[Trade Journal]

Publication: Electric Railway Review

Chicago, IL, United States

vol. 17, no. 24, p. 779-881, col. 1-2

A TEST OF INSULATORS FOR AN EXCEPTIONAL SERVICE.

BY SIDNEY SPROUT, ELECTRICAL AND MECHANICAL ENGINEER OCEAN SHORE RAILWAY.

The Ocean Shore Railway follows the shore of the Pacific ocean for nearly 80 miles between San Francisco and Santa Cruz, Cal. One of the first problems that presented itself to the engineers making plans for the electrical equipment of this road was that of determining the type of insulator that would give the most satisfactory service on the 33,000-volt transmission line, which It was planned to use for the distribution of power to the various substations from the power house.

Exceptional Conditions.

The problem of selecting an Insulator for 33,000-volt operation would not, under aordinary circumstances, be at all difficult, but the conditions In this particular case made the question one to which it was necessary to give a good deal of time and attention before any definite conclusion could be reached. These conditions are, briefly: (1) Heavy salt fogs from the ocean. (2) Salt spray which is carried by the wind for considerable distances, in certain places where the waves beat upon a rocky coast. (3) Yearly dry seasons of from four to six ·months, during which time the highways become very dusty and the insulators are not washed off. (4) The proximity of the transmission line to the county road for practically its whole length. (5) The trade winds blowing from the ocean for months during the dry foggy season. (6) The fact that no line had been operated under similar climatic conditions at over 11,000 volts. (7) An 11,000-volt line which would be paralleled for some 14 miles had had a great deal of trouble from burnouts caused by the insulators becoming covered with a coating of dust and salt.

| |||

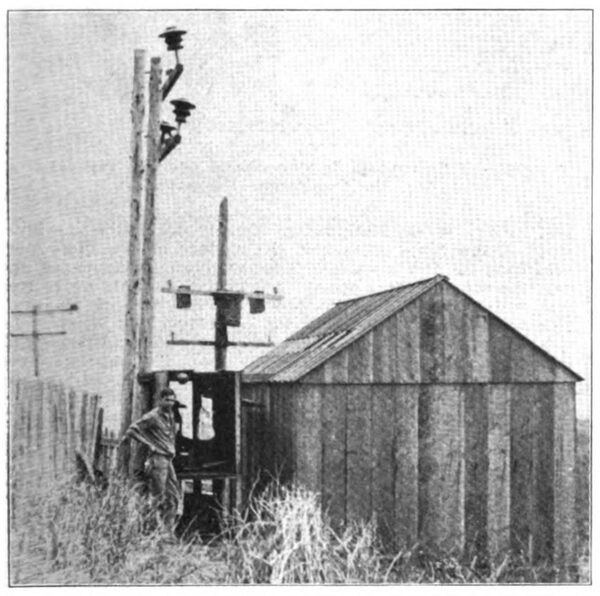

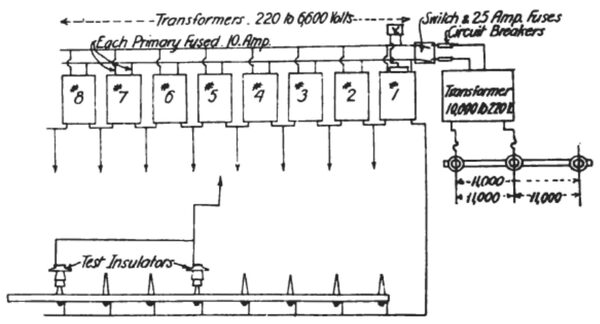

| Insulators for Exceptional Service -- Testing Box and Transformer House. |

After consulting the officials of the Big Creek Power Company relative to their experience in operating this latter mentioned 11,000-volt line, it was decided to establish a testing station at a place called Yellowbank, about 10 miles from Santa Cruz, where they reported that they had had a number of burnouts caused by the Insulators becoming coated with dust from the highway and salt from spray and fogs.

