[Trade Journal]

Publication: Electrical Age

New York, NY, United States

vol. 32, no. 3, p. 101-112, col. 1-3

Long-Distance Transmission of Energy

At High Electrical Tension

By M. H. GERRY, Jr., General Manager of the Missouri River Power Co., Helena, Montana

THE discovery of the elementary principle of transmitting mechanical energy by means of electrical currents from one dynamo machine, used as a generator, to another, employed as a motor, is claimed for Hippolyte Fontaine as a discovery made at Vienna in 1873, although it is probably of earlier origin. Marcel Desprez, by a series of experiments in 1881, directed attention to this branch of electrical engineering and demonstrated that energy could be transmitted electrically over considerable distances. The first commercial electrical transmission of any size is said to have been constructed in Switzerland, under the direction of C. E. L. Brown.

| |||

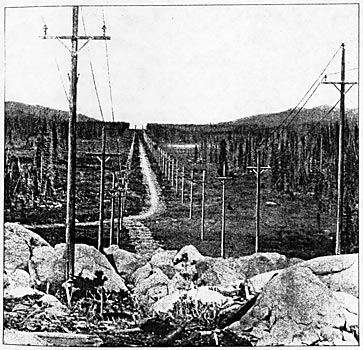

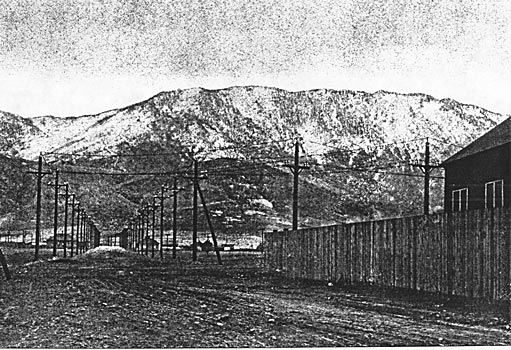

| The 57,000-Volt Double Transmission Line of the Missouri River Power Company at the Summit of the Continental Divide, 7,300 Feet Above Sea Level, Where the Lines Pass From the Atlantic to the Pacific Slope |

All of the earlier transmissions were undertaken with direct-current systems, but limitations in this direction were soon found, and electrical engineers turned to alternating currents for a solution of the problem. The advantages of the alternating system were recognized, but a great obstacle was presented in that no practicable alternating-current motor had been developed. Professor Ferraris in 1888, and Nikola Tesla, about the same time, developed in a primary form, a rotating field motor employing two or more alternating currents of the same period, but differing in phase relations. Dobrowolsky and Brown, together with other engineers both in Europe and America, soon developed this device into the present forms of induction motors.

With the invention of the induction motor, the most serious obstacle to die use of alternating currents for the transmission of power was removed, and the development from that time became quite rapid. At the Frankfort (Germany) electrical exhibition in 1892, the long-distance transmission from Lauffen to Frankfort, operating at 30,000 volts, was brought prominently- to the attention of engineers, and it became evident that such transmissions were feasible, if the engineering details were properly worked out.

