[Trade Journal]

Publication: Electrical World

New York, NY, United States

vol. 51, no. 20, p. 1058-1059, col. 1-2

Wires, Wiring and Conduits.

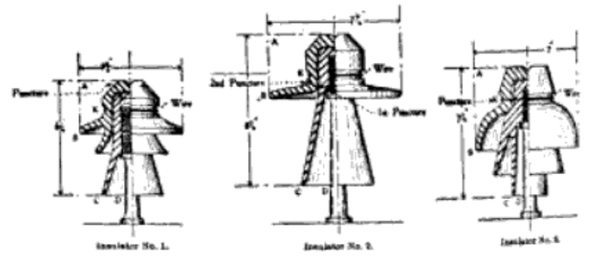

High-Tension Insulators.—C. J. GREENE.—The first part of a long article on high-tension insulators for overhead transmission lines. The author thinks that on nearly all overhead lines the size and cost of insulators have been needlessly great in consequence of a lack of exact knowledge: The author has carried out a number of tests at e.m.f s, up to 100,000 volts of three types of insulators of English make shown in Fig. 2, all of best quality vitrified porcelain, specially made for high; tension lines. In every case the pin was earthed, and the pressure was applied to a soft copper binding wire bound round the side groove of the insulator. The end of the wire, after being fastened to the insulator, was carried vertically upward so as not to reduce the arcing distance to the pin. The arcing distance during the test was, therefore, in every case K B C D for the dry insulators. The over-all diameter varied between 5 3/4 in. and 7 3/4 in. and the over-all height between 6 1/5 and 8 1/5. These insulators were tested dry and wet, and in general it seems that the average puncturing e.m.f. of the porcelain tested is approximately 100,000 volts per inch. Some special observations made during the tests are interesting. When an insulator of type No. 2 was wet all over with clean, fresh water and a rising pressure was applied, the first spark jumped across at 45,000 volts and an arc almost established itself, but the heat thus generated caused the insulator to dry and the arcing ceased. The pressure was then gradually increased, and with each slight increment of pressure, an arc attempted to establish itself, but was extinguished by the further drying of the insulator. At about 90,000 volts, when the insulator was probably quite dry, a permanent arc was coated with a mixture of coal dust and water. The process of the insulator drying and cleaning itself is interesting, but it is probable that it takes place with sufficient rapidity to be of service only at high voltages. An insulator does not by any means necessarily puncture in its thinnest place nor does its puncture necessarily form the shortest path of breakdown between line and pin. The insulator punctures at some point of local weakness which the electric pressure finds. It is probably quite a mistake to make any single part of an insulator with a thickness greater than 1 in. Masses of porcelain vitrified under great heat suffer from the same toughness as large masses of iron which cool unequally. By unequal cooling local internal stresses are set up which later result in a breakdown.—Lond. Elec. Rev., April 24.

|

| Fig. 2. - High-Tension Insulators. |