[Trade Journal]

Publication: Street Railway Journal

New York, NY, United States

vol. 27, no. 23, p. 896-905, col. 1-2

THE POWER TRANSMISSION LINE AND THIRD-RAIL

SYSTEM OF THE LONG ISLAND RAILROAD — I

BY W. N. SMITH

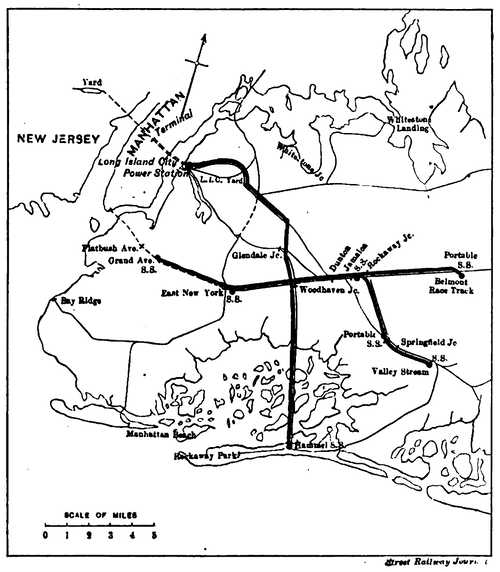

The high-tension electric transmission line of the Long Island Railroad constitutes the means of distributing to its sub-stations the electric current generated in the Long Island City power station of station of the Pennsylvania Railroad Company, described in the STREET RAILWAY JOURNAL for April 7. As the transmission system was naturally governed as to dimensions and length by the number of sub-stations and their location with reference to the powerhouse, it is proper to preface a detailed description of it with some general remarks on the arrangement of the power transmission and distribution system, as required properly to meet the demands of the electrically-operated traffic on the Long Island suburban lines. The lines first equipped comprise the Atlantic Avenue Division, between Flatbush terminal and Belmont Park, and the Rockaway Beach Division, between Woodhaven Junction and Rockaway Park. The equipment of this latter division has also been extended to enable electric operation via. Far Rockaway to Valley Stream.

|

| Fig. 1. — Map of Transmission Lines of Long Island Railroad |

A study of the traffic conditions to be met by the electrical equipment upon these divisions resulted in a preference for sub-station sites at Woodhaven Junction, East New York, Flatbush Avenue, Rockaway Junction and Hammel. These were ultimately selected as permanent sub-station locations, except that Grand Avenue, about one mile out from the terminal, was later on substituted for Flatbush Avenue. Since the original installation described in this article was completed, a sixth sub-station has been located at Valley Stream, receiving its power from an extension of the overhead line by way of Springfield Junction.

Two portable sub-stations, as illustrated in the STREET RAILWAY JOURNAL for Nov. 4, 1905, were also provided as the most economical method of supplying current for the very heavy periodic traffic to and from the Metropolitan race track south of Jamaica, and the new Belmont Park race track, about five miles east of Jamaica. These loads occur for two hours each day, for periods of two weeks, twice a year.

The portable sub-stations consist of 100-kw rotary-converter outfits, complete with transformers and switchboard, each mounted in a heavy steel box car. A lightly constructed house, built of structural steel and enclosed with expanded metal and concrete, is provided at each site to enclose the terminals and shelter the portable apparatus when in use. From Rockaway Junction sub-station, one branch of the high-tension transmission line is run to the portable sub-station terminal house built at Belmont Park, and another to that at Springfield Junction.

In reaching a decision as to whether the overhead or underground type of construction should predominate, a very careful study was made of the record of experience in operating lines of great length and of large carrying capacity. It appeared that the troubles in overhead lines were generally from the following causes: Wind, lightning and sleet storms, or structural weaknesses of poles, cross arms, pins, and insulators, or outside interference, either from branches of trees or mischief makers and thieves; and very rarely, by heat from a conflagration close to the route.

In case of conduit construction, it was found that break-downs were generally due either to capacity effects causing extraordinary voltages, or to depreciation of cable sheaths from electrolysis, or to short-circuits by reason of mechanical injury, imperfect insulation or failure of joints; and occasionally to overloading or to gas explosions in manholes.

Comparing the causes and effects of the troubles in the two classes of construction, the general conclusion was reached that, while an overhead line is liable to more frequent interruption through minor troubles than an underground line, the interferences with continuous operation on an underground line, when they do happen, are likely to be of a more serious character, and of longer duration. Experience showed conclusively, that the principal causes of interruption to service in overhead circuits could be prevented by proper attention to mechanical sufficiency in the overhead structures; a characteristic which, though necessary, has frequently been overlooked in the past. Although underground construction might, have been preferred, could its cost be brought down to something like an equality with overhead costs, financial considerations favor the adoption of the overhead type because its cost is only a fraction of that involved in high-tension cable and conduit work, and because its reliability is assured when properly installed. Overhead construction was, there-fore, adopted wherever it was usable.

The topography of the system is such that Woodhaven Junction sub-station becomes a natural distributing center between the power house and the other sub-stations, and it was, therefore, decided to make it the objective point of a main power transmission trunk line, which should bring directly to it the entire output of the power station for distribution among the sub-stations. The problem of line construction was therefore to build a trunk line from the main power station to Woodhaven Junction, with two branch transmission lines running along Atlantic Avenue, between Grand Avenue and Rockaway Junction, with two subordinate branches from Rockaway Junction to the two race tracks, and a third subordinate branch running directly south from Woodhaven to Hammel sub-station, across the Jamaica Bay trestle. Fig. 1 is a map showing the route followed by the transmission lines.

The general conditions controlling the location of the power transmission lines were such as to render difficult the construction of certain parts of it. Although the railroad right of way is, in most places, available, it is not always straight, and is sometimes so narrow as to make it difficult to meet the usual and desirable restrictions, with respect to close proximity of the line to telephone and electric light wires, trees and other abutting property, which are commonly regarded as conducive to safety in operation. Although the expense of underground cable construction precluded the possibility of recommending it uniformly for all locations, nevertheless, the impracticability of constructing high-tension overhead lines in thickly populated sections of Brooklyn and Queens required recourse to underground construction in two sections of the line. One of them comprises 1 1/8 miles of main trunk line, from the power station to Dutchkills Street, and the other traverses Atlantic Avenue, between Flatbush terminal and Dunton, just west of Jamaica. Except where sub-marine cables were used, at the Broad Channel and Beach Channel drawbridges in the Jamaica Bay trestle, the remainder of the transmission line is of the overhead type of construction.