| |||

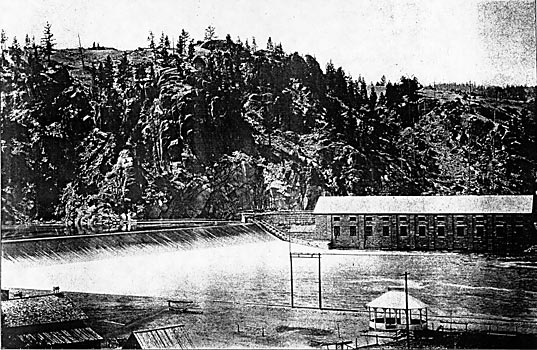

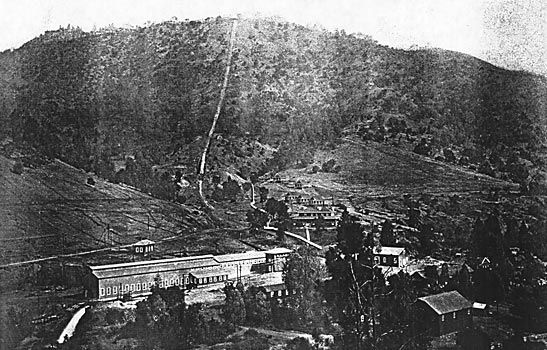

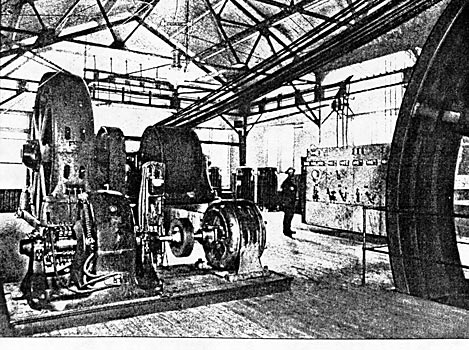

| Ten Thousand Horse-Power Are Available in the Power House of the Missouri River Power Company at Canon Ferry, Montana. |

Power is transmitted long distances for the same commercial reasons as are manufactured goods and materials. It was found that in certain places, owing to the existence of water-falls, an abundant supply of cheap fuel, or for other reasons, power may be produced in large quantities at a low price. This being the case, an electrical transmission becomes feasible whenever a market for the sale of the power is found at points within a practicable distance. As a commercial enterprise the generation and transmission of energy involve the problems of manufacture, transportation and sale, embracing economical production, efficient transmission, and a market where the product may be sold at a profit alike to the consumer and producer.

| |||

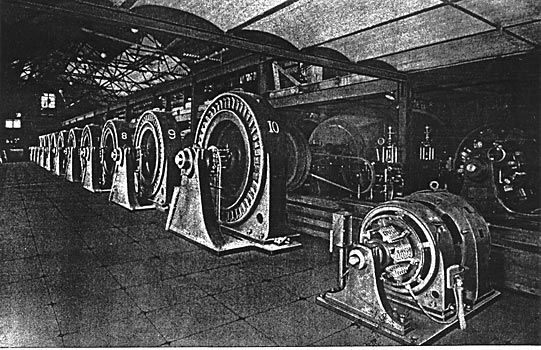

| The Interior of the Canon Ferry Power Station. |

The object of nearly all the transmissions thus far constructed has been the utilization of energy obtained from water-power at points distant from the place of development. From the earliest times water-falls have been regarded as among the great sources of power, well suited to the uses of civilized man. Before the day of electrical transmission this source of mechanical energy had been used only at points near the place of generation. There existed a few examples of transmission by means of ropes, compressed air, and other mechanical devices; but the efficiency attained was low, even for the short distances undertaken, and the performance generally was unsatisfactory, except under special conditions. Many water powers were so situated as to be of little value for commercial purposes, and this fact constantly appealed to the brain of the inventor. When electricity came into use commercially for lighting and other purposes, engineers at once appreciated its possibilities as an available agency for the transmission of energy over considerable distances, out the practical application was long delayed, awaiting the development of a proper system, and the production of materials and apparatus suitable for the purpose.

| |||

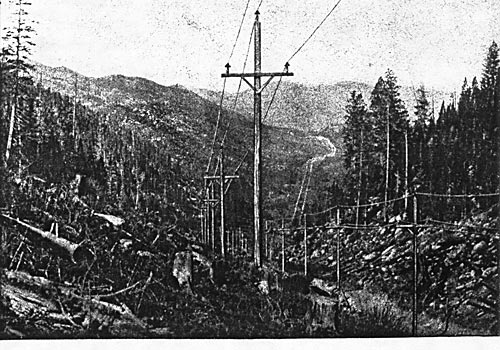

| The Transmission Line at 7,000 Feet Elevation. A Characteristic Rocky Mountain Region. |

| |||

| A View of the Power House of the Standard Electric Company of California, at Electra, Showing Also the Route of the Pipe Line. |

| |||

| Twenty-Mule Teams Were Not Uncommon in Hauling Machinery Over the Mountains for the Standard Electric Company of California. |

Lighting was the first commercial application, on a large scale, of electrical currents requiring considerable amounts of energy. The direct-current system came into general use for this purpose although there were many early experiments with alternating current. It soon became apparent, however, that aside from the many problems of the electric light as such, there was an underlying question involving the transmission of energy, and that if the energy were to be transmitted for this, or -any other purpose, this question must first be disposed of. Because of certain inherent advantages for transmission purposes, alternating currents from this time began to conic into use, and has ever since continued to gain in favor over direct-current systems.