| |||

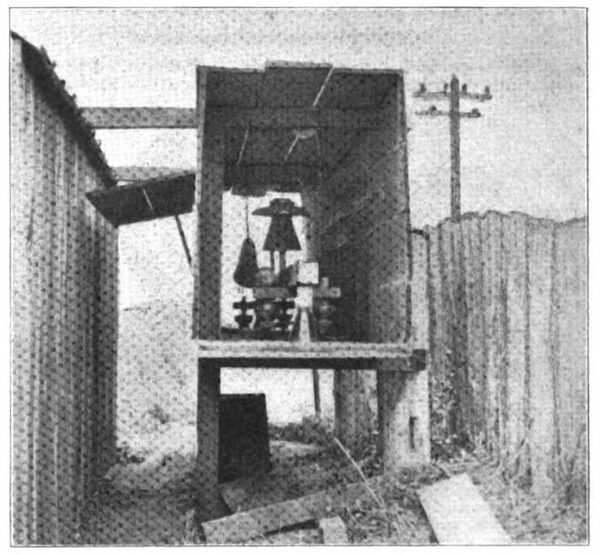

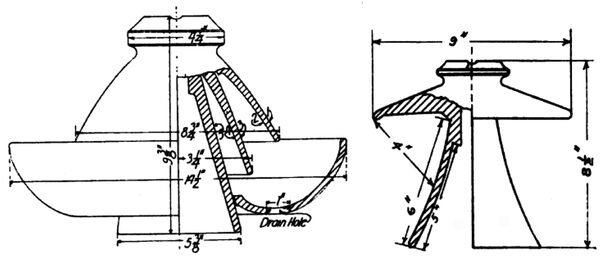

| Insulators for Exceptional Service -- Near View of Testing Box, Showing Insulator and Dust Bag. |

Testing Station.

The station as Illustrated was built at this place in the fall of 1905, and samples of different types of Insulators were placed on the insulated crossarms on the pole outside of the station. An 11,000 to 440-220-volt transformer was placed on a pole outside of the station, power being supplied from one leg of the three-phase, 11,000-volt, 60-cycle transmission line of the Big Creek Power Company. Eight 2-1/2 ki1owatt, 5,700-6,600 to 110-220-volt transformers were placed Inside of the station and connected as shown in the diagram, giving a test voltage ranging from 6,600 to 55,000 volts.

Plan of Testing.

When this station was built the plan was to test the insulators on the poles under the natural climatic conditions, but by the time the station was completed the rainy season had commenced, so that the station was closed up and tests suspended until the following summer. Meanwhile the insulators were left on the poles. When the tests were resumed the following summer it had been decided that instead of allowing the insulators to stand for a long enough time to be coated with dust and salt, under the natural conditions, It would be more advisable to test them under artificial conditions resembling the natural conditions as closely as possible. For this purpose the testing box shown in the Illustrations was built just outside of the station. This box was provided with a hinged door in the side. A compressed air sprayer was provided for spraying the insulator with a finely divided salt spray closely resembling the heavy fogs which come from the ocean. A cheese cloth bag of dust from the highway shaken at the windward end of the testing box was found to be a very efficient way of covering the insulators with dust. An electric fan was provided for the purpose of blowing the dust and salt spray on the Insulators under test, but it was found that the wind, blowing from practically the same direction all of the time, made its use unnecessary.

Results of Tests.

Before beginning the actual tests on the insulators it was necessary to make several changes In the arrangement of the transformer leads in order to prevent cases of sparking and abnormal static discharges. The results of the tests in detail were as follows:

60,000-Volt Porcelain Insulators.

Three on pole for eight months. Well coated with dust and salt on under surfaces and petticoats. Insulators in on for 10 minutes. No effect.

Connection to the top of Insulator from one side of transformer and around the bottom of second petticoat from other side. Then 56,640 volts was thrown on without results. Wire was then moved from bottom of second petticoat to just under corrugated top. Tested for 10 minutes. No effect.