|

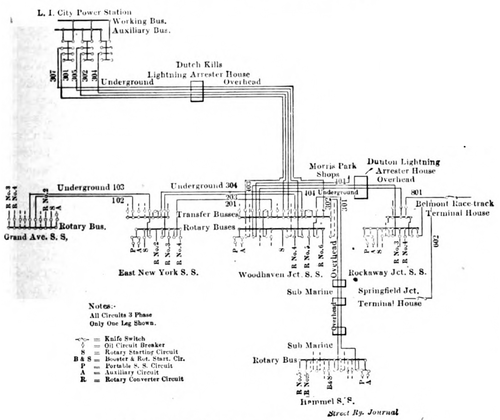

| Fig. 2. — Outline Diagram of Circuits |

The trunk line as originally built carries five circuits from the power station to Woodhaven Junction sub-station, running in an eighteen-duct conduit line to Dutchkills Street, thence on a line of steel poles which follows the right of way of the Main Line Division, to a point about due north of Glendale Junction, where it bends to the south across the fields for about a mile, until it strikes the Rockaway Beach Division, which it follows to Woodhaven Junction. A branch line of three circuits runs westward from Woodhaven Junction to the East New York sub-station, two circuits running thence to Grand Avenue sub-station, all these being run in underground conduits. To the east of Woodhaven Junction there are two circuits run underground to Dunton, where the transmission is changed from underground to overhead, continuing easterly on steel poles to Rockaway Junction sub-station. The branch circuits from Rockaway Junction to the portable sub-station terminal buildings at Belmont Park and Springfield Junction, are carried on wooden poles running along the Main Line and the Montauk Division, respectively, to their destination. Southward from Woodhaven two circuits follow the Rockaway Beach division across the Jamaica Bay trestle to Hammel sub-station. These circuits are carried on a line of steel poles to the southern outskirts of Ozone Park, half a mile or more from the sub-station, and the remainder of the distance on wooden poles.

| |||

| Fig. 3. — View of Pump House on Main Conduit Line, Near Long Island City |

The general arrangement of the transmission circuits is shown in Fig. 2. It will be noted in this diagram that the incoming-trunk line circuits at Woodhaven Junction are dis-tributed along a set of bus-bars called the "transfer bus," and divided into sections from which the outgoing transmission circuits lead in various directions. It is possible by manipulation of the bus junction switches to operate these circuits separately or together, from outlying sub-stations all the way back to the power station. The same general arrangement is carried out in a smaller degree by similar transfer buses at East New York and Rockaway Junction.

The lengths of the various sections of the transmission lines are as follows:

Conduit section of trunk line, power station to Dutchkills Street, 1.12 miles. Over-head trunk line, Dutchkills Street to Woodhaven junction, 7.85 miles. Conduit section, from Woodhaven to East New York, 3.23 miles, and from East New York to Grand Avenue, 3.04 miles, Woodhaven to Dunton, 1.7 miles. Overhead, from Dunton to Rockaway Junction, 1.73 miles; Rockaway Junction to Belmont Park, 3.71 miles; Rockaway Junction to Springfield Junction, 3.35 miles; Springfield Junction to Valley Stream, 2.57 miles; Woodhaven Junction to Hammel, 6.98 miles.

The total mileage of conduit lines now in use is therefore 9.09, and that of pole lines, 26.19 miles.

CONDUIT CONSTRUCTION

The duct line leading from the manhole directly outside of the Long Island City power station, runs out Fourth Street to West Avenue, thence to Sixth Street, which it follows to the railroad tracks. Thence it runs along near the northern edge of the railroad right of way to the arrester house at Dutchkills Street. Between the power station and the railroad tracks, the construction involved no serious complications , except such obstructions as are frequently met with in city streets. The remainder of the line involved not only some blasting through a ledge of rock, but was also rendered especially difficult because much of it was situated below the level of the ground water, which, for a large part of the distance, was nearly at the surface, so that special provision for the drainage of the ducts and manholes was necessary. The man-holes in this part of the line are connected by a line of 8-in. sewer pipe laid beneath the ducts and entering the manholes about 18 ins. from the bottom, thus forming a catch basin to prevent silt or other foreign matter from getting into and clogging the pipe. This conduit line is so pitched as to bring all the drainage into three sumps, one located at the power station, one about one-half mile from it, and the third near the Dutchkills Street end of the conduit line. These sumps are kept pumped outby electrically-driven submerged centrifugal pumps, automatically controlled, and discharging into the city sewer system. An illustration of the pumping house at the Dutchkills sump is shown in Fig. 3.

This conduit line is constructed of single vitrified-clay ducts, 18 ins. long, with square holes 3 13-16 ins., inside measurement, and walls 3/4 in. thick. They were designed especially for the construction, and the ducts are 7-16 in. greater diameter than usual in order to facilitate the installation of the three conductor high-tension cables, which are nearly 3 ins. in diameter. A single duct was preferred to multiple ducts because of the thicker wall between ducts, which is better able to resist heat in case of a possible short-circuit. A square hole, with rounded corners, was preferred as affording space for dirt and pebbles to slide to one side, instead of being dragged along underneath the cable and injuring the sheath, as would be the case if round ducts had been used. The ducts are laid in cement mortar in such a way as to break joints in all cases, and are surrounded on the top, bottom and sides by a covering of concrete 4 ins. thick, composed of one part Portland cement, two and one-half parts of sand and five parts broken stone. The ducts are arranged three wide and six high.

The foregoing type of duct construction was adopted after duly considering the merits of various other types of ducts.

| |||

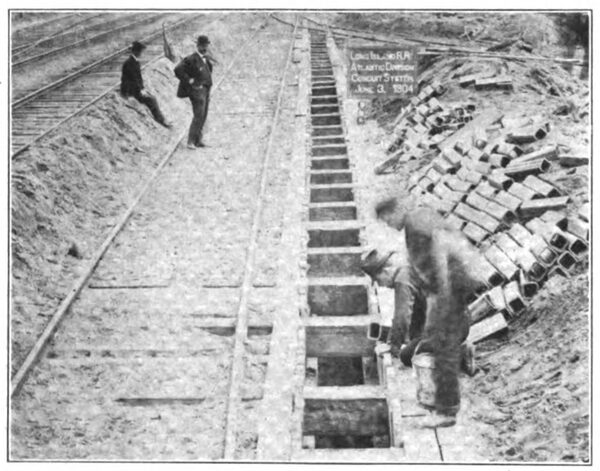

| Fig. 4. — Conduit Manholes Close to Track, Atlantic Division |

Manholes for drawing in and splicing the cables are located 400 ft. apart on straight work and a shorter distance on curves. The standard manhole for straight-line work is 8 ft. long, 4 ft. wide, and 6½ ft. high, inside dimensions. The corners are cut off, so that a horizontal section of the manhole resembles an elongated octagon. The side walls at the bottom are 12 ins. thick, and at the top 6 ins. thick, reinforced with expanded metal. The manholes are built of concrete, having a composition the same as that surrounding the ducts. An opening at the top is 25 ins. square, and is closed by two covers, the inner one of which can be locked, clamped, and packed gas tight if found desirable. Where, as sometimes happens, it was necessary to locate a manhole underneath the railroad tracks, it was strengthened by inserting additional I-beams in the roof. When the conduit line was placed between the edge of the right-of-way and the tracks, the limited space available made it necessary to change the shape of the manholes, which was done by making the side away from the tracks perfectly straight, and about on a line with the outside row of ducts. The interior arrangement was in every case such that cables could be spliced and carried across from one duct to another without introducing any sharp bends or leaving the cables unsupported.

