[Trade Journal]

Publication: The Journal of Electricity

San Francisco, CA, United States

vol. 4, no. 3, p. 58-59, col. 2, 1

HIGH POTENTIAL INSULATORS.

In no department of engineering has it been so fully or so frequently demonstrated that good work and good material pay as in the field of electrical applications of power. Cheap devices, like cheap labor, mean a constantly increasing repair account, the reduction of which unnecessarily large item of expense means dividends to the operating company. Moreover no feature in electrical transmission is more essential to absolute permanence and reliability of operation than the line and to perfect the materials used in line construction has been the untiring effort of Mr. Fred M. Locke, of Victor, N. Y., for years past.

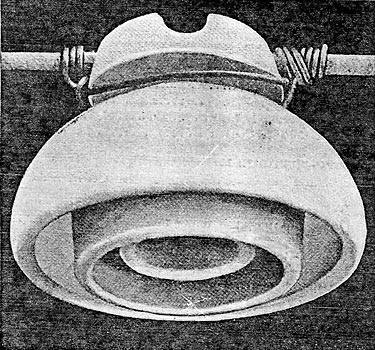

The latest of Mr. Locke's production is the extremely high potential insulator shown in outline in the accompanying cut. It is a two-part insulator designed to carry potentials up to 50,000 volts, and is made in different sizes according to the current carried. It has an outer shell of Chinaware on account of its high insulating surface and its mechanical and electrical strength, and has a center insulator of glass as shown in the accompanying sectional view to further insulate it and to prevent puncture by the high potential current. It is also made of two or more shells of china ware, the advantage of this over one solid insulator being that the shells being made separately ½ inch thick, each allows more uniformity in making and more through vitrifaction, than could be obtained otherwise in one solid insulator 1 inch thick. Besides this are secured four thicknesses of glazing from the two shells, which further increases its insulating qualities.

|

| Sectional View of the Locke Extremely High Potential Insulator. |

By repeated practical tests it has been found that a potential of 100,000 volts will not puncture the insulator; hence it will carry with safety and economy any voltage that is practicable for use in commercial application of electric power.

The body and glaze of all the Locke insulators are of simple earths only, fused together into a vitreous, homogeneous mass at the greatest heat. No lead or other metallic oxide being used in making, and the glaze is not a conductor. The body and glaze being of exactly the same material and fired at the same heat the insulating qualities are as high without as with the glaze.

These Insulators will not craze or crackle on the surface or "leak" as insulators made of inferior material will do when subjected to variations of temperature. The ware used in their construction will stand severe tensile strains or heavy blows without injury, and Neill not crack or chip from the effects of high potential currents.

Heat, cold, dampness, acids, alkalies cannot act to disintegrate or otherwise injuriously affect the properties of them, as their structure resists the action of gaseous and fluid substances as well as of other forces.

| |||

| The Locke Transmission Insulator. |

No other insulator possesses, or maintains to such a high degree, all the essential qualities of high insulation resistance here being the best, it is the cheapest.

The Locke pin is made especially for the heavy work and good insulation required in the highest potential transmissions. The belt has a diameter of 1/2 inch and has a wood top of five inches above the arm with a 2-1/2 inch base. It is boiled in paraffine, making it water-proof and a good insulator. The art of preparing the wood so it will absorb the paraffine is not generally known. In some instances when wood pins were supposed to be boiled in paraffine, a test showed them to be of little benefit; but if the pin is properly treated, it can be made to show a high resistance for years. The wood on these pins is properly treated. All Locke pins are made for standard cross-arms, but can be had for any size arm.

Mr. John Martin, is handling the Locke line materials as Pacific Coast agent, in conjunction with the agency of the Stanley Electric and Manufacturing Company, with offices and warerooms at 300 California street, corner of Battery street, San Francisco.