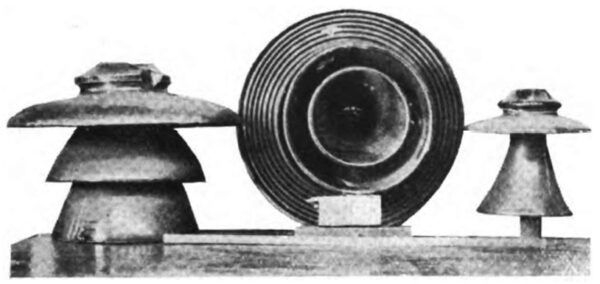

60,000-Volt, Corrugated Top, 16-lnch Insulator.

Insulator was put In the testing box and 56,600 volts thrown on with no effect. When heavy spray from side of box was 'turned on, current arced over. Spray was turned on the under sides of the petticoat with transformers off, and then as fast as they were thrown in, the circuit-breakers came out. Some dust was shaken on the insulator, and after it had dried off the Insulator stood the test all right. When covered with dust. and subjected to a test voltage of 35.700, duration five minutes, and heavy fog from spray at end of box for five minutes until water was dripping from the petticoats, there was no effect except slight snapping sound. A heavy spray from side of box caused current to arc over immediately.

| |||

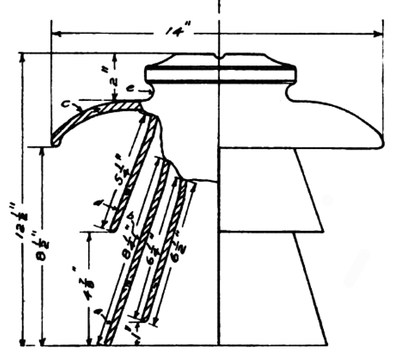

| Insulators for Exceptional Service -- 9 and 16 Inch Porcelain Insulators. |

Insulator manufactured by the Locke Manufacturing Company was cleaned and put in testing box. Test voltage of about 55,000 volts was thrown on; salt spray was turned on insulator from the side of the box but with no effect. After turning spray under the petticoats and getting insulator wet all over the current arced over as soon as thrown on.

Foggy Weather.

Insulator very wet from the fog of the previous night; drops of water were dripping from all petticoats. Eight transformers thrown on and a decided static was both audible and visible. Dust shaken in the box had no effect on the insulator.

| |||

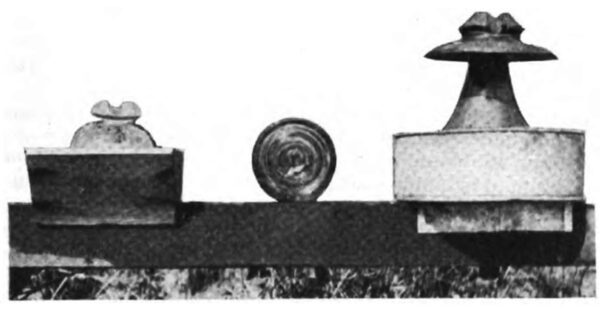

| Insulators for Exceptional Service -- Glass and Porcelain Insulators With Fog Bowls. |

60,000-Volt, Smooth Top, 14-lnch Insulator.

Insulator manufactured by the Thomas Insulator Company. Had been in the station all winter. Well covered with dust and also covered with moisture from fog. Was put In the testing box and tested up to 55,000 volts. No results. A thin wire was then connected to the pin and wrapped around the petticoat No. 2 at point "a" (section) and 55,000 volts thrown on. No results aside from a barely visible static at joints. Wire was then moved up to the point "b" and tested with 55,000 volts without results other than an increase of the static. The end of the wire on the top of the insulator was then brought In contact with the top of the Insulator at point "c," two Inches from the edge, and the static increased a good deal. It was noted here that visible static discharges jumped from the bottom of petticoat No. 3 to the wire around No.2. a distance of 1 inch instead of following the 7 Inches of dust-covered surface between the two points. The thin wire was next put around petticoat No. 3 at the point "d," about one inch from the bottom, and the wire on top restored to position "e"; 55,000 volts were thrown on. Current arced over the surface between the points "e" and "d," a distance of 14 inches.