During the construction of the conduit line out of Long Island City through the wet ground, it was necessary to line the trench with 3-in. tongued and grooved sheathing, and to use sump pumps continuously to remove the water. The sheathing was left in place at the completion of the work.

The conduit system on Atlantic Avenue comprises two kinds of construction. The portion lying between Atkins Avenue and Dunton, a distance of 4.4 miles, is in general identical with the above described construction for the main transmission line. It is installed on the south side of the tracks near the edge of the right of way. On this part of the construction the soil is of a very light sandy nature, so that the system is sufficiently drained by providing openings at the bottom of the manholes. As shown in Fig. 4, this section of the conduit construction was very close to the railroad track, in fact, the track overhung it for a good part of the distance, so that it became necessary to support the railroad track (which was in continual use) on one edge of the excavation, requiring a large amount of careful shoring to insure safe operation. The Atlantic Avenue Improvement conduits are built of four-way vitrified-clay duct, 36 ins. long, with square holes 33% ins. on a side. These ducts are laid in cement mortar, the joints being first covered by a wrapping of cotton cloth saturated in Portland cement grout. Where the ducts are laid beneath the surface of the street, the assembled ducts are surrounded by a wall of concrete, 3 ins . thick on the sides and 4 ins. thick on the top and bottom.

On the Subway portion of the Improvement, the manholes for the conduit lines consist of niches in the side walls, 5 ft. wide, 8 1/2 ft. in length, and 15 ft. high. These manholes are accessible from the street through regular manhole openings, and can also be reached from the Subway, as the side nearest the tracks is closed only by a rolling steel shutter.

On the other portions of the Atlantic Avenue Improvement the manholes are built of concrete, and are generally oval inform, 7 ft. long, 5 ft. wide, and 6 1/2 ft. high, inside. The roof of this type of manhole is supported by I-beams, having an opening through it 24 ins. square closed by two covers, one of which can be locked gas tight. The manholes are located not more than 400 ft. apart. Where necessary, several of the mare provided with a sump and automatically controlled electric-driven pumping apparatus. The pumps are of the sub-merged vertical centrifugal type, with 3-in. discharge, and when running at 840 r. p.m. will deliver 300 gals. per minute. They are controlled by an automatic starting device operated by means of floats, which prevent the water from rising above a certain height. The discharge pipes are connected to the city sewerage system. The motors are of the direct-current type, of 52-hp at 220 volts.

UNDERGROUND CABLES

The underground high-tension cables are of the three-conductor type, each conductor having a cross section of 250,000 circ. mils, and being composed of thirty-seven copper wires. Each conductor is covered with a wrapping of impregnated paper, 7-32 in. thick. The interstices between the insulated strands are then filled in with jute insulation and another layer of 7-32-in. thick paper insulation is wound over the entire group. The outside sheath is 9-64 in. thick, and is composed of lead, with about 1 1/2 per cent of tin added. The completed cable is 2 7/8 ins. outside diameter. Each length of the cable was tested at the factory by applying 30,000 volts. between each pair of conductors, and between each conductor and the sheath. After the cable was installed in the ducts and joined up ready for service, it was again tested by applying between each pair of conductors 30,000 volts, and between each conductor and the sheath 27,000 volts for a period of 30minutes.

At each end of every high-tension cable there is sweated on a spun-brass end-bell , which is filled with "No. 67" GE com-pound, to properly seal the ends of the cable and prevent injurious static discharges. The end-bell is about 7 3/4 ins. in diameter, and about 7 ins. high. The three conductors are brought out separately through a wooden head in the end-bell, after being wrapped with varnished cambric tape, and are surrounded by micanite tubes, to give additional insulation.

At the drawbridges in the Jamaica Bay trestle, the cables are of the armored submarine type, and the conductors are insulated with 7-32 in. of rubber around each strand, with another 7-32 in. of rubber around the group of three. This insulation is composed of 30 per cent pure Para rubber, and is covered with a sheathing 9-64 in. thick, and composed of lead with about 1 1/2 per cent of tin added. Over this is an armor of No. 4 B.& S. galvanized-iron wires laid spirally on the out-side of the lead covering, with a thin layer of jute between the lead and the armor. There are two such cables at each draw-bridge.

The high-tension cables are located in the lower portion of the conduit system wherever possible with the idea of separating them from any other cables for different purposes which may be installed subsequently. They are carried around the sides of the manholes in racks. The minimum radius of bend in this type of cable is 18 ins. Where exposed in the man-holes, and at the sub-station terminals, the cables are wrapped with a layer of hard-rolled asbestos mill board, 1/8 in. thick, and outside of the asbestos mill board there is a wrapping of asbestos listing 2 ins. wide, laid on until it averages 3/8 ins. thick. The whole is then wrapped with galvanized-iron tape, 1-64 in. thick and 1/2 in. wide, laid on with edges overlapping. At each manhole, there is a strip of sheet copper sweated onto the lead sheath and brought out through the wrappings, to allow of grounding the cable should it be necessary to protect it from electrolysis.

Before the cables were pulled into the ducts , a wooden mandrel, 3 ft. long and 3 1/8 ins. in diameter, was pulled through, to insure a clear passage.

At the Jamaica Bay drawbridges, the armored cables were laid across the channel, and allowed to settle to the bottom. A diver then arranged them so that they were properly separated, and they were sunk into the mud by means of a waterjet, supplied by pumps at 100-lbs. pressure. By means of this jet, the diver was able to scour out a trench wide enough to contain the cables, 4 ft. below the bottom of the channel. This method of installation was preferred to dredging because of the difficulty which would have been encountered in at-tempting to dredge the trench through the fender piles on either side, and because of the rapid current through the channels, which would fill with sand a trench so dredged immediately after excavation, unless the cables should be laid during the dredging process, which is obviously impracticable.

There is in all about 25 miles of high-tension underground cable installed, besides 418 miles of armored submarine cable.