The history of the electric railway is similar to that of electric lighting. At first, only direct current was used, on account of its apparent simplicity and ready application to motors; at a later day, however, the problem of the transmission of energy was found to enter very largely, and alternating current came into use for transmission purposes on long lines, although such current is afterwards converted into direct current for application to the cars, this having been done solely because, until latterly, no satisfactory alternating-current motor had been developed for traction purposes.

| |||

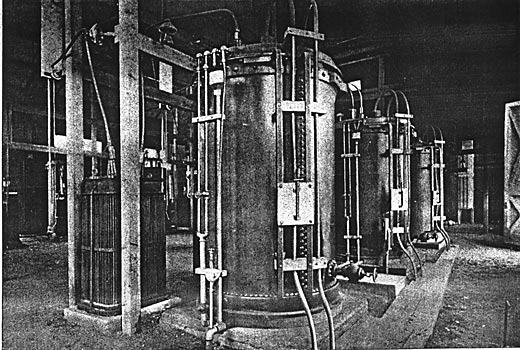

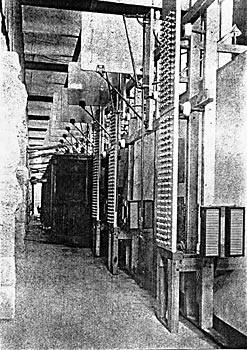

| The High-Tension Transformers in the Butte, Montana, Sub-Station of the Missouri River Power Company. |

From what has been said, it may seem that there is considerable advantage in the use of alternating current for the purposes of transmitting energy. This advantage arises almost entirely from one feature of the alternating system, and that is the ease with which the electrical tension, or voltage, may be increased or decreased, by means of simple and efficient apparatus. While this is easy of accomplishment with alternating current, it is comparatively difficult with direct current. The amount of electrical tension employed is the fundamental condition controlling the economical transmission of energy by means of electrical currents. With low tensions of a few hundred volts, as are employed directly in lighting and electrical traction, there can he no commercial transmission of energy over any great distance. With any given tension and a fixed percentage of loss, a distance is finally reached where the cost of the conductor becomes too great, and power transmission is then impracticable.

The great advantage of high tension being apparent, there has been a continual increase in the pressures utilized, but this has not been accomplished without many difficulties having been overcome. With tensions of a few thousand volts, it was comparatively easy to insulate both the transforming apparatus and the line, but with higher tensions the troubles increased, necessitating new designs and materials. The principal difficulties were experienced with the transformer and line insulation.

A great improvement was effected by the introduction of oil as an insulating material for transformers, and practically all transformers operating above 30,000 volts are now of the oil-insulated type. It was found, also, that in large transformers special means must be taken to remove the heat, and this has been accomplished in modern apparatus either by a forced air blast, for transformers operating at moderate tensions, or by, water circulation through coils immersed in the oil, for high-tension transformers. A great deal of scientific and experimental investigation has been devoted to the insulation of transformers, and a number of new materials have been developed which produce such excellent results in connection with oil insulation, that manufacturing companies are willing to guarantee apparatus of this nature, at the present time, to withstand 100,000 volts operating pressure. When it is considered that ten years ago almost the maximum tension for which apparatus could be obtained in America was 10,000 volts, the progress which has been made in this direction will be appreciated.

