[Trade Journal]

Publication: Electrical Review - London

London, England

vol. 62, no. 1575, p. 167, col. 1-2

PORCELAIN INSULATORS FOR 100,000 VOLTS.

FOR many years it has been customary to increase insulation by putting insulators in series, and the insulators in use to-day for very high pressures are generally made of several shells fastened together by means of cement or other material.

Two or three years ago, however, it was recognised by potters that the problem of manufacturing shells exceeding 13 in. in diameter became very serious, and made the expense of insulators of that diameter almost prohibitive; with the view of eliminating such large pieces of porcelain, several inventors have been at work, and it is now commonly accepted that an insulator of the underhung type must prove the final solution, not so much from an electrical standpoint as from that of cost.

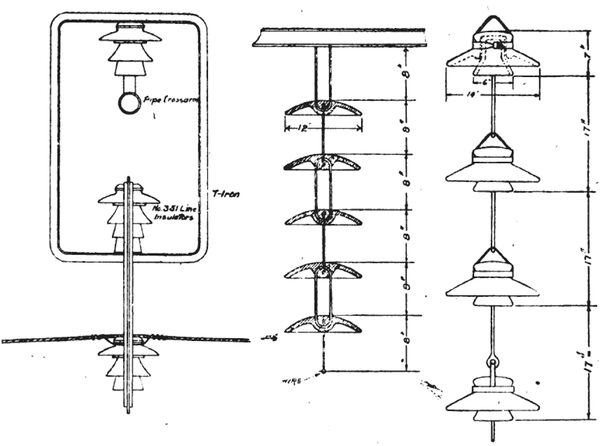

The original idea was to build two or three standard line insulators in series, but this arrangement was found to be mechanically weak, though electrically giving very good results. In order to overcome this difficulty, Mr. Locke, of the Locke Insulator Manufacturing Co., of Victor, N.Y., evolved the method shown in fig. 1, which depicts an underhung insulator for 100,000 volts, whose electrical qualities will be approximately three times that of any single one of the insulators; but mechanically this is an arrangement which engineers would hesitate to adopt. The most objectionable feature of this design is its great expense, since, to obtain any considerable mechanical strength, the "T" iron must be made very heavy; this condition is also very likely to prove disastrous electrically, since the introduction of any considerable amount of iron between the portions of a series insulator would probably make an enormous condenser of it, and would cause the bulk of the strain to be thrown upon the insulator to which attachment was made directly with the line. The above features, together with its great length, seem to rule it out as a possible future 100,000-volt insulator.

For the same service of 100,000 volts the General Electric Co. is proposing the use of disk insulators made up as shown in fig. 2, the several sections being fastened together by means of four or five turns of J-in. dia. stranded steel wire. It will be seen that this method calls for the drilling of two U-shaped intersecting holes in the porcelain, and of course demands that these holes shall not open one into the other, as to each shell a total pressure of some 60,000 volts must be applied.

This type of insulator has proved valuable in many ways, but it has the disadvantage that the metal loops between the sections compel it to act like several condensers in series, and in any series condenser the shock comes mainly upon the end plates; hence this type of insulator might, in the case of a line subject to surges and lightning strokes, prove itself incapable of standing the strain, since it would be impossible to interpose between the line wire and the first metal link more than one piece of porcelain—a condition which is absolutely necessary if strains of 60,000 volts or more are to fall upon it.

|

| Fig. 1, Fig. 2, Fig. 3 |

Work which has been done at the Locke insulator factory in the past year seems to indicate that insulators of the underhung type can be made which will withstand continuously very heavy strains both mechanically and electrically. Fig. 3 shows an underhung insulator which represents a considerable amount of work. The means of attachment consists merely of a metal strap and stirrup which has sufficient mechanical strength to resist 7,000 lb. pull—a value greatly in excess of anything which is met with upon modern transmission lines. It was found that the end shells of the insulator must be made strong enough to withstand the entire pressure of the line, and, in order to do this for a 100,000-volt line, it was necessary to interpose two pieces of porcelain, as shown in the figure. With this improvement the Locke Co. his been able to make a series insulator not over 5 ft. in length, and capable of being operated in the face of a heavy rain at 220,000 volts. The shells are simple, and the metal attachments inexpensive. Mechanically and electrically it is very strong, and no unusual procedure is involved at any point in its construction. As far as insulator manufacturers can guarantee, the makers guarantee this device good for 100,000 volts.

The agents for the United Kingdom and the Colonies for the Locke Insulator Manufacturing Co. are Messrs. Geipel & Lange, of Vulcan Works, St. Thomas's Street, London, S.E.