[Trade Journal]

Publication: Elektrotechnische Zeitschrift

Wuppertal, Germany

p. 372-373, col. 2-3

The exhibition of the Hermsdorf S.-A. porcelain factory was almost exclusively devoted to porcelain items for high-voltage purposes. Some of the exhibits consist of insulators for the power line.

Cable construction, of which the patented delta bells (Fig. 10) are particularly noteworthy, and on the other hand from porcelain parts that are used for high-voltage switches and other electrical devices.

|

| Fig. 10 |

The delta bells are manufactured for operating voltages of 5000 to 65,000 V in the sizes shown. All bells, grooved insulators and all porcelain parts intended for high-voltage purposes are tested in our own high-voltage test facility for at least 15 minutes before shipping with a voltage that is three to four times the value for small insulators and at least twice the value of the operating voltage for large insulators.

In addition, some insulators that had punctured during testing were exhibited to show the influence of manufacturing errors.

|

| Fig. 11 |

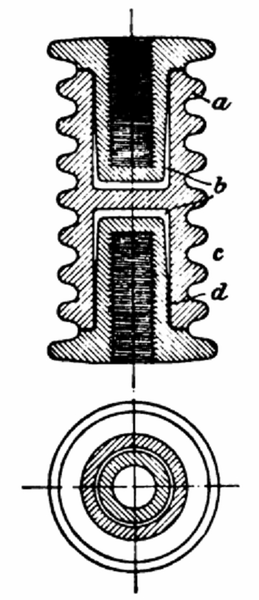

Most of the punctures are due to the manufacturing error that often occurs with a piece that is too thick, namely that the mass is not processed tightly enough and then has bubbles or cracks when fired. This disadvantage is remedied by the fact that in all cases where a strong body is required in order to achieve high dielectric strength, this is made in two or more parts. For this purpose (Fig. 11) piece ac with glaze layer d is fired together with part b.

The parts can be joined together without or with the inclusion of a limited air space. In both cases, a dense processing of the mass, complete burning through of the individual shards and thus the production of a homogeneous insulating material is achieved in the most perfect way possible.

The insulators, when manufactured using the new process mentioned, also produce better results in terms of mechanical strength. For example, in some of the insulators on display, the screwed-in support with a diameter of 37 mm had a horizontal tensile load of 1800 kg on the insulator head caused it to bend without the insulator itself showing any damage.