ARRESTER HOUSES

The vulnerability of underground cables to lightning and to other static disturbances which may be setup in the trans-mission line, require that the outlying ends of transmission cables exposed to lightning discharges be provided with protective apparatus. Wherever the underground cable section of the transmission line is jointed up with the overhead system, lightning arresters and choke coils are installed, suitable houses being provided to shelter this apparatus. There is one of these houses on the main transmission line at Dutch-kills Street, Long Island City, and another at Dunton, on the branch line running east of Woodhaven. Smaller houses were also provided for the same purpose at the two drawbridges.

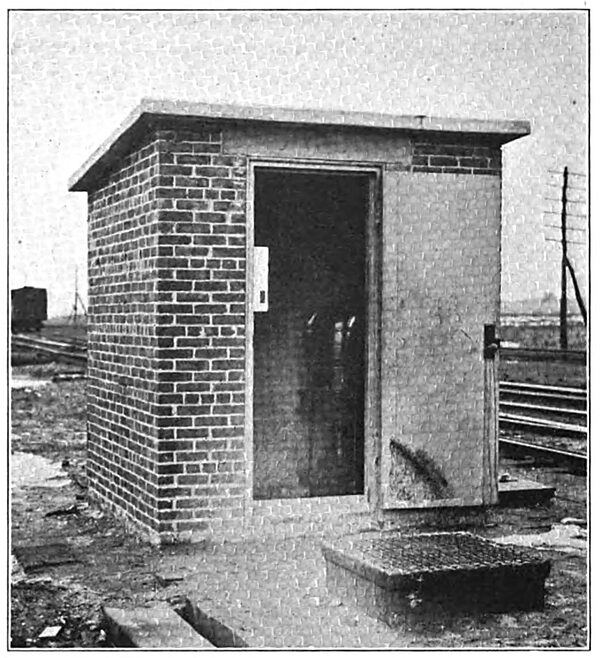

| |||

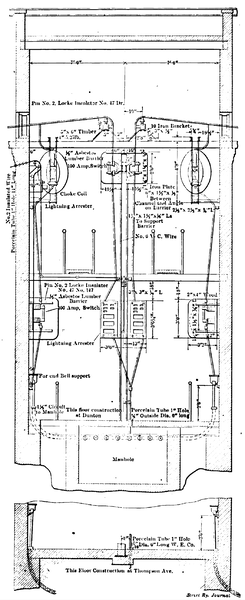

| Fig. 5. — Arrester House at Dutchkills Street |

The house at Dutchkills Street is a brick structure, a photographic view of which is shown in Fig. 5. This at present contains room sufficient for eight outgoing overhead circuits, which leave the house four on a side. The general design of the transmission line is such that the circuits on one side of the poles can be shut down for repairs without shutting down those on the other side, and this idea was carried out in the construction of the arrester house, so that there would be no confusion possible between live conductors and dead conductors whenever it might become necessary to do any repair work on the line. The arrester house is 33 1/2 ft. in length, 17 1/2 ft. wide and 30 1/2 ft. high, inside, and is con-structed of brick, with a concrete floor and roof. The disposition of the apparatus in the interior is shown in Fig. 6, and it will be noted that the steel beams supporting the apparatus extend to the outside of the building, forming a series of racks for the support of the transmission cables, which are dead ended upon them. The arresters are all provided with knife switches, so that they can be readily disconnected from the circuit. A choke coil is also provided in series with each main circuit, and another knife switch between the choke coil and the cable bell, enabling the cable to be entirely disconnected from the overhead line. The disposition of the material is such as to economize space, and at the same time makes each circuit capable of ready access without the necessity of incurring risk from other apparatus, in case it needs repair. Wood has been entirely omitted from the construction of this arrester house, making it fireproof. The incoming cables are carried through the floor by means of ducts reaching to the last manhole in the conduit line, and are arranged along the wall, running through switches and through the choke coils to the various outlets along the various portions of the outside walls. The arresters are mounted on either side of the steel framework in the center of the building, and the ground connections all run to a single ground lead, consisting of 5 1/2 square feet of copper plate buried in the ground between layers of crushed coke. The arresters are of the Westinghouse low-equivalent type, mounted on marble slabs, which in turn are carried upon porcelain insulators.

|

| Fig. 6. — Cross -Section of Lightning Arrester House. Main Trunk Line |

The outgoing cables on each side are anchored on a strain pole after leaving the racks upon the sides of the building, which in themselves are not intended to carry the longitudinal stresses of the overhead cables.

| |||

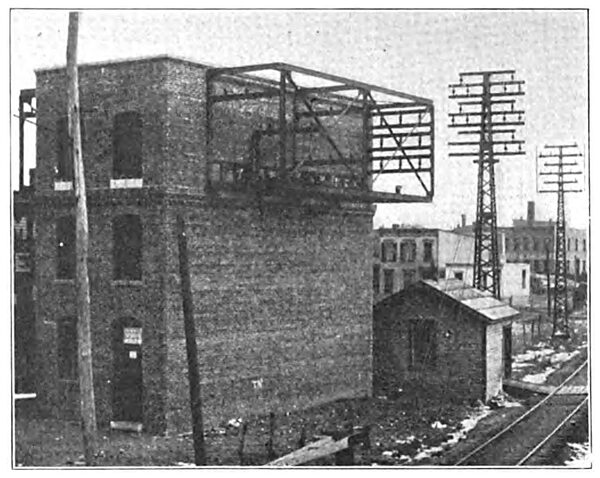

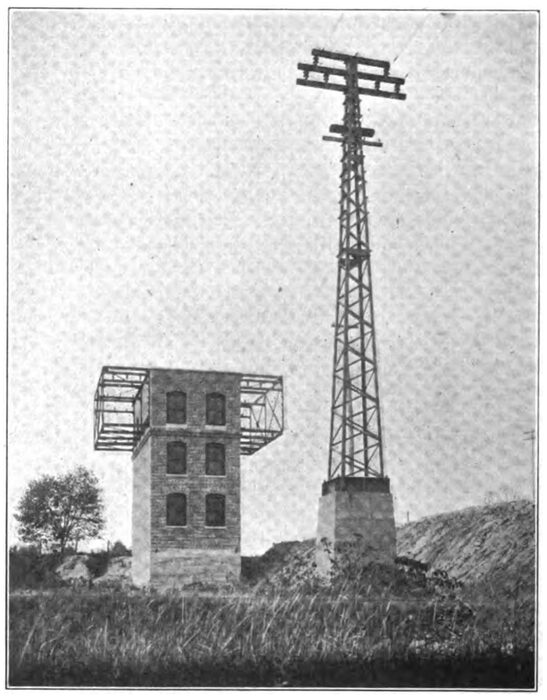

| Fig. 7. — Arrester House at Dunton and Adjacent Strain Pole |

The openings in the side of the house through which the cables run, are 18 ins. square, enclosed by two glass plates 3/8 in. thick, and separated 5 ins. with 2 1/2-in. holes in the centers, through which the cable passes without touching the glass. A thin disk of brass, 2 1/2 ins. in diameter, is attached to each wire midway between the glass plates, and thus prevents the direct access of rain or snow through the openings. Standard straight-line insulators are used for supporting the bare wires inside of the building.

