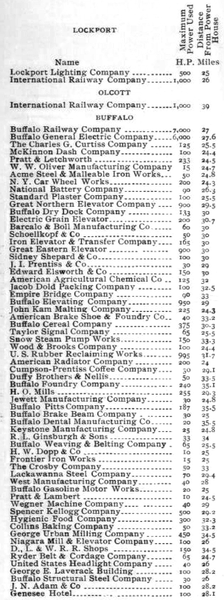

The Niagara power system now covers a very large territory; thousands of people are dependent upon it in their daily lives, and commercial interests of great importance are involved in it. The industrial world has learned that the Niagara power enterprise is no longer an experiment, and that it has already-become an important factor in the manufacturing status of this continent. Its extent and the great variety of the industries which it operates will be seen from the list which follows:—

|

The figures are for maximum power used in each case. Since the maximum in the various plants does not occur at the same time, the resultant maximum at the power house is somewhat less than their sum. At present is amounts to about 75,000 E. H. P.

In the industrial world to-day close competition in the market for manufactured products has greatly reduced margins of profit. All possible economies, therefore, in cost of production become necessary, and factory managers in whose processes power is an important element are investigating in a more scientific way what their power costs them per annum. Nowadays, when the work of the factory is carried on so largely by machines, and not by men, the power cost becomes one of the controlling features in a plant. For these reasons factory managers in many cases are turning their attention toward Niagara power for the economies resulting from its use.

| |||

| A Recent View of the Interior of the Power House No. 1 of the Niagara Falls Power Company, Capacity. 50,000 H. P. |

|

|

| Section and Elevation of One of the 10,000 H. P. Generators for the Canadian Niagara Power Co. |

|

In modern factory construction the steam engine as a prime mover, belted to a long line of counter-shafting ex-tending throughout the shop as a means of factory drive, has become largely obsolete. If a steam engine is used, it is direct-connected to an electric generator, which transmits power electrically throughout the shop to individual motors at each appliance or group of appliances. This has been the important development in factory operation which has educated the manufacturing public into the use of electricity and has helped to create the present demand for Niagara power. The factory manager about to start a new mill, having in mind the use of Niagara power, does not have to decide between a steam engine belted to counter-shafting on one hand and a complete electric motor equipment on the other, necessary for the use of Niagara power. He has probably made up his mind to use electric drive in any case. His decision, therefore, rests between a boiler room, smokestack and steam engine direct-connected to an electric generator as a means for supplying current to his motors, and the use of Niagara power for the direct supply of current to his factory circuits by simply bringing in wires from the street. The gain in simplicity in the latter case, and the economy of space, are self-evident. As to the cost of Niagara power drive, it can be stated that power is supplied from the Niagara system for less than one-half what it costs from any of the steam-driven central stations in the country, or from any isolated steam plant. Electro-chemical industries using large blocks of power continuously for twenty-four hours each day save 75 per cent. in their annual cost of power by obtaining it from the Niagara system.

| |||

| The Switchboard in Power House No. 2. |

What the exact status of the Niagara power system will be ten years hence is difficult to state, but that it will be vastly increased seems a certainty. The economy in the use of water-power for manufacturing and other purposes and the fact that all the small water-powers throughout the country are rapidly being taken up to their limit will, of necessity, turn the power user toward the Niagara frontier. Furthermore, the constantly increasing cost of coal tends to discredit the use of steam power for manufacturing.

No power system in the world can compare in point of reliability with that of the Niagara Falls Power Company, where three large independent generating plants are available for the supply of a single group of customers. By means of the electrical inter-connections which exist between these three plants any one of them could be completely shut down, and the customers, to whom the continuous supply of power is essential, supplied with power without interruption. This is a matter of great importance, especially from the standpoint of the possibility of the large steam railways using Niagara power, where continuous train service is demanded.

Discovery and invention in the electrochemical field is very active, and some processes are in sight which will require large blocks of power for their operation. All these tendencies in industrial conditions, which have been mentioned, result in an accelerating demand for power from Niagara Falls.