Second to the insulation of the transformers, the greatest difficulty was experienced with the insulation of the line. In the early experiments at Lauffen and other points in Europe, an attempt was made to utilize oil in the insulators, but it was soon discovered that this was impracticable, owing to the accumulation of dust, leakage, etc., and it has long since been abandoned. By improving the quality of both porcelain and glass insulators, it has been found that either of these materials may be made to fulfill the requirements for line insulation up to the highest tensions employed. Porcelain possesses greater mechanical strength, but it is more difficult of manufacture and more costly. Glass gives excellent results, but until recently has been difficult to obtain in the shapes and sizes required for insulators for very high tensions. At the present time there are a number of plants operating around 40,000 volts, some of them using glass and others porcelain insulators. There is a transmission operating in Canada at 50,000 volts employing porcelain insulators, and one in Montana at 57,000 volts, employing glass insulators.

High-tension lines should be constructed throughout with the utmost care, — the wires placed well apart, the grading of the pole tops carefully attended to, — in order to remove as far as possible the mechanical strains. Where feasible, such lines are often located on a private right of way, from which all timber and other obstructions are removed; and as a rule, where the nature of the service is important, the lines are duplicated, so that in case of an interruption on one line the other may be in readiness to maintain the service. It is necessary sometimes to locate transmission lines on railroad rights of way, or even along the public highways, but this is not desirable where it may be avoided. There are, however, a number of important transmissions in the West which are so located.

|

| Standard Insulator, Aluminum Cable and Tie, As Used on the Main Line of the Standard Electric Company of California. |

|

| Two Additional Types of Insulators Used for 60,000-Volt Current on the Bay Counties and Standard Electric Company Transmission Lines. All These Insulators Were Made by the Locke Insulator Manufacturing Company, Victor, New York. |

As already stated, a pole line designed for high-tension currents, and for continuous service, should be carefully designed and of the best material and workmanship. It has been customary in the past in constructing such lines to use the best quality of cedar poles, extra heavy wooden cross-arms, and either metal or wood braces. These make a substantial and reliable form of construction at a reasonable cost; but on account of the importance of some work undertaken and its magnitude, still more permanent and costly forms of construction are being advocated, and some plants are now building that employ steel towers in lieu of poles, and are making use of an entire metal structure, with the exception of the insulators, for supporting the circuits. It is probable that some form of steel structure will ultimately supersede the present wooden construction, whereever the undertaking is of sufficient magnitude and importance. While nearly all high-tension transmission lines have heretofore been placed above ground, the recent advances in constructing underground cables for high tensions render it probable that this form of construction may ultimately be used very largely instead of the present overhead methods. Except for the difficulty of insulation, underground cables have great advantages.

| |||

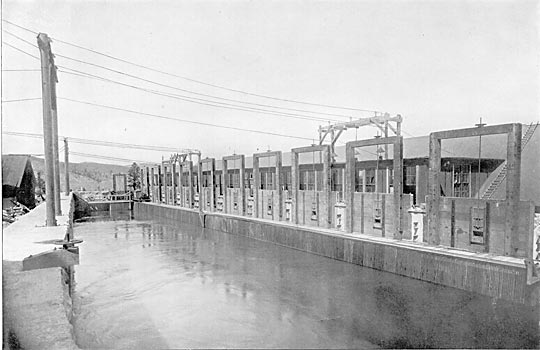

| The Canal and Headgates for the Canon Ferry Power House. |

In addition to the power wires, a telephone circuit is sometimes placed on the same poles for convenience in communicating between the generating station and the point of delivery, and also as a means of communication between various points along the line. In the early plants a great deal of trouble was experienced with these telephone circuits, but this difficulty has been almost entirely overcome, and a satisfactory telephone service may he maintained on the same poles with power circuits carrying the very highest pressures. It is customary for power companies engaged in the transmission of large amounts of power to maintain a complete telephone service connecting the plants, sub-stations, and even the large consumers.