A house similar to the foregoing is located at Dunton, where the branch transmission line running eastward from Woodhaven is changed from conduit to overhead construction. The design of this house and the arrangements of the apparatus inside it are identical with the one above described, but with capacity for six circuits instead of eight. An illustration of this house is shown in Fig. 7.

| |||

| Fig. 8. — Arrester House at Broad Channel Drawbridge |

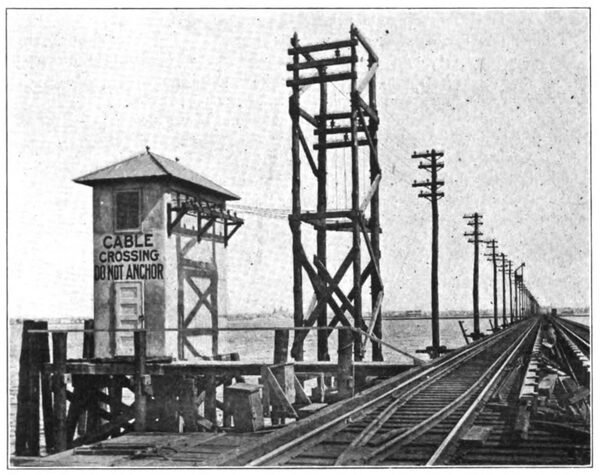

At the drawbridge channels in Jamaica Bay, three houses are provided to shelter similar apparatus. Each of these consists of a steel framework covered with expanded metal and concrete side walls, and a corrugated copper roof resting upon a pile foundation. The method of entrance of wires is similar to that above described, and the strains of the overhead line are taken by a separate anchorage, composed of four poles braced together, forming a stiff wooden tower, which carries the longitudinal strains of the line without guying. The pile foundation is protected from ice by clusters of fender piles suitably located around them. There are two of these houses at Broad Channel, and one for the north side of Beach Channel, as the south end of the submarine cable at the latter place after passing to the shore runs through ducts directly to Hammel sub-station, which is only a few hundred feet from the drawbridge. A photographic view of the arrester house at Broad Channel is given in Fig. 8.

OVERHEAD-LINE CONSTRUCTION

The overhead construction is of the most substantial character. Up to about five years ago, the line construction of almost every electric railway and power transmission system was patterned after the standards which were evolved from telegraph construction practice where the conditions were not particularly exacting, and the penalty for breakdown was not great. The ab-solute necessity for reliability in a transmission line that serves a public utility of such magnitude as the Long Island Railroad, re-quires a stability in all parts of the construction that calls for the exercise of engineering skill and foresight to a greater extent than has hitherto been usually brought to bear. To give the continuous service which conditions demand it is necessary to construct a line in which the chance of failure of any part is reduced to a minimum, and that cannot be torn down or seriously disabled, except through some extraordinary catastrophe which would compel the temporary suspension of railroad operation. Consequently, instead of building a pole line by rule of thumb methods, all lines of engineering experience were brought to bear upon the problem with the object of carrying its mechanical sufficiency and stability to a degree of perfection that would afford the least possible chance for a shutdown from any of the usual causes.

| |||

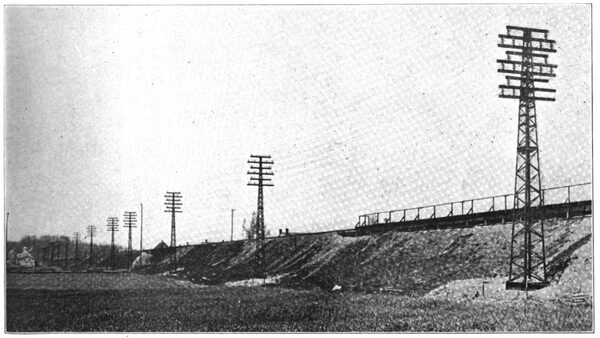

| Fig. 9. — Main Overhead Trunk Line Near Woodhaven Junction |

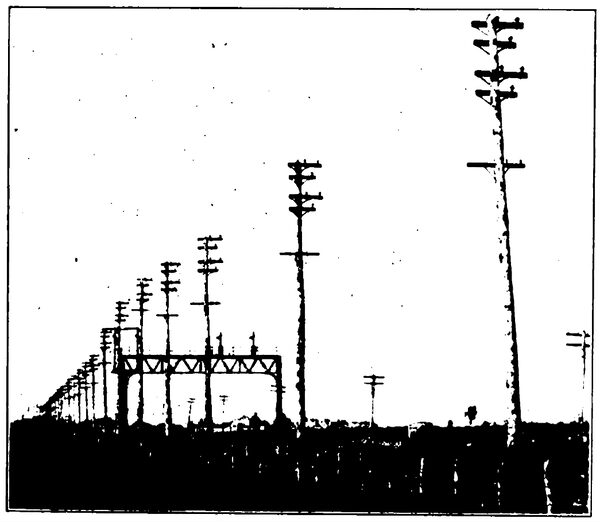

There are two general divisions of the overhead consturction [sic] construction, the trunk line between Dutchkills Street and Woodhaven Junction, and the branch lines between that point and the other outlying sub-stations. The trunk line, shown in Fig. 9 , is built of steel poles, and the branch line between Dunton and Rockaway Junction, through which the latter sub-station and two portable sub-stations are fed, and upon which the circuits to stations not yet constructed may eventually run, is also equally important with the trunk line, and is therefore built of steel. From Rockaway Junction, the branch pole lines to the separate outlying sub-stations are of wood, as shown by Fig. 10. From Woodhaven Junction south the poles are of steel to the southern outskirts of Ozone Park, because of the rather exceptional height at which the cables have to be carried to clear other wires, but from Ozone Park to Hammel they are of wood.

The pole lines have not been duplicated for the sake of greater security, as is sometimes done where plenty of room is available for pole lines, and where other conditions make it desirable. It was decided that a sufficient degree of insurance would be obtained by constructing a single-pole line in the most substantial manner. The suburban lines of the Long Island Railroad form several loops or meshes of a net work which may afford an opportunity for the construction of additional transmission lines by other routes, should future conditions require such a development.

