[Trade Journal]

Publication: Street Railway Journal

New York, NY, United States

vol. 31, no. 14, p. 571-572, col. 2, 1

INSULATORS FOR EXTREMELY HIGH VOLTAGE LINES

BY F. M. LOCKE.

The frame type insulator, shown in Fig. 1, is one which I have designed for lines requiring 150,000 volts, line pressure. It will stand a spray test of 280,000 volts, leaving a large factor of safety. It will carry a mechanical load of 20,000 lb., and can be constructed to carry as much as desired by increasing the I-beams and side rods and the bearing surface of the porcelain. The frames are inter-locked like a chain and the line cannot come down. All the porcelain parts are under compression and are designed to have a surface large enough to carry the required mechanical load with a large factor of safety. Under an electrical test this insulator does not show the usual static stresses, and is extremely quiet up to the arcing point, which takes place between the frames. In case of an arc from lightning, the arcing will occur between the frames and not injure the insulator. These insulators are furnished in any size for line voltages from 70,000 volts up to 300,000 with a factor of safety of two under a spray test, and any mechanical load desired. As will be seen, this is the only insulator made with which unlimited test voltage, unlimited mechanical strength and an unlimited factor of safety on all points can be secured.

| |||

| Fig. 1. - Frame Type Insulator |

It is designed for the hanging type, but can be supported at either end, and used horizontally or perpendicularly. It is manufactured exclusively by the Lima Insulator Company, Lima, N. Y., under my rights of patent which are now pending.

| |||

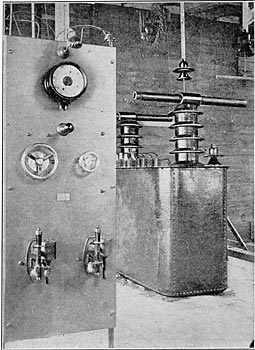

| Fig. 2. - 450,000-Volt, 150-Kw Transformer for Testing |

Fig. 2 illustrates my 450,000-volt, 150-kw transformer which I use to test the insulator described above. It is installed at the Lima Insulator Company's plant and was made by the Central Laboratory Supply Company, La Fayette, Ind.

| |||

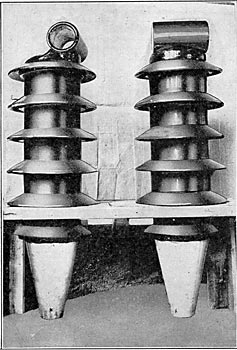

| Fig. 3. - Porcelain Bushings for Insulating Lead Wires of 450,000-Volt Line |

Fig. 3 shows porcelain bushings manufactured by the Lima Insulator Company for the Locke 450,000-volt, 150-kw transformer and is insulating successfully the lead wires. These bushings are oil filled and the holes through the top caps are to support the choke coils at each terminal. They weigh about 200 lb. each.