| |||

| The Switchboard in the Generating Station at Canon Ferry. |

In addition to the improvements in transformers and the lines, there have been advances in recent years, in the design and construction of auxiliary apparatus, including lightning arresters and switching devices for high tensions. Such details are of the greatest importance in connection with work of this kind, which requires very reliable service and freedom from interruptions. At one time lightning was a most serious obstacle in the operation of all transmission lines, and it was thought that it would never be possible to operate such lines continuously during periods of severe electrical atmospheric disturbances. This has been overcome, and with care and the proper adjustment of apparatus, transmission fines may be made to operate in a successful and reliable manner under all weather conditions. The improvement in switching apparatus has been made such that high-tension currents may be handled and transferred with the same reliability as currents of but a few hundred volts. These improvements, and many others of a minor nature, have made the operation of electrical transmissions trustworthy and feasible for the longest distances, tinder the most exacting conditions.

|

| One of the High Tension Insulators of the Missouri River Power Company, Made by the Hemingray Glass Company, Covington, Ky. |

The first requirement for a successful transmission is a cheap and reliable source of energy. Up to the present time this has generally consisted of a water power development. Such powers vary widely in their nature, from what are known as low-head plants, where the amount of water is large and the fall comparatively small, to high-head plants, where only a small amount of water is available, but the head is very great. Water powers are developed in different ways. Low-head powers generally utilize dams, often combined with short canals, deep wheel-pits and tunnel trail-races. High-head plants usually employ long flumes, or canals, together with pipe flumes designed to sustain great pressure. Low-head plants have been in use for many years, the apparatus and machinery are more or less standard, and have been improved in detail only to conform to the requirements of electrical service. Many of the high-head transmission plants are situated in the western part of the United States. Nearly all high-head plants employ some form of impact water wheel, the water being directed to the wheel by means of nozzles controlled by suitable governors. Such wheels operate at high speeds and produce higher efficiencies than are developed by the turbine type of wheels almost universally used for low heads.

| |||

| The 57,000-Volt Double Transmission Line of the Missouri River Power Company Near the Butte Sub-Station. in the Background the Main Range of the Rocky Mountains Can Be Seen, Constituting the Continental Divide. the Lines Are Made Up of Six Copper Wires. |

Between low-head developments which have usually been considered as limited to about 100 feet, and the high-head developments of between 500 and 2,000 feet, there are numbers of moderate-head plants working within the limits mentioned. The design of these plants has been a combination of that employed for the high and low developments, usually combining dams with moderate length canals, of large pipe lines, and sometimes wheel-pits and tunnels. A variety of turbines is often employed, but differing materially from the designs for low heads, as the greater water pressures necessitate much stronger construction and higher speeds. In some instances plants of moderate head employ water wheels of the impact type, but as a rule these are small installations.

| |||

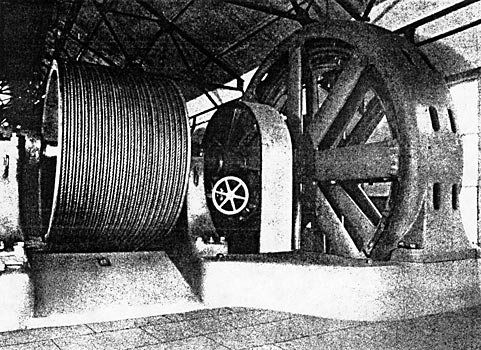

| A Large Motor Driving A Blowing Engine at the East Helena, Mont., Smelting Plant. |

In modern power plants the electrical generators are usually directly connected with the prime movers, whether steam engines or water wheels. This requires that the electrical generators be designed for the same speed. With water wheels the speed depends, to a certain extent, upon the head employed, but this may he varied with the design of the wheel. Alternating-current generators, usually of the three-phase type, are universally employed for transmission purposes. Such machines arc of the simplest construction, and in service give excellent results, with a very small amount of deterioration or repairs. The revolving parts are usually mounted either directly On the water wheel shaft, or on an extension of this shaft, connected through a coupling. In the older plants the current was generated at comparatively low pressure, rarely exceeding 1,006 volts; but in most of the later plants this pressure has been increased, in some cases to 10,000 or 15,000 volts at the generator. The high pressure entails a greater strain on the insulation, but the advantages in other directions, in the way of simplified construction, reduced dimensions of the bus-bars, conductors and switches, etc., more than offset the disadvantages due to the higher pressure.