The trunk line is designed to carry eight three-phase trans-missions circuits, consisting of three 250,000-circ. mil cables each, together with eight low-tension cables of 500,000 circ. mils each. As the latter, when installed must be 25 ft. above the ground, and as there must be a reasonable clear space between the low-tension and high-tension circuits, no argument is re-quired to demonstrate the necessity for using steel-tower construction to carry such an unusual weight of overhead conductors.

| |||

| Fig. 10. — Wood Pole Construction, Looking North From Jamaica Bay |

The branch line transmission circuits, however, are notintended to carry morethan two three-phase transmission cir-cuits and four low-tension cables on a single line of poles.This condition enabled the use of wooden poles , of which an extra heavy type was selected in order that the idea of stability might be consistently carried out.

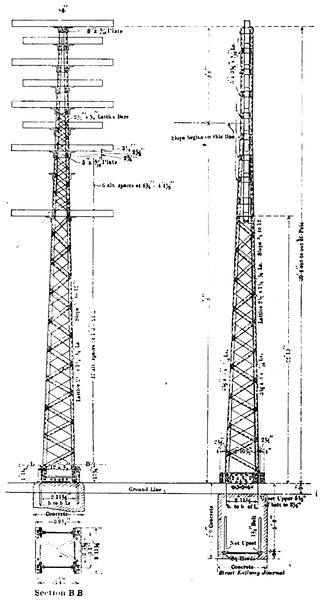

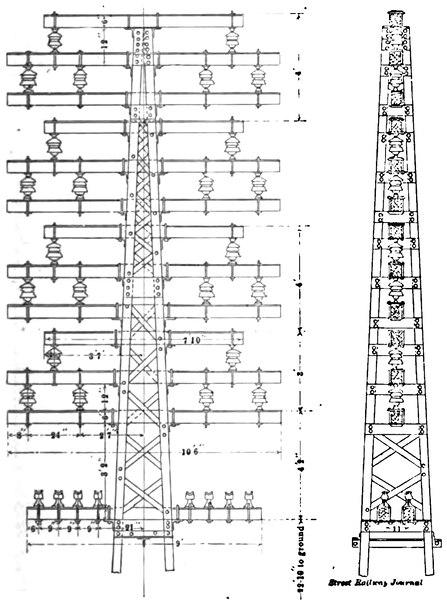

STEEL POLES

The steel poles are of various sizes to meet different conditions. They are all designed to carry twenty-four 250,000-circ. mil cables, on their upper portions, and underneath the man additional load of eight 500,000-circ. mil low-tension cables which local regulations require to be at least 25 ft. above the ground. The spans between steel poles average 150 ft. in length, except where turning corners or carrying the cables over railroad tracks. The poles when fully loaded as above, are able to carry safely a weight of 4500 lbs. of cable.

The steel poles are built of four corner angles, connected together by angles and plates forming a lattice type of construction . They are tapered uniformly to the top on two sides and to within about 7 1/2 ft. of the top on the other two sides, the taper being 3/8 in. per ft. This taper is uniform to the bottom of the pole and is the same for all lengths of poles. The tops are in every case 6 ins. x 11 ins. At the bottom the corner angles are tied to a base composed of plates and channels through the corners of which the four anchor bolts pass. This forms a sort of box construction around the base of the pole, and greatly increases its stiffness and stability. This type of construction enables a foundation to be built, and the anchor bolts set at any convenient time independent of the delivery of the poles. This permits the most desirable degree of flexibility in the organization of the pole-setting force, thus dividing it into practically two separate gangs, neither of which is hampered by the movements of the other.

|

| Fig. 11. — 39-Ft. 4-In. Steel Pole for Straight-Line and Curve Construction |

The standard poles are made in four lengths, increasing by 5 ft. from 39 ft. to 54 ft. in length, the 39-ft. pole being the standard, the other lengths being only used where necessary. On account of the above mentioned uniform taper, the sizes of the bases vary from 3 1/2 ft. x 4 ft. to 4 1/2 ft. x 5 ft., depending on the height of the pole. The foundations are therefore proportioned accordingly. From a detailed survey of the line, the length and the location of every pole was determined upon before construction began, and every foundation built to fit the size of pole assigned to that particular location.

The poles are designed to withstand a wind pressure at right angles to the line corresponding to a wind velocity of 100 miles per hour. This was calculated from data obtained in the Berlin Zossen high-speed railway tests, which showed the pressure on a flat surface due to a wind velocity of 100 miles per hour to be about 27 lbs. per square foot, which applies to the flat surfaces of poles and cross-arms. For the projected area of cylindrical conductors, one-half of this value or 13 1/2 lbs. per square foot was the factor used for the above wind velocity.

For standard straight-line poles, without side strains other than wind pressure, the corner angles are 3 ins. x 3 ins. x 3/8 ins. For the heavier strains at curves and corners, the general design of the poles is the same, but they are given greater strength by using heavier corner angles.

The design of the curve poles was made dependent on the distance by which the curve pole is offset from a straight line joining the two poles on either side of it. For offsets up to 6 ft., the corner angles of the pole construction are 32 ins. x 3 ins. x 7-16 ins., while the offsets between 6 ft. and 10 ft., the corner angles are 3 1/2 ins. x 3 ins. x 1/2 in. A drawing of the curve pole is shown in Fig. 11.

The foregoing types of pole are each designed in the four lengths. By reason of the uniform taper, an extra length does not result in an increase of the size of the corner angles, but only in the enlarged dimensions of the base. The moment of resistance at the base is thereby increased in proportion to the height of the pole.

|

| Fig. 12. — High -Tension Pole Construction on Jamaica Bay Trestle |

Besides the standard poles above described, designed to meet the ordinary conditions, an extra heavy pole was de-signed in three lengths. This type is called the strain pole, and is used for offsets up to 32 1/2 ft., for turning sharp corners, or for anchoring the line at special points. These poles are similar in design to the standard poles, but the taper is uniformly increased to 1/2 in. to the foot, and all four sides taper uniformly all the way to the top, which is 8 1/2 in. x 12 ins. The base of the 41-ft. pole is about 5 ft. square, that of the 51-ft. pole being about 5 ft. 9 1/2 ins. x 5 ft. 11 1/2 ins. The corner angles of these strain poles are 4 ins. x 4 ins. x 9-16 in.

All the poles are designed to withstand the side strains on 150-ft. spans due to the offsets above specified. For greater offsets the length of span is shortened. At all sharp turns, three poles of the heavy-strain type are used, two to take the longitudinal strains and guyed back to the base of the middle pole, which takes the side strains due to the offset.

| |||

| Fig. 13. — Wooden-Pole Construction on Jamaica Bay Trestle |

The three first-mentioned standard types of poles were designed to take the necessary side strains without guying. The longitudinal strains due to anchoring the lines are so great, however, that the strain poles used for anchorage are guyed fore and aft to the bases of the adjacent poles with 7-16-in.galvanized steel cable. On some sharp curves the poles were guyed laterally as an additionl [sic] additional precaution, using 7-16-in. guy cable and Stombaugh guy anchors.