Nine-Inch Top, 35,000-Volt, Porcelain Insulator

Had been on crossarm without disturbing. Coating of dust and salt accumulated by eight months' exposure to the weather. Put on the insulated crossarm in the testing box. Four transformers caused a heavy static discharge over the insulator. Not visible but 'made evident by a snapping sound. Five transformers increased the snapping. Six transformers, test voltage 42,000, 20 minutes. During the first few minutes static flashes were visible on the surface of the under petticoat from the top down, but these gradually disappeared until only the snapping was heard. Seven transformers were tried; test voltage, 48,720; 20 minutes. Decided dashing on under side to top petticoat and on top of bottom one for first few minutes, and then only an occasional flash. Eight transformers; voltage, 55,200; 30 minutes. The current arced over the insulator after a few seconds, throwing the breakers. When thrown on again only occasional flashes were visible for the rest of the time.

Similar Insulator had been Inside of the station for eight months. Was well covered with dust. Seven transformers: 48,300 volts; 20 minutes. Small bluish flashes near cemented joint for first few minutes. Eight transformers; 55,200 , volts; 15 minutes. Slight increase in flashing. At the end of 15 minutes salt spray was turned on Insulator and current arced over at once.

| |||

| Insulators for Exceptional Service -- Sketch Showing Test Rack and Step-Up Transformer Connections. |

Same insulator; test voltage, 56,160; 8 minutes, insulator well covered with dust before transformers were thrown on. Immediately current arced over the insulator and breakers came out. After putting the breakers in three times they stayed in for the rest of the test, blue flashes around the cemented joint being visible for the first few minutes.

Same insulator; test voltage, 35,700. Salt spray turned on insulator from end of testing box. No effect. Heavy spray turned on Insulator from side of box. Current arced over, throwing breakers. Salt spray turned under the petticoat. All of the insulator wet. Breakers would not stay in A 9-lnch Insulator well covered with dust and wet from the fog was tested with 35,000 volts. Arced over immediately, but stood up all right with 27,000 volts.

Similar Insulator. Covered alternately with salt spray and dust until muddy all over. Tested with 27,000 volts. Current arced over immediately, standing up at right with 20,000 volts.

A 9-Inch Insulator of the Locke No. 409 type was put in the testing box with a special galvanized Iron fog box and spray and dust put on It from end of testing box. The under side of the flat top was about as free from dust as the under side of Its single petticoat.

Fresh Water Tests.

The 9-Inch Insulator was wet with the moisture from the fog of the previous night on top and on outside of petticoat. Under side of top was just a little moist and under side of petticoat was covered with a very thin film of moisture, barely noticeable when rubbed off with the finger. Voltage, 35,000. Moisture of the night before on It. No effect beyond a faint static discharge near the cemented joint. A heavy fresh water spray was turned on the Insulator from one side and a little above. After a few seconds the current arced over. With transformers on again, the spray was turned on from the end of the box and from above at an angle of about 45 degrees, but the Insulator stood up all right, even when the spray was made so heavy that the water ran off of the top In streams almost continuous to the crossarm.

Kern Type Insulator.

An Insulator of the Kern type, manufactured by C. S. Knowles, was wiped clean and tested with 55,000 volts, salt spray being turned on It, but It stood up all right until the spray was turned under the petticoats.

Same insulator. Well covered with moisture from fog of night previous. Test voltage, 35,000. Very heavy static flashes on the surface of the insulator. Not heavy enough to throw the circuit-breakers.

Porcelain Fog Bowl Insulator.