From the generators the current passes through the switching apparatus to the transformers, where the electrical tension is increased to the extent required for transmission. After the pressure has been increased at the transformers, the current is conduced through other switching devices to the transmission circuits. At this point are connected the lightning arresters. which arc designed to carry off static charges from the atmosphere.

At the end of a transmission line the power circuits are usually conducted to a sub-station, in which are located transformers for reducing the pressure for distribution, or for direct application to motors or other apparatus. Besides the transformers, there are ordinarily placed in the sub-station lightning arresters similar to those in the main generating station, and also a switching arrangement for both the high-tension transmission and the low-tension distribution. The distributing tines from the sub-station may he either underground or overhead.

| |||

| Lightning Arresters in the Plant at Canon Ferry. |

The practical applications of electrical energy are numerous and varied. In the West, where are located most of the long-distance transmissions, a great deal of power is used for mining, ore milling and smelting operations, including the concentration of ores, the operation of air compressors, blowers, hoists, mine pumps, and other similar machinery. In some sections considerable power is used for pumping water for irrigation, and large amounts are employed for lighting, operating electric railways, and miscellaneous power uses. Electrolytic and electrochemical operations consume a constantly increasing- amount of transmitted energy, and in every line of industrial activity new applications for electrical power are being found.

The trend of development in power transmissions is towards higher tensions and longer distances. About 60,000 volts are the maximum tension now utilized in commercial service, but within a few years much higher tensions will he employed, and there will be in operation transmission lines longer than any now in existence. Commercial transformers can be obtained at present from manufacturing companies, suitable for 100,000 volts, and there are no serious obstacles in the way of the use of this tension when the conditions are such as to warrant the installation. There are, in truth, difficulties to be overcome, but they are only such as are met with in advanced engineering construction in any line. Each year brings more knowledge towards the solution of electrical problems and an increasing tendency towards better and more reliable forms of construction. The business of transmitting power is increasing rapidly and future development is fraught with great possibilities.

There are still a great many undeveloped water powers, inaccessibly located, which can be profitably utilized in the future. Besides water powers there are large deposits of coal which, owing to their low grade and the high cost of transportation, are now of little value. If these deposits were utilized locally and the power thus generated were transmitted some hundreds of miles, they would become of great value. This great field, now almost unoccupied, gives promise of future development, and awaits only .a more intimate knowledge on the part of engineers and the public of the methods and results of high-tension electrical transmissions.

In electrical railroading, on a large scale, high tensions must play an important part, as the fundamental problem is that of the transmission of energy. With a solution of this problem at hand, it requires only the perfection, in detail, of suitable motors and appliances to render practicable the operation, by electrical methods, of freight and passenger railway service of all classes. The change to electrical power would result in reducing operating costs and in improving the conditions of railway transportation. The financial outlay would be very great, but when viewed in the light of the present industrial development, even this may not long delay the adoption of electrical power.

| |||

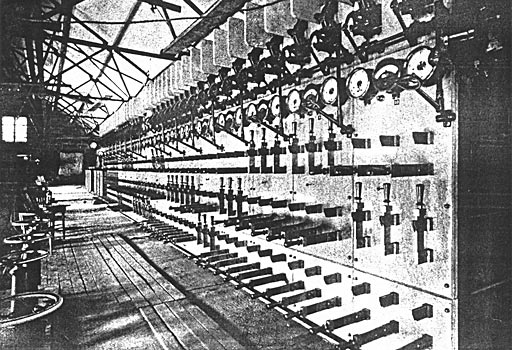

| One of the 800-Horse-Power Slow-Speed Induction Motors for Which the Missouri River Power Company Furnish Current. |

From what has been said it appears that mechanical energy can be produced at the lowest cost per unit in large plants favorably located, and that high-tension electrical transmission renders possible the delivery of this energy with small loss, in any amount, at a large number of points distributed over a wide area. By affording an efficient method of delivery, it makes practicable, from a commercial standpoint, the wholesale manufacture of power. This is in line with the present era of specialization, in accord with the spirit of the age, and with American methods of industrial economy.