The construction of the steel pole includes angle-iron seats for the cross-arms which pass through the pole structure, the weight of the cables holding the cross-arms down on the seats and requiring only the simplest type of fastening, which consists of two 34-in. "U" bolts, which clamp the cross-arms immovably to its seat. The use of the ordinary type of cross-arm brace is rendered unnecessary.

The ability of the steel pole to act as a lightning rod is turned to advantage, and each pole is thoroughly grounded to a copper plate beneath the foundation and connected to one of the anchor bolts by a copper wire.

The poles were transported from the steel works without "knocking down," and were erected whole upon their foundations with the aid of a gin pole. After erection, cement grout was run underneath the base and the pole permanently set by tightening the foundation bolts. There are now in position in the line 358 of the standard straight-line and curve poles, and nineteen of the heavier type of strain poles.

POLE FOUNDATIONS

The size of the concrete foundation varies with the height and character of the pole. For the straight-line pole the dimensions are 42 ft. to5 ft. square, averaging 8 ft. deep, with 1 3/8-in. anchor bolts. For the curve poles, the foundations averaging from 4 1/2 ft. x 6 ft. to 5 1/2 ft. x 7 ft. 3 ins. on the side faces, with a depth of between 7 ft. 9 ins. to 8 ft. 9 ins., and employing 1 3/4-in. anchor bolts. Strain pole foundations are from 7 ft. to 8 ft. square, and from 9 ft. to 10 ft. deep, and employ 1 7/8-in. anchor bolts. The tops of foundations are usually about 9 ins. above the ground level. After the poles were all set and the line construction entirely completed, the box-shaped bases of all the steel poles were filled with concrete, brought up to a pyramidal form, as shown in the pole drawings.

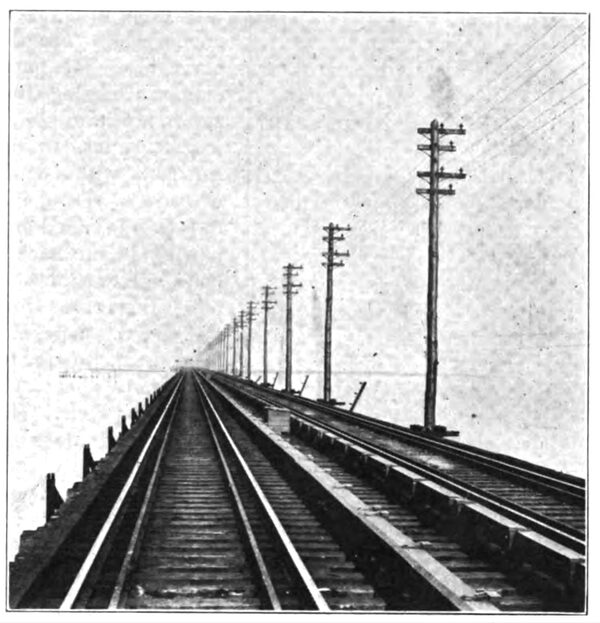

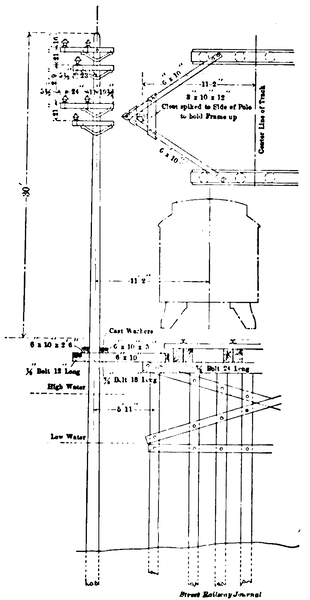

WOODEN POLES

The wooden poles are of two kinds; chestnut, which is the standard for ordinary work, and creosoted yellow pine, which is used only along the trestle over Jamaica Bay. The chestnut poles are 45 ft., 50 ft., and 55 ft. in length, and 25 ins. in circumference at the top. The creosoted poles are from 60ft. to 80 ft. long, with the same dimensions at the top, and treated with 15 lbs. of dead oil of coal tar per cubic foot of timber. Creosoted poles are all set 15 ft. into the bottom of the bay, by means of a water jet. They are all set so as to have the tops 30 ft. above the rails and are located far enough away on one side of the trestle to obviate any interference with the wires on the part of the pile driver that is used to renew the piles of the trestle bridge. These poles were braced to the trestle with creosoted yellow-pine timber, and a drawing of the pole and its setting is shown in Fig. 12. A general view of the pole line construction on trestle is given in Fig. 13.

| |||

| Fig. 14. — Method of Attaching Cross-Arms and Insulators in Wooden-Pole Line Construction |

This method of pole construction along the trestle was adopted only after a most careful consideration of various ways that were proposed for carrying a line across the bay. A separate trestle, carrying a line of conduits made up as when laid in a trench, was found too expensive. A pole line directly supported on the existing trestle would not afford the necessary clearance from traffic. Various plans were made for driving piles alongside the trestle and then splicing transmission poles to them, but even this construction, though practicable, does not compare in simplicity or durability with the long pole in one piece, which by the aid of a water jet can be driven down into the mud butt first, instead of being treated as an ordinary pile, and driven point first.

|

| Fig. 15. — Standard Pole Top for Straight-Line Pole |

This portion of the line is exposed in winter to a very severe strain, due to the movement of ice with the tide. The poles were set during a very severe winter, and the strains due to the ice were, at times, sufficiently great to cause the trestle to be moved out of line in places, but the poles set as above described successfully withstood the action of the ice. For a large part of this distance, the trestle runs across a series of low islands, which are covered with water at high tide only, so that it was difficult to reach them during construction, but, with very few exceptions, the poles were set by a floating pile-driving apparatus without going on the trestle or interfering with train operation.

The total number of steel poles employed is 377, of chestnut490, and of creosoted yellow-pine poles 264.