This Insulator was of special design, the idea being to make use of the advantages obtained from the fog box and at the same time by making the fog box of porcelain and supporting It on the under petticoat Instead of the crossarm to reduce the sparking istance required to the fog box. The several parts of this Insulator were not cemented together. The insulator was wiped clean and mounted on a piece of I-Inch iron pipe. Test voltage of 35,100 volts thrown on. After five minutes no effect. Salt spray turned on from end of box for five minutes. Water dripped from all of the petticoats. No effect. With the transformers off dust was shaken on the Insulator until the moisture was dried off and the outside of the Insulator was white with dust. On raising up the top petticoat its underside was found to be practically free from dust. Test voltage, 35,000. No effect.

|

| |||

| Insulators for Exceptional Service -- Three Types of Porcelain Insulators Subjected to Various Tests. |

Insulator again covered with dust. Test voltage, 56,600. After five minutes, no effect. Spray turned on from end of box. Very small amount of spray caused the current to arc over through the drain holes in the porcelain fog bowl.

Salt spray turned on this insulator from the top of the box at an angle of 45 degrees caused the current to arc over at 56,000 and 35,000 volts. Spray was turned on a 60,000-volt Insulator, well covered with dust from the top of the box, but to no effect. Fog bowl wet from, fog. Water dripping from petticoat. Eight transformers thrown on. No effect. Dust shaken In box. No effect.

Porcelain Fog Bowl and 9-lnch Fog Box Insulators.

The porcelain fog bowl insulator and the 9-lnch insulator in Its galvanized Iron fog box were left In the testing box overnight and became well covered with moisture. On the porcelain fog bowl insulator the moisture was heaviest on surface "3" (see illustration) and light on surfaces "2," "4" and "5." On the 9-lnch fog box Insulator the under side of the top and petticoat showed very little moisture.

Tested both Insulators to 35,000 volts. No result. Middle petticoat then removed from the porcelain fog bowl Insulator. No result.

About 55,000 volts were thrown on the 9-lnch fog box insulator. No result. Porcelain fog bowl Insulator arced over at 55,000 volts when the middle petticoat was removed. With all petticoats on there was no effect.

Nine-Inch Insulator covered with a thin fUm of moisture stood about 48,000 volts, but arced over at about 55,000 volts.

Creeping Distance.

On the surface of a clean, dry petticoat 35,000 volts formed an arc at a distance of 3.25 inches; 57,000 volts formed an arc at a distance of 5.50 Inches.

Conclusions.

From careful observations of the tests, briefly outlined, the following conclusions were deduced:

First: Under the climatic conditions as defined, any insulator used for 33,000 volts or over, i. e., any insulator used within the limits of size manufactured at present, would have to be cleaned every third or fourth year. It is doubtful if even a very considerable increase In size would be of any advantage.

Second: The use of the so-called "fog boxes" would afford a temporary relief on small Insulators and Increase the time between cleanings. On the larger Insulators, i. e., insulators for over 20,000 volts, the fog boxes would not be of any advantage owing to the fact that the distance between the boxes and the petticoats of the Insulator would have to be so large that it would afford no protection from dust and spray. The expense of fog boxes also would be prohibitive on larger size insulators.

Third: Of the three causes of trouble, namely, salt spray, dust and fog from the ocean, the latter is of minor consequence, and any transmission line away from the combined Influences of the first two would meet with comparatively little trouble.

Fourth: The most satisfactory Insulator for the conditions stated above is one having as few "still air" spaces as possible, i. e., an insulator exposing a large proportion of its surface to the action of the wind. An Insulator having as flat a top as practical to manufacture In the size desired. An insulator having one long petticoat, or, if necessary to get the required surface, two long petticoats, although the latter has the objection of providing a "still air" space between the two petticoats, reached neither by wind nor rain and difficult to clean.

Fifth: The results and conclusions suggest the possibility of an insulator for very high voltages being made up of several pieces of porcelain or glass shaped something like the present Insulator tops and placed one below the other.

Acknowledgment is due to W. G. Vincent, Jr., assistant electrical engineer, Ocean Shore Railway, for assistance in performing these tests.