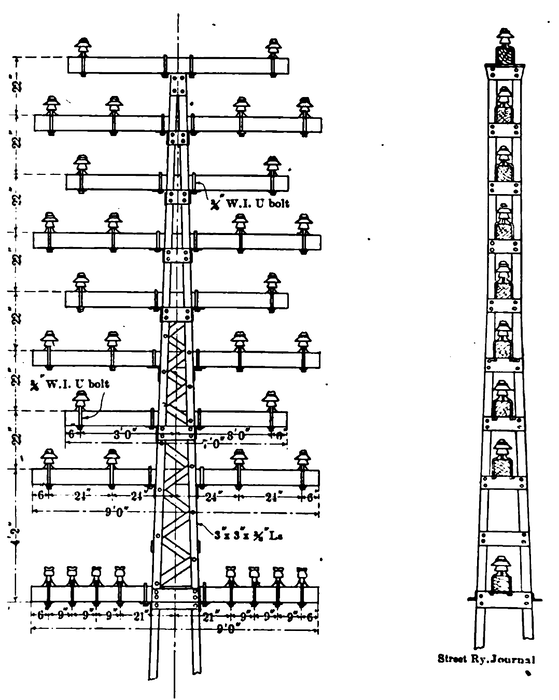

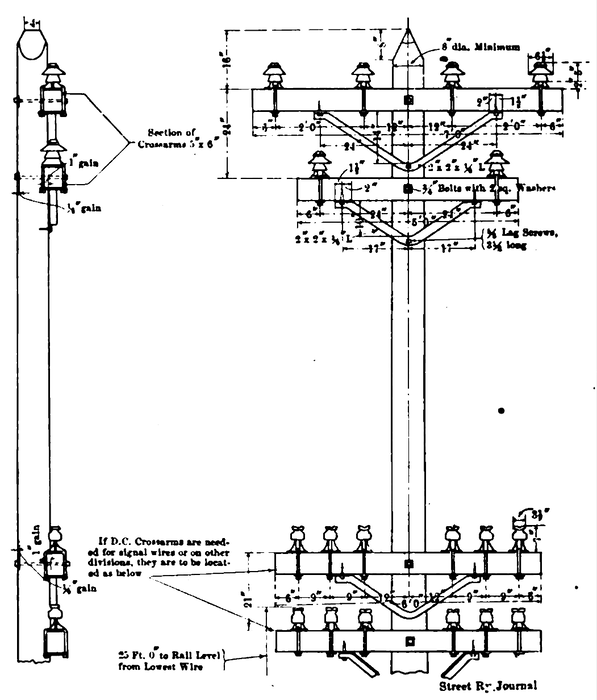

CROSS-ARMS

The cross-arms are of yellow pine, 5-in. x 6 in. cross section, housed on top to a 12-in. radius, and they are painted with one coat of asphaltum paint. The method of attaching them to the steel poles has already been described . On the wooden poles they are gained I in . into the pole and held by one 3/4-in. through bolt with 2-in. square washers, as shown in Fig. 14. Bracing, though unnecessary on the steel poles, was effected in the case of wooden poles by angle-iron braces made in one piece of 2-in. x 2-in. x 1/4-in. angle, bent into V-shape. For standard steel poles the arms are 7 ft. and 9 ft. long. For steel strain poles, they are 7 ft. 10 ins. and 10 ft. 6 ins.

The two circuits on the Jamaica Bay trestle and on the line immediately north of it, were carried one above the other on two sets of cross-arms on the side of the pole, the cross-arms being flush on the side of the pole opposite to the circuits. On the trestle itself, the circuits were both on the side of the pole away from the track, in order to get them as far as possible outside the sweep of the pile driver used to replace piles in the trestle bents. On the main line, to the north of the trestle, however, this position was reversed because, on account of the four tracks here laid, the poles had to be set as far as possible toward one side of the right-of-way, and there was not room enough to carry the wires on the outside of the pole without overhanging the adjoining property. The cross-arms here are 4 ft. and 5 ft. long, but the standard bracing and fastenings are used. On the steel-pole line, the apex of the triangle, at the points of which the wires are carried, is placed on top, while on wooden-pole portions of the line the apex is at the bottom .The latter position is that generally preferred for the arrangement of high-tension circuits, as it allows repair men to getup more easily between the circuits. On the trunk line, however, the necessity for carrying the maximum number of circuits made it desirable to reverse the usual order, and the apex was accordingly placed on top.

|

| Fig. 16. — Standard Wood Pole |

The drawing in Fig. 15 shows the design adopted for the pole top for the standard trunk-line pole on straight line and curves, and the arrangement of the insulators. Fig. 16 shows the corresponding arrangement for the standard wooden-pole top; Fig. 12 illustrates the unbalanced type pole top used on the Rockaway Beach Division. Fig. 17 shows the arrangement of the pole top for the strain pole.

PINS

The insulator pins consist of malleable-iron castings clamped to the cross-arms by means of U-bolts threaded through the body of the pin, and held by a plate fitting over the U-bolts and against the cross-arm. This type was first used on this transmission line, and represents a new departure in pin design, inasmuch as by its use all boring of the cross-arm is avoided. The strength of the cross-arm is maintained, and the depreciation resulting from entrance of moisture through holes bored in the arm from top to bottom, is obviated. The form of pin used is also of much greater strength than is possessed by a pin in which the bending moment where it enters the arm has to be met by small cylindrical cross section , which in case of the iron pin is some-times not more than 3/4 in. in diameter, and in a wooden pin, 1 1/2 ins. to 2 ins. The strongest part of this pin is at the base where it joins the cross-arm. It admits of easily following up any shrinkage of the cross-arm (which cannot be done in a pin which is set in a hole in the cross-arm), as all that is necessary, if the pin comes loose, is to tighten up the nuts on the underside of the clevis.

INSULATORS

The straight-line insulators are 6 1/2 ins. in diameter and 5 ins. high, made of porcelain in two parts, cemented together. The insulators are colored with a brown glaze to render them less conspicuous. They are designed particularly for the conditions here imposed. The pin and insular together carry 250-circ. mi cable 6 1/2 ins. above the cross-arm. The ties are made of ordinary soft copper wire, tied on top.

|

| Fig. 17. — Standard Pole Top for Steel Strain Pole |

The tests to which the insulators were subjected at the factory include a rain test at 30,000 volts, and a salt water flash test of 50,000 volts for two minutes. The insulators were further obliged to pass the test of plunging them into hot water and then into ice water without cracking. After the insulators were erected, and the cables strung upon them ready for operation, they were tested by applying 30,000 volts between the conductor and the ground for 4 minutes. The insulators underwent all these tests successfully.

The strain insulators are of the "spool" type and made in one piece, 7 1/2 ins. in diameter and 8 ins. high. Each strain insulator has two petticoats, one above and one below the point where the wire is attached. A 1 1/8-in. x 12-in. steel pin is cemented in the center of the insulator, and this steel pin rests in sockets at the top and bottom, which are firmly clamped by U-bolts to the cross-arms. This obviates the boring of arms, and thus preserves consistency with the design of the straight-line insular pins.